Abstract

In order to study the uniaxial mechanical properties and failure modes of granite under the condition of thermo-liquid coupling, the granite was subjected to thermo-liquid coupling cyclic treatment at different temperatures, and then its mechanical properties were analyzed by uniaxial compression test. The results reflect the following trends: (1) the stress–strain curve generally undergoes four stages, namely compaction, elastic deformation, yielding, and failure. (2) The peak intensity increases with temperature, decreasing by 11.51% when the temperature is in the range of 50–100 °C and decreasing by 1.77% when the temperature is in the range of 100–150 °C. The peak strain is fit by a linear relationship with the cycle temperature and decreases as the temperature increases. The modulus of elasticity first increases and then decreases with increasing temperature, increasing significantly by approximately 123.21%. (3) The peak intensity varies with the number of cycles and changes slowly before three cycles but changes obviously after three times. The peak intensity is reduced by 19.87% when the number of cycles is 3–4, and it is increased by 22.70% when the number of cycles is 4–5. The peak strain has a cubic fitting relationship with the number of cycles, and it is maximized at three cycles. The modulus of elasticity has a quadratic fit with the number of cycles, and it is minimized at three cycles. (4) In the contour map, the peak intensity is symmetrically distributed in three cycles when the temperature range is 50–100 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Studying the mechanical properties of various states and conditions of rock is one of the key topics in the field of rock engineering. The development and utilization of hot dry rock energy, the development of underground space in smart cities, the development of tunnels, etc., all involve rock engineering and are usually closely related to natural conditions such as temperature and groundwater. Therefore, domestic and foreign scholars have performed considerable research on the temperature cycle effect and dry–wet cycle effect of rock [1,2,3,4,5,6,7,8,9,10,11,12]. Xi and Zhao [13] studied the mechanical properties of granite at 600 °C in a high-temperature state and after cooling with water. It is concluded that the ultrasonic velocity, uniaxial compressive strength, tensile strength and elastic modulus decrease with temperature. Huang et al. [14, 15] performed uniaxial compression tests and acoustic wave tests on marble and limestone in a high-temperature state and after water cooling and natural cooling and analyzed and compared the peak intensity, elastic modulus, attenuation coefficient, longitudinal wave velocity and dominant frequency of the rock samples under different conditions. Zeng et al. [16] used polarized light microscopy to observe fine-grained marble after different high-temperature cycles. Through the statistics of microcrack length, opening degree and quantity, the propagation law of microcracks in the rock samples after different heating cycles was discussed. Ni et al. [17] studied the uniaxial compression mechanical properties of Sichuan Jinping marble samples after heating them to 100 °C, 300 °C, 450 °C, and 600 °C under 1, 10, and 20 temperature cycles. Fang [18] studied the stress–strain characteristics of marble in the F8 fault zone in the Luohu built-up area of Shenzhen at normal temperature (20–800 °C) and at high temperature (8–9 cycles) (100–700 °C). Zhu et al. [19] quantitatively described the mesostructure of the surrounding rock of a deep tunnel under temperature circulation. Xia et al. [20] performed a uniaxial compression test on basalt specimens with a cycle temperature of 60–90 °C. Zhang [21] studied the influence of temperature cycling on the mechanical properties of altered rock. Based on the analysis of experimental data, a functional expression was established to describe the deterioration of mechanical parameters of metamorphic rock under temperature cycling conditions. Ming and Fan [22] selected granite and sandstone for uniaxial compression tests under different temperature cycling conditions and analyzed the relationship between the compressive strength, elastic modulus, tensile strength and temperature cycling of granite. The longitudinal wave velocity of the rock specimens was measured, and the longitudinal wave velocity degradation degree was introduced to quantitatively analyze the damage of the temperature cycle to the rock.

In summary, the dry–wet cycle effect and temperature cycle effect are mainly studied independently, and the temperature effect includes real-time temperature. However, there are few temperature studies that consider water cooling and circulation temperature. The author analyzes the mechanical characteristics of rock by two factors and obtains the corresponding change law, which provides a reference for relevant engineering.

