Abstract

In this work, a sandwich-type electrochemical immunosensor was designed based on the modification of the carbon paste electrode consisting of ionic liquid and graphite for the effective detection of anti-thyroid peroxidase antibody (anti-TPO). The ionic liquid carbon paste electrode surface was electrodeposited by biocompatible and electrically conductive gold nanoparticles (NPs) as a sensing platform. The human recombinant TPO (Ab1), anti-TPO antibody (Ag) and horseradish peroxidase (HRP)-anchored anti-TPO secondary antibody (HRP-Ab2) were successively immobilized on the Au NPs/CILE surface to construct the immunosensor. The immunosensor response signal was recorded by differential pulse voltammetry based on HRP catalysis in the reaction of H2O2 with O-aminophenol. An elevation in anti-TPO antibody concentration increased the current responses, probably due to the immobilization of a high amount of HRP-Ab2 on the electrodes for higher anti-TPO antibody concentration. The immunosensor, under the optimized circumstances, presented a low limit of detection (LOD) (6.0 ng mL−1) towards the anti-TPO antibody determination with a broad linear range (0.02–60.0 μg mL−1). Moreover, the prepared immunosensor showed good reproducibility and good stability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Autoimmune thyroid disease (AITD) is a common autoimmune disease such as Graves’ disease and Hashimoto’s thyroiditis, with a public prevalence between 2 and 5% [1]. Thyroid peroxidase (TPO) is an essential enzyme in the biosynthesis of thyroid hormones like thyroxine or tetraiodothyronine (T4) and triiodothyronine (T3) in human beings [2]. In Hashimoto’s thyroiditis, one of the antigenic targets is autoantigen TPO for the autoantibodies [3]. It was the first known autoimmune disease, described more than 100 years ago. In this disease, an immune response is directed at the thyroid gland leading to the destruction of the thyroid (by CD8+ T-cell infiltration) [4]. These conditions stimulate the humoral response versus TPO, resulting in dysfunction of this enzyme and a gradual decrease in the biosynthesis of T3 and T4 hormones. Most body systems are influenced by the hormones T3 and T4, the deficiency of which causes neurological to physical manifestations with symptoms including diabetes, high blood pressure, muscle degeneration and seizures [5]. Methimazole (MMI) and propylthiouracil (PTU) suppress the TPO, and thyroid-stimulating hormone (TSH) triggers the TPO [6]. Hence, there is a need for an ultra-sensitive and analytical rapid technique to quantify the level of anti-TPO as a critical biomarker of autoimmune disorders in various biological solutions like blood serum.

Various analytical methods have been lately introduced to recognize such biomarkers, such as enzyme-linked immunosorbent assay (ELISA) [7, 8], fluorescence [9, 10], high-performance liquid chromatography (HPLC) [11] and colorimetric measurements [12]. While some of these methods have disadvantages, such as long sample preparation and analysis time and qualified personnel requirements. They are also not suitable for routine analysis and require expensive equipment.

The interest in electrochemical techniques has increased in recent years [13, 14]. Due to their important advantages, such as high sensitivity selectivity, low instrumentation cost, and the development of new materials for the modification of electrodes, electrochemical methods are widely used in the analysis of various compounds [15,16,17].

Biosensor technology is one of the promising applications of electrochemical methods for susceptible detection of biomarkers and is an alternative to advanced bioanalytical systems. Biosensors based on electrochemical immunosensors have spurred extensive interest in biomarker detection due to their special merits like exceptional sensitivity, high selectivity, rapid response, inexpensiveness, easy pretreatment, and feasibility of miniaturization and facile instrumentation [18,19,20]. In this regard, sandwich-type immunosensors mainly have been extensively applied because of their impressive sensitivity and specificity [21].

