Abstract

Mesoporous boehmite nanopowder was prepared by a simple route and used as an efficient adsorbent for chromium(VI) removal. Chromium(VI) is considered to be potentially carcinogenic to humans, thus, removal of Cr(VI) ions from aqueous solution is of great importance. Batch adsorption experiments were conducted to study the effects of contact time and initial concentration of Cr(VI). The boehmite prepared by neutralization of sodium aluminate solution from Bayer liquor and glucose as nonionic surfactant is environmentally friendly material for potential industrial scale production. It has the high specific surface area (296 m2/g) and high adsorption capacity (32.92 mg/g after 72 h) for the removal of Cr(VI) from aqueous solutions. This high removal percentage is in an excellent agreement with the capacity calculated by the pseudo-second order model (33.11 mg/g). The equilibrium isotherm data fitted well with the Langmuir model (R2 = 0.996), suggesting a uniform surface nature of the prepared nanoparticles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is an essential part of the everyday life of humans. It is used extensively in people's homes, industry, agriculture, etc. These days a great concern is devoted to water consumption and remediation of polluted water from industry and households. Even though it makes about two thirds of the Earth's surface, the amount of usable water is only about 0.3% (Bhattacharya et al. 2018). This is why there is an extensive effort to purify water in order to reuse it. Water often contains suspended colloids, bacteria, viruses, organic and inorganic pollutants that need to be removed. Nanopowders of various metal oxides could be one of the possible solutions for wastewater treatment due to their high specific surface area, adsorption capacity and chemical reactivity (Afkhami et al. 2010; He et al. 2019; Nagpal and Kakkar 2019).

Nanopowders based on aluminum oxide and hydroxide are well-known group of materials and they are usually referred to as alumina. Two of the most important types of alumina adsorbents are boehmite and γ-alumina. Boehmite is aluminum oxyhydroxide (AlOOH) which transforms into γ-alumina when heated above 400 °C (Hicks and Pinnavaia 2003). Due to the importance of boehmite, but also γ-alumina, in the heterogeneous catalysis, composite materials, adsorption, membranes, bioceramics, batteries, etc., (Hicks and Pinnavaia 2003; Kiss and Boskovic 2012; Kocjan et al. 2017; Laachachi et al. 2009; Luo et al. 2016; Majhi et al. 2009; Roy et al. 2018; Said et al. 2019; Solovev et al. 2019) boehmite is produced industrially at a very large scale and it is predicted that the global market of boehmite will reach 507.7 million $ until year 2027 (MarketWatch LLC, n.d.). There are several different methods to prepare pure boehmite usually by some modification of hydrothermal method (Cai et al. 2010, 2009; Filho et al. 2016; Ge et al. 2013; Ren et al. 2004; Zhang et al. 2009) or by using sol–gel synthesis and various surface modifications (Cai et al. 2014; Hicks and Pinnavaia 2003; Park et al. 2007; Said et al. 2019; Wang et al. 2013). However, hydrothermal method is time and energy consuming and sol–gel process involves expensive metal–organic precursors and chemicals which are usually environmentally hazardous. Milanovic et al. (Milanović et al. 2018) reported recently that pure boehmite nanopowder could be obtained at room temperature by using neutralization of sodium aluminate solution from Bayer liquor and glucose as nonionic surfactant. This process is both energy efficient and environmentally friendly. It gives boehmite nanocrystalline powder of high purity and high specific surface area.

Boehmite is unique since it is the only precursor for γ, δ and θ-alumina phases upon heating and before transforming to α-alumina (Hicks and Pinnavaia 2003; Santos et al. 2000). Phase transformations of boehmite from 400 to 1000 °C are a consequence of thermal dehydroxilation. They are usually topotactic transitions which preserve microstructural and textural features such as specific surface area, pore shape and diameter (Hicks and Pinnavaia 2003; Milanović et al. 2018; Santos et al. 2000). Since boehmite (AlOOH) has more surface –OH groups than γ-alumina (Al2O3), the adsorbing properties and selectivity can be tuned by processing and temperature treatment. This is why there are plenty of literature reports about the adsorption characteristics of boehmite and/or γ-alumina for wide range of both organic and inorganic species: Congo red (Cai et al. 2010; Nagpal and Kakkar 2019; Wang et al. 2013), phenol (Cai et al. 2009), phosphate (Hano et al. 1997; Tanada et al. 2003), arsenic (Dubey et al. 2017; Ogata et al. 2006), cadmium (Granados-Correa et al. 2011; Hota et al. 2008; Sun et al. 2019), chromium (Cai et al. 2014; Ge et al. 2013; Luo et al. 2016) and various other ions (Afkhami et al. 2010; Majhi et al. 2009; Yan et al. 2017).

