Abstract

This study examined the impact of smart manufacturing (SM) systems on small and medium enterprises (SMEs) in the Indian context. For this, we used the theory of change framework to investigate the intervention and impact of SM implementation. Through a literature survey, eight impact aspects were identified with two additional moderators. In addition, 452 responses from 80 SMEs were collected, and structural equation modelling was employed. The collected data were used to test 22 hypotheses based on the association of the implementation of the SM system and organisational resilience, industry ecosystem, innovation, sustainability, supply chain and urbanisation. It also evaluated the impact of these aspects on the Growth of Indian economy (GIE), along with analysing the moderating roles of Government Support and Enabling Technology. The novelty of this work lies in providing a comprehensive assessment approach to the impact of SM system implementation in Indian SMEs. The study finds that technologies play a significant role in advancing the Indian economy, with the impacts evaluated mostly being positive. Negative implications are also discussed, making this study a valuable resource for government officials and policymakers to make informed decisions by understanding the potential impacts post-implementation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The term ‘fourth industrial revolution (I4.0)’ refers to the technological advances that have transformed the manufacturing sector, exemplified by the smart manufacturing (SM) system (Saha et al., 2022; Shukla & Shankar, 2023). This revolution has enabled industries to predict needs accurately and identify bottlenecks and errors swiftly, enhancing innovation and productivity (Shukla & Shankar, 2022a). The SM system also supports industries in embracing new challenges, adapting to market changes, and ensuring survival (Höse et al., 2023). Its inherent flexibility facilitates rapid adaptation to changes in the industrial environment, particularly in product and process consistency. Moreover, SM technology has merged the physical and digital realms (Qi & Tao, 2018). In response, large Indian manufacturing firms are integrating advanced technologies to stay competitive, positioning themselves at the forefront of this digital shift. However, small and medium enterprises (SMEs) are trailing due to limited resources and financial constraints, and they remain uncertain about the potential outcomes of implementing the SM system. Thus, there is a need to explore the impact of SM systems from the perspective of SMEs. Impact analysis in the literature is defined as a critical component of the business and public management policy cycle (Burdge & Vanclay, 1996). It includes two primary methods: ‘ex-ante’ and ‘ex-post’ impact assessment. The ‘ex-ante’ method forecasts the potential effects of a policy or intervention, aiding managers and policymakers in strategic planning (Tscherning et al., 2008). By contrast, “ex-post” impact assessment evaluates the actual effects after a policy or intervention has been implemented (Oliveros-Romero & Aibinu, 2019). This study employs the “ex-ante” approach to assess the potential impacts of SM system implementation on Indian SMEs.

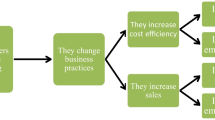

To further understand and measure the impact of SM implementation in Indian SMEs, this study employs the theory of change (ToC) framework. The ToC outlines the organisation’s intended path to impact by detailing the causal linkages within an initiative. As explained in UNICEF’s methodological briefs (Impact Evaluation No. 2), a ToC framework explains how activities are understood to produce a series of results that contribute to achieving the final intended impacts (Rogers, 2014). This framework helps to clarify both the benefits and disadvantages of SM integration. In this study, a general ToC framework is presented to guide expectations through impact analysis and outline the standard steps involved in impact assessment (Fig. 1). This figure is divided into main stages of evaluation: planning, implementation, assessment, and dissemination. Each stage is further broken down into assessment phases, which include understanding the current status of the SM system, collecting data, and concluding with suggestions and recommendations based on the outcomes.

The level of digital integration in SMEs is significantly lower in India than in developed countries. This gap has been exacerbated by the economic setbacks faced during the COVID-19 pandemic, emphasising the need for these businesses to embrace digital transformation. Regarded as the backbone of the Indian economy, SMEs are seen as a crucial sector for introducing I4.0 technologies (Sohal et al., 2022). According to the Confederation of Indian Industry (CII), there are approximately 63.4 million SME units across the country. These SMEs contribute about 6.11% to the manufacturing GDP and 24.63% to the service sector’s GDP for the fiscal year 2020–21 (MYCII, 2023). In addition, these enterprises generate 33.4% of India’s manufacturing output and maintain a high level of service provision (MYCII, 2023). They also provide employment to 120 million people and account for approximately 45% of India’s total exports (MYCII, 2023).

It is crucial to analyse the impact of new systems and technologies introduced into SMEs to enhance their production capabilities. Implementing systems such as SM is complex and financially demanding, and SMEs often cannot afford the risk of failure due to financial constraints. This study aims to provide SMEs with a comprehensive understanding of the impact of SM systems by conducting an ex-ante impact assessment on their implementation in Indian SMEs. A literature review was conducted to identify the key areas for impact assessment. The assessment explores eight potential aspects of SM system implementation that could affect industries: the implementation process itself, sustainability, innovation, industry ecosystem, supply chain, organisational resilience, urbanisation, and the growth of the Indian economy. Moreover, this study examines two moderator variables—’enabling technology (ET)’ and ‘government support (GS)’—to understand their roles in facilitating the implementation of SM systems, affecting the assessment aspects, and contributing to economic growth. In this context, the study addresses the following research questions (RQ):

-

RQ1:

What is the impact of SM system implementation in Indian SMEs?

-

RQ2:

Does ‘ET’ play a moderating role in assessing the impact of SM implementation in Indian SMEs?

-

RQ3:

Does ‘GS’ play a moderating role in assessing the impact of SM implementation aspects on the growth of the Indian economy?

To address the research questions, this study employs structural equation modelling (SEM) to analyse and validate the impact of SM systems in Indian SMEs across the identified aspects. This impact assessment approach is nascent and relies on the expertise of professionals and the integration of several theoretical frameworks. The model measures the relationships between independent variables, dependent variables, and moderator variables both directly and indirectly.

The remainder of the paper is organised as follows: Sect. “Background of the Study” provides the background of the study, detailing the context and significance of the research. Section “Theoretical base and development of hypothesis” discusses the development of hypotheses that guide the analysis. Section “Research Methodology” describes the research methodology used to gather and analyse data. Sections “Results” and “Discussion” present the results and discuss their implications, respectively. Finally, Sects. “Implications of the Study” and “Conclusion” highlight the broader implications of the findings and conclude the study.

Background of the Study

The impact of disruptive technologies on manufacturing systems is significant, marking a shift towards what is now known as the digitalisation era. This new phase is enhancing industries’ ability to improve quality, productivity, flexibility, and mass customisation, all while maintaining cost-effectiveness and production lead times (Friederich et al., 2022). SM harnesses I4.0 technologies, including cyber-physical systems (CPS), big data analytics (BDA), cloud computing, the Internet of Things (IoT), and artificial intelligence equipped with real-time operating systems capable of intuitive self-diagnosis and problem resolution (Kamble et al., 2020a). These advancements are crucial for SMEs to remain competitive in the market. SMEs play a vital role in India’s socio-economic development, being the second largest employment-generating sector after agriculture (Sharma et al., 2021). Similar to their larger counterparts, SMEs are increasingly adapting to and embracing digitalisation. However, adoption is limited because many SMEs are still unfamiliar with what SM entails and the potential benefits it offers (Kim, 2022). The COVID-19 pandemic has presented both challenges and opportunities, redefining the path of digital transformation across industries. The Indian government’s ‘Udhyam’ initiative, an MSME registration portal, indicates the sector’s significance with registrations of 92,71,743 micro-enterprises, 3,93,165 small enterprises, and 38,191 medium enterprises (Ministry of MSME, Government of India, 2023). These data highlight the extensive role of these enterprises in India’s industrial production, affirming their status as key drivers of the nation’s economic growth (Dutta et al., 2020).

The significant impact of I4.0 on manufacturing industries worldwide is well-documented in the existing literature. Within this global context, the implementation of SM systems is increasingly viewed as a pivotal future development for Indian SMEs. Recently, there has been a rising demand for low-cost products of acceptable quality in the global market (Mittal et al., 2012). In response, the Indian government and industry professionals are making concerted efforts to promote the adoption of SM technologies in economically disadvantaged manufacturing enterprises, particularly SMEs. This makes it particularly relevant and interesting to analyse the impact of SM implementation on Indian SMEs, exploring how it could transform their operational capabilities and competitive standing.

