Abstract

At welded joints, fatigue cracks usually initiate either at the weld toe or the weld root. The latter may be influenced by small defects or other irregularities or even by non-fused root faces forming a slit which acts like a crack. Weld root failure has therefore to be checked for several weld types. Different approaches exist for fatigue assessment, including the rather simple nominal stress approach, local stress approaches and the crack propagation approach which are partly well suited for the assessment of weld root fatigue. However, it is not easy to keep the overview and to decide which approach should be applied in the case in question. For this purpose, the guideline has been established giving an overview of the different approaches with special emphasis on weld roots and discussing their suitability and the limitations. Six typical examples are described where different approaches are applied and in some cases compared with fatigue tests, thus giving insight into the practical application and allowing own judgement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is well known that welded structures subjected to cyclic loading are prone to fatigue. Fatigue cracks initiate at locations with high stress concentration. These are the relatively sharp transitions between the parent and weld metal at the weld toes as well as weld roots, which are frequently characterised by sharp slits with non-fused root faces acting like crack starters.

The situation is often illustrated by the example of a cruciform joint with load-carrying fillet welds, see Fig. 1. Alternatively to cracks initiating from the weld toes, root cracks may start from the ends of the non-welded root faces, separating the weld throat during crack growth. Which crack type dominates depends mainly on the ratio between throat thickness a (including possible penetration) and plate thickness (t), but also on the type of loading, weld shape, misalignment, residual stresses etc.

Toe and root cracks can be distinguished in failure cases by their characteristic appearance. While toe cracks are located in the weld toe line, at least at the beginning, weld root cracks appear on the weld surface after penetrating through the weld material. Figure 2 shows examples of weld toe and root cracks at the fillet weld around a stiffener termination.

Weld root cracks are frequently considered to be more dangerous than weld toe cracks, as their initiation cannot be detected until they have grown through the whole weld thickness. On the other hand, the residual life of the structure after weld fracture can still be long, particularly in cases with stress variation along the weld; the continuous base plate may even remain intact. Nevertheless, an adequate fatigue strength assessment is necessary to ensure the integrity of the structure and to avoid early and unexpected fatigue failures. This is particularly necessary for optimised structures that have welds with minimised dimensions or post-weld treatment. The latter can improve only the weld toe and not the weld root.

There are various approaches to fatigue strength assessment [16] which are applicable not only to weld toe failure but also to weld root failure. The approaches differ mainly in the stress parameters used for the assessment:

-

Nominal stress approach, based on stress excluding any stress increase due to the structural detail or the weld; in the case of weld root failure, a nominal stress based on the weld throat thickness has to be used

-

Structural stress approach, based on stress including stress increase due to structural geometry but excluding that due to local weld geometry; the approach has been developed for weld toe failures but has been extended to some cases with weld root fatigue at fillet welds, using a linearised stress in the weld

-

Effective notch stress approach, based on local stress at the rounded weld toe or weld root notch, assuming ideal-elastic material behaviour and microstructural support effects to a certain extent

-

Approaches based on the stress intensity factor, using the notch stress intensity factor (N-SIF) of the weld toe with zero radius as the fatigue parameter. For the weld root, the stress intensity factor for crack tips is used

-

Crack propagation approach, using Paris’ law for determining the fatigue life of a propagating crack; while the actual non-fused part is considered as the initial crack at the weld root, an initial crack depth must be assumed for the weld toe

Before the weld root assessment is described and discussed for the different approaches, the scope of applications covered by this guideline is outlined. Finally, several demonstration examples are described, illustrating the range and details of practical application.

Reference is made to several papers, recommendations and guidelines giving more details of the different approaches. It is recommended that different approaches be applied to the actual problem in order to verify the results.

2 Scope of applications

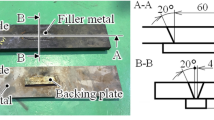

2.1 Butt joints

Typical butt joints with non-fused root faces at risk of weld root fatigue are shown in Fig. 3. In type (a), a two-sided butt weld with embedded root faces, the load-carrying section is reduced to 2·a. This case is contained in several catalogues of details in fatigue codes and guidelines, where the stress is to be based on the throat sectional area (2 × a) and a very low fatigue class is assumed. This leads to low fatigue strength so that this detail is not recommended for cyclic loaded structural members.

Non-fused root faces also occur in one-sided butt welds made without a backing bar (i.e. no permanent or ceramic type). In this case, the non-fused root faces can result in early cracks starting from the root. Secondary bending can worsen the situation. This case also typically appears in codes and guidelines, where a very low fatigue class is assumed, particularly in cases where the weld root cannot be checked by appropriate non-destructive testing (NDT).

If, however, the weld root is checked by appropriate NDT and contains rather small axial misalignment, the fatigue strength can be higher [25]. This is utilised in the design of pipelines by defining appropriate measures (NDT, low misalignment) and allowing significantly higher fatigue classes [8, 16].

2.2 Fillet welds

Figure 4 shows different types of cruciform joints with non-fused root faces. Types (a) and (b) are double bevel butt welds and two-side fillet welds without penetration. Here, the throat thickness a determines the weld stress and thus the risk of root fatigue. The depth e of the penetration (excluding possible root defects) increases the load-carrying section and hence the fatigue strength. Corresponding fatigue classes can be found in codes and guidelines (e.g. [16]).

The necessary weld throat thickness a or leg length c to avoid fractures initiating at the weld root can be determined from the fatigue classes based on fatigue tests or from fatigue assessment procedures described in the following section. A typical example for cruciform steel joints with partial penetration welds under axial loading is given in Fig. 5, showing limit curves separating geometries leading to fatigue fractures initiating at the weld toe and root, respectively, derived from fatigue tests. An increased leg length ratio c/b avoids weld root failures.

Limit curves separating fracture from weld toe and root in cruciform joints [24]

The one-sided welds (types (c) and (d) in Fig. 4) are less fatigue-resistant because the weld throat is subjected to additional bending in the case of axially loaded plates. Usually, such welds are only acceptable if weld bending is kept under control, e.g. by transverse stiffening plates. Also, circular or small rectangular hollow sections can provide sufficient restraint, allowing fatigue classes to be based on nominal axial stress only [16].

The welded joints are frequently subjected to loads varying along the weld line which may be due to the geometrical configuration. A typical case is the fillet-welded end of a loaded stiffener where a stress concentration normally occurs and the non-fused root faces terminate (Fig. 6). This requires a local stress analysis and corresponding fatigue assessment.

2.3 Other welds

Special welding processes create connections with limited penetration so that non-welded slits occur. Examples are spot-welds, laser-stake welds and one-sided laser welds, e.g. at T-joints, see Fig. 7. Fatigue cracks may occur at the ends of the slits, separating either the weld or parent metal depending on the loading condition.

The situation is similar to butt and fillet welds with partial penetration, so that the same approaches for fatigue assessment can be applied. One major difference is the loading, which is frequently dominated by shear forces in the connected planes. Thus, special internal forces and moments are defined in some cases, resulting in specific nominal and/or structural stresses [31].

3 Procedures for fatigue assessment

3.1 General aspects

3.1.1 General procedures

The fatigue assessment procedure can be based on

-

S–N curve showing the relationship between the fatigue life in terms of constant amplitude load cycles and a stress parameter, which may be the range of a nominal or local stress in the weld or a stress intensity at a notch. Variable amplitude stresses are taken into account using a damage accumulation hypothesis, normally the linear Palmgren–Miner rule (or Miner's rule).

-

Crack growth curve established with a crack propagation law such as the Paris–Erdogan law, based on fracture mechanics and assuming an initial crack length and appropriate material parameters for the analysis. Variable load amplitudes can be considered by an incremental analysis using single load cycles or blocks with different load amplitudes.

Further information is given, e.g. by Hobbacher [16] and by several textbooks on fatigue. The following sub-chapters outline the approaches using different stress parameters as well as the approach for crack propagation. The approaches are generally affected by several influence parameters; some of those relevant to root cracking are discussed in general below.

