Abstract

The objective of present study was to prepare composite microbeads of psyllium arabinoxylan and sodium alginate by ionotropic gelation method using calcium chloride as a cross linker and was further evaluated for release study. The effect of concentration of sodium alginate/arabinoxylan and concentration of calcium chloride on the entrapment efficiency and on % release were studied employing 2-factor, 3-level central composite experimental design. The results of the study revealed that interaction effect of the concentration of sodium alginate/arabinoxylan and calcium chloride influenced the entrapment efficiency and release of diclofenac sodium significantly. The optimal calculated parameters were found to be concentration of sodium alginate/arabinoxylan-5 and concentration of calcium chloride-0.75 M, that provided microbeads with entrapment efficiency-64.4 % and release of 28.5 % of the drug over 8 h period of study. Further, arabinoxylan–sodium alginate mucoadhesive microbeads were found to sustain the release of diclofenac sodium over a period of 8 h following zero order kinetics with the mechanism of release being diffusion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural polysaccharides and their derivatives represent a group of polymers widely used in the pharmaceutical and biomedical fields for the controlled release of drugs. Among the polysaccharides recently being used in the field of drug delivery, psyllium is one with desirable properties (Singh 2007). Psyllium seeds of the plant Plantago ovata, family plantaginaceae, a native of India and Pakistan. It is composed of densely substituted main chain of β-(1 → 4)-linked d-xylopyranosyl residues. Psyllium is an anionic polysaccharide that contains a high amount of xylan (arabinoxylan) along with Rhamnose and Galactose as minor sugar components (Fischer et al. 2004) as given in Fig. 1. Nutraceuticals, pharmaceuticals and medicinal properties of psyllium husk are being explored for the treatment of irritable bowel syndrome, obesity, colon cancer, constipation (Fernandez-Banares 2006), diabetes, high cholesterol, ulcerative colitis and atherosclerosis (Mishra et al. 2014). Psyllium seed husk has been reported for the treatment of hypercholesterolemia (Oliver 2000) and also as hydrogel polymer in sustained release formulations (Shidhaye et al. 2007). Psyllium mucilage is functionalized by chemical and physical modifications using techniques via. ethylation (Shazia et al. 2009), methacrylation (Singh 2007), cross linking (Singh and Kumar 2008), thiolation (Ahuja and Bhatia 2013), grafting (Mishra et al. 2003, 2004), and carboxymethylation (Ahuja and Bhatia 2015) etc. Psyllium seems to be capable to modulate drug release in the form of hydrogels or microparticles and it possesses the superdisintegrant property (Bindu et al. 2012). Psyllium is also used as a mucoadhesive polymer (Ahuja and Bhatia 2013). Further, the anionic nature imparted on polysaccharides by ionotropic gelation method covers the way for their exploration in preparation of mucoadhesive microbeads with cationic polymers like sodium alginate.

Alginate due to its gelling properties is widely used as a matrix material in medicine to achieve sustained drug delivery. The interactions between the carboxylic acid moieties and bivalent counter ions, such as calcium, lead, and copper; it is also possible to obtain an alginic acid gel by lowering the environmental pH value. Alginates have mucoadhesive properties and beads formed by it are usually fragile (George and Abraham 2006; Sandhu et al. 1981) that may be strengthened by incorporation of arabinoxylan in the microbeads formulation. Therefore, composite beads of arabinoxylan and sodium alginate were prepared. Diclofenac sodium is poorly soluble non-steroidal anti-inflammatory drug and its pKa 4.15. It causes the ulcer, pain and gastric irritation. Arabinoxylan–Sodium alginate microbeads has been prepared for improving the property of Diclofenac sodium in reducing gastric irritation.

In the present research work, ionotropic gelation method is used for the preparation of AX–SA microbeads. These are characterized by Fourier-transform infra-red spectroscopy (FT-IR), differential scanning calorimetry (DSC), scanning electron microscopy (SEM), and in vitro wash off mucoadhesion test. The preparation of arabinoxylan–sodium alginate mucoadhesive microbeads was optimized by using 2-factor, 3 level central composite experimental design. The optimized batch was evaluated for its in vitro release behavior and mucoadhesion time by wash off method.

