Abstract

Black cotton soil is found in many states of India and is found to be problematic soil for construction. It has low shear strength, high swelling, shrinkage and compressibility characteristics. As costs of waste disposal, transport and materials procurement continue to increase, the use of ground improvement techniques to prepare problematic soils for construction has become much more popular. The increased land use pattern has put pressure to develop techniques for ground improvement of problematic soil deposits. The ground improvement techniques are generally based on densification, inclusion of reinforcement, cementation and provision of drainage etc., these days chemical additives are becoming popular due to their resistance to seasonal changes, increase in strength with curing and longer serviceability. Generally lime and cement are widely used to improve black cotton soil having high swelling and compressibility. In this paper, an attempt is made to stabilise black cotton soil using Industrial by products such as calcium carbide residue (CCR), lime, sodium silicate and sodium silicate + lime (SS + L) blend. In this study an attempt is made to identify the effect of these chemical additives on Atterberg’s limits and compaction characteristics and critical factors governing the strength development of black cotton soil specimen stabilised with CCR, lime and sodium silicate + lime. The results have shown that the plasticity index decreases to 1/3rd of the initial value. The compaction behaviour is greatly influenced by soil pore fluid interaction and its effect on diffused double layer and soil structure. The combination of optimum content of sodium silicate and lime for black cotton soil stabilization is stable from the durability point of view. It is also found that the clay-water/admixture ratio (Wc/Admixture) and the curing period are the prime parameters controlling the strength development. Based on these parameters and Abrams’ law, the strength prediction equations for various curing times and combinations of clay-water content and chemical additive content are proposed and verified.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Black cotton soil causes severe damages to the structures particularly buildings, canal slopes and pavements due to swelling and shrinkage during wet and dry seasons. Black cotton soil is generally inundated with water during rainy season and it tends to soft state with high initial water content. Many foundations, canal slopes, road bases were reported to be under distress and failure. Thus, to utilize these soils in an effective way, there is a need for ground improvement before construction. The treatment could be either stabilization or replacement with a good soil. Replacing the black cotton soil with a good soil is not economical. Several ground improvement techniques such as densification, cementation (additive), reinforcement, and drainage are attempted to mitigate the problems. The additive techniques such as bituminous, lime, cement and chemical stabilizations have gained popularity and are widely used to improve the mechanical behavior. Out of these, chemical stabilization is becoming more popular these days due to their resistance to seasonal fluctuation, increased resistance to compression and strength development with increase in curing time and longer serviceability.

Calcium carbide residue (CCR) is a by-product of acetylene production process, which contains mainly calcium hydroxide, Ca(OH)2. It is an industrial waste and cementing agent for soil stabilization. Many researchers [1–4] have investigated the engineering properties of the calcium carbide residue stabilized clay to ascertain the performance in the fill and pavement applications. It has been reported that the calcium carbide stabilization is more effective than the lime stabilization in terms of engineering, economic and environmental viewpoints.

Sodium silicate grouts are popular due to their environmental and safety compatibility. Moreover, sodium silicates have been developed into a wide variety of different grout systems. Practically, all systems are assumed on reacting a silicate solution to form a colloid which polymerizes further to form a gel that binds sediment particles or soil together and fills voids. In addition, sodium silicate solutions are basic in nature. As this alkaline solution is neutralized, colloidal silica will aggregate to form a gel if the sodium silicate is present in concentrations above 1 or 2 % [5–7]. Sodium silicate solution in water known as water glass, in combination with other chemicals such as calcium oxide, calcium chloride, sodium hydroxide, calcium carbide, cement etc. can be used for stabilization of soil [8, 9]. Several investigators have attempted soil stabilization with lime as additive for generation of long term strength by pozzolanic action. The main benefits of using lime to stabilize clays are improved workability, increased strength, and volume stability. There by enhancing many of the engineering properties of the soil and thus, produces an improved construction material. The strength developed obviously is influenced by the quantity of cementitious gel produced, consequently on the amount of lime consumed and curing period [10–13].

Many constitutive models have been developed for strength prediction based on compression and shear behaviour [14–16]. The Abram’s law [17] based on the ratio of free water content to cement content is extensively used for predicting the strength of concrete. In soils, strength is found to be independent of the absolute contents of free water and cement content in the mix. Many researchers ( [18–23]) have identified the clay-water/cement ratio, (Wc/C) as a critical parameter influencing strength development in cement stabilized clays. It is believed that clay water content reflects the microfabric and the cement content influences the level of bonding of that fabric. Based on this parameter and Abrams’ law (Abrams 1918), it is revealed that for a given set of cement admixed clays, the strength development depends only on the clay-water/cement ratio, (Wc/C). Several investigators [18–20]), extended this analogy to the behaviour of soil stabilization and have brought out that the clay-water to cement ratio has been identified as controlling parameter for strength gain and generalized prediction equations ([24–28]) have been developed. The effect of different stabilizing agents used is different for different soils. The prediction equations are soil specific and are useful for those for which they are developed and other soils with similar geotechnical properties.