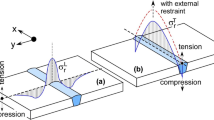

3.1.2 Residual stress

It is well known that residual stresses significantly influence fatigue behaviour [34]. High tensile residual stresses reduce fatigue life, while compressive residual stresses increase fatigue life provided the load ratio is not too high. Crack initiation as well as crack propagation is influenced, the latter mainly by crack closure.

At weld toes, it is usually assumed that unfavourable residual stresses due to welding are present which may reach the yield stress of the material. Therefore, test results for a high stress ratio (R = 0.5) are conservatively assumed for any loading [16]. However, weld toes at stiffener ends (Fig. 6) may also show compressive residual stresses because of welding [11].

Welding residual stresses are difficult to measure at the weld root. However, simulations of fillet and butt welds have shown compressive residual stresses at the weld root at a magnitude of the yield strength of the base material in mild strength steels for multi-pass welds [3]. Barsoum [4] also showed that the residual stresses at the weld root side depend on weld penetration and the number of weld passes, where increased compressive residual stresses were observed with increasing weld penetration and an increasing number of weld passes. However, the final residual stress at the weld root side for multi-pass welding also depends on the inter-pass time.

It has been observed that the crack initiation points at pipe-to-pipe connections depend to a great extent on the residual stress state being affected by the welding sequence.

As an unfavourable global residual stress state may be present because of the fabrication and erection of the whole structure, high residual stresses should be assumed also for the weld root unless more favourable conditions are proven. This is usually considered in fatigue strength assumptions in codes and guidelines.

3.1.3 Misalignment

Another factor affecting fatigue strength is misalignment, creating secondary bending stresses which have to be considered in all local approaches, including the crack propagation approach.

Misalignment effects are particularly large in welds at plates subjected to loading transverse to the weld. For instance, the axial misalignment e of an unrestrained cruciform joint (Fig. 8) creates an increase of the axial stress at the weld toe, which can be expressed by the following stress magnification factor k m:

The secondary bending stress is considerably reduced at the weld root, which has been investigated by Andrews [1]. He derived the following formula for the stress magnification at the weld root:

The right part applies to fillet welds with 45° flank angle. Other cases such as angular misalignment may be analysed by simple beam theory. Additional restraint in the weld direction, e.g. by stiffeners or curved shell effects, may require a 3D finite element analysis.

3.2 Nominal stress approach

3.2.1 Overview of the approach

The nominal stress approach uses for fatigue assessment a stress which disregards the local stress increase due to structural discontinuity (e.g. a stiffener termination) and also due to the local weld profile. These effects are included in notch cases containing structural details which are associated with design S-N curves allowing the fatigue life to be assessed (also called FAT classes).

In the case of weld root fatigue, a nominal stress in the weld is used. This might require a special analysis which is outlined below. As already mentioned in Section 2, several notch cases are defined in codes and guidelines for different types of joints (e.g. [16]). The associated fatigue class is relatively low (FAT 36–40), defining the characteristic fatigue strength of the design S–N curve at two million cycles for a survival probability of 97.7 %. The reasons for the low fatigue class are that a very sharp notch is present and that the nominal stress in the weld disregards any local bending effects.

In general, the nominal stress approach is the easiest to apply, requiring only a simplified stress determination. Several influence factors such as misalignment effects are implicitly taken into account to a certain extent, whereas others, such as weld throat bending, are neglected or only roughly considered. The nominal stress approach should thus be applied only to the cases and within the limits defined by the notch cases described in codes and recommendations.

3.2.2 Nominal weld stress

Nominal stress is often determined by formulas using load parameters, such as forces and bending moments, as well as section properties, such as section area and modulus. Alternatively, relatively coarse finite element models are used. It should be borne in mind that stress raisers which are not typical of the welded detail itself must also be taken into account (e.g. reduced effective widths).

In butt joints, the nominal weld stress can often be calculated directly from the nominal stress in the adjacent plate, taking into account any reduced sectional area, see Fig. 3. Weld reinforcement is usually neglected.

In fillet welds, a special weld stress is usually applied, illustrated in Fig. 9a by a cruciform joint with fillet welds. The weld stress σ n,w is based on averaged stress components in the weld throat which are also used in the static design of welds, i.e.

-

The stress σ ⊥ normal to the weld throat section

-

The shear stress τ ⊥ in the weld throat section

As illustrated in Fig. 9b, c, the horizontal or vertical leg sections, reduced to the throat thickness a, may also be considered to determine the averaged stress components σ ⊥ and τ ⊥.

The stress components are combined by vector addition into the nominal weld stress σ n,w, i.e.

In simple cases, the stress components can be determined by equilibrium conditions from the nominal stress σ n in the plate or, in more complex cases, by the finite element method using the forces or stresses in the weld.

In the case of the cruciform joint, the nominal weld stress can also be determined by simply referring the axial force in the plate (σ m × t) to the weld throat area (2a) and the bending moment (σ b × t 2/6) to the weld throat area multiplied by the distance between the weld legs (a × t):

Other cases can be treated analogously. Special cases are one-sided fillet and partial penetration Y-butt welds, where the secondary bending stress is casually considered in the nominal weld stress in connection with an increased fatigue class. The stress is frequently regarded as a structural stress, see Section 3.3.

3.2.3 Notch cases

Codes and guidelines based on the nominal stress approach usually contain several notch cases for weld root fatigue. Section 2 summarises such cases without stating all details.

The related fatigue classes according to the IIW Fatigue Design Recommendations [16] may be grouped according to the following principles:

-

Butt joints made from one side with weld root controlled by a backing bar or NDT are classified as FAT 71–80 for steel and FAT 25–28 for aluminium.

-

If butt joints contain embedded non-fused root faces and/or if the weld root cannot be controlled by NDT, the joint is classified as FAT 36 (steel) or FAT 12 (aluminium).

-

Fillet welds and partial penetration K-butt welds are classified as FAT 36 (steel) or FAT 12 (aluminium). Relatively thin fillet welds (a/t ≤ 1/3) are assessed one class higher. Exceptions are one-sided fillet and partial penetration Y-butt welds if the secondary bending stress is included (leading to FAT 71 for steel and FAT 25 for aluminium). Welds connecting the end of a hollow section are classified as FAT 36–45 for steel and FAT 14–16 for aluminium (depending on section shape and thickness)

-

Special cases are butt-welds of three-plate joints and fillet welds at lap joints. Here, the non-fused root faces are parallel to the loading direction. In the case of butt-welds, FAT 63–71 applies to steel and FAT 22 to aluminium. Double lap joints are classified as FAT 45 for steel and FAT 16 for aluminium, whereas overlap joints are downgraded to FAT 36 (steel) and FAT 12 (aluminium) due to the additional throat bending.

3.2.4 Multiaxial loading

Further stress components may be acting in addition to those shown in Fig. 9. The shear stress τ II parallel to the weld line is primarily relevant to fatigue. The interaction equation according to Gough—Pollard, which corresponds to the von Mises hypothesis, can be used to describe the combined effect of stress components, i.e. σ n,w and τ ‖ in this case:

with the multiaxial damage parameter D MA = 1 and the particular fatigue strengths (FAT) for normal and shear stresses at the anticipated number of load cycles N, see Sonsino and Wiebesiek [39], Hobbacher [16], Wiebesiek and Sonsino [45], Sonsino [36] and Sonsino [37].

If the normal stress component parallel to the weld σ ‖ is to be considered too, then this has to be done by deriving either the principal stress or the von Mises stress from σ n,w and σ ‖, but without the shear stress component τ ⊥.

A further alternative for the case of proportional stress components, an extension of Eq. (3.3), has been proposed [23], using the averaged parallel shear stress in the weld throat τ ‖:

The above proposed Eq. (3.5) results in acceptable evaluations for proportional loading with constant principal stress directions. However, in the case of non-proportional loading with changing principal stress directions, these equations, including Eq. (3.3), fail because they do not display the fatigue life reduction for ductile materials and overestimate fatigue life significantly, i.e. the calculations are on the unsafe side. For this, a modification of the Gough–Pollard Eq. (3.5) by the multiaxial damage parameter D MA = 0.5 is suggested, rendering good assessments, see Sonsino and Wiebesiek [39], Wiebesiek and Sonsino [45], Sonsino [36] and Sonsino [37].