Materials and methods

Materials

Diclofenac sodium was obtained as a gift sample from Maxtar Bio-genics Pvt. Ltd. (Baddi, India). Psyllium seeds were obtained from Sun Psyllium Industries (Unjha, India). Sodium alginate (SA), sodium hydroxide pellets and potassium dihydrogen ortho-phosphate anhydrous (monobasic) were obtained from High Purity Laboratory Chemicals (Mumbai, India). Calcium chloride dehydrated and hydrochloric acid were provided by SD Fine-Chem Ltd. (Mumbai, India). Di-sodium hydrogen phosphate dihydrate (Na2HPO4·2H2O) was provided by Hi-Media lab. Pvt. Ltd. All other chemicals were of reagent grade and were used as procured.

Methods

Isolation of arabinoxylan

Arabinoxylan (AX) was extracted from the Plantago ovata seeds by extraction method as described earlier (Shazia et al. 2008). Briefly, psyllium seeds were soaked in distilled water (5 % w/v) and bring to boiling for 10 min. The viscous solution so obtained was filtered with muslin cloth to remove any extraneous materials. Further, it was kept for drying in hot air oven after spreading on a glass plate at 40 °C overnight. The dried product was weighed and stored for further use.

Preparation of arabinoxylan–sodium alginate microbeads loaded with diclofenac sodium

AX–SA microbeads containing diclofenac sodium were prepared by ionotropic gelation method (Nayak et al. 2013) using calcium chloride (CaCl2) as a cross linker (Table 1). The dispersions of SA and AX were prepared separately in distilled water. Both dispersions were homogenized with a magnetic stirrer. Diclofenac sodium (50 mg) was added to the AX dispersion. Both the dispersions were then mixed in a ratio of 1:1 and stirred at 1000 rpm for 10 min. The resulting dispersion was then added dropwise via a 23# needle into agitated CaCl2 solutions (0.25–0.75 M). The resultant microbeads were retained in the CaCl2 solution for 20 min to complete the curing reaction and to produce spherical rigid beads. AX–SA microbeads were collected by decantation and washed with deionized water. Drug loaded microbeads were dried in a hot air oven at 40 °C for 48 h.

Experimental design

Design Expert Software (Version 9.0.3, Stat-Ease) was used for designing experimental plan for the preparation of AX–SA microbeads loaded with diclofenac sodium. A two-factor, three level central composite designs (CCD) was employed for the optimization. Sodium alginate/arabinoxylan (SA/AX) ratio and calcium chloride were selected as independent variables having fixed concentration of AX. Entrapment efficiency (%) and in vitro release of diclofenac sodium were selected as response factors. All other processing variables were kept invariant throughout the study (Table 1).

Characterization

FT-IR spectroscopy

AX, SA and AX–SA microbeads samples were subjected to Fourier-transform infrared spectroscopy using KBr pellets in a Fourier-transform infrared spectrophotometer (Perkin Elmer spectrum BX II) range from 4000–400 cm−1.

Differential scanning calorimetry

Differential scanning calorimetry (DSC) analysis of AX, SA and AX–SA microbeads were carried out by heating the samples from 30 to 300 °C at the rate of 10 °C per minute using DSC (SDT, Q600, TA instruments, USA).

Optical microscopy

Optical microscope (Compound Microscope-Zeiss Primo Star) was used to study the morphology of microbeads and average size of microbeads was determined by randomly selecting 50 microbeads employing vernier caliper (Aerospace, China).

Scanning electron microscopy

The shape and surface of the AX, SA and AX–SA microbeads were examined using scanning electron microscopy (SEM, Environmental Scanning Electron Microscope model FEI Quanta 200F with Oxford-EDS system IE 250 X Max 80, Netherlands). Prior to observation, samples were mounted on metal grids, using double-sided adhesive tape and coated by gold under vacuum before observation.