In this laboratory, the granite (similar to dry hot rock with high hardness) treated with thermo-liquid coupling was used for uniaxial compression test. The variation in stress–strain curve, peak strength, peak strain and elastic modulus of granite with temperature and thermo-liquid coupling times was analyzed.

Test Overview

Processing of Test Rock Samples

The rock sample used in this test is the granite of a stone factory in Baoding, Hebei Province. The main components are mica, quartz and feldspar. According to the requirements of the Chinese Society of Rock Mechanics (specimen size: φ50 * 100 mm; ratio of height to diameter: 2.0–2.5), the test rock sample is processed into a cylinder with a height of 100 mm and a diameter of 50 mm. The processing is divided into two stages. One is to drill a 50 mm core with a circular drill hole, and the other is to perform a segmental cutting to a height of 100 mm and smooth the ends. To reduce the test error, the size and shape of the rock samples were screened, and the rock samples with chipped edges and weak surfaces were removed. Finally, 45 similar rock samples were selected for testing. The partially processed rock samples are shown in Fig. 1.

Preparation of Rock Samples

Before uniaxial compression, the granite samples need to be treated with thermo-liquid coupling cycle. Specific operation steps are as follows:

-

1.

Group and number the processed rock samples. According to the heating temperature of 50 °C, 100 °C, 150 °C and the frequency of hydrothermal coupling one, two, three, four, five times, the two combinations were divided into 15 groups. Each group contains three samples.

-

2.

Conduct thermo-liquid coupling treatment of rock samples according to grouping Numbers. First of all, the rock samples are heated in the drying oven at the temperature of 50 °C, 100 °C and 150 °C. The heating time is more than 8 h. Then, a immersion test is performed in a cold water tank, where rock samples with a specified temperature are quickly placed in a cold water tank for 10 days. This process is a thermo-liquid coupling process. The thermo-liquid coupling process at each temperature was cycled for 1–5 times.

-

3.

Wipe the surface of the sample with a wet towel and wrap it in plastic wrap. Prepare for uniaxial compression experiment.

Test Equipment and Methods

This test uses China’s microcomputer-controlled electrohydraulic servo universal testing machine (see Fig. 2) for uniaxial compression tests and uses an electric drying oven for heating. The test machine is controlled by computer software throughout the process. The software can control the loading mode and loading rate and provide output parameters, curves, deformations, and so on.

During the uniaxial compression test, the displacement control method is used for loading. The loading rate is 0.5 mm/min. During the loading process, the test is completed according to the set requirements, and the relevant strength, load, displacement, and strain are recorded at the same time so that the test results can be analyzed and studied in the future.

Analysis of Uniaxial Mechanical Properties of Granite Under Thermohydraulic Coupling

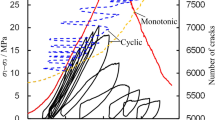

According to the data obtained by the uniaxial compression tests of the granite subjected to the hydrothermal coupling treatment (longitudinal displacement, longitudinal load, etc.), the stress–strain curves of the hydrothermal coupled tests are obtained by processing and analysis, as shown in Fig. 3. Furthermore, the peak intensity (i.e., uniaxial compressive strength), the peak strain (i.e., the strain corresponding to the peak intensity), and the elastic moduli are obtained, and the relationship among them is analyzed to obtain the variation law, as shown in Figs. 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 and 15 and Tables 1 and 2.

Characteristics of Stress–Strain Curves of Granite Samples with Thermo-liquid coupling Under Temperature Cycling

Figure 3a–c shows the stress–strain curves of the rock samples at 50 °C, 100 °C, and 150 °C, respectively. Each figure has a representative stress–strain curve for a portion of the cycles (1–5 times).

The stress–strain curve in Fig. 3 generally undergoes four stages: compaction, elastic deformation, yielding, and failure. At 100 °C, the stress–strain curve appears “sawed” in many places in the elastic and yielding stages, indicating that the granite is in brittle splitting and failure, and the first peak appears and the rock samples damaged during loading continue to be pressed together to make appear the next peak. Since the granite used in the test is a compact rock sample, the elastic strain phase of the stress–strain curve is longer, and the yielding stage is shorter. The rock sample immediately breaks down after the elastic deformation, and there is almost no slope to the stress–strain curve before the failure [8]. The curve shows that after the damage, the stress continues to increase, the rock bearing capacity decreases, the strain softening characteristics are exhibited, and brittle fracture occurs. During this stage, the microcracks of the rock gradually penetrate the sample.