Impact of I4.0 and SM on the Growth of the Indian Economy

Currently, the rapid advancements of the I4.0 are being felt across nearly all sectors, with significant benefits observed worldwide. In India, smart factories are poised to enhance resource efficiency and significantly boost the national economy (Mishra & Maheshwari, 2020). Additionally, initiatives such as ‘Make in India’ are expected to create new job opportunities and develop a skilled labour force, potentially leading to substantial economic growth (Goswami & Daultani, 2022). SM has demonstrated its potential to positively impact sustainable performance in SMEs and contribute to the Indian economy (Kamble et al., 2020b). By contrast, Nara et al. (2021) highlight potential drawbacks, such as job losses due to automation and the high costs associated with implementing these technologies, which could negatively affect economies. Urbanisation and sustainability are increasingly interconnected because urban growth significantly influences the three pillars of sustainability: economic, social, and environmental. Current disruptive technologies promise sustainability following their transformative integration (Kumar et al., 2022b). Thus, this study aims to explore the effects of smart systems on Indian SMEs, assessing both their potential benefits and challenges.

Companies undergoing technological transformations are witnessing significant effects on their supply chain processes, attracting considerable research interest. The potential impact of SM systems on the future of supply chains is considered substantial because SM integration enables data-centric supply chain management (Zeiringer & Thalmann, 2022). Moreover, digital transformation is expected to revamp India’s financial status, which has been impacted by the post-COVID-19 situation. The growth of the Indian economy heavily relies on its manufacturing sector, which is the second largest contributor to GDP after agriculture. Thus, the implementation of SM systems has garnered considerable attention among manufacturers, and the Indian government is keen to understand its impact on SMEs. Currently, Indian SMEs are transitioning from traditional manufacturing systems to smart and digital ones, which is anticipated to drive the country’s economic growth. The presence of SM systems in Indian SMEs is viewed as a potential game-changer, affecting areas such as innovation, supply chain, sustainability, and the industry ecosystem. Positive impacts in these areas could significantly contribute to the growth of the Indian economy. Table 1 presents a critical analysis of the literature, outlining various aspects and sub-aspects related to SMEs and their potential impact on economic growth.

Theoretical Base and Development of Hypothesis

In India, the manufacturing sector is rapidly emerging as a high-growth area with significant potential for large-scale employment (Sharma et al., 2021). For the economic development of the country, a dramatic transformation of the manufacturing sector is essential. Emerging technologies are greatly enhancing the value chain and work culture, evolving the processes involved in producing goods and services (Santos & Martinho, 2020). However, the implications of these technologies need further investigation, particularly within the context of Indian SMEs. This study employs the ToC model to explore the relationship between inputs and outputs in the implementation of SM systems. SM implementation affects various areas, including innovation (Chen et al., 2021; Hopkins, 2021), organisational resilience (Fettig et al., 2018; Höse et al., 2023), supply chain (Fatorachian & Kazemi, 2021; Sawangwong et al., 2023), sustainability (Gupta et al., 2018), the industrial ecosystem (Korhonen, 2001; Sagar & Frosch, 1997), and urbanisation (Bányai et al., 2019; Jiang et al., 2022). These factors collectively influence economic growth (Khanzode et al., 2021; Shukla & Shankar, 2022a, 2022b; Wuest et al., 2022). However, reporting on these impacts specifically within the Indian SME context remains limited. Moreover, as governments worldwide are promoting Industry 4.0 through various projects and grants (Shukla & Shankar, 2023), the role of government support in facilitating this transition should also be examined. Enabling technologies related to I4.0 are critical for pushing SM implementation in SMEs towards achieving the desired transformation. These constructs, along with their sub-constructs, are detailed and defined in Table 1 of the study, providing a comprehensive overview of the factors at play.

ToC

In every era, as disruptive technologies emerge with increasing complexity, the need for rigorous and thorough impact evaluation becomes crucial. A theory-based approach is an important preliminary step for such evaluations, offering a structured framework to understand the effects of these technologies (White, 2009). The ToC model enhances this process by providing conceptual clarity and transparency in the collection of data, the methodologies used, related outcomes, and expected impacts, articulated through qualitative statements (Befani & Stedman-Bryce, 2017). By contrast, Jackson (2013) argues that non-theory-based approaches to impact evaluation tend to deliver incomplete narratives by merely quantifying inputs and outputs, often overlooking the deeper story. He emphasises the importance of employing the ToC and suggests integrating it with other methods to enhance its effectiveness and accuracy. In this study, the ToC model is used to explore how and what impacts are expected from the implementation of SM systems in Indian SMEs. The causal chain linking inputs to outcomes is carefully elaborated, providing a detailed pathway of anticipated effects and interactions within this context.

Hypothesis Development and Conceptual Model Development

The ToC model offers a detailed explanation of how and why a desired change is expected to occur within a specific context. As previously discussed, the model incorporates eight key aspects and two moderating variables, which are illustrated in Fig. 2. Detailed descriptions of each aspect and moderator and how they interact to facilitate the expected change are provided in the following section.

Relationship Between SM Implementation, Innovation, and Growth of the Economy

Innovation is a key driver of I4.0, and its scope is expected to broaden as smart technologies become more prevalent in manufacturing firms. Sarbu (2021) introduced an econometric model illustrating the relationship between product innovation and Industry 4.0, with results indicating a positive correlation. The study suggests that product innovation benefits significantly from smart technologies, offering greater opportunities in the service industry compared with manufacturing firms.

Conversely, Hickie and Hickie (2021) describe Industry 4.0 as a disruptive and costly technology that nonetheless opens up extensive innovative opportunities for manufacturing firms. The dimension of innovation is crucial to examine, especially given the observed improvements in the global innovation index (GII) following initiatives by the Indian government such as SAMARTH, Digital India, and Make in India (Global Innovation Index, 2023). However, when assessing innovation performance specifically within Indian SMEs, the discussions often yield conflicting and inconclusive results (Batra et al., 2017). Therefore, it is essential to consider the innovation aspect of organisations in impact assessments, which serves as the foundation for the hypothesis developed in this study.

H1

SM implementation in Indian SMEs has a positive impact on innovation.

H7

Innovation exerts a positive impact on the growth of the Indian economy.

Relationship Between SM Implementation, Organisational Resilience, and Growth of the Economy

SM technologies have revolutionised more than just technological processes and smart factories; they have also significantly impacted organisational culture, personnel, planning, and functionality. According to Jung et al. (2017), SM systems have notably enhanced production processes and increased organisational resilience (Nayernia et al., 2022). Marcucci et al. (2022) further explored organisational resilience, treating it as a multi-disciplinary concept that varies across companies and distinguishing between internal and external resilience. The drive behind adopting technological transformations, such as SM, is to achieve operational excellence. However, understanding the full advantages and utilisation of SM technologies requires acknowledging their impact on operational performance (Dev et al., 2020). The integration of SM technologies into operational activities leads to more efficient production systems, often resulting in a lean system. Lean practices are crucial for operational excellence and Industry 4.0, enhancing the impact of these practices in manufacturing industries (Tortorella et al., 2019). The literature indicates a pronounced impact of SM on various aspects of organisational performance, such as order fulfilment, customisation, and on-time delivery, with a particularly strong effect on organisational resilience (Marcucci et al., 2022). However, there is a noticeable gap in the literature regarding evidence of these impacts within the context of SMEs. This gap indicates the need for further investigation, which lays the groundwork for the following hypothesis in this study.

H2

SM implementation in Indian SMEs has a positive impact on organisational resilience.

H8

Organisational resilience shows a positive impact on the growth of the Indian economy.