3.3 Structural stress approaches

3.3.1 Overview of the approaches

In contrast to nominal stress, structural stress contains the stress increase due to the structural configuration, e.g. caused by the structure-related stress concentration or additional plate bending including significant misalignment effects. Not considered is the local stress peak by the weld itself because of its sharp notches at the weld toe and root.

At weld toes, structural stress is usually determined by extrapolating the surface stress to the hot-spot, termed structural hot-spot stress [30]. Another way of omitting the local stress peak is stress linearisation in the thickness direction.

Surface stress extrapolation is not suitable for the fatigue assessment of weld roots. Therefore, approaches exist which utilise local nominal stress or structural weld stress derived from the forces and moments or from the stress distribution in the weld itself, partly restricted to definite cases of application. Figure 10 gives an overview of the different approaches together with the stress types used and the FAT classes for steel. The approaches are briefly described in the following.

In contrast to the nominal stress approach, the structural stress approach for weld root fatigue offers the possibility of considering explicitly the stress increase in a weld because of local structural stress concentrations and/or local weld throat bending caused by geometrical configuration or misalignment effects. Here, the approach offers advantages over the nominal stress approach, though it is still based on rather simple analysis models. This implies on the other hand the assumption of a simplified stress distribution in the weld throat by averaging or linearising it. The approach has been verified by several examples which define and limit its scope of application.

3.3.2 Approach for fillet-welded attachment ends

In fillet welds around loaded attachment ends, as illustrated in Fig. 6, increased stresses occur due to the concentrated force flow in the corner. The increased stress averaged in the weld throat area around the attachment end can be estimated from the transmitted force F e as outlined in Fig. 11 [13] while the local weld throat bending is neglected. This stress can be considered as structural weld stress or local nominal weld stress, averaged over a definite area.

Geometry and loading of the end of an attachment similar to that in Fig. 6

One must distinguish between two cases. In the first case, the plate stress σ p in the attachment is acting perpendicular to the fillet weld (Fig. 11) without any other significant stress component such as a shear stress parallel to the weld. Weld root failure is caused by the stress transferred through a fillet weld with throat thickness a.

It is assumed that the force F e at the end of the attachment, representing the local plate stress σ p in a reference area up to t/2 from the attachment end (t = plate thickness), is transferred through the hatched effective weld area in Fig. 11 (section A–A). The averaged local nominal weld stress σ n,w,loc in this effective weld area due to this force F e becomes:

Here, the weld area is conservatively assumed to have throat thickness a (not leg length). It has been shown that the stress intensity factors of this complex 3D situation at attachment ends and of the corresponding 2D case of cruciform joints are almost the same [13]. As a consequence, the fatigue assessment can be based on the same fatigue class as for cruciform joints (FAT 36–40 for steel).

The local nominal or structural weld stress can be determined from a finite element model with shell or solid elements in the attachment having a breadth of t/2 or even t. Their stresses are used to derive the force F e from the averaged local plate stress σ n,p,loc in the reference area t × t/2. As an alternative, the local nominal weld stress may be determined directly in the section A–A, where the normal stress components can be evaluated from selected weld elements of a finite element model. It should be mentioned that the load transmitted has to be referred to the effective weld area shown in Fig. 11. If the non-fused slit is modelled, nodal forces rather than element stresses should be evaluated in coarse finite element meshes [13]. However, the evaluation of the loads transmitted is also possible when the slit is not modelled.

In the second case, not only are there normal stresses acting perpendicular to the weld, as assumed in Fig. 11, but also significant shear stresses acting parallel to the weld. These are present particularly in attachment ends with soft toes, where weld root failures may also occur.

Two possibilities for their consideration have been proposed. In the first, the averaged stress components in the effective weld area are used, i.e. normal stress σ⊥ and parallel shear stress τ ║, see Fig. 12a. They can be evaluated in the same way as described above. The following equivalent weld stress has been proposed for the fatigue assessment:

The alternative approach uses the resultant force F e at the attachment end acting in the reference area t × t/2 in the plate next to the weld. This force and its angle φ from the normal may be derived from the averaged principal stresses at the nodal points in the reference area. It is assumed that the total force F e is transferred through the effective weld area, reduced according to the angle φ, see Fig. 12b. Then the resulting local nominal stress in the weld becomes:

The averaged principal stress σ 1,n,loc acts on the projection of the reference area t × t/2, which is considered as follows when calculating the force F e:

As shown in Eq. (3.9), the evaluation is no longer valid for large angles φ, which may occur when the reference area for stress evaluation comes too close to the upper surface of the soft toe.

An application of the approach is demonstrated in Section 4.2.

3.3.3 Approach for local weld throat bending using stresses in the weld leg

Local weld throat bending occurs particularly in one-sided fillet or partial-penetration welds (see Fig. 4c, d) and is caused by eccentric load transfer or bending of the attached plate. Fricke et al. [15] presented an approach for the fatigue assessment of fillet welds which are predominantly subjected to throat bending. They proposed using the linearised stress in the leg plane in the extension of the root face (section A–A in Fig. 13a), and not in the weld throat, because fatigue tests as well as crack propagation analyses at cruciform and hollow section joints had shown that the crack path was closer to this plane than to the weld throat section. In addition, the stress in the leg section—in contrast to that in the throat section—is characterised in several cases mainly by normal stresses (i.e. axial and bending stress, σ m,w and σ b,w, respectively) and less by shear stresses τ w. This facilitates the stress analysis and even allows the evaluation of linearised stresses in one-sided welds from the loads in the attached plate by equilibrium conditions as outlined below. The leg length should be limited to the thickness of the attached plate to avoid non-conservative results.

If mainly axial and bending stresses are acting and shear stresses are small, fatigue class FAT 80 has been found from different fatigue test series to be appropriate for welds of steel. The fatigue class is higher than that mentioned in the previous sub-section because the bending portion is now included. It should be noted that larger shear stresses τ w change the direction of the principal stress and, hence, the crack path. If in doubt, the amount of τ w and the applicability of the approach should be checked (it has been proposed that it should be less than 20 % of the normal stress, which changes the principal stress direction by about 10°).

Using finite element models with solid elements

The stresses or forces in the leg section can be directly linearised to obtain the membrane and bending portion σ m,w and σ b,w, respectively, of the structural weld stress σ s,w:

where σ(z) is the stress normal to the leg section, z the coordinate along the weld leg and ℓ the leg length, see Fig. 13a. In the same way, the shear stresses τ w can also be linearised.

The determination of structural weld stresses from finite element models can become unreliable due to the influence of the notch singularity at the weld root [14]. Therefore it is recommended that internal nodal forces be used instead of element stresses for the integration according to Eqs. (3.12) and (3.13), as these naturally satisfy equilibrium conditions.

If a one-sided weld is present, as shown in Fig. 13a, the structural weld stress can also generally be derived from the membrane and bending portion σ m and σ b of the structural stress in the attached plate by using equilibrium conditions between the weld and the plate sections. This means that a relatively coarse mesh established for the analysis of structural hot-spot stresses can be used.

An application of this approach is demonstrated in Section 4.3.

Using finite elements models with shell elements

In a model with shell elements, the structural stress components can be directly obtained from the internal forces and moments f w and m w per unit length acting at the weld leg mid-line, see Fig. 13b, by the following equations:

f w and m w can also be obtained from an appropriate shell element model such as the one described for a one-sided weld by Turlier et al. [42]. Element nodes are located at mid-height of the leg section (point B). The internal forces and moments are obtained by transformation of nodal forces using the shell element shape functions. Metal sheets are represented by their mid-surfaces, meshed with shell elements. In order to assess fatigue, node locations are forced at the root and the toes, see Fig. 14a.

The weld is represented by shell elements which are connected to the sheets using the FEA gluing technique. Weld leg nodes are projected on the mid-surfaces and linked with rigid body elements. Finally, the projected nodes are coupled with sheet element nodes using multipoint constraints.