Chromium is one of the most dangerous pollutants in wastewaters. It exists in several oxidation states, but the most common species are the chromium(VI) and chromium(III). Chromium(VI) is highly toxic and carcinogenic. Therefore, a great effort has been undertaken to remove it from water (Granados-Correa and Jiménez-Becerril 2009; Johnston and Chrysochoou 2015). There are several reports that alumina nanopowders, mostly pure or modified boehmite and γ-alumina, could be considered as suitable for chromium adsorption and its removal from water (Afkhami et al. 2010; Cai et al. 2014; Granados-Correa and Jiménez-Becerril 2009; Johnston and Chrysochoou 2015; Luo et al. 2016; Zhang et al. 2011).

The aim of this study was to prepare the boehmite nanopowder through an environmentally friendly route and to use it as an adsorbent for chromium ions. Furthermore, equilibrium, adsorption isotherms and kinetics were studied in order to understand the adsorption mechanism of Cr(VI) onto obtained boehmite.

Materials and methods

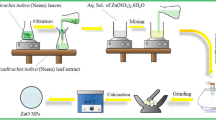

Synthesis of nanocrystalline boehmite

All chemical reagents except distilled water and sodium aluminate solution obtained in the factory "Alumina" Ltd. Zvornik are of analytical grade and were used without further purification. Nanocrystalline boehmite powder was synthetized according to the published procedure (Milanović et al. 2020), from sodium aluminate solution (concentration of 75 g/l Na2Ok) prepared from Bayer liquor. Glucose (D-( +)-Glucose, anhydrous, Alfa Aesar, Fisher Scientific, UK) was used as a surfactant, with the molar ratio of Al2O3/glucose = 1:10. The solution was neutralized with the use of 1 M sulfuric acid (Aurubis, Bulgaria). During neutralization procedure, solution was stirred at 70 °C for 60 min. The obtained white precipitate was separated by vacuum filtration, washed with distilled water to remove residual ions and dried at 110 °C for 3 h.

Batch adsorption experiments

Adsorption experiments were performed in a batch mode by adding 0.1 g of the adsorbent into 200 ml of K2Cr2O7 solution (Centrohem, Serbia) of different initial chromium(VI) ions concentrations (10–1000 mg/l) and pH = 2 adjusted with nitric acid. The mixture was continuously shaken at different time intervals (2 min to 24 h) at room temperature. Adsorbent was separated from the solution by filtration on fiber glass round filter, type MN 85/70 BF, 45 mm (MACHEREY–NAGEL, Germany) and in obtained filtrates, residual concentration of chromium(VI) ions was determined by oxidation reduction titrations (Lide 2006). The amount of adsorbed ions per mass of the adsorbent (q) was calculated as follows:

where m is the mass of an adsorbent added per liter of solution, C0 (mg/l) is the initial Cr(VI) concentration and C is the Cr(VI) concentration after adsorption.

Characterization techniques

The crystallographic structure of obtained boehmite powder was analyzed by X-ray diffraction (XRD) using Rigaku MiniFlex 600 diffractometer (CuKα radiation, λ = 1.5406 Å) in 2θ range 10–70° with a scan rate of 0.03°/s. The Fourier-transformed infrared spectroscopy (FTIR) was performed on Nicolet-Nexsus 670 spectrophotometer in the range 4000–400 cm–1. Adsorption/desorption characteristics of the sample were measured by nitrogen adsorption at 77 K (Micromeritics ASAP 2010 instrument) and specific surface area was calculated by the BET method. Pore size distribution was obtained by fitting the Barret–Joyner–Hallender (BJH) model to the desorption isotherm. The zeta potential of suspension was measured using a Malvern Zetasizer Nano ZS instrument.