Relationship Among SM Implementation, Supply Chain, and Growth of the Economy

The impact of I4.0 on supply chains has been a significant topic of debate among researchers in recent years. An effective supply chain is critical for operational excellence; however, improving supply chain performance remains a challenging endeavour (Fatorachian & Kazemi, 2021; Varma et al., 2024). In this context, Ghadge et al. (2020) recognised the necessity for a digitised supply chain and encouraged companies to enhance their supply chains by making them more transparent, flexible, and resilient. They highlighted that I4.0 significantly affects the supply chain because technologies, such as CPS and the IoT, enable remote sensing, real-time monitoring, and efficient information sharing. These capabilities have been particularly beneficial for industries such as ‘engineer-to-order,’ thereby greatly enhancing supply chain efficiencies (Müller & Voigt, 2018). Further emphasising the role of information sharing, Preindl et al. (2020) noted that disruptions in transformation have shifted the dynamics towards more effective decision-making. Managing the supply chain of perishable items becomes considerably more complex because it is essential to monitor and minimise wastage, leading to the growing adoption of smart transportation systems as a vital solution for these companies. Additionally, I4.0 technologies have improved connectivity between customers and suppliers through intelligent warehousing and sophisticated data management, enabling minimal wastage and reduced risks (Ivanov et al., 2019). To fully understand the significance of SM in the supply chains of industries and its effect on economic growth, it is crucial to analyse the impact of these technological transformations. Thus, this discussion forms the basis for the following hypotheses, which aim to investigate these impacts further.

H3

SM implementation in Indian SMEs has a positive impact on the supply chain.

H9

The supply chain exerts a positive impact on the growth of the Indian economy.

Relationship Among SM Implementation, Sustainability, and Growth of the Economy

The existing literature indicates the importance of impact assessment for evaluating effective organisational activities and understanding the effects of technological implementation on sustainable development. Oláh et al. (2020) explored the environmental impact of Industry 4.0, drawing from studies focused on environmental sustainability. Impact assessments that apply sustainability criteria, particularly those using the triple bottom-line framework that encompasses economic, social, and environmental aspects, are increasingly popular among researchers. Nara et al. (2021) developed a sustainability-oriented model to assess the impact of Industry 4.0 technologies on the sustainability goals of the plastic industry in Brazil. Their findings indicated varying impacts of technologies, with CPS, BDA, and sensors identified as key drivers of sustainability. These findings contradict those of Oláh et al. (2020), suggesting that the impact of technological interventions can vary, being either positive or negative depending on the specific scenario. Similarly, Bai et al. (2022) expressed concerns about social sustainability in the wake of emerging and disruptive technologies. They advocated for integrating sustainable development goals (SDGs) through a circular economy approach to facilitate a transition towards sustainability. Given these discussions, there is a clear need to further investigate how SM implementation influences sustainability and contributes to economic growth. This necessity provides the foundation for the following hypothesis:

H4

SM implementation in Indian SMEs has a positive impact on sustainability.

H10

Sustainability exerts a positive impact on the growth of the Indian economy.

Relationship Among SM Implementation, Industrial Ecosystem, and Growth of the Economy

The industry ecosystem, also known as a business ecosystem, involves a strategic collaboration among two or more entities aimed at working towards a mutual goal more efficiently and creating collective value for a shared customer base. In the post-pandemic landscape, the trend of collaborative operations has become more prevalent as industries, each impacted in unique ways by the pandemic, find such partnerships increasingly suitable. The challenges of rapid changes in customer demand, high customisation requirements, and complexity in supply chain management make it difficult for any single organisation to handle these aspects alone. Therefore, the future of industry ecosystems not only involves increased collaboration with other companies and organisations but also emphasises leveraging shared resources such as data, operations, applications, and expertise. However, the move towards digital transformation and the sudden disruptions caused by COVID-19 have severely impacted these value chains. Thus, industries—especially SMEs—require a new business model that includes creating a flexible industry ecosystem. Nonetheless, establishing a robust ecosystem presents challenges, including risks to company security and the complexities of legal collaboration. Therefore, it is crucial to explore the impact of SM implementation on the industry ecosystem of Indian SMEs. The introduction of SM in Indian industries has already significantly altered the working culture and environment within organisations. Thus, investigating how SM implementation affects the industrial ecosystem and contributes to economic growth is essential. This inquiry forms the basis of the following hypothesis.

H5

SM implementation in Indian SMEs has a positive impact on the industry ecosystem.

H11

The industry ecosystem exerts a positive impact on the growth of the Indian economy.

Relationship Among SM Implementation, Urbanisation, and Growth of the Economy

The technological surge brought about by I4.0 has significantly accelerated the process of urbanisation, a phenomenon that has been widely debated among researchers since the first industrial revolution. The establishment of new factories tends to attract a large workforce, offering employment opportunities and potentially leading to significant demographic shifts. Although I4.0 may result in the loss of traditional jobs, it also creates new opportunities, helping the workforce to adapt and thrive amidst these transformations (Sumer, 2018). The implementation of smart systems in emerging industries can attract business activities, which may catalyse infrastructure development, population shifts, and the concentration of urban centres (Pradhan et al., 2021). Conversely, Jaysawal et al. (2014) argued that sudden industrialisation negatively affects urbanisation, leading to overpopulation in cities, a haphazard lifestyle, and unplanned infrastructure development. Therefore, the effect of industrialisation on urbanisation can be both positive and negative and warrants thorough examination. In the context of Indian SMEs, the introduction of SM is likely to have substantial implications for working conditions, whether positive or negative. This impact needs to be meticulously analysed to understand how SM interventions can shape the urban landscape and influence the quality of life within urban settings. This critical analysis forms the basis for the following hypothesis.

H6

SM implementation in Indian SMEs has a positive impact on urbanisation.

H12

Urbanisation exerts a positive impact on the growth of the Indian economy.

ET as a Moderator

ETs are crucial components of the SM system, enhancing conventional systems significantly. According to a McKinsey report, successful implementation of SM technologies can lead to a 30 to 50% reduction in machine downtime, a 10% to 30% increase in production output, and a 15 to 30% improvement in labour productivity (Gregolinska et al., 2022). These ETs are powerful, data-driven tools that offer a range of benefits, such as improving decision-making capabilities through advanced analytics, which in turn fosters innovation, organisational resilience, and sustainability (Shukla & Shankar, 2022a). Adopting these new technologies allows SMEs to focus on their core competencies rather than being constrained by operational limitations. Automated technologies can eliminate the need for manually performing repetitive tasks within these enterprises. However, adopting new technology comes at a cost, and it is crucial to understand the extent and nature of ETs’ moderating effects, particularly on the six aspects discussed from Sects. ”Relationship between SM implementation, innovation, and growth of the economy” to “Relationship among SM implementation, urbanisation, and growth of the economy” in Indian SMEs. Given this, the following hypothesis regarding the impact of ETs in this context needs to be thoroughly investigated.

H13

ET moderates the relationship between SM implementation and innovation.

H14

ET moderates the relationship between SM implementation and organisational resilience.

H15

ET moderates the relationship between SM implementation and the supply chain.

H16

ET moderates the relationship between SM implementation and sustainability.

H17

ET moderates the relationship between SM implementation and the industry ecosystem.

H18

ET moderates the relationship between SM implementation and urbanisation.

Government Support as a Moderator

SM is a technology-driven system that utilises Internet-connected machinery to monitor production processes (Tao et al., 2018). Its primary aim is to capitalise on opportunities for process automation and enhance manufacturing performance through data analytics. Indian SMEs face challenges, such as inadequate technological infrastructure, bureaucratic licensing procedures, disrupted supply chains, and a lack of skilled labour (Shukla & Shankar, 2023). SM systems address these challenges by employing a data-driven approach that facilitates improved decision-making. The Indian government has been instrumental in supporting this transition through various initiatives such as SAMARTH Udyog, Make in India, Atmanirbhar Bharat, and numerous public–private partnerships. These initiatives have enabled SMEs to cultivate new business ideas and strategies (Srivastava et al., 2022). The Make in India initiative, launched in 2014, promotes local manufacturing and encourages investment to develop world-class manufacturing infrastructure. The Atmanirbhar Bharat Abhiyan, aimed at fostering self-reliance, has introduced various schemes to support Indian SMEs. Following the launch of this campaign, the need to accurately quantify the number of SMEs led to the creation of the Udhyam registration—a free, paperless platform based on self-declaration. This platform not only gathers precise data but also helps the government to effectively plan and strategise for SME development. Furthermore, the SAMARTH Udyog initiative by the Ministry of Heavy Industry & Public Enterprises, Government of India, focuses on delivering technical solutions to Indian industries. Additionally, public–private partnerships, such as those involving the CII, analyse the potential of SMEs and work towards making India Industry 4.0-ready. Given these efforts, it is crucial to assess how government interventions moderate the impact on various aspects of the Indian economy, enabling SMEs to make informed decisions about SM implementation. The hypothesis to be explored, based on this context, is formulated as follows:

H19

GS moderates the relationship between the supply chain and the growth of the Indian economy.