With weld throat thickness assigned as the shell thickness and the gluing technique avoiding additional rigidity, the model is representative regarding the stiffness of the assembly, see Fig. 14b. Moreover, local nominal weld stress can be determined by extracting the loads on the shell element. The shear stress component is obtained if thick shell element formulation is used.

The approach is applied to different examples in Section 4.

3.3.4 Approaches for local weld throat bending using stresses in the weld throat

A specific procedure for the fatigue assessment of weld root failure using stresses in the weld throat has been proposed by Sørensen et al. [40], allowing various load combinations to be considered. The weld is modelled by isoparametric 20-node hexahedronal elements such that two elements describe the throat section line, see Fig. 15. Linear elements would require a finer mesh.

Fillet weld modelling by 20-node hexahedronal elements and evaluation of the hot-spot weld stress by linear extrapolation (after [40])

The structural stress evaluation is based on an extrapolation of the stresses evaluated at two points located one quarter of the throat thickness apart from the weld root or weld surface respectively. The stresses at these 'quarter points' are linearly extrapolated to the weld root, where a stress singularity exists, thus defining the ‘hot-spot weld stress’ σ hs,w. The authors showed that in several cases it was sufficient to evaluate and extrapolate the first principal stress σ 1 at the mid-side nodes of the two elements. In more complex load cases, the recommendation is to extrapolate the six stress components σ x, σ y, σ z, τ xy, τ yz, and τ zx to the weld root and then to evaluate the first principal stress there. Specific meshing rules have to be observed in the neighbourhood of the weld.

The hot-spot weld stress was successfully used to describe a uniform narrow scatter band of fatigue test results for fillet-welded cover plates and cruciform specimens made of structural steel, comprising different degrees of weld throat bending. An evaluation with the prescribed inverse slope exponent m = 3 results in a characteristic fatigue strength of 61 N/mm2 based, however, on a probability of survival P s = 95 %.

A similar approach was proposed by Hong [17] using the axial and bending stress in the weld throat in connection with the same stress parameter used in previous proposals for the weld toe, thus considering effects of thickness and stress gradient. A similar approach has been applied to the ends of longitudinal attachments by Maddox et al. [26]. In order to fit Maddox’s test results with fatigue strength of FAT 80, the idea is to transpose the linearised structural stress calculation as described in Section 3.3.2 to any section through the weld throat. Turlier et al. [43] have developed an analytical formula based on weld leg line forces and moments and weld throat sizes. It gives the structural stress at the weld root depending on the angle of the weld throat section. The maximum structural stress may be evaluated. This has been also used in the case of asymmetric fillet welds subject to pure bending. In special cases, the stress in the plate adjacent to the weld may additionally have to be taken into account, particularly in the case of high penetration joints [43].

3.3.5 Approach using the 1-mm stress

Xiao and Yamada [48] proposed applying their structural stress approach using the 1-mm stress not only to weld toes, but also to weld roots. The idea behind the approach is that the stress at a distance of approx. 1 mm from the local notch in the direction of the expected crack propagation is representative of the early crack propagation phase which accounts for the major part of the fatigue life.

The approach has successfully been applied to various fillet-welded joints with weld toe failure, resulting in characteristic fatigue strength of FAT 100. The application to cruciform joints with weld root failure indicated a fatigue class reduced to approx. FAT 71.

The stress analysis requires a relatively fine finite element mesh with elements having a size of max 1 mm (better 0.5 mm), allowing stress evaluation at the nodal point at a distance of 1 mm from the weld root. It is not fully clear which stress component should be used for the fatigue assessment. In case of doubt, the first principal stress should be evaluated conservatively.

3.4 Effective notch stress approach

3.4.1 Overview of the approach

The effective notch stress approach considers the increase in local stress at the notch formed by the weld toe or the weld root, based on theory of elasticity, i.e. without consideration of elastic–plastic material behaviour. The micro-structural support effect of the material, which considers the effect on fatigue behaviour of the inhomogeneous material structure under a stress gradient, may be taken into account by averaging the stress over a definite area.

This approach is mainly used in the form of fictitious notch rounding, see Fig. 16 [12, 16, 31]. The basic idea behind this approach is that the stress reduction in a notch due to averaging the stress over a certain depth can alternatively be achieved by a fictitious enlargement of the notch radius ρ f.

Fictitious notch rounding (graph according to [16])

In a ‘worst case’ or conservative way, Radaj assumed a fictitious radius of r ref = 1 mm, meanwhile termed reference radius. This reference radius derived for welded joints in steel is also used for welded joints in aluminium and magnesium alloys.

The notch rounding with a reference radius of 1 mm may cause problems in thin structures less than 5 mm thick. In particular, the groove created by this radius at the weld root causes a substantial reduction in cross-section and hence modifies the stress distribution, which affects the results of the fatigue assessment.

Therefore, a small-size notch approach which uses a reference radius r ref = 0.05 mm has been proposed for assessing root failure of welded joints in thin-sheet material (steel, aluminium and magnesium alloys) in particular. The re-evaluation of tests shows that it seems to be better suited also to the fatigue assessment of relatively thick laser stake-welded T-joints if the slope exponent m = 3 is assumed for the S–N curve [10].

The main advantage of the effective notch stress approach over the nominal and structural stress approaches is that the local stress in the relevant notch is explicitly taken into account so that influencing factors like the actual local geometry including weld throat thickness and the local stress distribution etc. are considered. However, the weld geometry still has to be idealised, particularly at the weld root, so that irregularities and other effects such as residual stresses can only be considered by the S–N curve chosen.

3.4.2 Modelling and numerical analysis

The rounding of the roots of non-penetrating fillet welds is shown in Fig. 16. The length of the non-welded root faces is retained by locating the vertex point of the circle at the weld root, see Figs. 17 and 18. Different shapes are possible [32], among others the keyhole notch and the U-shaped notch, Fig. 17b, c. The latter reduces the high stress concentration in the keyhole notch for loading parallel to the non-welded root faces, but it should be noted that it can also lead to an underestimation of the required notch stress for assessing potential fatigue failure in the weld throat. Therefore, it cannot generally be recommended.

In thin-walled structures it might be necessary to compensate for the increase in net section stress due to the notch depth [31].

Usually, notch stress is computed numerically using the finite element method. The stresses may be solved by 3D or a 2D analysis, the latter being restricted to special cases where variations of the geometry and loading in the 3rd direction can be neglected. In this case, plane strain conditions are usually assumed, as biaxial stresses occur in the notches due to restraint in the 3rd direction.

The discretisation of the structure is normally performed such that a relatively coarse overall mesh is established, which is locally refined in the neighbourhood of the notches under consideration. The mesh should be gradually refined towards the notched area, avoiding large steps in element size and excessive element distortion. Figure 19 shows a typical example for a weld root modelled with a keyhole notch.

Recommended element sizes at the notch root rounded with radius r are r/4 or less for elements with higher-order displacement functions and accordingly reduced for elements with linear displacement function [12]. It should be observed that this element size applies to the directions along the rounded notch surface as well as those perpendicular to it, in the latter preferably even smaller in size because of the steep stress gradient.

Notch stresses on the rounded surface of the notch are evaluated, using the tangential and normal stresses in the section and the shear stresses on the notch surface. From these, principal or equivalent stresses can be derived.

Further aspects for modelling and stress evaluation are discussed by Fricke [12].

3.4.3 S–N curves and FAT classes

The FAT classes to be used for the S–N curve in the effective notch stress approach were derived from a statistical analysis of relevant fatigue test results obtained from welded joints and associated notch stress analyses. The results of the analyses are summarised in the left part of Table 1 for the reference radius r ref = 1 mm and in the right part for the reference radius r ref = 0.05 mm. It should be noted that these fatigue classes have been derived based on the assumption that the S–N curve has a slope exponent of m = 3. Different slope exponents, e.g. m = 5, have been observed, particularly in thin-walled structures, leading to suggestions for modified approaches [38].