The present paper reports the results of strength development of black cotton soil by stabilizing with calcium carbide, lime and sodium silicate as additives. An attempt is made to formulate prediction equations for strength development based on Abram’s law for black cotton soil stabilized with these additives and their validation for use by field engineers for ground improvement.

Materials and Methods

Materials

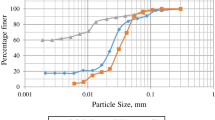

Black cotton soil was procured from Hiriyur Taluk, Chitradurga District. The soil was collected at a depth of about 1 m from the ground level after removing all the vegetation matter. The soil was air dried and pulverized to break the lumps. After sieving through 2.00 mm sieve, it was stored in air tight bags. As and when required, the soil was oven dried at 105 °C for 24 h and then cooled to room temperature before use. The results of index properties, gradation and standard Proctor tests are presented in Table 1. The soil is silty-clay of high compressibility with the group symbol CH–MH. Figure 1 shows grain size distribution of black cotton soil. It is a very high swelling clayey soil with the free swell ratio greater than 1.35 [29]. The consistency limits are LL = 72 %, PL = 41 %, Ip = 31. The modified Proctor parameters are γdmax = 16.5 kN/m3 and optimum moisture content (OMC) = 22 %.

Physico-chemical Properties

The Physico-chemical properties were determined as per standard test procedures.

About 10 gm of crushed oven dried soil sample is taken and concentrated HNO3 is added to it such that all the soil particles are suspended. Shake well the suspension, boil for 5 min and cool it. It is then filtered through what mans filter paper. The residue along with the filter paper is placed in a silica crucible which is then placed in muffle furnace and heated till red hot. The residue left in the crucible gives the percentage of silica present in the soil. The filtrate is collected and made up to 250 ml (stock solution) which is then used for further experiments.

Take 25 ml of stock solution and add 10 mg of ammonium chloride and ammonium hydroxide (1:1) till excess white/reddish brown precipitate appears. The solution is then subjected to centrifuge for 10 min. Precipitate is separated with the help of filter paper. Sodium hydroxide is added to the residue collected from the filter paper and again filtered. The residue along with the filter paper is collected and placed in silica crucible which is then placed in muffle furnace and heated till red hot. The residue left in the crucible gives the percentage of iron present in the soil.

Ammonium hydroxide is added to the filtrate obtained in the previous step till it forms precipitate and then filtered. The residue along with the filter paper is collected and placed in silica crucible which is then placed in muffle furnace till red hot. The residue left in the crucible gives the percentage of alumina present in the soil.

Take 25 ml of stock solution and add 10 mg of ammonium chloride and ammonium hydroxide (1:1) till excess white/reddish brown precipitate appears. The solution is then subjected to centrifuge for 10 min. Filtrate is collected and ammonium carbonate is added till white precipitate is formed and then filtered. The residue along with the filter paper is then placed in silica crucible which is then placed in muffle furnace till red hot. The residue left in the crucible gives the percentage of calcium present in the soil.

Ammonia is added to the filtrate collected in previous step and filtered. The residue along with the filter paper is then placed in silica crucible which is then placed in muffle furnace till red hot. The residue left in the crucible gives the percentage of magnesium present in the soil.

The pH of the soil specimen was determined by the electrometric method as per IS: 2720 (part 26)-1987. The cation exchange capacity of the soil specimen was determined as per IS: 2720 (part 24) 1976. The specific surface area of the soil specimen was determined as per ASTM C837, Methylene blue titration method. The chemical properties of black cotton soil are reported in Table 2.

Additives Used

Calcium carbide residue (CCR), lime and sodium silicate (SS) were considered as additives in the present investigation.

Calcium Carbide (CaC2) Residue

Calcium carbide residue (CCR) was used as an additive for stabilising black cotton soil. The CCR mainly contains calcium carbide and minimum assay was 75 %. The quantity of calcium carbide used was varied from 0 to 8 % by dry weight of soil. Calcium carbide having molecular weight of 64.1 g was used.

Lime

Quick lime was used in this investigation and it mainly contains calcium hydroxide and minimum assay was 90 %. The quantity of lime used was varied from 0 to 9 % by dry weight of soil. The physico-chemical properties of quick lime are shown in the Table 3.