H20

GS moderates the relationship between sustainability and the growth of the Indian economy.

H21

GS moderates the relationship between the industrial ecosystem and the growth of the Indian economy.

H22

GS moderates the relationship between urbanisation and the growth of the Indian economy.

Research Methodology

The testing of the conceptual model depicted in Fig. 2 follows a three-step process as outlined by Kumar et al. (2022a). The first step involves conducting an exploratory factor analysis (EFA). EFA is used to identify the underlying factor structure of a measure and to assess the internal reliability of the items used in the structural equation modelling (SEM) (Hair et al., 2016). To determine the appropriateness and suitability of the data for factor analysis, the Kaiser–Meyer–Olkin (KMO) test and Bartlett’s test of sphericity are employed (Kumar et al., 2022a). The second step involves confirmatory factor analysis (CFA), which tests whether the identified factor structure fits the data being analysed (Hair et al., 2016). This step is crucial for validating the structure and ensuring the accuracy of the model. Finally, the proposed hypothesis and the conceptual model are evaluated using covariance-based SEM in AMOS 28.0. SEM is a sophisticated statistical technique that allows for testing and evaluation of hypotheses by examining the relationships between observed and latent variables (Rigdon, 1998).

Research Instruments

Based on an extensive review of the literature, theoretical insights, and knowledge of existing measurement tools, 54 instruments were initially developed for this study. These instruments were then reviewed by experts with substantial experience in Indian manufacturing firms to ensure their relevance and accuracy (Nayal et al., 2022). The structure and content of the developed questionnaire were specifically designed to align with the objectives of the study and to facilitate hypothesis testing (Kumar et al., 2022a). After achieving consensus among the experts, a pilot study was conducted using a randomly selected small sample of the study’s participants. This pilot study aimed to ensure the quality of the responses (Motamarri et al., 2020). Feedback from participants was used to refine the wording of the questionnaire to enhance clarity and comprehensibility (Nayal et al., 2022). Instruments that did not adequately meet the study’s objectives were removed, resulting in a refined version of the questionnaire containing 49 instruments. The final survey, aimed at assessing the impact of SM system implementation in Indian SMEs, used a 7-point Likert scale to determine the level of agreement with each statement. Following data collection, the responses were analysed using EFA to validate the instrument structure, and CFA was used to test the fit of the structure (Kumar et al., 2022a). The hypotheses tested in this study are illustrated in Fig. 2.

Data Collection

This study collected data from relevant respondents, specifically targeting industry and academia experts involved in SM system implementation and related fields. Academics participating in the survey had experience in conducting projects and consulting on SM implementation in Indian SMEs. Notably, many of these academics were engaged in projects granted by SAMARTH Udyog, an initiative by the Ministry of Heavy Industry & Public Enterprises, Government of India, which focuses on the implementation of Industry 4.0 and SM. The questionnaire, included in the annexure, was distributed to 742 individuals identified through conferences, seminars, and consortia related to technological transformations in SMEs. These individuals were primarily from SMEs, with a few academic experts who are actively working in the same area. We received a total of 465 responses, of which 452 were deemed usable for further analysis. These responses were obtained from employees at all hierarchical levels—top, middle, and bottom—from 80 different SMEs. Participants varied in educational attainment from graduates to Ph.D. holders, with graduates being the most numerous. Responses were collected using a standard 7-point Likert scale, ranging from “strongly disagree” (1) to “strongly agree” (7) (Motamarri et al., 2020). Participant demographics and other relevant details are provided in Table 2. To address potential nonresponse bias, we compared the mean responses of the first 50% of participants with those of the last 50%. This analysis revealed no significant nonresponse bias (Gupta & Shankar, 2022), indicating that the questionnaire was clear and straightforward for respondents, facilitating ease of completion.

Results

EFA Results

In this study, the factor structure was examined using EFA, a widely used multivariate statistical method. EFA was performed to identify the smallest number of hypothetical constructs and to explore the underlying theoretical structure related to the impact assessment of SM implementation in Indian SMEs. This analysis helps identify and extract the factors that explain the maximum variance in the original variables using the principal component factor analysis method. Further, the reliability of the constructs was assessed using the KMO and Bartlett’s Test performed using SPSS 28.0 software. These tests measure the adequacy of each construct, indicating the portion of the variance that might be caused by underlying factors. The KMO measure of sampling adequacy was found to be 0.826, which is significant and exceeds the acceptable threshold of 0.8, indicating no need for further changes in the sample size (Kumar et al., 2022a). Additionally, the loading factor (LF) of each latent variable, average variance explained (AVE), and composite reliability (CR) are detailed in Table 3. Each latent variable’s LF was above 0.5, making it acceptable. Furthermore, the AVE and CR for each construct were also found to be satisfactory, with each construct having an AVE of more than 0.5 and a CR of more than 0.7 (Hair et al., 2016). These parameters indicate the achievement of convergent validity, as all measures in Table 3 fall within the acceptable range (Kumar et al., 2022a).

CFA Results

CFA is a multivariate statistical method used to test how well measured variables represent constructs. CFA helps demonstrate how latent variables (unseen factors) explain observed variables (Priyadarshinee et al., 2017). In this study, CFA was conducted to validate the factors affected by the implementation of SM systems in Indian SMEs. Through this analysis, each item representing the factors was examined individually. Items that met the criteria for acceptable fit values were retained in the impact model, whereas those that did not meet these criteria were excluded (Nayal et al., 2022). The results of the model fit are presented in Table 4.

Reliability and Validity Test

In addition to CFA, this study employed various methods to validate the factors involved. One such method is the reliability test, which ensures that the dataset used is complete, accurate, and capable of producing reliable results if repeated (Hair et al., 2016). Moreover, content validity was employed to assess the appropriateness of the instruments measuring a theoretical construct, ensuring that each item adequately represents the construct it is intended to measure. Construct validity was also evaluated to determine how effectively the tests measure the constructs they are designed to measure. This involved assessing convergent validity and discriminant validity (Kumar et al., 2022a). Convergent validity ensures that items that are supposed to be related are indeed related, whereas discriminant validity confirms that items that are not supposed to be related are actually distinct. The internal consistency of the tests and the AVE for each construct were examined to further validate the constructs. All factors were validated and found to be significant for the analysis. The results for convergent validity are presented in Table 3.

Discriminant validity was assessed using the criteria set by Fornell and Larcker (1981), which involves a thumb rule stating that the square root of the AVE for each latent variable should be greater than its highest correlation with any other latent variable. Additionally, the AVE should exceed both the maximum shared variance and the average shared variance among variables. The findings of the discriminant validity assessment are detailed in Table 5.

CMV

The study involves the simultaneous collection of endogenous and exogenous variables using the same instrument, which could introduce bias. CMV is a concern because it represents a spurious correlation that may arise when both independent and dependent variables within a study are collected using the same survey method (Craighead et al., 2011). To mitigate potential biases related to data collection, several preliminary steps were taken during the survey stages. Initially, a pretest was conducted with a few experts, after which the survey instrument was revised for readability and necessary formatting adjustments were made. These experts were expected to respond to the pretest without bias, and procedural remedies were applied to ensure the feasibility of the data. Additionally, statistical methods were employed to assess whether the constructs share a significant amount of common variance. Among these methods, Harman’s single factor test (SFT) was used to analyse all first-order constructs using SPSS software. The maximum variance explained by a single factor for each impact construct was found to be 21.4%, which is well below the threshold of 50% often considered acceptable (Gupta & Shankar, 2022). However, some researchers criticise Harman’s SFT for being unreliable and not providing robust results. Consequently, the Marker’s variable test was also applied to the dataset to compare the original correlation between the constructs with the adjusted CMV correlation. In this study, the difference was very small (0.035) across all constructs. Therefore, it can be concluded that CMV does not significantly affect the validity of the dataset for the required analysis in this work.