Results and discussion

Structural and textural characterization

The XRD pattern of the as-synthesized sample, shown in Fig. 1, refer to the pure boehmite phase with an orthorhombic unit cell (JCPDS No. 21–1307) (Granados-Correa and Jiménez-Becerril 2009; Milanović et al. 2018). The broad peaks indicate a low crystallinity, as well as the nanocrystalline nature of the powder. The bands in the FT-IR spectrum of the sample, Fig. 2, matched with the boehmite phase according to the literature data (Alex et al. 2013; Milanović et al. 2020; Vo et al. 2018), confirming its purity. The band at 1073 cm–1 and the shoulder at 3090 cm–1 refer to the (Al)O–H bending and stretching vibrations of boehmite, respectively. FTIR bands at around 498, 625 and 720 cm−1 correspond to the vibration modes of AlO6. Two prominent bands at 3410 and 1634 cm–1 can be assigned to the OH stretching and HOH bending modes of the adsorbed water, respectively.

The N2 adsorption/desorption isotherm and pore size distribution of the boehmite powder are shown in Fig. 3. The isotherm belongs to the type IV which is typical for mesoporous materials while hysteresis loop is of H3 type, according to the IUPAC classification. Such isotherm is characteristic for the aggregates of plate-like particles that have slit-shaped mesopores (Mikhaylov et al. 2017; Mohammadnezhad et al. 2016; Wang et al. 2009). This result is in accordance with our previously published paper (Milanović et al. 2020), where the lamellar framework of the flower-like boehmite nanoparticles is obtained under similar conditions. The slit-shaped pores are about 3 nm in width as calculated by the Barrett–Joyner–Halenda (BJH) method. The BET surface area and total pore volume of boehmite are 296 m2/g and 0.23 cm3/g, respectively. This large surface area and porous particles that have rough surfaces provide excellent adsorbent characteristics. Namely, the large surface area means there is more surface available for adsorption, which results in greater adsorption efficiency.

Chromium(VI) adsorption isotherms

In order to investigate the Cr(VI) ions adsorption process onto mesoporous boehmite nanoparticles, adsorption equilibrium studies were conducted. For interpretation of this process, various isotherm models can be used. These models are actually mathematical equations which express a relationship between adsorbed amount of adsorbate and the amount left in the solution in the state of equilibrium. Furthermore, equilibrium constants give more details about mechanism of adsorption or adsorbent affinity toward adsorbate. This information is essential for designing efficient adsorption systems. In this study, most commonly used Langmuir and Freundlich models were applied in their linear form (Table 1).

Fitting experimental data to Langmuir model resulted in maximum capacity of 59.5 mg/g and correlation coefficient value of 0.996. Compared to Freundlich correlation coefficient value, high R2 for Langmuir isotherm indicates that adsorption of chromium(VI) ions follows this model as shown in Fig. 4. Unlike Freundlich model, which suggests heterogeneous surface, Langmuir model assumes the formation of adsorbate monolayer on the homogeneous surface of adsorbent and the absence of interactions between adsorbed molecules (Farouq and Yousef 2015; Kaveeshwar et al. 2018). According to dimensionless separation factor, RL, expressed as:

it can be determined if the adsorption is linear, favorable, unfavorable or irreversible. Value of RL for adsorption of chromium(VI) by mesoporous boehmite is between 0 and 1 which indicates favorable process (Hameed et al. 2008). Moreover, maximum Langmuir adsorption capacity is in agreement with experimentally obtained value (58.9 mg/g) while Freundlich constant KF, which also indicates adsorption capacity, is much lower. The obtained results are in agreement with the literature data for alumina-based adsorbents. Li et al. (Li et al. 2016) investigated adsorption of chromium(VI) onto mesoporous alumina and concluded that the process is best described by Langmuir with the maximum Cr(VI) uptake capacity of 46 mg/g. Luo et al. (Luo et al. 2016) and Islam et al. (Islam et al. 2020) reported that adsorption of chromium(VI) ions onto boehmite can also be fitted well with the Langmuir equation reaching adsorption capacities of 12.26 and 66.35 mg/g, respectively. Mikhaylov et al. (Mikhaylov et al. 2017) investigated adsorption of chromium(VI) onto composite γ-AlOOH/α-Fe2O3 and concluded that the process is best described by the Langmuir equation.

Adsorption kinetics

The studies of chromium(VI) ions adsorption onto boehmite were also carried out as a function of time. The kinetics of adsorption process is one of the factors that influences the overall efficiency of the process. The experimental results are shown in Fig. 5.