Determination of drug entrapment efficiency

The entrapment efficiency (%) of diclofenac sodium in microbeads was estimated by taking microbeads (25 mg) were crushed and transferred into 25 mL volumetric flask containing phosphate buffer (pH 6.8). The solution has sonicated for 30 min on ultrasonicator and centrifuged for 40 min at 5000 rpm using centrifuge (REMI Equipments, Mumbai). The supernatant was separated and the amount of diclofenac sodium in supernatant was estimated spectrophotometrically by measuring the absorbance at 276 nm in UV–Visible spectrophotometer (Cary 2000, Varian Austria). The percentage drug entrapment was calculated as follows in Eq. (1)

In vitro release study

In vitro release profile of diclofenac sodium from various batches of AX–SA microbeads was studied under varying pH conditions using USP type II dissolution apparatus (TDL-08L Electrolab, India). An accurately weighed sample of microbeads was placed in a tea bag, which was tied securely to the paddle of dissolution apparatus. AX–SA microbeads were tested for drug release firstly in HCl buffer (pH 1.2) and maintained at temperature of 37.0 ± 0.5 °C and stirred at 50 rpm for 2 h. The dissolution media was then replaced with phosphate buffer (pH 6.8) and drug release study was carried out for further 6 h. An aliquot of 5 mL of sample was withdrawn at various interval of time. The content of diclofenac sodium in the release media were analysed spectrophotometrically by measuring absorbance at wavelength of 276 nm. The mechanism of drug release from the microbeads was determined by fitting the release data to several release kinetic models like zero order, first order, Higuchi and Korsmeyer–Peppas plots (Higuchi 1961; Mathew et al. 2009).

Mucoadhesion testing by in-vitro wash-off method

The mucoadhesive property of optimized batch of AX–SA microbeads was evaluated by an in vitro mucoadhesion testing method known as wash-off method as described earlier (Pendyala and Talasila 2012). Briefly, freshly excised piece of intestinal mucosa (2 × 2 cm) from chicken were mounted on to glass slides (3 × 1 inch) with cyanoacrylate glue. Two glass slides were connected with a suitable support, about 100 microbeads were spread on to each wet rinsed tissue specimen and immediately thereafter the support was hung on to the arm of a USP tablets disintegrating test machine. When the disintegrating test machine was operated, the tissue specimen was given slow, regular up-and-down moment in the test fluid (distilled water) at 37 ± 0.5 °C. At the end of 1 h, and at the hourly intervals up to 8 h, the machine was stopped and number of microbeads still adhering to tissue was calculated. The studies were carried out three times.

Results and discussion

Ionotropic gelation technique has been used for the modification of arabinoxylan with sodium alginate to develop the crosslinked polymeric micobeads using calcium chloride as a cross linker. The microbeads were characterized by various parameters.

FT-IR spectroscopy

Figure 2 exhibits the FT-IR spectra of arabinoxylan (AX), sodium alginate (SA) and arabinoxylan–sodium alginate microbeads (AX–SA BEADS) in the frequency range from 4000–400 cm−1. The IR spectrum of AX shows a peak at 3431 cm−1 which may be attributed to stretching of alcohols. The peak appearing at 2928 cm−1 can be ascribed to –CH stretch of alkanes while the peak appearing at 1406 cm−1 is due to bending of –CH2. The polymer back-bone bendings are represented by peaks at 896 and 613 cm−1. The spectra of SA present an absorption band at 3430 cm−1 due to stretching of alcohol, a peak appearing at 1023 cm−1 is due to stretch of alcohol. The spectra shows the characteristic peak at 1623 cm−1 ascribed to stretch of ester. In addition, the bands at 1623 and 1421 cm−1 are ascribed to asymmetric and symmetric stretching peaks of carboxylate salt groups, a broad band at 3430 cm−1 corresponded to the hydroxyl groups. The spectra of AX–SA microbeads shows an absorption band at 1080 cm−1 due to C–O stretching of primary alcohol. A broad band appearing at 3422 cm−1 is ascribed to overlapping of stretch of alcohol contributed by AX and SA. The peak appearing at 1430 cm−1 is due to symmetric stretching of carboxylate of SA and contributed by AX.