SEM Results

The current study analysed 22 hypotheses, with the first 12 (H1 to H12) investigating the direct relationships between the constructs. The remaining 10 hypotheses (H13 to H22) examine the moderating effects on various factors. Specifically, hypotheses H13 through H18 involve the moderator ET and are expected to illustrate moderation effects between the implementation of SM and six aspects: innovation (IV), organisational resilience (OR), sustainability (ST), supply chain (SC), industrial ecosystem (IE), and urbanisation (UB). Hypotheses H19 through H22 involve the moderator GS and aim to demonstrate moderation between ISM and aspects including SC, ST, IE, UB, and GIE. The SEM methodology was employed to test the data structure and fitness, assessing the impact of SM implementation in Indian SMEs. The model fitness results are detailed in Table 4. Although the adjusted goodness of fit index (AGFI) was identified as the weakest link, it is not expected to detrimentally affect the overall outcomes of the analysis (Kumar et al., 2022a).

In this study, hypotheses H1, H2, H3, H4, H5, H7, H8, H9, H10, and H11 were found to be acceptable with p values less than 0.01. By contrast, H6 and H12 did not meet the acceptance criteria, with p values of 1.64 and 0.667, respectively, which are greater than the threshold of 0.01, as detailed in Table 6. The moderation analysis, which involved exploring the interactions between the constructs, yielded results that are presented in Table 7. Regarding the hypotheses related to the moderation effect of ET, H13, H14, H15, and H16 were found to have acceptable p values. However, H17 and H18 did not meet the criteria for acceptable p values. For the hypotheses concerning the moderator GS, H19, H20, and H21 were supported and found to be acceptable. However, H22 was not supported, with a p value of 0.357, indicating no significant moderation effect of GS on UB and GIE.

The effect of ET is analysed in two categories: Low ET and High ET. This categorisation is visually represented in Figs. 3, 4, 5, 6, 7 and 8, which correspond to hypotheses H13 to H18. Similarly, the moderating effects of GS are depicted in Figs. 9, 10, 11 and 12 for hypotheses H19 to H22. In these figures, orange and blue lines represent the high and low effects of the moderators, respectively, on the related hypotheses. Graphically, the results indicate that an increase in the effect of ET corresponds with a lower impact on urbanisation. However, for other aspects measured under ET, the opposite trend is observed: as the level of moderation increases, so does the impact on these aspects. A similar pattern is observed with the moderating effect of GS on UB, where a higher moderating effect of GS correlates with a higher impact. For the other aspects influenced by GS, a high moderating effect also corresponds with a high impact. These significant outcomes are clearly illustrated in the graphical representations.

Discussion

The present study examined the impact of SM implementation in Indian SMEs, analysing eight aspects and two moderators (ET and GS) using SEM. We investigated the effects of the moderators ET and GS on the association between the implementation of SM (ISM) and various aspects, such as IV, OR, SC, ST, IE, and UB, as well as the interactions between these aspects and the GIE. To articulate these relationships, the study developed a theoretical model and 22 hypotheses that help interpret the supporting and non-supporting characteristics of the constructs. For example, hypothesis H1, which posits that SM implementation in Indian SMEs positively impacts innovation, is supported. This suggests that SM systems effectively enhance the innovation capabilities of SMEs. India’s SMEs are pivotal in introducing innovative products globally, as evidenced by their performance in the GII. Additionally, hypotheses H2, H3, H4, and H5 are also supported, indicating positive impacts of SM on the supply chain, industry ecosystem, organisational resilience, and sustainability, respectively. SM systems enhance organisational resilience by integrating new technologies and improve the industrial ecosystem. They also streamline the supply chain through enhanced real-time monitoring, data analytics, and cybersecurity, contributing to overall sustainability. By contrast, hypothesis H6, which asserts that SM implementation in Indian SMEs positively impacts urbanisation, is not supported due to the negative environmental impacts associated with urbanisation, such as biodiversity loss and pollution. Other aspects such as IV, OR, SC, ST, IE, and UB’s association with GIE are explored, with all but UB found significant. A well-managed supply chain enhances SME productivity and competitiveness, fostering economic growth. Although the SM system aims to meet human needs and promotes sustainable practices, massive industrialisation can lead to negative outcomes such as population growth from worker migration, deforestation, and inadequate worker accommodations. However, experiences from developed countries show that I4.0 can lead to better infrastructure development and improved worker lifestyles. Thus, the impact of Industry 4.0 may vary based on a country’s development status, with potential for both positive and negative outcomes.

ET is a critical component of I4.0 and plays a pivotal role throughout the implementation process. In this study, ET is demonstrated to moderately affect the implementation of the SM system and the associated aspects. Specifically, hypothesis H13, which posits that ET moderates the relationship between SM implementation and innovation, is supported. This indicates that ET not only strengthens the association between ISM and IV but also enhances the positive impact of SM on innovation. Similarly, hypotheses H14, H15, and H16, which explore the moderation effects of ET, are also supported. Hypothesis H14 indicates that ET enhances the relationship between ISM and OR, suggesting that technologies play a crucial role in maintaining effective production and making systems resilient against disruptions. Hypothesis H15 confirms the moderating effect of ET on the relationship between ISM and the SC, aligning with literature that suggests technology investments enhance supply chain visibility, streamline processes, and boost efficiency. Hypothesis H16 demonstrates that ET moderates the relationship between ISM and Sustainability (ST), reflecting the expectation that new technologies should yield sustainable outcomes and that SM systems promote lean and clean manufacturing practices. However, hypotheses H17 and H18, which examine the moderation effects of ET on other aspects, are not supported. According to the results presented in Table 6, while the IE shows a positive relationship with ISM, ET does not moderate this relationship. In the case of UB, the results indicate neither a positive relationship with ISM nor any moderating effect of ET, suggesting that ET does not influence the impact of SM on urbanisation as expected.

In this study, GS was analysed as another moderator to assess its effect between relevant aspects and the GIE. The hypotheses concerning GS are H19, H20, H21, and H22. Hypotheses H19, H20, and H21 are supported, indicating a positive moderating effect of GS, while H22 is not supported. GS significantly influences the supply chain (H19) because governmental policies and monetary benefits can greatly affect the cost, speed, and reliability of supply chains. Government intervention can streamline regional supply chain operations and encourage SMEs to engage in new collaborative arrangements with larger industries, providing platforms and funding for these collaborations. Additionally, the Indian government actively supports environmentally friendly initiatives in industries, which aligns with hypothesis H20. This is exemplified by collaborations with the Small Industries Development Bank of India (SIDBI) to support start-ups and SMEs through the ‘Sustainable Finance Scheme’. This scheme funds sustainable development projects that promote energy efficiency and cleaner production. Hypothesis H21 is supported by the government’s role in helping industries manage their ecosystems efficiently. This is achieved by aligning various organisations with similar goals to foster collaboration. In contrast, hypothesis H22, which concerns the interplay between industrialisation and urbanisation, is not supported. While industrialisation and urbanisation typically go hand in hand, government intervention is deemed less significant in this dynamic. However, in areas such as affordable housing and infrastructure development, the role of the government remains crucial.

Implications of the Study

This study provides the following significant insights that can help managers or decision-makers of the organisation analyse the effect of SM implementation.

-

(i)

The findings of this study indicate that the implementation of SM has the most significant impact on the IE. Currently, there is a noticeable shift in the IE model, primarily characterised by resource sharing and collaboration both within and external to companies. This trend towards collaboration has become particularly evident in SMEs post-pandemic because COVID-19 has uniquely impacted nearly every organisation. A robust ecosystem is crucial for SMEs, given the numerous challenges they face—such as the aftermath of the pandemic, market changes, product complexity, supply chain issues, and the need for digitisation. These challenges are often too complex for a single company to tackle alone. Thus, managers are encouraged to seek partnerships with companies that share similar goals, enabling them to accelerate productivity and reap mutual benefits through collaboration.

-

(ii)

Smart technologies are revolutionising industries by enabling innovation through their advanced features. To remain competitive, manufacturers and managers need to anticipate changes and adopt smart practices that enhance their production capabilities. The integration of an SM system can support manufacturers at every stage of the production process and improve the efficiency of supply chain activities, thereby enhancing organisational sustainability. Consequently, SM implementation has demonstrated a positive relationship with IV, SC, and ST.