Nanotechnology has enormous potential for providing innovative solutions to various applications [22,23,24,25,26,27,28,29]. Noise reduction and signal amplification are key parameters for fabricating a high-performance electrochemical immunosensor. Recent advances in nanotechnology and nanoscience introduced numerous NPs as labels within amplification platforms to reinforce the intensity of electrochemical immunosensor signals and provide ultra-sensitive bioassays [30,31,32,33]. The nano-materials integration with electrochemical immunoassay has provided the basis for ultra-sensitive biomarker determination. For example, Au NPs are of particular importance owing to their specific features, such as large surface area, impressive catalytic activity, admirable biocompatibility and appreciable electrical conductivity [34, 35]. Hence, the Au NPs can provide biological platform for binding sulfhydryl or amino groups on antibody molecules to gold nanoparticles through S–Au or N–Au bonds [36]. Another important class of novel materials for various electrochemical applications are ionic liquids (ILs), due to long-term stability, good electrical conductivity, ultra-low vapor pressure, and wide electrochemical window [37].

To the best of our knowledge, there are no electrochemical immunosensors for anti-TPO antibody detection has yet been reported, therefore, we aimed to selectively and sensitively detect the anti-TPO antibody by a sandwich-type electrochemical immunosensing system based on a CPE modified by IL and Au NPs followed by immobilized Ab1. A significant elevation was created in the immunosensor sensitivity via a huge loading of HRP- Ab2 on the surface of the electrode. Thus, the reduction measurement signal was increased due to the catalytic activity of HRP on the immunosensor. Electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV) were recruited to characterize all production processes of the immunosensor. Moreover, an optimization occurred for various effective experimental parameters in the determination of anti-TPO antibody.

Experimental

Apparatus and chemicals

A potentiostat/galvanostat AUTO LAB PGSTAT 302 N (Switzerland) was utilized for all DPV, CV, and EIS measurements and characterizations. The electrochemical immunoassays were carried out by a three-electrode system consisting of a working electrode (bare or modified CPE), a reference electrode (Ag/AgCl electrode) and an auxiliary electrode (platinum wire). A 713 pH-meter (Metrohm) equipped with a glass electrode was utilized to measure the pH values of solutions. All the solutions freshly prepared with deionized water (Direct-Q® 8 UV water purification system; Millipore; Germany).

Sigma-Aldrich Co. was selected for purchasing potassium ferricyanide 98% (K3[Fe(CN)]6), potassium ferrocyanide 98% (K4[Fe(CN)6]), tetrachloroauric acid 99% (HAuCl4), hydrogen peroxide > 35% (H2O2), graphite powder, O–aminophenol ≥ 98.0% (OAP), paraffin oil and ionic liquid 99% (1-butyl-3-methylimidazolium hexafluorophosphate). Merck was also selected for purchasing potassium chloride 99% (KCl), bovine serum albumin ≥ 98% (BSA), sulfuric acid 98% (H2SO4), potassium nitrate 99% (KNO3), phosphoric acid 85% (H3PO4), hydrochloric acid [HCl (> 37%)] and sodium hydroxide > 98% (NaOH). Analytical grade was regarded for all chemicals, with no need for any purification.

Fabrication of the sandwich-type electrochemical immunosensor

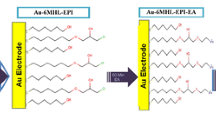

The ionic liquid carbon paste electrode (CILE) was prepared by grounding graphite powder (1 gr) with IL and paraffin oil (at 10/90 ratio, % v/v) for half an hour by a mortar and pestle. Part of the produced paste was packed in a glass tube cavity by inserting a copper wire to make an electrical contact. As-prepared electrode surface was achieved by pressing a bit paste out of the tube and polishing the surface of the electrode on a soft paper. The Au NPs were electrodeposited on the CILE surface by applying a constant potential (− 0.4 V vs. Ag/AgCl) for 400 s in HAuCl4 solution (6.0 mM) consisting of KNO3 (0.1 M, produced in deionized water and deaerated by nitrogen bubbling) [38]. Then, the Au NPs-modified CILE was washed by deionized water for eliminating any free ions from the surface of CILE. Next, the CV method was used for electrochemical cleaning of modified CILE at different potentials (between 0.1 and 1.5 V) in 0.1 M H2SO4 and the 0.1 V/s scan rate, resulting in a new electrode called as Au/CILE.