The FAT classes are based on the range of maximum principal stress in the notch root. A reduction by one category is recommended should the equivalent von Mises stress be assessed. This is recommended particularly for cases with predominant shear loading parallel to the weld line, characterised by principal stresses on the notch surface having different signs. Further details have been given, e.g. by Fricke [12] and Sonsino [35].

3.4.4 Multiaxial fatigue

Multiaxial stress states with proportional loading can be assessed using either the range of the maximum principal stress—as long as both principal stresses have the same sign—or the equivalent von Mises stress as described in the previous section. The interaction equation presented in Section 3.2.4 can be used too, using the local stress components and respecting the stated limitations between proportional and non-proportional loading.

3.5 Approaches based on the stress intensity factor

3.5.1 Overview of the approaches

The theoretically infinite stress at sharp V-notches with notch opening angle 2α can be described by a N-SIF in a similar way as for crack tips. Local stress distributions in plane configurations are given as a combination of a symmetric and skew-symmetric stress field. The N-SIFs K 1 and K 2 for modes I and II loading quantify the magnitude of the asymptotic stress distribution according to the theoretical solution of Williams [46].

The N-SIFs can be used directly to describe the crack initiation at sharp corners [5, 44]. Lazzarin and Tovo [18] developed an N-SIF approach for welded joints and showed that fatigue test results of various welded joints form an S–N curve with reasonable scatter if based on N-SIF.

The N-SIF approach requires knowledge of the elastic stress field in the region very close to the notch tip. In a similar way as for the stress analysis at crack tips, finite element meshes must be very fine in this region.

However, the N-SIFs K 1 and K 2 can be related to the total elastic strain energy density (SED) \( \overline{W} \) averaged over a cylindrical sector with a given characteristic radius R 0 in the case of the modes I and II stress distributions under plane strain conditions by the following equation:

where: E = Young's modulus

λ 1, λ 2 = the eigenvalues of the stress field for K 1 and K 2 modes (see Fig. 20)

Eigenvalues defining the order of stress singularity at sharp V notches depending on 2α (from [31])

e 1, e 2 = parameters depending on the notch opening angle 2α.

When 2α is 135°, a typical value for fillet-welded joints, the mode I stress distribution is singular (1 − λ 1 = 0.326), whereas the mode II distribution is not (1 − λ 2 = -0.302). For 2α = 0°, all distributions are singular and reflect the characteristic stress field at a crack tip. The parameters e 1 and e 2 have been described analytically by Lazzarin and Zambardi [19]. For 2α = 135°, these are e 1 = 0.118 and e 2 = 0.111 and for 2α = 0° e 1 = 0.133 and e 2 = 0.34.

The control radius R 0 is material-dependent and has been proposed by Lazzarin and Zambardi [19] and Livieri and Lazzarin [22] to be 0.28 mm, considering the failure behaviour of conventional fillet-welded joints under mode I loading for steel. For an opening angle of 0°, this value is conservative. Corresponding considerations would result in R 0 = 0.36 mm.

The correlation between the average elastic SED and the N-SIF offers a practical way of computing the relevant fatigue parameter with a coarser finite element model. The average SED can be used directly as the fatigue parameter (SED approach), which allows the results of different notches (i.e. weld toes and roots) to be included in the same diagram (whereas the N-SIFs have different units). A presentation of the results for 650 welded joints has been given by Lazzarin et al. [20], see Fig. 21 (mostly transverse non-load carrying fillet-welded joints)

Fatigue strength of fillet-welded joints as function of the range of the average strain energy density \( \varDelta \overline{W} \) [20]

A uniform control radius R 0 = 0.28 mm has been used for both weld toe and weld root failure. The thickness of the main plate ranged from 6 to 100 mm, so that its effect is included. The scatter band given in Fig. 21 refers to ±2 standard deviations, giving a characteristic fatigue strength of Δ\( \overline{W}=0.058\kern0.5em \mathrm{N}\mathrm{mm}/{\mathrm{mm}}^3 \).

A relationship with stresses can be found using the simple expression

with E' = E/(1 − ν 2) for plane strain conditions [20]. Equation (3.17) describes the equivalent stress for a calculated SED averaged over a definite volume. Using this equation, the vertical axis in Fig. 21 could be converted into an equivalent stress range, resulting in a slope exponent m = 3 because of the square root in Eq. (3.17).

An alternative approach based on the N-SIF is the so-called Peak Stress Approach proposed by Meneghetti [27, 28]. This approach utilises the ratio K FE* between the notch stress intensity factor K 1 and the nodal stress σ peak in the V-shaped notch for a finite element mesh with given global element size d and displacement functions, which is valid as long as the mode II stress contribution to the local stress field is absent or negligible. In the case of a mesh where only two elements share the nodal point in the weld toe and four elements the one in the weld root (see Fig. 22), the following relationship has been found for certain linear 2D elements (PLANE42 of ANSYS element library):

Pattern of finite elements to analyse a welded joint by means of the Peak Stress Method [29]

It should be borne in mind that this and the following relations are only valid for the element type mentioned. The opening angle α may be between 0 and 135°. It must be taken into account that different element types and mesh patterns lead to different peak stress values, mainly because of varying internal element stresses and stress extrapolation rules from the integration points to the nodal points.

A link between the range of the peak stress Δσ peak and the strain energy density SED averaged within the control radius R 0 was found by Meneghetti and Lazzarin [29] by using the range of the equivalent stress Δσ eq, resulting in:

The range of the average strain energy density is given by Eq. (3.16). The factor f w is listed in Table 2 for the factor in Eq. (3.19), ν = 0.3, d = 1 mm, R 0 = 0.28 mm and λ 1 and e 1 according to Lazzarin and Zambardi [19].

The weighted peak stress range f w × Δσ peak can be used as an alternative parameter for an S–N curve [29].

In general it can be said that the approaches based on the notch stress intensity factor offer similar opportunities and benefits to those of the effective notch stress approach. One advantage is that the original idealised weld geometry can be used without inserting the fictitious notch radius, which might affect geometry, particularly at weld roots. The validation includes weld roots in addition to weld toes. The other limitations are the same as for all approaches based on S–N curves.

3.5.2 Computation of notch stress intensity factors or strain energy density

Different possibilities exist for computing the stress parameter for the application of the notch stress intensity factor approach described above:

-

Direct computation of the notch stress intensity factor N-SIF. As mentioned before, this requires an extremely fine finite element mesh [41] from which the stress distribution can be compared with the theoretical solution of V-notches to derive the N-SIFs.

-

Computation of the average SED in a control volume with radius R 0 allowing the N-SIF to be derived (Eq. 3.16). Alternatively, the SED or the equivalent stress can be used directly for the fatigue assessment. The approach requires finite element sizes of R 0 or less.

-

Lazzarin et al. [20] have shown that the computation of the average SED for a larger control radius of R * = 1 mm and converting it to 0.28 mm using Eq. (3.16) yields results with sufficient accuracy at the weld toe where only mode I stress distribution is singular. In principle, Eq. (3.16) can also be used under mixed mode conditions when the degree of singularity of the mode I and mode II stress fields is the same, as at the weld root region (λ 1 = λ 2 = 0.5).

-

However, at the roots of non-penetrating welds with loading parallel to the slit, the effect of the T-stress (i.e. the constant stress component parallel to the slit [47]) has to be taken into account. This means that the main contribution of the T-stress σ T to the strain energy density at weld roots, i.e.

$$ \varDelta {\overline{W}}_T={\sigma}_T^2/2\;E\prime, $$(3.20)has to be deducted from the average strain energy \( \varDelta \overline{W}\left({R}^{*}\right) \) before converting the strain energy density by Eq. (3.16). By so doing, it is possible to compute the increase to the local strain energy density due only to the singular stress fields. After conversion ΔW T must be included again. The calculation remains approximate because the effect of further terms [21] has not been considered here for the sake of simplicity.

-

Computation of the peak stress σ peak and converting it into the notch stress intensity factor (Eq. 3.18) or the SED (Eq. 3.19 and 3.17). A typical FE mesh has been shown in Fig. 22.