The adsorption of chromium(VI) ions is fast in the first 180 min probably due to a large number of free active sites on the outer surface of the adsorbent particles. After this period, 70% of total amount of adsorbed ions is already bound. The adsorption process continued slowly for the whole period studied. The maximum adsorption capacity obtained after 72 h was 32.92 mg/g. Granados-Correa et al. (Granados-Correa and Jiménez-Becerril 2009) studied adsorption of chromium(VI) onto boehmite and reported adsorption capacity of only 0.038 mg/g in the state of equilibrium which was reached after only one hour, while Vo et al. (Vo et al. 2018) obtained adsorption capacity of 17.08 mg/g for Cr(VI) by γ-AlOOH after 350 min. The high adsorption capacity of the synthesized boehmite nanoparticles in this work could be explained by the value of zeta potential at the surface of the particles, as well as the nature of Cr(VI) ions present at specific pH. Namely, the measured zeta potential of the boehmite in aqueous solution at pH 2 is about + 27 mV. At low pH value, Cr(VI) ions mainly exist in the form of negatively charged HCrO4− or Cr2O72− ions (Granados-Correa and Jiménez-Becerril 2009; Luo et al. 2016; Vo et al. 2018), so they can easily move toward the positive surface of the adsorbent owing to the electrokinetic attractive force, thus favoring the adsorption. Furthermore, the adsorption capacity of the synthesized boehmite nanoparticles is higher than most reported alumina-based adsorbents shown in Table 2.

A simple comparison of the synthesis method used in this work with those used in the literature and presented in Table 2 (Cai et al. 2010; Li et al. 2016; Luo et al. 2016; Vo et al. 2018) gives further evidence of the economic and environmental advantages of the obtained nanocrystalline boehmite. The price of the sodium aluminate solution per unit mass is one or two orders of magnitude lower than for precursors usually employed in the sol–gel or hydrothermal synthesis. Also, the time spent on the preparation as well as low energy consumption without the need for high temperature conditions additionally lower the costs and manufacturing environmental footprint. Further on, the synthesis process itself could be incorporated as a side stream of the main Bayer process and use low concentration aluminate solution, thus reducing the amount of waste from the Bayer process but with the additional benefit of obtaining new boehmite product with fine size, high specific surface area and excellent adsorption characteristics. So this material could be regarded as a potentially cheap and environmentally friendly adsorbent for Cr(VI) removal.

For interpreting kinetic data and elucidating a mechanism of chromium ions adsorption onto boehmite, the most commonly used models such as pseudo-first, pseudo-second order and Elovich model were employed (Rziga 2021). The results of experimental data fitting for used models are shown in Table 3. In these equations qe indicates adsorption capacity at equilibrium (mg/g), qt (mg/g) is the amount of adsorbed ions in a specific period, k1 is adsorption rate constant of pseudo-first model (min−1), k2 is rate constant of pseudo-second order model (g/mg min), α is initial rate of adsorption (mg/g min) and β is desorption constant (g/mg).

The value of R2 indicates that the pseudo-second order model provides the best fit (R2 = 0.999) while other two applied models showed significantly lower values of correlation coefficient. Moreover, the value of adsorption capacity calculated by the second-order model (33.11 mg/g) is in an excellent agreement with experimentally obtained capacity (32.92 mg/g). This confirms that the model accurately describes the adsorption kinetics throughout the period of experiments. According to the assumptions of the model, adsorption of chromium(VI) ions onto mesoporous boehmite nanoparticles occurs as chemical reaction which could be the rate-controlling step (Ho and McKay 1999).

Adsorption mechanism

Kinetic models do not provide any information about diffusion mechanism so Weber-Morris model was applied in order to gain insight into mechanisms of adsorption and rate limiting step of the process. It is usually expressed as (Weber and Morris 1963):

where kid is intraparticle diffusion rate constant and q is adsorbed amount of adsorbate at time t.

According to this model, if a plot qt versus t1/2 is a straight line passing through the origin then the only rate limiting step of adsorption process is intraparticle diffusion. The plot for adsorption of chromium(VI) onto boehmite shown in Fig. 6, implies that the process is complex and not governed only by the intraparticle diffusion. Three linear portions can be identified which represent faster diffusion through boundary layer and adsorption onto outer surface, slower diffusion into pores and adsorption onto inner surface and equilibrium, respectively.