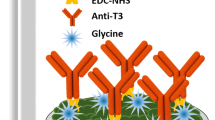

After that, the Au/CILE was incubated with Ab1 for 2 h at ambient temperature, resulting in the fabrication of a modified Ab1/Au/CILE that was washed with phosphate buffer solution (PBS, pH 7.4). The electrode was incubated in BSA solution (1.0 wt.%) for half an hour at the ambient temperature to block probable residual active sites and elude non-specific adsorption. Afterwards, the Ab1/Au/CILE was incubated with different concentrations of Anti-TPO antibody at 37 °C for 40 min. The possible free antibody were removed by washing the TPO/Ab1/Au/CILE with PBS. At last, to form the sandwich format, the TPO/Ab1/Au/CILE was incubated with an HRP-tagged anti-TPO secondary antibody at the ambient temperature for half an hour. The possible free Ab-tracer was removed by washing with PBS, and finally, the resultant HRP-Ab2/TPO/Ab1/Au/CILE was maintained at 4 °C for the next testing.

The production processes of sandwich-type electrochemical immunosensor are illustrated in Scheme 1.

Results and discussion

Characterization of Au NPs on the CILE

The CILE surface was electrochemically deposited by the Au NPs at − 0.4 V. The deposited Au NPs was monitored and quantified by electric quality passing through the cell. The CV method was used to determine the electrochemical characteristics of the Au NPs on CILE in 0.1 M HCl at the 0.1 V/s scan rate (Fig. 1, curve b). For comparison, the voltammogram of bare CILE is also given in Fig. 1 (curve a). For better comparison, the CV curve of Au NPs-modified CPE (i.e. without IL) was shown in curve c. The peak positions were identical to the curve b, while the peak currents were lower than curve b, which means much higher conductivity of CILE modified with Au NPs than that of CPE modified with Au NPs.

Field emission scanning electron microscopy (FE-SEM) characterization of Au/CILE

The morphology and structure of the as-prepared Au NPs-modified CILE was investigated using FE-SEM. Figure 2 shows the FE-SEM images of Au/CILE at different magnifications. The FE-SEM images show that the Au NPs are well deposited on the CILE. The Au NPs with spherical morphology showed good monodispersity, with a uniform size of approximately 60 nm.

Characterization of the stepwise modified electrodes by CV

Figure 3 shows the use of CV to determine the characteristics of stepwise different modified electrodes in 0.1 M PBS containing 5.0 mM redox probe [Fe(CN)63−/4−] and 0.1 M KCl at 100 mV/s scan rate. Following the CILE modification with Au NPs (Fig. 3, curve b), a reversible CV curve was found for the redox-label [Fe(CN)63−/4−] with two distinct redox peaks. There was a significant elevation in the anodic and cathodic peak currents of [Fe(CN)63−/4−] at the Au/CILE when comparing with the CILE (curve a) because of excellent electrochemical activity of Au NPs capable of accelerating the electron transfer in the electrode surface. The peak currents were highly reduced following the Ab1 immobilization on the Au/CILE surface (curve c), meaning the successful immobilization of antibodies on the electrode surface. The immobilized Ab1 serves as a blocking layer for electron communication and mass transfer for insulating redox-label [Fe(CN)63−/4−] electron transfer with the electrode. The interaction of anti-TPO antibody with Ab1 on the Ab1/Au/CILE surface decreased the peak currents (curve e) because of produced Ab1/anti-TPO antibody immune-complex capable of insulating the conductive support and stopping electron transfer to the electrode surface. The incubation of modified Ab1/anti-TPO antibody/Au/CILE with HRP-Ab2 decrease the peak currents again because of produced secondary immune-complex between HRP-Ab2 and a anti-TPO antibody. These results indicated that the formed immune-complex covered the active surface area of the electrode and reduced the electron transfer tendency of the electrode.

Characterization of the stepwise modified electrodes by EIS

The assembly steps of the immunosensor were investigated by the EIS technique (Fig. 4). The Nyquist plots of various electrodes were drawn in PBS (0.1 M) consisting of [Fe(CN)63−/4−] (5.0 mM) and KCl (0.1 M). The changes obviously can be observed in Nyquist plots. As seen in Fig. 3 (curve a), a big semicircle is observed at the bare CILE, indicating a high transfer resistance. In the next step, by electrodeposition of Au NPs on the surface of the diameter of the semicircle is decreased (curve b), which means appreciable conductivity of Au NPs. However, the immobilization of the capture antibody on the Au/CILE surface increased the curve semicircle (curve c), which means the nonconductive nature of the capture antibody capable of blocking Fe(CN)63−/4−electron transfer. Further incubation of immunosensor with anti-TPO antigen (curve d) and HRP-Ab2 bioconjugates (curve e) significantly increased the semicircle. These events might be due to elevated resistance to Fe(CN)63−/4− electron transfer at the interface of the electrode following the antigen–antibody immune-complex formation.