Differential scanning calorimetry

Figure 3a, b, c exhibits the thermogram of differential scanning calorimetry (DSC) analysis of SA, AX and AX–SA microbeads. Thermogram of AX and SA shows endothermic peak at 70.29 °C with heat of fusion of 181.3 J/g and 144.38 °C with heat fusion of 345.92 J/g respectively. But the thermogram of AX–SA microbeads shows two endothermic peaks at 229.07 and 178.27 °C with heat fusion of 108.75 and 217.83 J/g respectively. Thus, the shifts in the endothermic peaks indicate that modification of AX and SA has been taken place due to cross linking.

Optical microscopy

Optical microscopy was used to study the morphology of different AX–SA microbeads at ×10 as shown in Fig. 4. The AX–SA microbeads were found to be spherical and irregular shape with rough surfaces. The mean particle size of the various formulations of microbeads was found to be lying in the range between 1.098 ± 0.054 and 1.501 ± 0.037 mm.

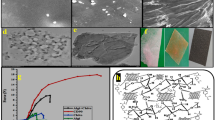

Scanning electron microscopy

Figure 5a, b, c exhibits the scanning electron microscopy (SEM) showing surface morphology of AX, SA and AX–SA microbeads. The SEM micrograph of AX shows the polyhedral structure with slightly smooth surfaces. SA shows the thin flaky and rough surface while AX–SA microbead shows the granular shape with some agglomeration. It may be observed that the physical change is there on interacting AX with SA.

Experimental design

Design Expert Software (Version 9.0.3, Stat-Ease) was used for designing experimental plan for the preparation of AX–SA microbeads loaded with diclofenac sodium. A two-factor, three level central composite designs (CCD) was employed for the optimization. The size distribution and swelling properties study of the beads was not performed as the focus of the study was on entrapment efficiency and on in vitro release study. The concentration of Sodium alginate/arabinoxylan (SA/AX) and calcium chloride (CaCl2) were selected as independent variables. Entrapment efficiency (%) and in vitro release (%) of diclofenac sodium were selected as response factors (Table 1).

The results of optimization studies of AX–SA microbeads done using response surface methodology employing CCD have been represented in (Table 1). The data obtained was fitted into various polynomial models and ANOVA test was applied to models to estimate their significance. Among the various polynomial models, the response Y1 (entrapment efficiency) and Y2 (% drug release) fitted best into the response surface quadratic model. The results of ANOVA analysis showed that the models to be significant with non-significant lack of fit and quadratic terms were generated for all the response variables. The polynomial models showing relationship between the independent variables and the response Y1 and Y2 are expressed by the following equations

where X1 is the sodium alginate/arabinoxylan (SA/AX), X2 is the calcium chloride, Y1 is the % entrapment efficiency and Y2 is the % drug release

Table 2 portrays the statistical summary for response surface quadratic model. The R2 value for all the response models was >0.9, which indicated a good correlation between the experimental and predicted responses. The value of “adequate precision” was greater than 4 which is desirable and indicates an adequate signal.

The results of factor effects of responses Y1 and Y2 are given in Eq. (2, 3). P value results from the data explained that the response Y1 is significantly affected by X1, X2, X1X2 interaction and by quadratic contribution of X1 and X2. The response Y2 is affected by X1, X2 and the quadratic contribution of X1 and X2.

Figure 6a shows the combined effect of concentration of SA/AX ratio and calcium chloride on the percentage entrapment of diclofenac sodium. It can be inferred from the plot that at lower level of calcium chloride, increase in the ratio of SA/AX causes slight increase in entrapment. But as the concentration of calcium chloride increases, at lower level of SA/AX ratio there is pronounced increase in entrapment efficiency which can be attributed to higher crosslinking. Further, it can be observed at higher level of calcium chloride, increase in the SA/AX ratio leads to significant fall in drug entrapment which indicates that at higher level of SA/AX ratio, even the higher level of calcium chloride is inadequate to produce good cross linking.