-

Figure 23 shows a fine-meshed FE model for the 2D analysis of the average SED in a control volume with R 0 = 0.28 mm at the weld toe as well as the weld root. The alternative with a coarse mesh is illustrated in Fig. 24, using triangular elements around the notch tip having quadratic shape function and a length of 1 mm. Suggestions for meshing and several applications have been shown by Lazzarin et al. [20] and Fischer et al. [9].

3.6 Crack propagation approach

3.6.1 Overview of the approach

The crack propagation approach allows the phase of crack growth between an initial and a final crack length to be evaluated. This is based on linear elastic fracture mechanics, as plastic zones are rather small during fatigue crack propagation. The crack propagation rate da/dN can be estimated using the stress intensity factor at the crack tip and the power law by Paris and Erdogan, describing the linear relationship between the crack propagation rate and the range of the stress intensity factor ΔK in bi-logarithmic scale:

with the material parameters C and m. The linear relationship is valid between the threshold value ΔK th with no crack propagation beneath and the transition to an unstable fracture with the critical stress intensity factor K c, see Fig. 25. Different variants exist to consider, e.g. the stress ratio R.

Example for relationship between the crack growth rate da/dN and the range of the stress intensity factor ΔK [31]

The approach is well suited to the fatigue assessment of welded joints where the crack initiation life is short and the fatigue life is mainly determined by the crack propagation phase. This is particularly the case for weld root fatigue where the slit between the non-fused root faces acts like an initial crack. In contrast to the S–N approaches, which are based on one stress value, the effect of the complete stress field on fatigue is considered. This increases the analysis effort but offers a better fatigue life estimation in several cases.

In the following, some remarks are given on the application of the approach to weld root fatigue. Further information on the approach can be found in the relevant literature (e.g. [2, 7, 16, 31, 33]).

3.6.2 Stress intensity factors

As a first step, crack intensity factors have to be determined for different crack lengths or shapes. Different possibilities exist, such as the use of tabulated factors in handbooks and the application of numerical methods. Here, the stress intensity factors can be determined indirectly by the so-called weight factor method or directly by the finite element method, using the strain energy release rate during virtual or real crack extension or the J-integral.

Finite element models have to be very fine-meshed around the crack tip. If isoparametric elements with mid-side nodes are used, the results can be improved by using a special feature, i.e. shifting the mid-side nodes nearer the crack tip to the quarter points in all elements around the crack tip (preferably elements of triangular shape), see Fig. 26. In this case, they fulfil the r -0.5 singularity of the local stress field.

It is important to consider the local geometry around the crack and the loading, which is taken into account by the so-called geometry factor in standard cases. Also, the crack shape and crack path may affect the results considerably. The crack may be assumed as a continuous 2D crack or a local crack with semi-elliptical shape. If a long non-fused slit acts as an initial crack, a continuous 2D crack is usually assumed. The crack path is mainly determined by the ratio between the stress intensity factors for the sliding mode K II and opening mode K I. A pronounced K II (shear mode) results in a deviation of the crack path in a direction which is perpendicular to the max. principal stress (range).

3.6.3 Determination of fatigue life

The fatigue life consumed by crack propagation is determined by integrating the power law (3.21) of Paris and Erdogan. Material constants C and m as well as ΔK th are proposed in different guidelines (e.g. [6, 16]), assuming upper bound values for predictions on the safe side.

The critical crack length or stress intensity factor K c affects the crack propagation only marginally, as the crack growth rate is already very high when the linear relationship (Eq. 3.21) approaches K c.

Crack closure may be more important, making the stress cycle effective only during the portion where the crack is open. This can be smaller than the tensile part of the stress cycle because of local plastification. Usually, an effective part of the range of the stress intensity factor ΔK eff is defined for the determination of the crack growth rate according to Eq. (3.21).

4 Demonstration examples

In total, six demonstration examples are described. Table 3 gives an overview of the different approaches applied. For each approach, at least two examples are given.

4.1 Cruciform joint

4.1.1 Description of the detail

The cruciform joint with partial penetration shown in Fig. 27 is selected as example. The chosen geometry parameters are:

Limit curves separating weld toe and root fracture in cruciform joints [24], the geometry investigated here is indicated by a circle

Plate thickness | 2b = 25.0 mm |

Length of root face | 2a = 12.5 mm |

Leg length | c = 17.7 mm (= 12.5·√2 mm) |

In Fig. 27, this geometry is just below the limit curve for 25 mm so that the fatigue strength computed for the weld toe should be slightly above that for the weld root. The characteristic fatigue strength based on nominal axial stress range is to be determined for weld toe and weld root failure.

4.1.2 Application of the nominal stress approach

In the nominal stress approach, weld toe failure in partial penetration cruciform joints is frequently associated with fatigue class FAT 63, see No. 413 in the IIW Fatigue Design Recommendations [16]. Weld root failure, however, is associated with FAT 36, based on nominal weld stress. If the throat thickness is defined by the shortest distance between the end of the slit and the weld surface, i.e. 16.9 mm in the example, the ratio between the stresses in the weld throat and in the plate is 0.739, so that the fatigue class for weld root fatigue becomes FAT 49 if based on plate stress. This means that weld root fatigue is more critical than weld toe fatigue which agrees well with Fig. 27.

4.1.3 Application of the structural stress approach

The 2D finite element model shown in Fig. 28 was created assuming plane strain condition. The axial load is applied at the right end (σ n = 100 MPa).

For fatigue assessment of the weld toe, stress values were extracted at a distance 0.4 t and 1.0 t on the plate surface and linearly extrapolated to the weld toe [16], yielding a structural hot-spot stress of σ hs = 100.8 MPa.

For fatigue assessment of the weld root, nodal forces were extracted in the vertical weld leg section and summed up according to Fig. 13 and Eqs. (3.12–3.13). This gives the following results:

-

membrane stress in weld leg σ m,w = 52 N/mm2

-

bending stress in weld leg σ b,w = 67 N/mm2

-

structural stress in weld leg σ s,w = 119 N/mm2

The transverse shear stress in the weld is within the limits of the approach (τ w = 14 N/mm2), i.e. less than 20 % of the structural stress.

The structural stresses at the weld toe, σ hs = 100.8 MPa, and at the weld root, σ s,w = 119 MPa, are compared with their corresponding fatigue classes (FAT90 at toe and FAT80 at root). The ratios between structural stress and the corresponding fatigue class show an advantage for root failure. Based on nominal stress in the main plate, the characteristic fatigue strengths are 89 MPa for the weld toe and 68 MPa for the weld root.

The alternative with shell elements described in Section 3.3.3 shows smaller bending stresses in the weld; hence, it is on the non-conservative side.

4.1.4 Application of the effective notch stress approach

The 2D finite element model shown in Fig. 29 has been created representing one quarter of the joint. Symmetry conditions have been utilised at the left und lower boundaries. 2D plane strain elements with quadratic shape function have been used. The mesh fineness in the critical points, i.e. in the weld toe and weld root (modelled by a keyhole notch), corresponds to the recommendations by Fricke [12]. An axial load is acting on the right-hand side.

The following fatigue notch factors K f at the weld toe and root, based on the stress in the abutting plate, have been computed:

-

Weld toe, K f = 3.75

-

Weld root, K f = 4.43

The notch stress at the weld root is about 18 % higher than that at the weld toe which agrees with Fig. 27 where weld root fatigue is more critical.

4.1.5 Application of the strain energy density approach

The calculation of the strain energy density (SED) \( \overline{W} \) averaged within a control radius of R 0 = 0.28 mm with the finite element model shown in Fig. 30 yields the following values at the weld toe and root for an axial stress of 100 N/mm2.

-

Weld toe, \( \overline{W}=0.192\ \mathrm{Nmm}/{\mathrm{mm}}^3 \)

-

Weld root, \( \overline{W}=0.224\ \mathrm{Nmm}/{\mathrm{mm}}^3 \)

Here, the SED at the weld root is about 17 % higher than that at the weld toe.