Optimization of experimental conditions for the detection of anti-TPO antibody

The optimized experimental conditions in this study were the pH value, the incubation temperature and the incubation time. The protein activity can be declined, and the protein microstructure can be destroyed in the vicinity of strongly acidic or alkaline media. So in this work, the immunosensor activity was measured over the range of pH 5.0 to 8.0 of PBS containing 4.0 mM OAP and 1.0 mM H2O2 for detection of anti-TPO antibody (7.5 μg mL−1). Figure 5 reveals an elevation in the current response by increasing pH to 7.4 from 5.0, and then a reduction in the response by further increasing pH was observed. The pH value of 7.4 was associated with the highest signal. Hence, the optimal PBS pH value of 7.4 was selected.

The incubation time has a significant role in the reaction of immune-complex formation between Ag-Ab, so different times were considered for the TPO incubation. According to the results, an elevation in the current response by increasing incubation time ranged from 10 to 40 min, and then a constant value was observed. Hence, the optimal incubation time of 40 min was selected. Moreover, the effect of incubation temperature of anti-TPO antibody was examined between 20 °C and 45 °C. There was a gradual elevation in the current response by increasing temperature, which showed the highest value at 37 °C. Accordingly, the optimal incubation temperature of 37 °C was selected for the subsequent electrochemical tests.

Electrochemical response of the immunosensor to anti-TPO antibody

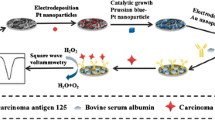

The HRP catalyzes the oxidation reaction of OAP by H2O2, as described previously (Scheme 2) [39].

The electrochemical response mechanism of the prepared immunosensor to anti-TPO antibody is based on the redox process (Scheme 2). The anti-TPO antibody was quantified on the basis that the anti-TPO antibody concentration was proportional to the reduced peak currents of 3-aminophenoxazone produced from the OAP oxidation reaction. After anti-TPO antibody anchoring on the Ab1-immobilized surface, the HRP-Ab2 could be specifically recognized with anti-TPO antibody. The electrochemical response of the as-fabricated immunosensor towards anti-TPO antibody was based on the following steps (1) HRP was responsible for the catalysis of OAP oxidation by H2O2, so that the OAP was oxidized to 3-aminophenoxazone; (2) the 3-aminophenoxazone was reduced by a rapid reaction; simultaneously, the DPV was used to record the peak currents of reductive response. The DPV under the optimized conditions was recorded for the immunosensor in different anti-TPO antibody concentrations. Figure 6 shows the relationship between the anti-TPO concentration and current response. There was a linear elevation in the catalytic current by increasing the anti-TPO concentration (0.02–60.0 μg mL−1). The linear regression equation was obtained to be Ipa (μA) = −3.8289CAnti TPO (μg mL−1)-21.191 for anti-TPO antibody, with the correlation coefficient (R2) value of 0.9998 and the limit of detection (LOD) of 6.0 ng mL−1.

Stability and reproducibility of immunosensor

The DPV was used to determine the stability of the immunosensor kept at 4 °C. Based on the findings, the peak current of anti-TPO antibody on the HRP-Ab2/TPO/Ab1/Au/CILE remained at 95.8%, 92.9% and 90.3% of its initial current after 1, 2 and 3 weeks, respectively, thereby confirming the admirable long-term immunosensor stability.

The immunosensor reproducibility for the determination of anti-TPO antibody was tested by detecting anti-TPO antibody using five identical HRP-Ab2/TPO/Ab1/Au/CILE immunosensors for comparison of the anti-TPO antibody response currents, the results of which were the same DPV response with the relative standard deviation (RSD) of 3.9%, thereby verifying acceptable reproducibility of our immunosensor.