Since the Weber-Morris model suggested that adsorption is complex process, Boyd model (Boyd et al. 1947) was additionally applied:

where F is the fractional attainment of equilibrium at different times, and Bt is function of F which could be expressed as:

where qt and qe are adsorption capacities in specific time and equilibrium, respectively. For F < 0.85 Reichenberg’s approximation was then used (Viegas et al. 2014):

This model is based on the assumption that the intraparticle diffusion is rate-controlling step of the process if plot Bt vs. t is linear with zero intercept. The plot for adsorption of Cr(VI) is shown in Fig. 7. Its nonlinearity indicates that the film diffusion or chemical reaction might be the rate limiting step (Boyd et al. 1947; Viegas et al. 2014).

Conclusion

Simple approach for synthesis of boehmite nanopowder is developed. The study shows that at relatively low temperature, it is possible to obtain mesoporous nanocrystalline boehmite powder, with very large specific surface area and appropriate pore size distribution which could have a great potential as an absorbent in water treatment and other adsorption fields. In particular, the results show that thus obtained mesoporous boehmite could be an effective adsorbent for the removal of Cr(VI) ions from aqueous solutions under the tested experimental conditions. The adsorption kinetics studies suggested that the kinetics rate for the adsorption of Cr(VI) could be best described by the pseudo-second order model and that the sorption process occurs as chemisorption. The maximum adsorption capacity obtained after 72 h was 32.92 mg/g. According to the adsorption isotherm studies, Langmuir adsorption isotherm model fit the experimental data very well with the maximum adsorption capacity of 59.5 mg/g while the experimentally obtained capacity was 58.9 mg/g. Diffusion studies showed that the process is complex and it is probably not governed only by the intraparticle diffusion. Beside the high adsorption capacity, the main advantage of the obtained mesoporous boehmite nanopowder essential for its practical application is straightforward, ecofriendly and cost-effective synthesis. This method has a potential for industrial scale applications where it could save time and offer energy efficient synthesis of high-quality boehmite while reducing environmental footprint of the process.

References

Afkhami A, Saber-Tehrani M, Bagheri H (2010) Simultaneous removal of heavy-metal ions in wastewater samples using nano-alumina modified with 2,4-dinitrophenylhydrazine. J Hazard Mater 181:836–844. https://doi.org/10.1016/j.jhazmat.2010.05.089

Alex TC, Kumar R, Roy SK, Mehrotra SP (2013) Leaching behaviour of high surface area synthetic boehmite in NaOH solution. Hydrometallurgy 137:23–32. https://doi.org/10.1016/j.hydromet.2013.04.004

Bhattacharya S, Gupta AB, Gupta A, Pandey A (2018) Introduction to Water Remediation: Importance and Methods. In: Bhattacharya S, Gupta AB, Gupta A, Pandey A (eds) Water Remediation. Springer, Singapore, pp 3–8. https://doi.org/10.1007/978-981-10-7551-3_1

Boyd GE, Adamson AW, Myers LS (1947) The Exchange adsorption of ions from aqueous solutions by organic zeolites. II Kinetics J Am Chem Soc 69:2836–2848. https://doi.org/10.1021/ja01203a066

Cai W, Tan L, Yu J, Jaroniec M, Liu X, Cheng B, Verpoort F (2014) Synthesis of amino-functionalized mesoporous alumina with enhanced affinity towards Cr(VI) and CO2. Chem Eng J 239:207–215. https://doi.org/10.1016/j.cej.2013.11.011

Cai W, Yu J, Cheng B, Su BL, Jaroniec M (2009) Synthesis of boehmite hollow core/shell and hollow microspheres via sodium tartrate-mediated phase transformation and their enhanced adsorption performance in water treatment. J Phys Chem C 113:14739–14746. https://doi.org/10.1021/jp904570z

Cai W, Yu J, Jaroniec M (2010) Template-free synthesis of hierarchical spindle-like γ-Al2O3 materials and their adsorption affinity towards organic and inorganic pollutants in water. J Mater Chem 20:4587–4594. https://doi.org/10.1039/b924366f

Dubey SP, Dwivedi AD, Sillanpää M, Lee H, Kwon Y-N, Lee C (2017) Adsorption of As(V) by boehmite and alumina of different morphologies prepared under hydrothermal conditions. Chemosphere 169:99–106. https://doi.org/10.1016/J.CHEMOSPHERE.2016.11.052

Farouq R, Yousef NS (2015) Equilibrium and Kinetics Studies of adsorption of Copper (II) Ions on Natural Biosorbent. Int J Chem Eng Appl 6(5):319–324. https://doi.org/10.7763/IJCEA.2015.V6.503