Sodium Silicate (Na2O SiO2·9H2O)

Sodium silicate and lime were blended and used to stabilise black cotton soil. Sodium silicate used in this investigation is having molecular weight of 284.2 g/mol. The quantity of sodium silicate used was varied from 0 to 6 % by dry weight of the soil. The details of sodium silicate are shown in the Table 4.

Mechanism of Soil–Lime Interaction

Lime reacts chemically with clay soil to alter molecular interactions. Untreated black cotton soils have a molecular structure similar to some polymers, and possess plastic properties. The structure can trap water between its molecular layers, causing volume and density changes. The following equations show the reactions involved.

The initial consumption of lime gives an indication of the minimum quantity of lime that must be added to the soil in order to achieve significant change in properties. This quantity must first satisfy the affinity of the soil for calcium and so it is not available for pozzolanic reactions.

Mechanism of Soil–Sodium Silicate and Lime Interaction

Sodium silicate is good for soil stabilisation on account of its binding behaviour but clay particles of black cotton soils typically have a net negative charge on their face and a positive charge along their edges due to broken bonds. When sodium silicates are added to black cotton soil, the negative silicate ions from the sodium silicates are attracted and attach to clay particle edges causing entire clay particles to become negatively charged. If the entire clay particles have a negative charge, they will repel one another and the clay structure will become dispersed and weak. Sodium silicate may strengthen the clay if lime is added along with the sodium silicate, addition of calcium hydroxide makes the soil environment basic and increase of pH and with the presence of both calcium ions and silicate ions, calcium silicate gel can form, hydrate, and harden thereby cementing the clay particles together. The following equations show the reactions involved,

Finally, if sufficient supply of calcium ions is not available, excess silicate ions might attach to the edges of the clay particles and deflocculates the clay structure. And if fewer calcium ions are available for ion exchange, strength of the soil will decrease.

The gel-forming property of sodium silicate is used as advantage in soil stabilisation. Sodium silicate solutions, along with reacting chemicals such as calcium hydroxide (lime), calcium chloride, sodium hydroxide etc., have been used for the consolidation of porous soil structures for many years.

Experimental Investigations

Sample Preparation

Black cotton soil was sieved through a 2-mm sieve to remove pieces of shell and other coarser particles. The black cotton soil was mixed with the corresponding additives such as calcium carbide, lime, sodium silicate and combination of sodium silicate and lime and allowed for 1 h for chemical reactions to take place, thereafter the tests were conducted as per the procedure laid out in relevant IS Codes. The calcium carbide content was varied from 0 to 8 % at an increment 2 % by dry weight of the soil. The lime content was varied from 0 to 9 % by dry weight of the soil. The sodium silicate was varied from 3 to 6 %. The black cotton soil was mixed with combination of sodium silicate (5 mol) and lime, and allowed for 1 h for chemical reactions to take place, thereafter the tests were conducted. The optimum content of sodium silicate (SS) was determined based on plasticity index of SS and black cotton soil mix which decreased and attained a constant value with increase in additive content. The SS content was kept at optimum percentage and lime content was varied. Unconfined compressive strength (UCS) tests were conducted under soaked condition at respective maximum dry unit weight of soil-additive mix. Three samples were prepared and tested for each test and the average of three trails was recorded to maintain the consistency of test results.

Soaking

The UCS tests were conducted for curing periods of 0, 7, 14 and 28 days in desiccators at 100 % relative humidity. The cured samples were soaked for 1 day. The soaked UCS tests were conducted to simulate the durability under wet condition. The samples were soaked by immersing them in a container filled with water such that the top of sample is 1 cm above the level of water. The samples were mounted on porous stones on the bottom and covered by rubber membrane. The samples were saturated by back saturation technique under a head of water 1 cm less than the height of sample. The soaked samples were kept in air for about 30 min for drying and then subjected to unconfined compressive strength test. For all tests 6–8 % of additional water content determined based on trial tests, was required for chemical reactions.

Durability

The calcium carbide, lime and sodium silicate stabilized soil specimen were prepared at optimum percentage of additive content at MDD and OMC using UCS mould. After compaction the specimens were kept for 24 h at room temperature then it is wrapped in polythene bags and stored in humidity chamber to maintain optimum moisture content for about 7 days. After 7 days curing the sample is taken and porous stone was placed at the bottom of the specimen then it was covered with membrane and submerged in water at room temperature for 5 h and then volume was measured. Then they were dried in the oven at a temperature of 40–45 °C for 3 h and air dried at room temperature for 24 h and again volume was measured. This completes one cycle of wetting and drying. Similarly the specimens were subjected to wetting and drying cycles to ascertain the durability behaviour.