Conclusion

The current work introduced a sandwich-type electrochemical immunosensing system to detect anti-TPO on the CPE modified with IL and Au NPs. The electrochemical immunosensing system was prepared by sandwiching the anti-TPO antibody between the Ab1 on the CILE surface modified with Au NPs and the AB2 labeled with HRP. The combination of the good conductivity of IL and the advantages of the Au NPs, and conjugated HRP increased the sensitivity of the immunosensor. Based on the DPV findings, under optimized circumstances, the proposed electrochemical immunosensor could sensitively determine the anti-TPO, with a broad linear concentration range (0.02–60.0 μg mL−1), a low LOD value (6.0 ng mL−1). Also, The prepared immunosensor demonstrated good stability and reproducibility to analyze anti-TPO.

References

Medici, M., Porcu, E., Pistis, G., Teumer, A., Brown, S.J., Jensen, R.A., Peeters, R.P.: Identification of novel genetic loci associated with thyroid peroxidase antibodies and clinical thyroid disease. PLoS Genet. 10, e1004123 (2014)

Taurog, A., Dorris, M.L., Doerge, D.R.: Mechanism of simultaneous iodination and coupling catalyzed by thyroid peroxidase. Arch. Biochem. Biophys. 330, 24–32 (1996)

Czarnocka, B., Ruf, J., Ferrand, M., Carayon, P., Lissitzky, S.: Purification of the human thyroid peroxidase and its identification as the microsomal antigen involved in autoimmune thyroid diseases. FEBS. Lett. 190, 147–152 (1985)

Williams, D.E., Le, S.N., Godlewska, M., Hoke, D.E., Buckle, A.M.: Thyroid peroxidase as an autoantigen in hashimoto’s disease: structure, function, and antigenicity. Horm. Metab. Res. 50, 908–921 (2018)

Ai, J., Leonhardt, J.M., Heymann, W.R.: Autoimmune thyroid diseases: etiology, pathogenesis, and dermatologic manifestations. J. Am. Acad. Dermatol. 48, 641–662 (2003)

Roy, G., Mugesh, G.: Selenium analogues of antithyroid drugs–recent developments. Chem. Biodivers. 5, 414–439 (2008)

Liu, W., Li, J., Zhang, P., Hou, Q., Feng, S., Liu, L., Luo, Y.: A novel pan-cancer biomarker plasma heat shock protein 90alpha and its diagnosis determinants in clinic. Cancer. Sci. 110, 2941–2959 (2019)

Li, W., Yuan, R., Chai, Y., Chen, S.: Reagentless amperometric cancer antigen 15–3 immunosensor based on enzyme-mediated direct electrochemistry. Biosens. Bioelectron. 25, 2548–2552 (2010)

Zheng, J., Hu, Y., Bai, J., Ma, C., Li, J., Li, Y., Shi, M., Tan, W., Yang, R.: Universal surface enhanced Raman scattering amplification detector for ultrasensitive detection of multiple target analytes. Anal. Chem. 86, 2205–2212 (2014)

Luo, Y., Wang, C., Jiang, T., Zhang, B., Huang, J., Liao, P., Fu, W.: Interference-free determination of ischemia-modified albumin using quantum dot coupled X-ray fluorescence spectroscopy. Biosens. Bioelectron. 51, 136–142 (2014)

Han, S.H., Lee, K.R., Lee, D.G., Kim, B.Y., Lee, K.E., Chung, W.S.: Mutation analysis of BRCA1 and BRCA2 from 793 Korean patients with sporadic breast cancer. Clin. Genet. 70, 496–501 (2006)

Lai, K.K., Renneberg, R., Mak, W.C.: Multifunctional protein particles with dual analytical channels for colorimetric enzymatic bioassays and fluorescent immunoassays. Biosens. Bioelectron. 32, 169–176 (2012)

Ansari, S., Ansari, M.S., Satsangee, S.P., Alam, M.G., Jain, R.: Electrochemical sensing platform based on ZrO2/BiVO4 nanocomposite for gastro-prokinetic drug in human blood serum. J. Nanostructure. Chem. (2022). https://doi.org/10.1007/s40097-022-00473-6

Taqvi, S.I.H., Solangi, A.R., Buledi, J.A., Khand, N.H., Junejo, B., Memon, A.F., Ameen, S., Bhatti, A., Show, P.L., Vasseghian, Y., Karimi-Maleh, H.: Plant extract-based green fabrication of nickel ferrite (NiFe2O4) nanoparticles: an operative platform for non-enzymatic determination of pentachlorophenol. Chemosphere 294, 133760 (2022)