Relationship Between the Mechanical Properties of Granite Samples and Temperature and Cycle Times

Peak Intensity and Temperature and Cycle Times

Figures 4 and 5 show the graphs of the relationships between the peak intensity of the granite sample and the temperature and cycle times. The peak intensity is the uniaxial compressive strength of rock, that is, the ultimate failure strength of the rock only under longitudinal compression.

-

1.

Analysis of the relationship between the peak intensity and temperature

Figure 4 illustrates the corresponding relationship between the peak intensity of the granite under thermo-liquid coupling and temperature cycling, where each peak intensity is the test average under the same conditions.

Figure 4 shows that after five cycles of thermo-liquid coupling, the average peak intensity of the granite at three temperatures is 64.56 MPa, 57.13 MPa, and 56.12 MPa, respectively. Compared with the peak intensity of granite at 50 °C, those at 100 °C and 150 °C decreased by approximately 11.51% and 13.07%, respectively. Therefore, according to the test results, the peak intensity of the granite decreases continuously with the increase in the cycle temperature within this temperature cycle.

In this temperature range, the peak intensity is divided into two phases (both descending segments) as the cycle temperature increases:

-

(a)

In the period of rapid decrease in the range of 50–100 °C, the peak intensity sharply decreases with increasing temperature. The absolute value of the slope of this segment is approximately 0.15, and the peak intensity is approximately 11.51%. Because the temperature is in the normal stage during this temperature cycle, a crack inside the rock is initially formed, and the internal structure is destroyed, so the peak intensity drops sharply.

-

(b)

In the decreasing phase at 100–150 °C, the peak intensity decreases slowly with increasing temperature. The absolute value of the slope of this segment is approximately 0.0202, which is much smaller than the previous phase. From 100 to 150 °C peak intensity, the decline is approximately 1.77%, much smaller than in the previous stage. Therefore, this stage slowly reduces the section. Due to the increase in temperature during this stage, coupled with the rapid stimulation of cold water, the temperature difference is large, and the internal structure of the rock forms a large number of cracks. Therefore, the peak intensity value gradually decreases with the increase in temperature.

-

2.

Analysis of the relationship between the peak intensity and cycle times

As shown in Fig. 5, the peak intensity is not only related to the size of the circulation temperature but also depends on the number of cycles.

To analyze the influence of the number of water cycles on the peak intensity of granite, the peak intensities under the same number of cycles were averaged, and Fig. 5 is obtained.

It can be seen from Fig. 5 that after the hydrothermal coupling cycle of three temperature points, the average peak strengths of the granites for the five different cycles are approximately 62.92 MPa, 60.57 MPa, 60.63 MPa, 50.40 MPa, and 61.84 MPa. Compared with the peak intensity of one cycle, these peak intensities decreased by 3.73%, 3.64%, 19.90%, and 1.72%, respectively. Therefore, according to the test results, the peak strength of granite is the maximum when the thermo-liquid coupling is once, and when the thermo-liquid coupling times are 1–4, the peak strength of granite decreases with the increase in hydrothermal coupling cycles. However, when the number of cycles is 5, the peak strength of the rock sample is relatively increased, indicating that when the granite is subjected to the fifth thermo-liquid coupling, the number of cold and hot stimulations increases, and the internal structure changes greatly. The structural reorganization with the liquid results in the change in internal structure and increase in the peak strength of the rock.

The peak intensity is divided into four stages as the number of hydrothermal coupling cycles changes:

-

(a)

The change in the peak intensity between one and two cycles is a slow decrease, and the decrease is 3.73%.

-

(b)

The change in the peak intensity between the two and three cycles is a slow increase. The increase was 0.10%.

-

(c)

The change in the peak intensity between three and four cycles is a fast decrease with a decrease of 19.87%.

-

(d)

The change in the peak intensity between the four and five cycles is a fast increase with an increase of 22.70%.