4.1.6 Application of the Peak Stress approach

According to Meneghetti and Lazzarin [29], the weighted peak stress is determined at the toe and root of the joint. A free mesh of four-node quadrilateral elements (PLANE 42 elements of the ANSYS element library) shown in Fig. 31 was adopted in the numerical analysis, and the global element size was set to 1 mm. The maximum principal stress at the toe and root locations was determined and then multiplied by the coefficient f w reported in Table 2. The resulting equivalent stresses obtained for an axial stress of 100 N/mm2 are included in Fig. 31, showing that root failure rather than toe failure is predicted, with the stress being 18 % higher.

4.1.7 Application of the crack propagation approach

The crack propagation approach is applied using the Paris–Erdogan law (Eq. 3.21) with material parameters m = 3 and C = 5.21 · 10−13 (units, Newton and millimeters) recommended by Hobbacher [16], representing the upper limit of the scatter band (2.3 % probability of failure). The fatigue life is computed for a constant stress range ∆σ n = 100 N/mm2. End of life is defined when the crack length reaches half the plate thickness for toe cracks and half the throat thickness for root cracks. The remaining lifetime is rather short.

Crack propagation from the weld root

The length of the weld root face (12.5 mm) is assumed as the initial crack length. A continuous 2D crack is assumed for the whole propagation phase so that a 2D model is sufficient for the numerical analysis of the stress intensity factor (SIF). The finite element method was applied using the program FRANC2D [49]. Figure 32 shows the basic mesh created with 2D elements having quadratic displacement function. Plane strain was assumed. Symmetry conditions were utilised in two planes resulting in a quarter model.

Figure 32a also shows the computed crack path, which is slightly curved due to the presence of K II. The fatigue life up to a crack length of half the weld throat thickness is 265,000 cycles.

Crack propagation from the weld toe

Two numerical analyses were performed. The first again assumes a continuous 2D crack. Figure 32b shows the basic mesh created for the computation in FRANC2D [49], again indicating a curved crack front.

The initial crack length was assumed as a i = 0.15 mm, as recommended by Hobbacher [16]. The resulting fatigue life up to a crack length of half plate thickness was found to be 143,000 cycles. This is much shorter than the crack propagation life of the weld root, which does not correspond to Fig. 27. Even a much smaller initial crack length of a i = 0.05 mm does not change this, as the fatigue life would increase only to 158,000 cycles.

A possible explanation for the unexpected result is the assumption of a continuous 2D crack at the weld toe, whereas semi-elliptical cracks initiating from small defects or high notch effects are often observed in practice. Therefore, a second analysis of the SIFs with a 3D model was performed, using the program ANSYS 13.0 offering an iterative approach for the development of the crack front.

Figure 33 shows the finite element model chosen. The width of the model was assumed to be 50 mm, being typical for fatigue test specimens. The model consists of solid elements with quadratic displacement function. Along the semi-elliptical crack front, elements with mid-side nodes shifted towards the crack front, i.e. to the quarter points, were used to model the stress singularity, see Fig. 26. Symmetry conditions were utilised at half width.

The SIFs of the semi-elliptical shape were again computed at the vertex points. In order to avoid any influence of the singularity of the sharp weld toe at the outer vertex point (see right part of Fig. 33), the stress intensity factor at this point has been calculated by quadratic extrapolation of the adjacent results along the crack front.

The initial crack has been assumed to be semi-circular with a i = c i = 0.15 mm. The development of the crack front was assumed in accordance with the computed stress intensity factors at the vertex points, using the iterative approach mentioned. The iteration ended with a crack depth of 3.6 mm at 292,000 load cycles. Afterwards, a 2D crack is assumed, resulting for instance from coalescence of neighbouring cracks. This 2D crack reaches half plate thickness after a total of 324,000 load cycles.

The crack propagation life calculated in the 3D analysis with semi-elliptical crack shapes is much longer than that computed with 2D cracks. Furthermore, it is also longer than the computed life for the weld root crack (265,000 cycles) which is in agreement with Fig. 27.

4.1.8 Comparison of the results

A comparison between all results can be performed on the basis of the characteristic fatigue strength ∆σc at 2 · 106 cycles for survival probability P s = 97.7 % referring to nominal plate stress which can be derived from the computed local stress or SED, the assumed nominal stress and the characteristic value of the S-N curve. The latter has been assumed as FAT 225 for the effective notch stress and 0.058 Nmm/mm3 for the characteristic SED, see Fig. 21. Regarding the Peak Stress Method, the SED can be derived from the equivalent stress using Eq. (3.17). All approaches show that weld root failure is more probable, which is in agreement with Fig. 27, see Table 4. There are some differences between the results which include the test results evaluated by Maddox [24].

The results of the approaches, except for the nominal stress approach, do not yet consider the effects of axial misalignment. If a misalignment of 15 % of the plate thickness is assumed, the secondary bending stress is particularly high at the weld toe, resulting in a stress magnification of k m = 1.45 according to Eq. (3.1). For the weld root, the corresponding Eq. (3.2) yields k m = 1.09. This would mean that the results of the structural and nominal stress approaches are closer together. The notch stress, strain energy and crack propagation approaches are more conservative than the aforementioned ones and would then expect crack initiation at the weld toe. Their assessment might be valid, as it remains unclear to what extent axial misalignment was present in the tests forming the basis of Fig. 27.

4.2 Fillet weld around attachment end

4.2.1 Description of the detail

Figure 34 shows a specimen designed for the investigation of weld toe and root failure at attachment ends. The load in the plate is transferred into the attachments by shear stresses parallel to the weld which has a throat thickness a = 4 mm. In addition, pronounced bending stresses are acting in the attachments. The fatigue-critical detail is the soft nose of the right-hand attachment in Fig. 34, where the fillet weld is subjected to axial and shear stresses.

As the detail is relatively complex, only the structural stress and the stress intensity approaches are applied, allowing the fatigue strength of the weld toe and the weld root at the end of the attachment to be assessed.

4.2.2 Fatigue tests

Constant amplitude fatigue tests were performed with a total of

-

twenty specimens in as-welded state with a nominal stress range ∆σ n = 28 N/mm2 and 20 N/mm2 at a stress ratio R ≈ 0

-

ten specimens in as-welded state with ∆σ n = 23.5 N/mm2 at R = 0.5

-

ten specimens in stress-relieved state with ∆σ n = 20 N/mm2 at R ≈ 0

The tests, which are described by Fricke and Doerk [13], showed weld root failure in almost all specimens. The detailed results will be used in the subsequent investigations for comparison with the approaches.

4.2.3 Application of the structural stress approach with solid elements

The stresses were computed for a force in the vertical plate of F = 50 kN, corresponding to a nominal stress of σ n = 41.7 N/mm2. A relatively coarse finite element model was created which is shown in Fig. 35 together with the deformations and distribution of the max. principal stress.

The structural hot-spot stress at the upper weld toe, calculated acc. to [16], amounts to σ hs = 267 N/mm2, which means a structural stress concentration factor K s = 6.4 referring to the nominal stress in the vertical plate strip.

The bending moment in the transverse attachment creates a nominal bending stress in the weld throat of σ n,w = 183 N/mm2, based on the section modulus of the weld throat area concentrated at the root line. More relevant is the local nominal stress at the end of the weld, which has been derived with the approach illustrated in Fig. 12b. An inclination angle of φ = 32.6° was found for the principal stress in the reference area (t × t/2). The local nominal stress in the effective weld area according to Eq. (3.9) results in σ n,w,loc = 346 N/mm2, which is almost twice as high as the nominal stress in the weld. The evaluation of the weld stresses according to Eq. (3.8) and Fig. 12a gave almost the same result (337 N/mm2).

The fatigue assessment in Table 5 is performed by comparing the local stress ranges for a cyclic force of ∆F = 50 kN and the corresponding FAT classes. FAT 90 is assumed here for partial-load carrying weld toes on a plate surface. The comparison of the numbers shows that root cracking is much more probable than toe cracking due to the smaller ratio between endurable stress (FAT class) and applied stress range.

The fatigue lives from the tests are plotted in Fig. 36 in relation to the range of the local nominal weld stress ∆σ n,w,loc. They show that the results are only slightly affected by the stress ratio R and the residual stresses, which is in contrast to relatively stiff attachment ends where compressive residual stresses have been observed in the attachment.