-

(iii)

The current study introduces two moderators in the assessment of SM implementation impacts, one of which is ET. ET has been found to moderate the relationships between SM implementation and aspects such as IV, SC, OR, and ST. In the context of Industry 4.0, new technologies assist manufacturers in maintaining machinery, ensuring part traceability, controlling quality, and stabilising production processes. The results indicate that ET plays a critical role in the manufacturing process, suggesting that SMEs should consider its integration. The adoption of these technologies does not necessarily need to encompass all available options; instead, SMEs can selectively implement those that align with their core competencies and are financially feasible. Managers play a crucial role in helping companies leverage the benefits of new technologies while considering financial constraints.

-

(iv)

The moderator GS has demonstrated its moderating effects on ST, SC, and IE, although it did not show a significant impact on UB with respect to the GIE. The Government of India, in collaboration with major market players and service providers, is aiding SMEs by introducing investment policies and opportunities that enhance SM implementation. Managers are encouraged to engage in collaborative efforts with the government to foster urbanisation and optimise implementation solutions across the country.

-

(v)

In contrast to other aspects, UB is the only aspect that has shown a negative effect on SM implementation in Indian SMEs. In India, urbanisation driven by the industrial revolution has posed significant urban challenges, including an ever-increasing demand for labour that results in migration and shifts away from farming occupations. Additionally, the rapid expansion of small towns near factories and mines into cities has brought about environmental and social concerns. Therefore, it is crucial for governments and businesses to effectively manage urbanisation. Proper management can promote the use of green technologies, improve lifestyles, and attract foreign businesses, turning these challenges into opportunities for sustainable development.

The present work offers several theoretical implications, notably extending the literature on SM by evaluating the impact assessment dimensions for Indian SMEs. It also explores the effects of two key moderators, ET and GS, on these impact assessment aspects. The study adopts a comprehensive approach by integrating ToC with SEM, a methodology that can be applied to study the effects of any desired or unintended intervention across various systems. This approach encourages future studies to examine each aspect in greater detail to facilitate the desired changes through the implementation of SM systems.

Conclusion

Manufacturing represents a clear example of the transformative power of innovation and industrial breakthroughs. Thus, leveraging SM system implementation is critical for Indian industries, particularly SMEs, which have demonstrated their capability as incubators of entrepreneurial talent, contributing to job creation and driving economic growth in smaller regions. These enterprises are progressively adopting I4.0 technologies and integrating smart systems into their traditional practices. This study addresses three research questions: first, by analysing the impact of eight dimensions identified through a literature review; second, by examining the moderating roles of ET and GS on relevant constructs; and finally, by developing a conceptual model to test these relationships. A total of 22 hypotheses were formulated to explore the associations between the constructs. The analysis, conducted using SEM, involved responses from 452 participants across 80 Indian manufacturing firms, providing robust insights into the implementation and effects of SM in this sector.

The study concludes with several significant findings, including evaluations of moderating effects. The research revealed that SM implementation positively impacts various aspects, except for urbanisation. SM systems have significantly benefited Indian SMEs by fostering innovation, enhancing product quality and variety, and increasing visibility in supply chain processes through real-time operations. This visibility helps in better understanding customer needs for customisation and strengthens customer relationships. SM has shown the most substantial impact on the industrial ecosystem, although its implementation faces complexities that require SMEs to seek industrial collaborations and resource sharing with larger companies.

The results also highlight that ET and GS have notable moderating effects on most aspects considered. ET enables SMEs to monitor their processes more efficiently, which necessitates investments in technology. Meanwhile, Indian government initiatives such as Atmanirbhar Bharat, Make in India, and Digital India aim to support SME development, reduce import dependencies, and generate local employment. The government’s production-linked incentives scheme is particularly ambitious, promoting advanced manufacturing to enhance production, improve the supply chain, and support digital transformation in the industry ecosystem.

However, the study has some limitations. It is confined to companies within India, which means the results may not be generalisable to other contexts. Future research could involve a larger participant pool to yield more reliable results. Exploring additional moderators, such as financial and management support, could provide new insights. Moreover, although the current study focuses on qualitative impact dimensions, future research could incorporate quantitative variables to more accurately estimate the impact of the SM system. Additionally, future studies could also focus more on the environmental impacts of technology intervention, particularly regarding carbon neutrality and achieving net zero goals.

References

Aggarwal, A., Gupta, S., Jamwal, A., Agrawal, R., Sharma, M., & Dangayach, G. S. (2021). Adoption of smart and sustainable manufacturing practices: An exploratory study of Indian manufacturing companies. Proceedings of the Institution of Mechanical Engineers, Part b: Journal of Engineering Manufacture, IMECHE, 236(5), 586–602. https://doi.org/10.1177/09544054211040646

Bai, C., Orzes, G., & Sarkis, J. (2022). Exploring the impact of Industry 4.0 technologies on social sustainability through a circular economy approach. Industrial Marketing Management, 101, 176–190. https://doi.org/10.1016/j.indmarman.2021.12.004

Bányai, T., Tamás, P., Illés, B., Stankevičiūtė, Ž, & Bányai, Á. (2019). Optimization of municipal waste collection routing: impact of industry 4.0 technologies on environmental awareness and sustainability. International Journal of Environmental Research and Public Health, 16(4), 634. https://doi.org/10.3390/ijerph16040634

Batra, S., Sharma, S., Dixit, M. R., & Vohra, N. (2017). Does strategic planning determine innovation in organizations? A study of Indian SME sector. Australian Journal of Management, 43(3), 493–513. https://doi.org/10.1177/0312896217734893

Befani, B., & Stedman-Bryce, G. (2017). Process tracing and Bayesian updating for impact evaluation. Evaluation, 23(1), 42–60. https://doi.org/10.1177/1356389016654584

Burdge, R. J., & Vanclay, F. (1996). Social impact assessment: A contribution to the state of the art series. Impact Assessment, 14(1), 59–86. https://doi.org/10.1080/07349165.1996.9725886

Chen, M., Sinha, A., Hu, K., & Shah, M. I. (2021). Impact of technological innovation on energy efficiency in industry 4.0 era: moderation of shadow economy in sustainable development. Technological Forecasting and Social Change, 164, 120521. https://doi.org/10.1016/j.techfore.2020.120521

Craighead, C. W., Ketchen, D. J., Dunn, K. S., & Hult, G. T. M. (2011). Addressing common method variance: Guidelines for survey research on information technology, operations, and supply chain management. IEEE Transactions on Engineering Management, 58(3), 578–588. https://doi.org/10.1109/TEM.2011.2136437

Dev, N. K., Shankar, R., & Qaiser, F. H. (2020). Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resources, Conservation and Recycling, 153, 104583. https://doi.org/10.1016/j.resconrec.2019.104583

Dutta, G., Kumar, R., Sindhwani, R., & Singh, R. K. (2020). Digital transformation priorities of India’s discrete manufacturing SMEs—a conceptual study in perspective of industry 4.0. Competitiveness Review: an International Business Journal, 30(3), 289–314. https://doi.org/10.1108/CR-03-2019-0031

Fatorachian, H., & Kazemi, H. (2021). Impact of industry 4.0 on supply chain performance. Production Planning & Control, 32(1), 63–81. https://doi.org/10.1080/09537287.2020.1712487

Fettig, K., Gačić, T., Köskal, A., Kühn, A., & Stuber, F. (2018). Impact of industry 4.0 on organizational structures. IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), pp. 1–8. https://doi.org/10.1109/ICE.2018.8436284.

Fornell, C., & Larcker, D. F. (1981). Structural equation models with unobservable variables and measurement error: Algebra and statistics. Journal of Marketing Research, 18(3), 382–388. https://doi.org/10.1177/002224378101800313

Friederich, J., Francis, D. P., Lazarova-Molnar, S., & Mohamed, N. (2022). A framework for data-driven digital twins of smart manufacturing systems. Computers in Industry, 136, 103586. https://doi.org/10.1016/j.compind.2021.103586

Ghadge, A., Er Kara, M., Moradlou, H., & Goswami, M. (2020). The impact of industry 4.0 implementation on supply chains. Journal of Manufacturing Technology Management, 31(4), 669–686. https://doi.org/10.1108/JMTM-10-2019-0368

Global Innovation Index (2023). Innovation in the face of uncertainty. Available at: https://www.wipo.int/edocs/pubdocs/en/wipo-pub-2000-2023-en-main-report-global-innovation-index-2023-16th-edition.pdf. Accessed on 27/12/2023.