Granite is a hard rock and is not easily affected by external conditions. Therefore, after one, two or three thermo-liquid coupling cycles, the internal structure changes slowly and the peak strength decreases slightly. Once the damage limit is reached, the peak intensity changes dramatically, such as after four cycles and five cycles. After four cycles, the internal structure of the rock sample changes, resulting in a decrease in strength to a minimum. After five cycles, the rock is soaked again, reacts with the liquid, and recombines to increase the peak strength.

Peak Strain and Temperature and Cycle Times

The peak strain is the strain at which the rock specimen reaches its peak strength. Two relationship diagrams are drawn in Figs. 6 and 7 to reveal the correspondence between the peak strain and the temperature and water cycles.

-

1.

Analysis of the relationship between the peak strain and temperature

Figure 6 is a plot of the average peak strain of the granite under thermo-liquid coupling as a function of cycle temperature. After five cycles of thermo-liquid coupling, the average peak strain of the granite at three temperature levels was 1.70%, 1.60%, and 1.45%, respectively. Compared with the peak strain of granite at 50 °C, the peak strains at 100 °C and 150 °C decreased by approximately 5.88% and 14.71%, respectively. Therefore, when the cycle temperature changes from 50 to 150 °C, the elasticity of the granite is weakened, and the brittleness increases.

According to the experimental results, the relationship between the average peak strain and the temperature is fitted by the least-squares method. The fitted linear equation is

$$ \varepsilon = 1.8277 - 0.002T,\;(R^{2} = 0.98885). $$ -

2.

Analysis of the relationship between the peak strain and cycle times

The corresponding relationship between the peak strain of the granite under thermo-liquid coupling and the number of cycles is shown in Fig. 7. After experiencing the thermo-liquid coupling cycle of three temperature points, the average peak strains of the granite under the five different cycles were approximately 1.64%, 1.66%, 1.75%, 1.68%, and 1.18%. As the number of cycles increases, the peak strain gradually decreases, the plastic deformation decreases, and the brittleness increases.

With the increase in the number of cycles, the peak strain changes piecewise. When the number of cycles is 1–3 times, the peak rock strain increases gradually. When the number of cycles is 3–4 times, the peak strain of rock slowly decreases. When the number of cycles is 4–5 times, the peak strain of rock decreases rapidly. This indicates that granite is hard rock and is less affected by external environmental conditions. Only after several cold and hot cycles does the peak strain of the rock change significantly. When the number of cycles is 1–3, the elastic deformation stage of the rock in the compression process slowly increases, and the toughness increases. When the number of cycles is 3–5, the elastic deformation time in the rock deformation is less, and the toughness decreases, indicating that the internal structure is constantly changing.

According to the test results, a least-squares fitting is applied to the relationship between the average peak strain and the number of cycles. The equation of the fitted curve (the number of times is represented by x) is

Modulus of Elasticity and Temperature and Cycle Times

According to the experimental data, the relationships between the elastic modulus of the granite under thermo-liquid coupling and the temperature cycling and water circulation are plotted, as shown in Figs. 8 and 9.

-

1.

Analysis of the relationship between the elastic modulus and temperature

Figure 8 is a graph showing the relationship between the elastic modulus and the cycle temperature. The graph shows the average elastic moduli at three temperature points, the values of which are 3696.6 MPa, 8251.13 MPa, and 7448.07 MPa, respectively. Compared with the elastic modulus at 50 °C, the elastic moduli at 100 °C and 150 °C increase by 123.21% and 101.35%, respectively.

It can be seen from the figure that in the studied temperature range (50–150 °C), the elastic modulus can be divided into two stages according to the change in the cycle temperature:

-

(a)

When the temperature is in the range of 50–100 °C, the elastic modulus gradually increases as the temperature increases. The elastic modulus increased from 3696.6 to 8251.13 MPa, with an increase of approximately 123.21%, and the change was obvious.

-

(b)

When the temperature is in the range of 100–150 °C, the elastic modulus gradually decreases with increasing temperature. The elastic modulus decreased from 8251.13 to 7407.07 MPa, and the decrease was approximately 9.83%, with no significant change.