Atterberg Limits

The Atterberg limits for black cotton soil treated with CCR, lime, sodium silicate and sodium, silicate plus lime mixes were determined. The Atterberg limits tests results for various additives used for stabilization of black cotton soil are presented in Figs. 2, 3, 4 and 5. The results show that the liquid limit reduces with the addition of additive contents in all soils whereas plastic limit increases after certain additive content. The decrease in liquid limit is due to increased electrolyte concentration which suppress the double layer thickness and hence flocculation takes place which will decrease the plasticity index. The increase in plastic limit after certain percentage of additive content is due to formation of soil-additive gel during initial hydration reaction. However, plasticity index continuously decreases with the addition of additives as a result the soil classification changes from CH–MH (untreated soil) to MH after treated with additives. The optimum additive contents are 4 % CCR, 7 % lime and 4.5 % SS and 7 % lime as evident from Figs. 2, 3, 4 and 5. This indicates that the treated soil will undergo less volume change due to moisture fluctuation.

Compaction Characteristics

The modified Proctor compaction tests on black cotton soil treated with CCR, lime, SS and SS + lime soil mixes were determined as per IS:2720 (part 7).

Figure 6 shows the compaction curves for black cotton soil mixed with 2–8 % calcium carbide. It is observed that there is increase in maximum dry density and optimum moisture content remains same with the addition of calcium carbide. Maximum adsorption capacity of the Ca2+ ions by the soil occurs at 4 % calcium carbide beyond 4 %, due to excess free lime and liberation of acetylene gas, causes unsoundness and hence reduction in density.

Figure 7 shows compaction curves for Black Cotton soil mixed with 3, 5, 7 and 9 % lime. It is observed that there is change in maximum dry unit weight and optimum moisture content with the addition of lime. The optimum moisture content is increasing and maximum dry density is decreasing with the addition of lime content. This is due to flocculation of soil particles. The OMC is in the range of 22–24 % and dry density decreases from 16.48 to 15.52 kN/m3.

Figure 8 shows variation of MDD with respect to Sodium silicate content. Soil typically have negative charges on their faces and positive charge on their edges, negative silicate ions from sodium silicate attract towards edges of the clay particle at high concentration and causing entire clay structure to be negatively charged and hence repulsion this results in dispersed structure leading to large void ratio and reduction in density.

Figure 9 shows compaction curves for black cotton soil mixed with 4.5 % sodium silicate +3–9 % lime. It is observed that there is increase in maximum dry density and the optimum moisture content remains same with increase in additive content. This increment in density is due to the exchange of silicate ions on the clay surface from calcium ions and also active enhanced reactions due to supply of silicate ions from sodium silicate results in closer structure of clay particles causing deflocculation which leads to densification.

Strength Characteristics

Table 5 outlines the experimental program for UCS of black cotton soil with stabilisers such as calcium carbide, lime, sodium silicate and combination of sodium silicate and lime.

Effect of Calcium Carbide Residue (CCR) on Unconfined Compressive Strength

Figure 10 shows UCS versus CCR content, at any given CCR content, UCS increases with increase in curing period. UCS is maximum at CCR content of 4 %. Beyond 4 %, there is a decrease in UCS with higher CCR content. It is observed from the results that there is an increase in the UCS value by 100 % at 0 day for 4 % CCR content. At 4 % CCR content the dry unit weight is maximum beyond 4 % the dry unit weight decreases. The variation of 0 day strength can be attributed to the effect of density. The results indicate significant short term strength gain due to cation exchange, flocculation and aggregation. Figure 11 shows UCS versus curing period. UCS increases with increase in curing period. The contribution of pozzolanic reaction is clearly evident at 4 % CCR content due to the formation of aluminate hydrates as cementitious compound. Higher additive content retard the strength gain which is due to insufficiency of natural pozzolanic materials to react with excess Ca(OH)2 and release of acetylene gas at higher dosages of calcium carbide. In the field applications, CCR has to be mixed uniformly and thoroughly with soil in dry condition, an addition of 6–8 % water over and above the OMC has to be made available for hydration then the soil has to be compacted to Proctor condition. The dosage level shall be kept equal to the optimum additive content.

Effect of Lime on Unconfined Compressive Strength

Figure 12 shows UCS versus lime content for curing periods up to 28 days.