Goswami, M., & Daultani, Y. (2022). Make-in-India and industry 4.0: technology readiness of select firms, barriers and socio-technical implications. The TQM Journal, 34(6), 1485–1505. https://doi.org/10.1108/TQM-06-2021-0179

Grabar, A. A., Koykova, T. L., Prokopenko, L. K., & Shchinova, R. A. (2019). The innovative mechanism of government support for the investment activities of digital universities for provision of region’s investment attractiveness in the conditions of industry 4.0. On the Horizon, 27(3/4), 159–165. https://doi.org/10.1108/OTH-07-2019-0041

Gregolinska, E., Khanam, R., Lefort, F., & Parthasarathy, P. (2022). Capturing the true value of Industry 4.0. Available at: https://www.mckinsey.com/business-functions/operations/our-insights/capturing-the-true-value-of-industry-four-point-zero. Accessed on 23/11/2023.

Gupta, L., & Shankar, R. (2022). Adoption of battery management system in utility grid: An empirical study using structural equation modeling. Global Journal of Flexible Systems Management, 23(4), 573–596. https://doi.org/10.1007/s40171-022-00319-8

Gupta, S., Dangayach, G. S., Singh, A. K., Meena, M. L., & Rao, P. N. (2018). Implementation of sustainable manufacturing practices in Indian manufacturing companies. Benchmarking an International Journal, 25(7), 2441–2459. https://doi.org/10.1108/BIJ-12-2016-0186

Hair, J., Anderson, R., Black, B., & Babin, B. (2016). Multivariate Data Analysis. Pearson Education.

Hickie, D., & Hickie, J. (2021). The impact of industry 4.0 on supply chains and regions: innovation in the aerospace and automotive industries. European Planning Studies, 29(9), 1606–1621. https://doi.org/10.1080/09654313.2021.1963048

Hopkins, J. L. (2021). An investigation into emerging industry 4.0 technologies as drivers of supply chain innovation in Australia. Computers in Industry, 125, 103323. https://doi.org/10.1016/j.compind.2020.103323

Höse, K., Amaral, A., Götze, U., & Peças, P. (2023). Manufacturing flexibility through industry 4.0 technological concepts—impact and assessment. Global Journal of Flexible Systems Management, 24(2), 271–289. https://doi.org/10.1007/s40171-023-00339-y

Ivanov, D., Dolgui, A., & Sokolov, B. (2019). The impact of digital technology and industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research, 57(3), 829–846. https://doi.org/10.1080/00207543.2018.1488086

Jackson, E. T. (2013). Interrogating the theory of change: Evaluating impact investing where it matters most. Journal of Sustainable Finance & Investment, 3(2), 95–110. https://doi.org/10.1080/20430795.2013.776257

Jaysawal, D., Saha, S., et al. (2014). Urbanization in India: An impact assessment. International Journal of Applied Sociology, 4(2), 60–65.

Jiang, L., Sakhare, S. R., & Kaur, M. (2022). Impact of industrial 4.0 on environment along with correlation between economic growth and carbon emissions. International Journal of System Assurance Engineering and Management, 13(1), 415–423. https://doi.org/10.1007/s13198-021-01456-6

Jung, K., Choi, S., Kulvatunyou, B., Cho, H., & Morris, K. C. (2017). A reference activity model for smart factory design and improvement. Production Planning & Control, 28(2), 108–122. https://doi.org/10.1080/09537287.2016.1237686

Kamble, S., Gunasekaran, A., & Dhone, N. C. (2020b). Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. International Journal of Production Research, 58(5), 1319–1337. https://doi.org/10.1080/00207543.2019.1630772

Kamble, S. S., Gunasekaran, A., Ghadge, A., & Raut, R. (2020a). A performance measurement system for industry 4.0 enabled smart manufacturing system in SMMEs-A review and empirical investigation. International Journal of Production Economics, 229, 107853.

Khanzode, A. G., Sarma, P. R. S., Mangla, S. K., & Yuan, H. (2021). Modeling the industry 4.0 adoption for sustainable production in micro, small & medium enterprises. Journal of Cleaner Production, 279, 123489. https://doi.org/10.1016/j.jclepro.2020.123489

Khin, S., & Kee, D. M. H. (2022). Factors influencing industry 4.0 adoption. Journal of Manufacturing Technology Management, 33(3), 448–467. https://doi.org/10.1108/JMTM-03-2021-0111

Kim, H. (2022). Open-source software for developing appropriate smart manufacturing technology for small and medium-sized enterprises (SMEs). Journal of Appropriate Technology, 8(3), 109–116. https://doi.org/10.37675/jat.2022.00206

Korhonen, J. (2001). Four ecosystem principles for an industrial ecosystem. Journal of Cleaner Production, 9(3), 253–259. https://doi.org/10.1016/S0959-6526(00)00058-5

Kumar, S., Raut, R. D., Priyadarshinee, P., Mangla, S. K., Awan, U., & Narkhede, B. E. (2022a). The impact of IoT on the performance of vaccine supply chain distribution in the COVID-19 context. IEEE Transactions on Engineering Management., 2022, 1–11. https://doi.org/10.1109/TEM.2022.3157625

Kumar, V., Vrat, P., & Shankar, R. (2022b). Factors influencing the implementation of industry 4.0 for sustainability in manufacturing. Global Journal of Flexible Systems Management, 23(4), 453–478. https://doi.org/10.1007/s40171-022-00312-1

Longo, F., Nicoletti, L., & Padovano, A. (2019). Emergency preparedness in industrial plants: A forward-looking solution based on industry 4.0 enabling technologies. Computers in Industry, 105, 99–122. https://doi.org/10.1016/j.compind.2018.12.003

Marcucci, G., Antomarioni, S., Ciarapica, F. E., & Bevilacqua, M. (2022). The impact of operations and IT-related industry 4.0 key technologies on organizational resilience. Production Planning & Control, 33(15), 1417–1431. https://doi.org/10.1080/09537287.2021.1874702

Ministry of MSME, Government of India (2023). Available at: https://udyamregistration.gov.in/Government-India/Ministry-MSME-registration.htm. Accessed on 27/01/2023.

Mishra, H., & Maheshwari, P. (2020). Achieving sustainable development goals through fourth industrial revolution: An Indian perspective. Indian Journal of Commerce and Management Studies, 11(2), 63–75.

Mittal, K., Kaushik, P., & Khanduja, D. (2012). Evidence of APQP in quality improvement: An SME case study. International Journal of Management Science and Engineering Management, 7(1), 20–28. https://doi.org/10.1080/17509653.2012.10671203

Mittal, S., Khan, M. A., Romero, D., & Wuest, T. (2018). A critical review of smart manufacturing & industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). Journal of Manufacturing Systems, 49, 194–214. https://doi.org/10.1016/j.jmsy.2018.10.005

Motamarri, S., Akter, S., & Yanamandram, V. (2020). Frontline employee empowerment: Scale development and validation using confirmatory composite analysis. International Journal of Information Management, 54, 102177. https://doi.org/10.1016/j.ijinfomgt.2020.102177

Müller, J. M., & Voigt, K.-I. (2018). The impact of industry 4.0 on supply chains in engineer-to-order industries—an exploratory case study. IFAC-PapersOnLine, 51(11), 122–127. https://doi.org/10.1016/j.ifacol.2018.08.245

MYCII (2023). CII 9th Edition MSME Summit on Towards a Sustainable Future: ESG/Finance/Digitization/Exports. Available at: https://cam.mycii.in/OR/EventDetailOR.html?id=E000063172. Accessed on 15/12/2023.