The reasons for the above phenomena of elastic modulus of rock are as follows: When the temperature is 50–100 °C, the change rate of stress in the elastic deformation process of rock is accelerating while the change rate of strain is decreasing or unchanged, or it may be that the change rate of stress is unchanged while the change rate of strain is decreasing. When the temperature is 100–150 °C, the change rate of stress slows down while the change rate of strain accelerates or does not change. It may also be that the change rate of stress does not change, while the change rate of strain accelerates. It indicates that when the temperature is 100 °C, the elastic modulus of the rock is the largest, the rigidity is the largest, and it is not easy to deform.

-

2.

Analysis of the relationship between the elastic modulus and number of cycle times

Figure 9 shows the correspondence between the elastic modulus and the number of cycles. After experiencing the coupled thermo-liquid cycling with three temperature points, the average elastic moduli of the granite for the five different cycles are approximately 7544.78, 6413.11, 5705.44, 6026.67, and 6623 MPa. When the number of cycles is 1–3 times, with the increase in the number of cycles, the elastic modulus of the rock becomes smaller, the stiffness of the rock becomes smaller, and the rock is prone to deformation. When the number of cycles is 3–5 times, with the increase in the number of cycles, the elastic modulus of the rock becomes larger, the rock stiffness becomes larger, and the difficulty of deformation in the process of compression increases. In this experiment, when the number of cycles is 3, the elastic modulus and stiffness of granite rock are the least, and the rock is most prone to deformation.

According to the test results, the relationship between the average elastic modulus and the number of coupled thermo-liquid cycles is fitted by the least-squares method, and the equation of the quadratic curve (x represents the number of cycles) is

Relationship Between the Mechanical Properties and Thermo-liquid Coupling of Granite Samples

The mechanical properties of granite have a certain relationship with the temperature and cycle times. The following research was performed to explore the relationship between thermo-liquid coupling, as shown in Figs. 10, 11, 12, 13 and 14.

Analysis of the Relationship Between the Peak Intensity and Thermo-liquid Coupling

The coupling relationship between the peak intensity of the granite sample and the temperature and cycle times is plotted, as shown in Fig. 10, and a straight line diagram is also drawn, as shown in Fig. 11.

It can be seen from Fig. 11 that at the cycle temperatures of 50–150 °C, with 1–5 thermo-liquid coupling cycles, the peak intensity decreases as the cycle temperature increases, and vice versa. In other words, the peak intensity after three cycles is the maximum and gradually decreases with increasing or decreasing cycles.

Analysis of the Relationship Between Peak Strain and Thermo-liquid Coupling

The coupling relationship between the peak strain of the granite sample and the temperature and cycles is plotted, as shown in Fig. 12, and the straight-line diagram is also drawn, as shown in Fig. 13.

It can be seen from Fig. 13 that in the range of the cycle temperature of 50–150 °C and 1–5 thermo-liquid coupling cycles, as the cycle temperature increases and the number of thermo-liquid coupling increases, the peak strain decreases; otherwise, the peak strain increases.

Analysis of the Relationship Between the Elastic Modulus and Thermo-liquid Coupling

The coupling relationship between the elastic modulus of the granite and the temperature and cycles is plotted, as shown in Fig. 14, and the straight-line diagram is also drawn, as shown in Fig. 15.

As shown in Fig. 15, when the temperature is 50–150 °C and the thermo-liquid coupling cycle times are 1–5, the elastic modulus of granite increases with the increase in cycle temperature and thermo-liquid coupling cycle times. Conversely, the elastic modulus of granite decreases. During the whole experiment, the peak strain of granite sample reached its maximum value when the temperature was 100 °C and the thermo-liquid coupling cycle was four times.

Comparative Analysis of the Effects of the Temperature and Cycles on the Mechanical Properties

The relationship between the number of water cycles and the mechanical properties (σ, ε, E) at the same temperature is shown in Table 1. The relationship between the temperature and the mechanical properties (σ, ε, E) under the same number of cycle times is shown in Table 2. All data are experimental measurements, and part of the fitted curve relationship is drawn.

Comparative Analysis of the Relationship Between the Mechanical Properties and the Number of Cycles

-

1.