At any given lime content, UCS increases with increase in curing period. UCS increases with increase of lime content till 7 % at which strength is maximum for all curing periods considered. Beyond 7 %, UCS remains constant. It is observed from the results that there is an increase in the UCS value by more than 100 % at 0 day for 7 % lime content. This indicates significant short term strength gain due to cation exchange, flocculation and aggregation. Figure 13 shows UCS versus curing period. The UCS increases with increase in curing period. The contribution of pozzolanic reaction is clearly evident at 7 % lime content due to the formation of aluminate hydrates as cementitious compound. UCS increases up to 14 days after that there is no increase in strength. This is due to non-availability of soluble clay silica and soluble clay alumina. After the optimum percentage of lime, the strength of the soil slightly decreases due to affinity of the soil for calcium ions comes to end at optimum dosage and after that it is not available for pozzolanic reactions hence excess free lime cause unsoundness and reduces the strength. Higher additive content retards the strength gain due to insufficiency of natural pozzolanic materials to react. In field, lime can be added in dry form at pre-determined dosage levels, mixed thoroughly and compacted. In case of in situ low strength deposits, lime can be injected in slurry form by grouting.

Effect of Sodium Silicate (SS) on Unconfined Compressive Strength

Figure 14 shows the variation of UCS versus sodium silicate for 0, 7, 14, and 28 days. At any given sodium silicate content, UCS increases marginally. But it is observed that for 6 % SS UCS value decreases when compared to 4.5 % sodium silicate. This is because large dosage of sodium silicate creates large concentration of sodium ions which weakens and disperses the clay structure due to ion exchange occurring between the high concentrations of sodium ions and any more positively charged cations on the clay particle surface. Finally if sufficient supply of calcium ions is not available, excess silicate ions attached to the edges of the clay particles deflocculate the clay structure. The optimum additive content is 4.5 % with a UCS of 339 kPa at 28 days. The curing period effect is marginal.

Effect of Sodium Silicate (SS) and Lime on Unconfined Compressive Strength

Sodium silicate alone results in marginal strength increase. In order to utilise sodium silicate combination of optimum content of sodium silicate (4.5 %) and lime was considered (Fig. 15).

Figure 16 shows UCS versus SS(4.5 %) + lime content. At any given SS(4.5 %) + lime content, UCS increases with increase in curing period. UCS increases with increase in addition of SS + lime content till 4.5 % SS + 7 % lime (optimum additive content) at which strength is maximum. Beyond the optimum additive content, UCS is constant with increase in additive content. It is observed from the results that there is an increase in the UCS value by 75 % at 0 day for 4.5 % SS + 7 % lime content. This indicates significant short term strength gain due to cation exchange, flocculation and aggregation. The contribution of pozzolanic reaction is clearly evident at 4.5 % SS + 7 % lime content due to the formation of aluminate hydrates as cementitious compound. Higher additive content retard the strength gain which is due to insufficiency of natural pozzolanic materials to react. Figure 17 shows that, UCS increases with increase in curing period. UCS increases up to 14 days after that there is no increase in UCS. This is because the addition of excess silicate ions from the sodium silicate enhances the cation exchange process which causes active reactions and formation of strong bond between calcium and silicate sheets of the clay particles up to 14 days of curing. The affinity of clay particles towards calcium ions end after 14 days of curing, results in decrease in pozzolanic activity and hence constant strength. In case of SS and lime mixture, lime can be initially added in dry condition to the soil and thoroughly mixed, to this SS solution can be injected to ensure a uniform distribution and compacted to proctor conditions.

Durability Test

Figure 18 shows variation of differential volumetric strain with respect to wet-dry cycles for 4 % CCR, 7 % lime and 4.5 % SS + 7 % lime. It is observed that, for 4 % CCR differential volumetric strain reduces from 11.88 to 2.18 % at the end of 5 cycles. For 7 % lime differential volumetric strain reduces from 8.48 to 3.79 % at the end of 5 cycles. For 4.5 % SS + 7 % lime volumetric strain reduces from 7.55 to 3.88 % at the end of 3 cycles. From the above results it is noticed that, for 4.5 % SS + 7 % lime the differential volumetric strain almost remains constant from the second cycle itself therefore this combination is more stable than 4 % CCR and 7 % lime.

Strength Prediction

The UCS results have indicated the dependence of strength of black cotton soil on Wc/CCR ratio and curing period. The results have also confirmed the fact that strength increases up to optimum Wc/CCR ratio and further increase in Wc/CCR decreases the UCS due to increase in CCR content. The strength development follows a polynomial function of second degree as shown in Fig. 19. It is observed that, the strength development depends on various indices of soil such as plasticity index (Ip), CCR content, and base strength along with curing period. The contribution of pozzolanic reaction is clearly evident at 4 % CCR content (Fig. 10) due to the formation of aluminate hydrates as cementitious compound. At higher additive content, additional water is necessary for chemical reactions to form Ca(OH)2 resulting in insufficient water for hydration reaction. In addition, at higher CCR content, calcium hydroxide consumed for pozzolanic reaction is nearly constant beyond optimum CCR content. The excess Ca(OH)2 remains unutilised due to insufficient pozzolanic materials.CCR also reacts with water to form acetylene gas and quick lime. These reactions consume more water. In addition, more heat is generated which would evaporate more water than would be evaporated by lime hydration alone. This leads to insufficient water for hydration reaction. Due to these reasons strength decreases for CCR content greater than optimum content and the same trend is observed in Fig. 19.