Nara, E. O. B., da Costa, M. B., Baierle, I. C., Schaefer, J. L., Benitez, G. B., da Santos, L. M., & Benitez, L. B. (2021). Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustainable Production and Consumption, 25, 102–122. https://doi.org/10.1016/j.spc.2020.07.018

Nayal, K., Raut, R. D., Yadav, V. S., Priyadarshinee, P., & Narkhede, B. E. (2022). The impact of sustainable development strategy on sustainable supply chain firm performance in the digital transformation era. Business Strategy and the Environment, 31(3), 845–859. https://doi.org/10.1002/bse.2921

Nayernia, H., Bahemia, H., & Papagiannidis, S. (2022). A systematic review of the implementation of industry 40 from the organisational perspective. International Journal of Production Research, 60(14), 4365–4396. https://doi.org/10.1080/00207543.2021.2002964

Oláh, J., Aburumman, N., Popp, J., Khan, M. A., Haddad, H., & Kitukutha, N. (2020). Impact of industry 4.0 on environmental sustainability. Sustainability, 12(11), 4674. https://doi.org/10.3390/su12114674

Oliveros-Romero, J., & Aibinu, A. A. (2019). Impact evaluation of PPP projects: An exploratory research”. Built Environment Project and Asset Management, 9(2), 315–330. https://doi.org/10.1108/BEPAM-01-2018-0036

Pasi, B. N., Mahajan, S. K., & Rane, S. B. (2022). Development of innovation ecosystem framework for successful adoption of industry 4.0 enabling technologies in Indian manufacturing industries. Journal of Science and Technology Policy Management, 13(1), 154–185. https://doi.org/10.1108/JSTPM-10-2020-0148

Pradhan, R. P., Arvin, M. B., & Nair, M. (2021). Urbanization, transportation infrastructure, ICT, and economic growth: A temporal causal analysis. Cities, 115, 103213. https://doi.org/10.1016/j.cities.2021.103213

Preindl, R., Nikolopoulos, K., & Litsiou, K. (2020). Transformation strategies for the supply chain: The impact of industry 4.0 and digital transformation. Supply Chain Forum: an International Journal, 21(1), 26–34. https://doi.org/10.1080/16258312.2020.1716633

Priyadarshinee, P., Raut, R. D., Jha, M. K., & Gardas, B. B. (2017). Understanding and predicting the determinants of cloud computing adoption: A two staged hybrid SEM-Neural networks approach. Computers in Human Behavior, 76, 341–362. https://doi.org/10.1016/j.chb.2017.07.027

Qi, Q., & Tao, F. (2018). Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access, 6, 3585–3593. https://doi.org/10.1109/ACCESS.2018.2793265

Raut, R. D., Gotmare, A., Narkhede, B. E., Govindarajan, U. H., & Bokade, S. U. (2020). Enabling technologies for industry 4.0 manufacturing and supply chain: concepts, current status, and adoption challenges. IEEE Engineering Management Review, 48(2), 83–102. https://doi.org/10.1109/EMR.2020.2987884

Rigdon, E. E. (1998). The equal correlation baseline model for comparative fit assessment in structural equation modeling. Structural Equation Modeling: A Multidisciplinary Journal, 5(1), 63–77. https://doi.org/10.1080/10705519809540089

Rogers, P. (2014). Theory of change. Methodological Briefs: Impact Evaluation, 2(16), 1–14.

Sagar, A. D., & Frosch, R. A. (1997). A perspective on industrial ecology and its application to a metals-industry ecosystem. Journal of Cleaner Production, 5(1–2), 39–45. https://doi.org/10.1016/S0959-6526(97)00006-1

Saha, P., Talapatra, S., Belal, H. M., & Jackson, V. (2022). Unleashing the potential of the TQM and industry 4.0 to achieve sustainability performance in the context of a developing country. Global Journal of Flexible Systems Management, 23(4), 495–513.

Santos, R. C., & Martinho, J. L. (2020). An industry 4.0 maturity model proposal. Journal of Manufacturing Technology Management, 31(5), 1023–1043. https://doi.org/10.1108/JMTM-09-2018-0284

Sarbu, M. (2021). The impact of industry 4.0 on innovation performance: Insights from German manufacturing and service firms. Technovation, 113, 102415. https://doi.org/10.1016/j.technovation.2021.102415

Sawangwong, A., & Chaopaisarn, P. (2023). The impact of applying knowledge in the technological pillars of Industry 4.0 on supply chain performance. Kybernetes, 52(3), 1094–1126. https://doi.org/10.1108/K-07-2021-0555

Sharma, M., Luthra, S., Joshi, S., & Kumar, A. (2021). Implementing challenges of artificial intelligence: Evidence from public manufacturing sector of an emerging economy. Government Information Quarterly, 39(4), 101624. https://doi.org/10.1016/j.giq.2021.101624

Shukla, M., & Shankar, R. (2022a). An extended technology-organization-environment framework to investigate smart manufacturing system implementation in small and medium enterprises. Computers & Industrial Engineering, 163, 107865. https://doi.org/10.1016/j.cie.2021.107865

Shukla, M., & Shankar, R. (2022b). Modeling of critical success factors for adoption of smart manufacturing system in Indian SMEs: An integrated approach. Opsearch, 59(4), 1271–1303. https://doi.org/10.1007/s12597-021-00566-w

Shukla, M., & Shankar, R. (2023). Readiness assessment for smart manufacturing system implementation: multiple case of Indian small and medium enterprises. International Journal of Computer Integrated Manufacturing, 37, 1–19. https://doi.org/10.1080/0951192X.2023.2228268

Sohal, A., Nand, A. A., Goyal, P., & Bhattacharya, A. (2022). Developing a circular economy: An examination of SME’s role in India. Journal of Business Research, 142, 435–447. https://doi.org/10.1016/j.jbusres.2021.12.072

Srivastava, D. K., Kumar, V., Ekren, B. Y., Upadhyay, A., Tyagi, M., & Kumari, A. (2022). Adopting industry 4.0 by leveraging organisational factors. Technological Forecasting and Social Change, 176, 121439. https://doi.org/10.1016/j.techfore.2021.121439

Sumer, B. (2018). Impact of industry 4.0 on occupations and employment in Turkey. European Scientific Journal, 14(10), 1–17. https://doi.org/10.19044/esj.2018.v14n10p1

Tao, F., Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal of Manufacturing Systems, 48, 157–169.

Tortorella, G. L., Giglio, R., & van Dun, D. H. (2019). Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. International Journal of Operations & Production Management, 39, 860–886. https://doi.org/10.1108/IJOPM-01-2019-0005

Tripathi, S., & Gupta, M. (2021). A holistic model for global industry 4.0 readiness assessment. Benchmarking: an International Journal, 28(10), 3006–3039. https://doi.org/10.1108/BIJ-07-2020-0354

Tscherning, K., König, H., Schößer, B., Helming, K., & Sieber, S. (2008). Ex-ante impact assessments (IA) in the European commission—an overview (pp. 17–33). Springer.

Varma, S., Singh, N., & Patra, A. (2024). Supply chain flexibility: Unravelling the research trajectory through citation path analysis. Global Journal of Flexible Systems Management, 25(2), 199–222.

White, H. (2009). Theory-based impact evaluation: Principles and practice. Journal of Development Effectiveness, 1(3), 271–284. https://doi.org/10.1080/19439340903114628

Wuest, T., Romero, D., Khan, M. A., & Mittal, S. (2022). The triple bottom line of smart manufacturing technologies: an economic, environmental, and social perspective. Handbook of Smart Technologies: An Economic and Social Perspective (pp. 310–330). Routledge. https://doi.org/10.4324/9780429351921-20

Zeiringer, J. P., & Thalmann, S. (2022). Knowledge sharing and protection in data-centric collaborations: An exploratory study. Knowledge Management Research & Practice, 20(3), 436–448. https://doi.org/10.1080/14778238.2021.1978886

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

Given that the research is a non-experimental voluntary survey, no ethical approval is necessary. Furthermore, the self-administered survey that is non-experimental in nature was conducted under complete anonymity for the participants. No personal or sensitive information that can be used to identify the respondents was collected. Besides, the informed consent of all the respondents to partake in the survey was sought before the survey was executed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Part A: Demographic questions

-

(1)

Name:

-

(2)

Gender:

-

(3)

Education qualification:

-

(4)

Designation:

-

(5)

Years of experience:

Part B: Main survey question