The figure also shows that FAT 40 is a good basis for fatigue assessment, as the characteristic fatigue strength of the test series is slightly above this class. This was also shown for other tested geometries with different toe radii and weld throat thicknesses [13].

4.2.4 Application of the structural stress approach with shell elements

For the same load condition (F = 50 kN), the finite element analysis has been performed using shell elements and the technique described in Fig. 14. Mesh nodes have been introduced at the t/2 reference locations according to Fig. 11. The von Mises stress distribution is displayed in Fig. 37a. Structural hot-spot stress is calculated using through-thickness forces integration over the weld boundary as shown in Fig. 37b. The structural hot-spot stress range in the plate at the attachment end was found to be ∆σ hs = 254 N/mm2 (5 % less than in the solid model).

The local nominal weld stress is calculated with the forces extracted from the attachment (see Fig. 38) and Eq. (3.9) with φ = 36.4°, resulting in σ n,w,loc = 368 N/mm2 (6 % more than the solid model).

Related to their respective fatigue classes of FAT90 for the weld toe and FAT40 for the weld root, the highest ratio is obtained at the weld root where the crack might occur. The stresses calculated with shell elements are slightly larger than those from the solid model described above.

4.2.5 Application of the strain energy density approach

The strain energy density approach based on the notch stress intensity factor has been applied to this detail by Lazzarin et al. [21]. A nominal stress of σ n = 100 N/mm2 was assumed in the vertical plate strip. The strain energy density has been evaluated by means of 3D finite element analysis using 20 node brick elements. A 3D circular sector with R* = 1 mm surrounding the crack initiation points has been used and then reconverted to R 0 = 0.28 mm by means of the following equation, based on Eq. (3.16) neglecting K 2.

Table 6 shows the computed strain energy densities for the weld toe and weld root. It turns out that the weld root is more critical (for R 0 = 0.28 mm). Figure 39 shows the test data in an S-N diagram based on the range of the strain energy density \( \varDelta \overline{W} \). The results agree well with the scatter band proposed by Lazzarin et al. [20], see also Fig. 21.

S-N results in terms of the range of the average strain energy density \( \varDelta \overline{W} \) [21]

4.3 One-sided fillet weld around rectangular hollow section joint

4.3.1 Description of the detail

The third detail is a fillet-welded connection between two rectangular hollow sections (RHS), see Fig. 40. The dimensions of the RHS are 120 × 80 × 6 mm (height × width × thickness). Two hollow sections are connected to a 15-mm-thick intermediate plate by a single-sided fillet weld. Two types of welding process were applied: manual metal-arc welding with covered electrode, resulting in a mean throat thickness of a = 4.3 mm, and the MAG process with flux-cored wires, resulting in a = 5.1 mm. The gap between the intermediate plate and the hollow section is assumed to be zero, see “DET A” in Fig. 40.

Two load cases were investigated:

-

1.

axial load at the end of the RHS, applied to nine of the manual metal-arc welded specimens

-

2.

vertical three-point bending, applied to six of the manual metal-arc welded specimens and seven MAG-welded specimens

In the stress analysis, symmetry conditions were utilized, and a constant stress of 100 N/mm2 was applied to the right end. In the bending load case, a distributed shear force of 17.25 N was applied to the right end creating the nominal bending stress of 100 N/mm2 at the weld.

4.3.2 Fatigue tests

The fatigue tests were performed with constant load amplitudes and a frequency of approximately 30 Hz. A high stress ratio R = 0.5 was chosen according to the IIW Fatigue Design Recommendations [16]. One or two load levels were selected for the tests of each series of specimens. All specimens failed due to root cracking. The failure criterion for terminating the tests was a through-thickness crack. After this, the remaining life of the specimens was very short.

The test results, which are further described by Fricke et al. [15], are shown in Fig. 41 in terms of the nominal stress range in the RHS member at the weld. The S-N curves given for a probability of survival of 50 and 97.7 % were obtained from statistical analysis assuming a fixed slope exponent m = 3. The results for the bending load show that the welding process affects fatigue life, which is probably due to differences in the sharpness of the weld root.

4.3.3 Application of the nominal stress approach

In the IIW Fatigue Design Recommendations [16], this detail is classified as FAT 45 (structural detail no. 424). It should be borne in mind that the nominal stress for root failure is referred to the weld throat area.

When converting the nominal stress in the 6-mm-thick RHS wall to the weld throat thickness of a = 4.3 mm and 5.1 mm, the tests under axial load show a fatigue class just below FAT 36, whereas the bending tests yield a fatigue class above FAT 45. The difference can be explained by the effect of local weld throat bending. Under axial load, the fatigue cracks appear at the long side of the RHS joint, which is less restrained with respect to local bending, whereas during bending they appear at the short upper side of the joint, which is the most highly stressed one and where local bending is more restrained.

The same reason might be responsible for the non-conservative fatigue assessment under axial load. Local approaches should be able to consider these effects.

4.3.4 Application of the structural stress approach using solid elements

The numerical analysis of the structural stress was performed with the finite element model shown in Fig. 42, using 20-node solid elements. Only one element was arranged over the wall and weld thickness. The axial loading is realised by the forces F1, while the force F2 creates the three-point bending.

The structural weld stress was analysed in the weld leg section according to Fig. 13 using the nodal forces. The last column of Table 7 shows the computed stress concentration factors K s,w, i.e. the ratio between structural weld stress and nominal stress in the RHS member. The stress concentration factors clearly show the effect of increased local bending under axial load mentioned above. Furthermore, it can be seen that the weld throat thickness also influences the stress concentration factor, which explains the longer fatigue lives of the MAG-welded specimens as plotted in Fig. 41.

Figure 43 shows the test results in an S-N diagram lying well above the design S-N curve FAT 80 based on structural stress ranges mentioned earlier. It can be seen from Fig. 43 that the results for axial load are in the lower part of the scatter band, while those for bending load are in the upper part. This might be due to the more localised stress concentration under bending, resulting in semi-elliptical cracks showing slower crack propagation.

4.3.5 Application of the structural stress approach using shell elements

Corresponding finite element modelling is performed using shell elements and the technique described in Fig. 14. The structural stress is computed at the weld leg section according to Eqs. (3.11), (3.14), and (3.15). Figure 44 gives the distribution of the structural stress concentration factor along the weld line. For the axial load, maximum K s,w is obtained at mid-height of the RHS member, while for the bending load, it is located at mid-distance of the upper weld seam, which corresponds to the crack locations in the tests.

The maximum stress concentration factors K s,w are given in Table 8. These are about 10 % smaller than those calculated with the solid model (see Table 7). However, with these factors too the test results would be above the design S-N curve according to FAT 80, which can be concluded from Fig. 41 based on the solid finite element model. The last columns in Table 8 show the bending portion of the structural weld stress and the shear stress in the weld leg section, which is rather small so that the approach is applicable.

4.3.6 Application of the effective notch stress approach

Several computations with the effective notch stress approach were performed in a round robin for the IIW Guideline on this approach [12]. One representative analysis is described here, using the actual mean weld throat thicknesses given above [14].

The computation of the notch stresses was performed using the submodel technique. The coarse model shown in Fig. 42 was slightly refined in order to obtain improved prescribed displacements for the submodels. These were created with very fine meshes and subjected to prescribed deformations at the boundaries taken from the coarse model. Figure 45 shows typical submodels.

The weld root was modelled with a keyhole shape and a reference notch radius r ref = 1 mm. Eight-noded solid elements were chosen, having a length of about 0.1 mm at the notch.

To account for the different weld throat thicknesses given above, two models have been created. The computed fatigue notch factor K f along the weld root line, related to the nominal stress in the RHS, is shown in Fig. 46 with a max. value K f = 9.03 for the axial load case and K f = 6.50 for the bending load case. The latter is decreased to K f = 5.97 if the throat thickness is increased to a = 5.1 mm for the MAG-welded joints. The distribution differs slightly from that in Fig. 44.