UCS of black cotton soil stabilised with CCR is a function of parameters such as clay-water to CCR ratio, CCR content, curing period, plasticity index and base strength as given below in Eq. (7).

Strength prediction equation is developed by non-linear regression analysis for black cotton soil stabilised with CCR considering various parameters such as clay-water to CCR ratio, CCR content, curing period, plasticity index and base strength has given in Eq. (8).

where, Wc/CCR clay-water to CCR ratio, D curing period in days, LI liquidity index, CCR content in %, I p plasticity index, BS base strength i.e., UCS at zero CCR content, E constant which depends on base strength of soil and equal to 2.70 for black cotton soil considered.

The results of prediction of UCS using Eq. (8) are presented in Table 6. From the results, it is observed that predicted strengths are in good agreement with laboratory strengths with an R2 value of 0.93 and a mean absolute percentage error (MAPE) of 8.28 % which is acceptable from the practical point of view. This error is mainly due to the factors such as chemical reactions and curing temperature.

Figure 20 shows the predicted UCS values versus experimental UCS values for the data of present investigation and literature [3]. There is a good correlation of experimental and predicted values with an R2 value of 0.90. The validation results correspond to CCR content of more than 5 % and curing period up to 90 days.

Strength Prediction of Black Cotton Soil Treated with Lime as Additive

The UCS results have indicated the dependence of strength of black cotton soil on Wc/lime ratio and curing period. The results have also confirmed the fact that strength increases when Wc/lime ratio is low and vice versa. In this background, the strength development can be analysed using the concept of Abram’s law for additive treated soils. This concept was successfully adopted to predict strength development for cement stabilised soils. The power function of the following form is widely used to predict the strength development of cement stabilised coarse and fine grained soils [24].

where, q u unconfined compressive strength, A and B are empirical constants.

The parameter ‘A’ accounts for soil type and curing time and ‘B’ is generally taken as a constant though it varies over a narrow band for a particular soil.

Figure 21 shows the present experimental values of unconfined compressive strength with clay-water/lime ratio for curing periods of 7–28 days. The results indicate that the UCS values of the soil for low Wc/lime ratio are higher and vice versa. The strength can be expressed in the form of a power function as shown in Fig. 21.

The stabilised strength at any curing time ‘D’ and for a given Wc/lime (Wc/L) ratio can be expressed in terms of 28 days strength as shown in Eq. (10) on the basis of Abram’s law.

where, D is the curing time (days) and \(q_{{(Wc/L)_{D} }}\) is strength at D days of curing.

At a particular Wc/lime ratio, the strength development depends on curing time. A linear regression of the test data yields the following relation (11).

where, D is the curing time (days) and qD is strength at D days of curing.

The generalized interrelationship for strength prediction based on Wc/lime and curing period can be expressed as (12) below for lime stabilised black cotton soil (CH–MH).

where, \(q_{{(Wc/L)_{D} }}\) strength of lime admixed black cotton soil to be estimated at clay-water/lime ratio after D days of curing.

\(q_{{(Wc/L)_{28} }}\) strength of lime admixed black cotton soil at clay-water to lime ratio after 28 days of curing.

The predicted UCS values using Eq. (12) are tabulated in Table 7. The mean absolute percentage error (MAPE) in prediction is equal to 6.33 %.

Strength Prediction of Black Cotton Soil Treated with Sodium Silicate (SS) and Lime Combination as Additive

The UCS results have indicated the dependence of strength of black cotton soil on Wc/(SS + lime) ratio and curing period. The results have also confirmed the fact that strength increases when Wc/(SS + lime) ratio is low and vice versa. The strength development can be analysed using the concept of Abram’s law for SS + lime treated black cotton soil also.

Figure 22 shows the present experimental values of unconfined compressive strength with clay-water/(SS + L) ratio for curing periods of 7–28 days. The results indicate that the UCS values of the soil for low Wc/(SS + L) ratio are higher and vice versa. The strength can be expressed in the form of a power function as shown in Fig. 22.

The generalized interrelationship for strength prediction based on Wc/(SS + lime) and curing period can be expressed as (13) on the same lines as lime stabilised black cotton soil.

The predicted UCS values using the Eq. (13) are tabulated in Table 8 below. The mean absolute percentage error (MAPE) in prediction is equal to 7.26 %.