Filho RWND, De Araujo RG, Montes CR, Vieira-Coelho AC (2016) Synthesis and characterization of boehmites obtained from gibbsite in presence of different environments. Mater Res 19:659–668. https://doi.org/10.1590/1980-5373-MR-2016-0019

Ge J, Deng K, Cai W, Yu J, Liu X, Zhou J (2013) Effect of structure-directing agents on facile hydrothermal preparation of hierarchical γ-Al2O3 and their adsorption performance toward Cr(VI) and CO2. J Colloid Interface Sci 401:34–39. https://doi.org/10.1016/j.jcis.2013.03.028

Granados-Correa F, Corral-Capulin NG, Olguín MT, Acosta-León CE (2011) Comparison of the Cd(II) adsorption processes between boehmite (γ-AlOOH) and goethite (α-FeOOH). Chem Eng J 171:1027–1034. https://doi.org/10.1016/j.cej.2011.04.055

Granados-Correa F, Jiménez-Becerril J (2009) Chromium (VI) adsorption on boehmite. J Hazard Mater 162:1178–1184. https://doi.org/10.1016/j.jhazmat.2008.06.002

Hameed BH, Mahmoud DK, Ahmad AL (2008) Equilibrium modeling and kinetic studies on the adsorption of basic dye by a low-cost adsorbent: Coconut (Cocos nucifera) bunch waste. J Hazard Mater 158:65–72. https://doi.org/10.1016/j.jhazmat.2008.01.034

Hano T, Takanashi H, Hirata M, Urano K, Eto S (1997) Removal of phosphorus from wastewater by activated alumina adsorbent. Water Sci Technol 35:39–46. https://doi.org/10.1016/S0273-1223(97)00112-1

He Z, Lyu Z, Gu Q, Zhang L, Wang J (2019) Ceramic-based membranes for water and wastewater treatment. Colloids Surfaces A Physicochem Eng Asp 578:123513. https://doi.org/10.1016/j.colsurfa.2019.05.074

Hicks RW, Pinnavaia TJ (2003) Nanoparticle assembly of mesoporous AlOOH (boehmite). Chem Mater 15:78–82. https://doi.org/10.1021/cm020753f

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Hota G, Kumar BR, Ng WJ, Ramakrishna S (2008) Fabrication and characterization of a boehmite nanoparticle impregnated electrospun fiber membrane for removal of metal ions. J Mater Sci 43:212–217. https://doi.org/10.1007/s10853-007-2142-4

Islam MA, Angove MJ, Morton DW, Pramanik BK, Awual MR (2020) A mechanistic approach of chromium (VI) adsorption onto manganese oxides and boehmite. J Environ Chem Eng 8:103515. https://doi.org/10.1016/j.jece.2019.103515

Johnston CP, Chrysochoou M (2015) Mechanisms of chromate adsorption on boehmite. J Hazard Mater 281:56–63. https://doi.org/10.1016/j.jhazmat.2014.05.067

Kaveeshwar AR, Ponnusamy SK, Revellame ED, Gang DD, Zappi ME, Subramaniam R (2018) Pecan shell based activated carbon for removal of iron(II) from fracking wastewater: adsorption kinetics, isotherm and thermodynamic studies. Process Saf Environ Prot 114:107–122. https://doi.org/10.1016/j.psep.2017.12.007

Kiss E, Boskovic G (2012) Impeded solid state reactions and transformations in ceramic catalysts supports and catalysts. Process Appl Ceram 6:173–182. https://doi.org/10.2298/PAC1204173K

Kocjan A, Konegger T, Dakskobler A (2017) Hierarchical macroporous–mesoporous γ-alumina monolithic green bodies with high strength. J Mater Sci 52:11168–11178. https://doi.org/10.1007/s10853-017-0894-z

Laachachi A, Ferriol M, Cochez M, Lopez Cuesta JM, Ruch D (2009) A comparison of the role of boehmite (AlOOH) and alumina (Al2O3) in the thermal stability and flammability of poly(methyl methacrylate). Polym Degrad Stab 94:1373–1378. https://doi.org/10.1016/j.polymdegradstab.2009.05.014

Li G, Cui X, Tang S (2016) Removal of Cr(VI) using mesoporous alumina with different kinds of pore structures. J Porous Mater 23:919–926. https://doi.org/10.1007/s10934-016-0149-4

Lide DR (Ed.) (2006) CRC Handbook of Chemistry and Physics, 87th ed. CRC Press Taylor & Francis Group 6000 Broken Sound Parkway NW, Suite 300 Boca Raton, FL 33487–2742.