According to the comparison between the peak intensity σ and the number of cycles at the three temperatures, the relationship between the peak intensity and the number of cycles is the same curve trend at each temperature, that is, decrease, increase, and decrease. In the curve, the minimum and maximum values of the experimental data were obtained at two and four cycles, and the peak intensity of the rock sample subjected to five cycles was obtained. According to the data, a least-squares fit is performed to obtain cubic fitting equations (where x represents the number of cycles):

According to the comparison between the peak strain ε and the number of cycles at the three temperatures, the relationship between the peak strain and the number of cycles is the same curve trend at each temperature, which is M-shaped. When the number of cycles is 2 or 4, the maximum value is obtained, and when the number of cycles is 3 or 5, the minimum value is obtained.

At the three temperatures, the relationship between the elastic modulus E and the number of cycles is analyzed. The relationship between the elastic modulus and the number of cycles is the same curve trend at each temperature and is consistent with the trend of peak intensity with number of cycles, that is, decrease, increase, and decrease. The minimum and maximum values of the experimental data were obtained when the number of water cycles was 2 and 4. A least-squares fit was performed on the elastic moduli of 100 and 150 °C with the number of cycles to obtain cubic equations (where X represents the number of cycles):

Comparative Analysis of the Relationship Between the Mechanical Properties and Temperature

-

1.

Under 1–5 cycles, the comparison of peak intensity σ and cycle temperature shows that the peak intensity increases with temperature. This indicates that the higher the heating temperature, the higher the compressive strength and the stronger the bearing capacity of the rock when the thermo-liquid coupling times are 1–5. A least-squares fitting is performed on the data from two, three, and five water cycles, and the linear equations are obtained (where X represents the number of water cycles):

$$ \begin{aligned} & \sigma = 35.8726 + 0.0856T,R^{2} = 0.9864.\;(X = 2) \\ & \sigma = 38.0127 + 0.0884T,R^{2} = 0.9739.\;(X = 3) \\ & \sigma = 19.6772 + 0.17351T,R^{2} = 0.92489.\;(X = 4) \\ \end{aligned} $$ -

2.

Comparing the peak strain ε and the temperature for 1–5 water cycles shows that for one and three water cycles, the peak strain decreases with increasing temperature. It indicates that when the thermo-liquid coupling times are 1–3, the higher the heating temperature is, the greater the peak strain of rock is. For two, four, and five water cycles, the peak strain changes with temperature in two stages: a reduced section and a rising section. The minimum peak strain is obtained at 100 °C. Among them, the least-squares fitting is performed on the data of the peak strain with temperature changes of three water cycles, and the equation is obtained (where X represents the number of cycles):

$$ \varepsilon = 1.88 - 0.003T,R^{2} = 0.91045.\;(X = 3) $$ -

3.

With 1–5 water cycles, the comparison between the elastic modulus E and the cycle temperature shows that the change in the elastic modulus with temperature increases in two stages: a rising phase and a falling phase. When the cycle temperature was 50 °C, the minimum modulus of elasticity was obtained, and at 100 °C, the maximum modulus of elasticity was obtained. It indicates that when the temperature is 50–100 °C, the elastic modulus and stiffness of the rock increase, while when the temperature is 100–150 °C, the elastic modulus and stiffness of the rock decrease, making it easier to be deformed by external forces.

Analysis of Variance Between the Mechanical Properties and the Number of Water Cycles and Cycle Temperature

To better compare the influence of the cycle temperature and the number of water cycles of the hydrothermal coupling on the mechanical properties of the granite, two-way variance processing was performed on the test data, and the following results were obtained, as shown in Tables 3–5.

Repeatable two-way ANOVA was performed on all the measured values to obtain Table 1, with a level of significance of 0.05. The samples in Table 3 represent the cyclic temperature factors, and the columns represent the cyclic secondary factors. All Fcrit > F and F values are in the acceptance domain, so both factors have no significant effect on the peak intensity of the granite.

The peak strain test values of the same test conditions were averaged, and then the average number was analyzed by repeating two-way ANOVA. The results of Table 4 were obtained, and the level of significance was 0.05. It can be seen from the data that P values > 0.05 have no significant effect on peak strain.

The elastic modulus test values of the same test conditions were averaged, and then the average number was analyzed by repeating two-way ANOVA. The results of Table 5 were obtained, and the level of significance was 0.05. It can be seen from the results in the table that the cycle temperature factor Fcrit < F; the cycle temperature has a significant effect on the elastic modulus of the granite, but the cycle number is not significant.