Tables 7 and 8 show the predicted strengths are in very good agreement with the laboratory strengths. It is found that the error from the prediction is acceptable for engineering practices with the mean absolute percent error (MAPE) of 6.33 and 7.26 % for prediction equation for lime alone, sodium silicate and lime admixed black cotton soil at various curing days.

The Eq. (13) can be generalised for additives (A) used i.e., lime alone and SS plus lime as mentioned below in Eq. (14). The empirical coefficient B has values of 0.53 and 1.16 respectively.

Figure 23 shows predicted and experimental values of black cotton soil stabilised with lime alone and SS plus lime obtained using generalized prediction equation shown in Eq. (14).

There is an excellent correlation of experimental and predicted values with an R2 value of 0.95.

From the experimental results, it has been observed that CCR and combination of SS(4.5 %) + lime (7 %) provides a good strength of 1200 kPa at their respective optimum content (4 % CCR and 4.5 % SS + 7 % lime), followed by lime with a strength of 900 kPa at 7 % and 350 kPa with 4.5 % SS.

CCR and combination of SS + lime are more effective than lime. However, CCR poses problems for mixing and compaction in the field. There are chances of health hazard due to release of acetylene gas. Presence of excess CCR than optimum level will retard strength gain significantly to an extent of 50 % of the peak strength.

In addition, the black cotton soil stabilised with CCR shows large initial differential volumetric strain under wetting and drying cycles though it stabilises in three cycles.

In field, lime and SS combinations can be mixed in dry form or as grouts. These additives can be added individually or in combination at predetermined optimum dosage levels mixed thoroughly and compacted. In case of in situ deposits they can be injected in slurry form by grouting.

Beyond optimum dosage levels, strength remains constant. Another advantage of SS + lime combination is, it undergoes low initial volume change and stabilises within two cycles under alternate wetting and drying process.

Therefore, it is more stable volumetrically and can be considered as very effective stabilising agent from the point of strength development, durability and sustainability.

Conclusions

The strength development equations based on clay-water/additives ratio, curing period and other parameters are proposed. Based on the results the following conclusions are drawn.

-

1.

The additives CCR, SS, lime and combination of SS + lime are effective in reducing the plasticity of black cotton soil by 1/3rd of its initial value at their respective optimum contents.

-

2.

The compaction characteristics depend on the type of additive. Sodium silicate results in dispersed structure resulting in reduced dry density. With CCR, the structure of the soil collapses on compaction resulting in higher density till optimum additive content, lime results in flocculated structure causing reduction in dry density and increase in OMC. Whereas combination of sodium silicate and lime results in higher density due to deflocculation.

-

3.

The strength development depends on additive content, ratio of water content to additive content, curing period. The strength is highest with CCR and combination of sodium silicate and lime followed by lime and sodium silicate being the least. From the durability point of view, the black cotton soil stabilized with combination of sodium silicate and lime is more stable volumetrically under alternate wetting and drying cycles.

-

4.

The proposed predictive equation for the strength development of black cotton soil stabilized with CCR, lime and combination of SS + lime are useful to estimate the laboratory strength of black cotton soil for an additive content up to a maximum of 7 %. A common relationship based on Abram’s law can be used for lime, and combination of SS + lime admixed soil for a ‘B’ value of 0.53 and 1.16 respectively.

-

5.

UCS value of black cotton soil treated with CCR increases by tenfold at 28 days of curing at 4 % optimum additive content in soaked condition. Beyond optimum percentage, the UCS decreases for all curing periods due to insufficiency of natural pozzolanic materials to react with excess Ca(OH)2 and release of acetylene gas at higher dosage of calcium carbide.

References

Kumpala A, Horpibulsuk S, Prongamanee N, Chinkulkijniwat A (2013) Influence of wet-dry cycles on compressive strength of calcium carbide residue—fly ash stabilized clay. J Mater Civil Eng ASCE 26:633

Jaturapitakkul C, Roongreung B (2003) Cementing material from calcium carbide residue-rice husk ash. J Mater Civil Eng ASCE 15:470

Horpibulsuk S, Phetchuay C, Chinkulkijniwat A (2012) Soil stabilization by calcium carbide residue and fly ash. J Mater Civil Eng ASCE 24:184

Vichan S, Rachan R, Horpibulsuk S (2013) Strength and microstructure development in Bangkok clay Stabilized with Calcium carbide residue and Biomass ash. Res Artic Sci Asia 39:186–193

Madurwar KV, Dahale PP, Burile AN (2013) Comparative study of black cotton soil stabilization with RBI grade 81 and sodium silicate. Int J Innov Res Sci Eng Technol 2(2):493–499

Moayedi H, Huat BBK, Moayedi F, Asadi A, Parsaie A (2011) Effect of sodium silicate on unconfined compressive strength of soft clay. EJGE 16:289