Luo L, Cai W, Zhou J, Li Y (2016) Facile synthesis of boehmite/PVA composite membrane with enhanced adsorption performance towards Cr(VI). J Hazard Mater 318:452–459. https://doi.org/10.1016/j.jhazmat.2016.07.019

Majhi A, Monash P, Pugazhenthi G (2009) Fabrication and characterization of γ-Al2O3-clay composite ultrafiltration membrane for the separation of electrolytes from its aqueous solution. J Memb Sci 340:181–191. https://doi.org/10.1016/j.memsci.2009.05.030

MarketWatch LLC, n.d. Boehmite Market: Industry Analysis by Size 2021, Future Growth Outlook With Top Countries Data & Share, Revenue, Key Players, Current Trends, Development Strategy, Business Prospect and Forecast to 2027 - MarketWatch [WWW Document]. URL https://www.marketwatch.com/press-release/boehmite-market-industry-analysis-by-size-2021-future-growth-outlook-with-top-countries-data-share-revenue-key-players-current-trends-development-strategy-business-prospect-and-forecast-to-2027-2021-04-12 (accessed 4.19.21).

Marzouk I, Dammak L, Hamrouni B (2013) Adsorption of chromium onto activated alumina: kinetics and thermodynamics studies. Water Environ Res 85:99–104. https://doi.org/10.2175/106143012X13560205144137

Mikhaylov VI, Maslennikova TP, Krivoshapkin PV (2017) Characterization and sorption properties of γ-AlOOH/α-Fe2O3 composite powders prepared via hydrothermal method. Mater Chem Phys 186:612–619. https://doi.org/10.1016/j.matchemphys.2016.11.044

Milanović M, Obrenović Z, Stijepović I, Nikolić L (2020) Flower-like boehmite nanopowders obtained at low temperature from Bayer liquor. Process Appl Ceram 14:168–172. https://doi.org/10.2298/PAC2002168M

Milanović M, Obrenović Z, Stijepović I, Nikolić LM (2018) Nanocrystalline boehmite obtained at room temperature. Ceram Int 44:12917–12920. https://doi.org/10.1016/j.ceramint.2018.04.103

Mohammadnezhad G, Akintola O, Plass W, Steiniger F, Westermann M (2016) A facile, green and efficient surfactant-free method for synthesis of aluminum nanooxides with an extraordinary high surface area. Dalt Trans 45:6329–6333. https://doi.org/10.1039/c6dt00611f

Nagpal M, Kakkar R (2019) Use of metal oxides for the adsorptive removal of toxic organic pollutants. Sep Purif Technol 211:522–539. https://doi.org/10.1016/j.seppur.2018.10.016

Ogata F, Kawasaki N, Nakamura T, Tanada S (2006) Removal of arsenious ion by calcined aluminum oxyhydroxide (boehmite). J Colloid Interface Sci 300:88–93. https://doi.org/10.1016/j.jcis.2006.03.026

Park HS, Yang SH, Jun Y-S, Hong WH, Kang JK (2007) Facile route to synthesize large-mesoporous γ-alumina by room temperature ionic liquids. Chem Mater 19:535–542. https://doi.org/10.1021/cm0620887

Ren TZ, Yuan ZY, Su BL (2004) Microwave-assisted preparation of hierarchical mesoporous-macroporous Boehmite AlOOH and γ-Al2O3. Langmuir 20:1531–1534. https://doi.org/10.1021/la0361767

Roy S, Maity A, Mandal P, Chanda DK, Pal K, Bardhan S, Das S (2018) Effects of various morphologies on the optical and electrical properties of boehmite nanostructures. CrystEngComm 20:6338–6350. https://doi.org/10.1039/C8CE01171K

Rziga B, Guesmia F, Sillanpää M, Hamrouni B (2021) Modelling and optimization of hexavalent chromium removal from aqueous solution by adsorption on low-cost agricultural waste biomass using response surface methodological approach. Water Sci Technol 84(3):552–575. https://doi.org/10.2166/wst.2021.233

Said S, Mikhail S, Riad M (2019) Recent progress in preparations and applications of meso-porous alumina. Mater Sci Energy Technol 2:288–297. https://doi.org/10.1016/j.mset.2019.02.005

Santos PS, Santos HS, Toledo SP (2000) Standard transition aluminas. Electron Microscopy Studies Mater Res 3:104–114. https://doi.org/10.1590/s1516-14392000000400003