In summary, the two factors of cycle temperature and number of dry and wet cycles have an effect on the mechanical properties of hydrothermal coupled granite, and the cycle temperature is more significant than the number of cycles.

Conclusion

-

1.

The stress–strain curve undergoes four stages: compaction, elastic deformation, yielding, and failure (brittle failure occurs).

-

2.

The mechanical properties of the granite samples are related to the cycle temperature (50–150 °C). The peak intensity increases with increasing temperature; when the temperature is in the range of 50–100 °C, the reduction is approximately 11.51%, and when the temperature is in the range of 100–150 °C, the reduction is approximately 1.77%. As the temperature difference of the hydrothermal fluid increases, the degree of stimulation of the rock sample increases, so that the peak intensity is weakened, and the peak intensity value changes more slowly. The peak strain has a linear fit relationship with the cycle temperature. As the temperature increases, the peak strain decreases, the rock sample weakens, and the brittleness increases. The modulus of elasticity first increases and then decreases with increasing temperature, and the increase is approximately 123.21%.

-

3.

The mechanical properties of the granite samples are related to the number of hydrothermal coupling cycles. The peak intensity varies with the number of cycles. Different changes occur before three cycles, and the subsequent changes are obvious. From three cycles to four cycles, the reduction is 19.87%. From four cycles to five cycles, the rate of increase is 22.70%. The peak strain has a cubic fitting relationship with the number of cycles, R2 = 1, and the maximum value in the experiment is obtained for three cycles. The elastic modulus has a quadratic fitting relationship with the number of cycles, and the minimum value of the experiment is obtained with three cycles.

-

4.

The mechanical properties of the granite samples are related to hydrothermal coupling. The peak intensity contour map, for 50–100 °C, is symmetrically distributed among three cycles. The peak strain decreases with increasing cycle temperature and number of cycles; a bimodal distribution appears in the elastic modulus contour map. At the same time, as the temperature increases, the number of cycles increases and the modulus of elasticity increases.

-

5.

By curve fitting and performing an analysis of variance for the experimental values and their averages, it is concluded that the effect of cyclic temperature is significant.

References

Du B, Bai H, Ma Z, Li M, Wu G (2018) Experimental study on dynamic tensile mechanical properties of red sandstone under dry and wet cycles. Chin J Rock Mech Eng 37(7):1671–1679. https://doi.org/10.13722/j.cnki.jrme.2018.0039

Fu Y, Wang Z, Liu X, Yuan W (2017) Study on meso-damage evolution and macroscopic degradation of sandstone under dry-wet cycle. Chin J Geotech Eng 39(9):1653–1661. https://doi.org/10.11779/CJGE201709013

Li K, Zheng D, Huang W (2013) Neural network simulation of mechanical properties and constitutive model of sandstone under wet and wet cycle. Rock Soil Mech 34(S2):168–173. https://doi.org/10.16285/j.rsm.2013.s2.028

Liu X, Li D, Zhang L (2016) Effects of dry and wet cycles on mechanical properties and microscopic structure of argillaceous sandstones. Chin J Geotech Eng 38(7):1291–1300. https://doi.org/10.11779/CJGE201607017

Liu X, Wang Z, Fu Y, Zhang L, Yuan W (2017) Study on strength and failure criterion of argillaceous sandstone considering dry-wet cycle. Rock Soil Mech 38(12):3395–3401. https://doi.org/10.16285/j.rsm.2017.12.001

Mao X, Liu R, Zhang L (2014) Experimental study on the effect of loading rate on mechanical properties of limestone under different temperature conditions. Chin Sci Technol Pap 9(5):574–577. https://doi.org/10.3969/j.issn.2095-2783.2014.05.017

Wu G, Wang D, Yan S (2012) Acoustic emission characteristics of sandstone after high temperature under uniaxial compression. Rock Soil Mech 33(11):3237–3242. https://doi.org/10.16285/j.rsm.2012.11.006

Xu C, Zhou H (2016) Experimental study on triaxial compressive strength of coarse sandstone after high temperature. Chin J Rock Mech Eng 35(S1):2811–2818