Satayanarayana PVV, Naidu G, Adiseshu PS, Reddy P (2012) A study on strength characteristics of fly ash, lime and sodium silicate mixtures at their free pouring conditions. Int J Comput Eng Res 2(4):1102–1108

Nigussie E, Dinku A (2011) Evaluation of sodium silicate and its combination with cement/lime for soil stabilization, MSc Thesis. Addis Ababa University, Ethopia

Yang K-H, Song J-K (2009) Workability loss and compressive strength development of cementless mortars activated by combination of sodium silicate and sodium hydroxide. J Mater Civil Eng ASCE 21:119

Ahmed B, Alim MdA, Sayeed MdA (2013) Improvements of soil strength using cement and lime admixtures. Earth Sci 2(6):139–144

Liu MD, Indraratna B, Horpibulsku S, Suebsuk J (2012) Variations in strength of lime-treated soft clays. Proc Inst Civil Eng Ground Improv 165(G14):217–223

Nadgouda KA, Hegde RA (2010) The effect of lime stabilization on properties of black cotton soil. In: Indian geotechnical conference-2010

Honghua Z, Liu J, Guo J, Zhao C, Gong B (2015) Reexamination of lime stabilization mechanisms of expansive clay. J Mater Civil Eng ASCE 27(1). doi:10.1061/(ASCE)MT.1943-5533.0001040

Horpibulsuk S, Liu MD, Liyanapathirana DS, Suebsuk J (2010) Behaviour of cemented clay simulated via the theoretical framework of the Structured Cam Clay model. Comput Geotech 37:1–9

Suebsuk J, Horpibulsuk S, Liu MD (2010) Modified Structured Cam Clay: a constitutive model for destructured, naturally structured and artificially structured clays. Comput Geotech 37:956–968

Suebsuk J, Horpibulsuk S, Liu MD (2011) A critical state model for overconsolidated structured clays. Comput Geotech 38:648–658

Abrams DA (1918) Design of concrete mixtures. Structural Materials Research Material, Bulletin 1. Lewis Institute, Chicago, pp 22

Horpibulsuk S, Miura N (2001) A new approach for studying behavior of cement stabilized clays. Proc Int Conf Soil Mech Geotech Eng 3:1759–1762

Horpibulsuk S, Miura N, Nagaraj TS (2005) Clay-water/cement ratio identity for cement admixed soft clays. J Geotech Geo Environ ASCE 131(2):187–192

Miura N, Horpibulsuk S, Nagaraj TS (2001) Engineering behavior of cement stabilized clay at high water content. Soils Found 41(5):33–45

Rahman MM, Siddique A, Uddin MK (2012) Clay-water/cement ratio is the prime parameter for fine grained soil improvement at high water content. DUET J 1(3):1

Nagaraj TS, Miura N, Yaligar P, Yamadera A (1996) Predicting strength development by cement admixture based on water content. In: Yonekura R et al (ed) Proceedings of IS-Tokyo’96, the second international conference on ground improvement geosystems, grouting and deep mixing, vol 1, pp 431–436, Tokyo, 14–17 May 1996

Uddin K, Balasubramaniam AS, Bergado DT (1997) Engineering behavior of cement-treated bangkok clay. Geotechn Eng SEAGS 28(1):89–119

Horpibulsuk S, Miura N, Nagaraj TS (2003) Assessment of strength development in cement admixed high water content clays with Abram’s law as a basis. Geotechnique 53(4):439–444

Horpibulsuk S, Runglawan R, Suddeepong A, Chinkulkijniwat A (2011) Strength development in cement admixed bangkok clay: laboratory and field investigations. Soils Founds 51(2):239–251

ASTM D5102 Standard test method for unconfined compressive strength of compacted soil-lime mixtures

Narendra BS (2005) Stabilisation of soft soils in high water contents. PhD Thesis, Indian Institute of Science, India

Naveena PC, Mamatha KH, Dinesh SV (2013) Prediction of strength development in stabilized sandy clay at high water contents. Int J Geol 7(1):9–23

Prakash K, Sridharan A (2004) Free swell ratio and clay Mineralogy of fine-grained soils. Geotech Test J 27(2):220–225

Acknowledgments

We take this opportunity to express our gratitude and appreciation to all those who have helped us directly or indirectly towards the successful completion of the present work. We would like to thank our institution “Siddaganga Institute of Technology (SIT)”, Tumakuru, which provided facilities for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naveena, P.C., Dinesh, S.V., Gowtham, B. et al. Prediction of Strength Development in Black Cotton Soil Stabilised with Chemical Additives. Indian Geotech J 47, 286–302 (2017). https://doi.org/10.1007/s40098-016-0209-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-016-0209-3