Buledi, J.A., Mahar, N., Mallah, A., Solangi, A.R., Palabiyik, I.M., Qambrani, N., Karimi, F., Vasseghian, Y., Karimi-Maleh, H.: Electrochemical quantification of mancozeb through tungsten oxide/reduced graphene oxide nanocomposite: a potential method for environmental remediation. Food. Chem. Toxicol. 161, 112843 (2022)

Khand, N.H., Palabiyik, I.M., Buledi, J.A., Ameen, S., Memon, A.F., Ghumro, T., Solangi, A.R.: Functional Co3O4 nanostructure-based electrochemical sensor for direct determination of ascorbic acid in pharmaceutical samples. J. Nanostructure Chem. 11, 455–468 (2021)

Khand, N.H., Solangi, A.R., Ameen, S., Fatima, A., Buledi, J.A., Mallah, A., Memon, S.Q., Sen, F., Karimi, F., Orooji, Y.: A new electrochemical method for the detection of quercetin in onion, honey and green tea using Co3O4 modified GCE. J. Food. Meas. Charact. 15, 3720–3730 (2021)

Bhavsar, K., Fairchild, A., Alonas, E., Bishop, D.K., La Belle, J.T., Sweeney, J., Joshi, L.: A cytokine immunosensor for multiple sclerosis detection based upon label-free electrochemical impedance spectroscopy using electroplated printed circuit board electrodes. Biosens. Bioelectron. 25, 506–509 (2009)

Lin, D., Wu, J., Ju, H., Yan, F.: Signal amplification for electrochemical immunosensing by in situ assembly of host–guest linked gold nanorod superstructure on immunocomplex. Biosens. Bioelectron. 45, 195–200 (2013)

Zhao, Y., Liu, L., Kong, D., Kuang, H., Wang, L., Xu, C.: Dual amplified electrochemical immunosensor for highly sensitive detection of Pantoea stewartii sbusp. Stewartii. ACS Appl. Mater. Interfaces 6, 21178–21183 (2014)

Pei, X., Zhang, B., Tang, J., Liu, B., Lai, W., Tang, D.: Sandwich-type immunosensors and immunoassays exploiting nanostructure labels: a review. Anal. Chim. Acta 758, 1–18 (2013)

Toufani, M., Kasap, S., Tufani, A., Bakan, F., Weber, S., Erdem, E.: Synergy of nano-ZnO and 3D-graphene foam electrodes for asymmetric supercapacitor devices. Nanoscale 12, 12790–12800 (2020)

Seid, L., Lakhdari, D., Berkani, M., Belgherbi, O., Chouder, D., Vasseghian, Y., Lakhdari, N.: High-efficiency electrochemical degradation of phenol in aqueous solutions using Ni-PPy and Cu-PPy composite materials. J. Hazard Mater. 423, 126986 (2022)

Berkani, M., Smaali, A., Kadmi, Y., Almomani, F., Vasseghian, Y., Lakhdari, N., Alyane, M.: Photocatalytic degradation of penicillin G in aqueous solutions: kinetic, degradation pathway, and microbioassays assessment. J. Hazard Mater. 421, 126719 (2022)

Karthika, V., Kaleeswarran, P., Gopinath, K., Arumugam, A., Govindarajan, M., Alharbi, N.S., Benelli, G.: Biocompatible properties of nano-drug carriers using TiO2-Au embedded on multiwall carbon nanotubes for targeted drug delivery. Mater. Sci. Eng. C 90, 589–601 (2018)

Doan, V.D., Huynh, B.A., Le Pham, H.A., Vasseghian, Y.: Cu2O/Fe3O4/MIL-101 (Fe) nanocomposite as a highly efficient and recyclable visible-light-driven catalyst for degradation of ciprofloxacin. Environ. Res. 201, 111593 (2021)

Vasseghian, Y., Doan, V.D., Nguyen, T.T.T., Vo, T.T.T., Do, H.H., Vu, K.B., Vu, Q.H., Lam, T.D., Tran, V.A.: Flexible and high-sensitivity sensor based on Ti3C2–MoS2 MXene composite for the detection of toxic gases. Chemosphere 291, 133025 (2022)