Figure 6b represents the combined effect of concentration of sodium alginate/arabinoxylan (SA/AX) and concentration of calcium chloride (CaCl2) on the in vitro release of diclofenac sodium from microbeads. It can be observed from the plot that the concentration of calcium chloride has more prominent effect on the percentage in vitro release than concentration of sodium alginate/arabinoxylan. As the concentration of calcium chloride increases at lower level of sodium alginate/arabinoxylan (SA/AX) ratio, there is significant decrease in percentage drug release which can be attributed to relatively higher concentration of sodium alginate as compared to arabinoxylan. The acidic character of arabinoxylan is much less than sodium alginate to allow formation of strong ionically gelled network, as a result beads having relatively higher concentration of sodium alginate (SA/AX-7.5 or 10) were more effective in sustaining the release than the beads having lower concentration of sodium alginate (SA/AX-5 or 0). The delay in drug release with increase in calcium chloride can be explained by the fact that increasing the calcium chloride concentration results in the formation of highly cross linked microbeads having a greater amount of entrapped drug and a sustained release is observed over a longer period of time.

To develop an optimized formulation of diclofenac sodium loaded microbeads, a numerical optimization technique along with desirability approach was employed. The optimization of the sodium alginate/arabinoxylan (SA/AX) ratio and calcium chloride was done with the goal of preparing microbeads with maximum percentage entrapment efficiency and minimum drug release of diclofenac sodium. The optimization tool provided different sets of solutions.

An optimized batch of diclofenac sodium loaded microbeads was prepared and analyzed for entrapment efficiency and in vitro release. The optimized batch of formulation was predicted to concentration of sodium alginate/arabinoxylan 5 and calcium chloride concentration 0.75 M. The optimized batch of diclofenac sodium loaded microbeads was found to have the entrapment efficiency 64.4 % (predicted 65.54 %) and in vitro drug release of 28.5 % (predicted 26.64 %). Hence, a good correlation between the predicted and observed values was obtained, indicating the reliability of the model.

In vitro release study

In vitro release profile of diclofenac sodium from various batches of AX–SA microbeads was studied under varying pH conditions using USP type II dissolution apparatus. AX–SA microbeads were tested for drug release firstly in HCl buffer (pH 1.2) and maintained at temperature of 37.0 ± 0.5 °C and stirred at 50 rpm for 2 h. The dissolution media was then replaced with phosphate buffer (pH 6.8) and drug release study was carried out for further 6 h.

Figure 7 shows the drug release profile only of optimized batch. It was observed from the plot that the drug release at pH 1.2 was less than 8 % within 2 h and in buffer (pH 6.8), the amount of drug released in a sustained manner. Drug dissolution was carried out for 8 h. It can be inferred from the graph that at the end of 8 h, only 28.5 % of drug was released. Therefore, it may be opted for sustained drug release formulations.

Table 3 shows the modeling and release kinetics of optimized batch. The release rate of diclofenac loaded microbeads was fitted into various kinetics models to estimate their release kinetics and mechanism of release. The release kinetics data was found to be fitted best into the zero order kinetics. Further, the value of ‘n’ (n < 0.5) the release exponent of Korsmeyer–Peppas equation revealed that the drug release from the microbeads followed diffusion mechanisms.

In vitro wash off mucoadhesion test of optimized batch

The results of mucoadhesion study conducted on optimized batch using wash-off method revealed good mucoadhesive property of sodium alginate/arabinoxylan beads with 43 % of beads remaining adhered to the intestinal mucosa at the end of 8 h period of study (Fig. 8).

Conclusion

Arabinoxylan–sodium alginate microbeads were prepared by ionotropic gelation method. The formation of mucoadhesive microbeads was confirmed by FT-IR, DSC, SEM. The preparation of microbeads was optimized using central composite experimental design. The optimized batch of arabinoxylan–sodium alginate microbeads had entrapment efficiency of 64.4 % and % drug release of 28.5 %. The release kinetic profile of the drug from microbeads was found to follow zero order model. Further the results of modeling of release kinetics revealed that drug release followed zero order kinetics with mechanism of release being diffusion through the matrix. Mucoadhesive microbeads of diclofenac sodium consisting of arabinoxylan as a mucoadhesive polymers exhibited good mucoadhesive properties and determined by in-vitro wash off test for mucoadhesion. On the basis of this study it can be concluded that interaction between sodium alginate/arabinoxylan ratio and calcium chloride can be employed for the development of sustained release formulations.