Xu X, Gao F, Zhang Z (2014) Experimental study on triaxial compression of granite after high temperature action. Rock Soil Mech 35(11):3177–3183. https://doi.org/10.16285/j.rsm.2015.08.008

Xu X, Gao F, Zhang Z (2015) Experimental study on the effect of loading rate on granite mechanical properties under real-time high temperature. Rock Soil Mech 36(8):2184–2192. https://doi.org/10.16285/j.rsm.2015.08.008

Zhai S, Wu G, Zhang Y, Wu X (2014) Study on mechanical properties of high temperature salt rock under uniaxial compression. Chin J Rock Mech Eng 33(1):105–111. https://doi.org/10.13722/j.cnki.jrme.2014.01.009

Zhang L, Mao X (2010) Study on mechanical effects of loading rate on limestone under high temperature condition. Rock Soil Mech 31(11):3511–3515. https://doi.org/10.16285/j.rsm.2010.11.026

Xi B, Zhao Y (2010) Experimental study on mechanical properties of granite in high temperature state at 600 °C after cooling with water. Chin J Rock Mech Eng 5:892–898

Huang Z, Zhang Y, Sun Y (2016) Study on mechanical and acoustic properties of limestone under high temperature water-cooling. J Cent South Univ Sci Technol 12:4181–4189. https://doi.org/10.11817/j.issn.1672-7207.2016.12.029

Huang Z, Zhang Y, Wu W (2016) Analysis of mechanical and wave characteristics of high temperature marble treated with water cooling. Rock Soil Mech 2:367–375. https://doi.org/10.16285/j.rsm.2016.02.008

Zeng Y, Rong G, Peng J, Sha S (2018) Experimental study on crack propagation of marble after high temperature cycling. Rock Soil Mech S1:220–226. https://doi.org/10.16285/j.rsm.2017.1922

Ni X, Li X, Huang D (2016) Experimental study on uniaxial compression mechanics of marble after different high temperature cycles. J Hydroelectr Eng 9:95–100. https://doi.org/10.11660/slfdxb.20160911

Fang, R. (2005). Experimental study and comparison of mechanical properties of marble after high temperature and high temperature cycling. In: Rock Mechanics Committee of China Society of Rock Mechanics and Engineering. Proceedings of 9th Nat. Conf. Rock Dyn. Rock Mechanics Committee of China Society of Rock Mechanics and Engineering: Chinese Society of Rock Mechanics and Engineering, vol 5

Zhu Z, Li D, Jiang Z, Liu J, Yang Y (2009) Quantitative description of the meso-structure of surrounding rock of deep tunnel under temperature cycling. Rock Soil Mech 11:3237–3241+3248. https://doi.org/10.16285/j.rsm.2009.11.027

Xia C, Zhou S, Hu Y (2015) Study on mechanical properties of basalt under cyclic uniaxial stress and cyclic temperature. Chin J Geotech Eng 6:1016–1024. https://doi.org/10.11779/CJGE201506007

Zhang Y (2017) Study on the deterioration law of mechanical parameters of altered rock after temperature cycling. J Eng Geol 2:410–415. https://doi.org/10.13544/j.cnki.jeg.2017.02.019

Ming X, Fan C (2017) Influence of temperature cycling on physical and mechanical properties of rocks. Sci Technol Eng 13:261–265. https://doi.org/10.3969/j.issn.1671-1815.2017.13.048

Acknowledgements

Support was provided by the College of Civil Engineering and Architecture, Hebei University, Baoding, Hebei 071002, China (964630415@qq.com). Funding was provided by the Hebei Province Education Department Fund (BJ2018046), Post-graduate’s Innovation Fund Project of Hebei University (hbuss020) and by the Center for Hydrogeology and Environmental Geology, China Geological Survey, Baoding, “project implementation and resource pilot production of natural gas hydrate in sea area”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, L., Yan, M., Chen, Y. et al. Experimental Study on Uniaxial Mechanical Properties of Granite Under Thermo-liquid Coupling. Indian Geotech J 50, 935–947 (2020). https://doi.org/10.1007/s40098-020-00428-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-020-00428-0