Nguyen, T.H.A., Nguyen, V.C., Phan, T.N.H., Vasseghian, Y., Trubitsyn, M.A., Nguyen, A.T., Chau, T.P., Doan, V.D.: Novel biogenic silver and gold nanoparticles for multifunctional applications: green synthesis, catalytic and antibacterial activity, and colorimetric detection of Fe (III) ions. Chemosphere 287, 132271 (2022)

Smaali, A., Berkani, M., Merouane, F., Vasseghian, Y., Rahim, N., Kouachi, M.: Photocatalytic-persulfate-oxidation for diclofenac removal from aqueous solutions: modeling, optimization and biotoxicity test assessment. Chemosphere 266, 129158 (2021)

Lu, J., Liu, S., Ge, S., Yan, M., Yu, J., Hu, X.: Ultrasensitive electrochemical immunosensor based on Au nanoparticles dotted carbon nanotube–graphene composite and functionalized mesoporous materials. Biosens. Bioelectron. 3, 29–35 (2012)

Wu, Y., Chen, C., Liu, S.: Enzyme-functionalized silica nanoparticles as sensitive labels in biosensing. Anal. Chem. 81, 1600–1607 (2009)

Li, Y., Zhang, Y., Li, F., Li, M., Chen, L., Dong, Y., Wei, Q.: Sandwich-type amperometric immunosensor using functionalized magnetic graphene loaded gold and silver core-shell nanocomposites for the detection of Carcinoembryonic antigen. J. Electroanal. Chem. 795, 1–9 (2017)

Dai, L., Li, Y., Wang, Y., Luo, X., Wei, D., Feng, R., Wei, Q.: A prostate-specific antigen electrochemical immunosensor based on Pd NPs functionalized electroactive Co-MOF signal amplification strategy. Biosens. Bioelectron. 132, 97–104 (2019)

Yang, Y., Yan, Q., Liu, Q., Li, Y., Liu, H., Wang, P., Dong, Y.: An ultrasensitive sandwich-type electrochemical immunosensor based on the signal amplification strategy of echinoidea-shaped Au@ Ag-Cu2O nanoparticles for prostate specific antigen detection. Biosens. Bioelectron. 99, 450–457 (2018)

Beitollahi, H., Nekooei, S., Torkzadeh-Mahani, M.: Amperometric immunosensor for prolactin hormone measurement using antibodies loaded on a nano-Au monolayer modified ionic liquid carbon paste electrode. Talanta 188, 701–707 (2018)

Ma, C., Zhao, C., Li, W., Song, Y., Hong, C., Qiao, X.: Sandwich-type electrochemical immunosensor constructed using three-dimensional lamellar stacked CoS2@C hollow nanotubes prepared by template-free method to detect carcinoembryonic antigen. Anal. Chim. Acta 1088, 54–62 (2019)

Wei, D., Ivaska, A.: Applications of ionic liquids in electrochemical sensors. Anal. Chim. Acta 607, 126–135 (2008)

Ding, C., Zhao, F., Ren, R., Lin, J.M.: An electrochemical biosensor for α-fetoprotein based on carbon paste electrode constructed of room temperature ionic liquid and gold nanoparticles. Talanta 78, 1148–1154 (2009)

He, Y.N., Chen, H.Y., Zheng, J.J., Zhang, G.Y., Chen, Z.L.: Differential pulse voltammetric enzyme-linked immunoassay for the determination of Helicobacter pylori specific immunoglobulin G (IgG) antibody. Talanta 44, 823–830 (1997)

Acknowledgements

This research was financially supported by the Iranian National Science Foundation (INSF) (Grant No. 95012096) and Institute of Science and High Technology and Environmental Sciences, Graduate University of Advanced Technology, Kerman, Iran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tajik, S., Beitollahi, H. & Torkzadeh-Mahani, M. Electrochemical immunosensor for the detection of anti-thyroid peroxidase antibody by gold nanoparticles and ionic liquid-modified carbon paste electrode. J Nanostruct Chem 12, 581–588 (2022). https://doi.org/10.1007/s40097-022-00496-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-022-00496-z