References

Ahuja M, Bhatia M (2013) Thiol modification of psyllium husk mucilage and evaluation of its mucoadhesive applications. Sci World J, 1–7

Ahuja M, Bhatia M (2015) Psyllium arabinoxylan: carboxymethylation, characterization and evaluation for nanoparticulate drug delivery. Int J Biol Macromol 72:495–501

Bindu D, Bharat P, Kumar AC (2012) Psyllium: a potential carrier to control the drug delivery. Int Res J Pharm 3(7):39–44

Fernandez-Banares F (2006) Nutritional care of the patient with constipation. Best Pract Res Clin Gastroenterol 20:575–587

Fischer MH, Yu N, Gray GR, Ralph J, Anderson L, Marlett JA (2004) The gel-forming polysaccharide of psyllium husk (Plantago ovata Forsk). Carbohydr Res 339:2009–2017

George M, Abraham TE (2006) Polyionic hydrocolloids for the intestinal delivery of protein drugs: alginate and chitosan- a review. J Control Release 114:1–14

Higuchi T (1961) Rate of release of medicaments from ointment bases containing drugs in suspension. J Pharm Sci 50:874–875

Mathew ST, Devi SG, Prasanth VV, Vinod B (2009) Formulation and in vitro-in vivo evaluation of ketoprofen-loaded albumin microspheres for intramuscular administration. J Microencapsul 26:456–469

Mishra A, Srinivasan R, Gupta R (2003) Plantago psyllium-g-polyacrylonitrile: synthesis and characterization. Colloid Polym Sci 281:187–189

Mishra A, Yadav M, Agarwal S, Rajani S (2004) Polyacrylonitrile grafted Plantago psyllium mucilage for the removal of suspended and dissolved solid from tannery effluent. Colloid Polym Sci 282:300–303

Mishra S, Sinha S, Dey KP, Sen G (2014) Synthesis, characterization and applications of polymethylmethacrylate grafted psyllium as flocculant. Carbohydr Polym 99:462–468

Nayak AK, Pal DK, Santra K (2013) Plantago ovata F. mucilage-alginate mucoadhesive beads for controlled release of glibenclamide: development, optimization, and in vitro-in vivo evaluation. J Pharm, 1–11

Oliver SD (2000) The long-term safety and tolerability of ispaghula husk. J R Soc Health 120:107–111

Pendyala Y, Talasila S (2012) Formulation and evaluation of chitosan loaded mucoadhesive microspheres of ramipril. Int J Pharm Chem Sci 1(3):904–911

Sandhu JS, Hudson J, Kennedy JF (1981) The gel nature and structure of the Lotfipour F, Mirzaeei S, Maghsoodi M. Preparation and characterization of alginate and psyllium beads containing Lactobacillus acidophilus. Sci World J, 1–8

Shazia S, Iqbal MS, Hussain MA, Koschella A, Heinze T (2008) Structure characterization and carboxymethylation of arabinoxylan isolated from Ispaghula (Plantago ovata) seed husk. Carbohydr Polym 74(2):309–317

Shazia S, Iqbal MS, Koschella MA, Heinze T (2009) Ethylation of arabinoxylan from ispaghula (Plantago ovata) seed husk. Carbohydr Polym 77:125–130

Shidhaye S, Desai A, Kadam VJ (2007) Possible use of psyllium husk as a release retardant. Indian J Pharm Sci 69(2):206–210

Singh B (2007) Psyllium as therapeutic and drug delivery agent. Int J Pharm 334:1–14

Singh B, Kumar S (2008) Synthesis and characterization of psyllium-NVP based drug delivery system through radiation crosslinking polymerization. Nucl Instrum Methods Phys Res Sect B 266:3417–3430

Acknowledgments

The authors (M. Ahuja, M. Bhatia, K. Saini) declare that they have no conflict of interest. This article does not contain any studies with human and animal subjects performed by any of the authors. The authors are grateful to IIT, New Delhi, for carrying out the SEM studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahuja, M., Bhatia, M. & Saini, K. Sodium alginate–arabinoxylan composite microbeads: preparation and characterization. Journal of Pharmaceutical Investigation 46, 645–653 (2016). https://doi.org/10.1007/s40005-016-0244-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-016-0244-1