Solovev YV, Prilepskii AY, Krivoshapkina EF, Fakhardo AF, Bryushkova EA, Kalikina PA, Koshel EI, Vinogradov VV (2019) Sol-gel derived boehmite nanostructures is a versatile nanoplatform for biomedical applications. Sci Rep 9:1176. https://doi.org/10.1038/s41598-018-37589-1

Sun Q, Liu C, Cui P, Fan T, Zhu M, Alves ME, Siebecker MG, Sparks DL, Wu T, Li W, Zhou D, Wang Y (2019) Formation of Cd precipitates on γ-Al2O3: Implications for Cd sequestration in the environment. Environ Int 126:234–241. https://doi.org/10.1016/j.envint.2019.02.036

Tanada S, Kabayama M, Kawasaki N, Sakiyama T, Nakamura T, Araki M, Tamura T (2003) Removal of phosphate by aluminum oxide hydroxide. J Colloid Interface Sci 257:135–140. https://doi.org/10.1016/S0021-9797(02)00008-5

Viegas RMC, Campinas M, Costa H, Rosa MJ (2014) How do the HSDM and Boyd’s model compare for estimating intraparticle diffusion coefficients in adsorption processes. Adsorption 20:737–746. https://doi.org/10.1007/s10450-014-9617-9

Vo TK, Park H-K, Nam C-W, Kim S-D, Kim J (2018) Facile synthesis and characterization of γ-AlOOH/PVA composite granules for Cr(VI) adsorption. J Ind Eng Chem 60:485–492. https://doi.org/10.1016/j.jiec.2017.11.036

Wang C, Huang S, Wang L, Deng Z, Jin J, Liu J, Chen L, Zheng X, Li Y, Su B-L (2013) Gas leaching as a path to build hierarchical core–corona porous alumina nanostructures with extraordinary pollutant treatment capacity. RSC Adv 3:1699–1702. https://doi.org/10.1039/C2RA22202G

Wang Y, Wang G, Wang H, Cai W, Liang C, Zhang L (2009) Template-induced synthesis of hierarchical SiO2@γ-AlOOH spheres and their application in Cr(VI) removal. Nanotechnology 20:155604. https://doi.org/10.1088/0957-4484/20/15/155604

Weber WJ, Morris JC (1963) Kinetics of Adsorption on Carbon from Solution. J Sanit Eng Div 89:31–59. https://doi.org/10.1061/jsedai.0000430

Yan Z, Xu Z, Yu J, Jaroniec M (2017) Effect of microstructure and surface hydroxyls on the catalytic activity of Au/AlOOH for formaldehyde removal at room temperature. J Colloid Interface Sci 501:164–174. https://doi.org/10.1016/j.jcis.2017.04.050

Yang X, Wang X, Feng Y, Zhang G, Wang T, Song W, Shu C, Jiang L, Wang C (2013) Removal of multifold heavy metal contaminations in drinking water by porous magnetic Fe2O3@AlO(OH) superstructure. J Mater Chem A 1:473–477. https://doi.org/10.1039/c2ta00594h

Zhang L, Jiao X, Chen D, Jiao M (2011) γ-AlOOH Nanomaterials with Regular Shapes: Hydrothermal Fabrication and Cr2O72-Adsorption. Eur J Inorg Chem 2011:5258–5264. https://doi.org/10.1002/ejic.201100793

Zhang L, Lu W, Yan L, Feng Y, Bao X, Ni J, Shang X, Lv Y (2009) Hydrothermal synthesis and characterization of core/shell AlOOH microspheres. Microporous Mesoporous Mater 119:208–216. https://doi.org/10.1016/j.micromeso.2008.10.017

Acknowledgements

The authors acknowledge the financial support from the Serbian Ministry of Education, Science and Technological Development, Project No. 451-03-68/2020-14/200134.

Funding

ministarstvo prosvete,nauke i tehnološkog razvoja,451–03-68/2020–14/200134

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Parveen Fatemeh Rupani.

Rights and permissions

About this article

Cite this article

Milanović, M., Stijepović, I., Obrenović, Z. et al. Chromium(VI) adsorption onto boehmite nanoparticles obtained by cost effective “green” synthesis. Int. J. Environ. Sci. Technol. 19, 10189–10198 (2022). https://doi.org/10.1007/s13762-021-03819-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03819-9