Abstract

The generation and management of wastes constitute today one of the major challenges of societies due not only to the huge amounts that are produced, but also to the need of implementing new treatments that can be more sustainable at an environmental level. The present work explored the production, management and policies adopted in the treatment of relevant typologies of solid wastes in Portugal, in particular, municipal solid wastes and construction and demolition wastes and sewage sludge, and tried to quantify the energetic potential that can be achieved through gasification processes. In addition, a techno-economic study to evaluate the feasibility of the construction and operation of a small-scale gasification plant was also developed. Results indicated that there are various methods which are considered more sustainable for the treatment of such wastes like bio-digestion, pyrolysis and gasification, and which may replace the current techniques of incineration or landfilling that are largely adopted but have caused a number of problems to communities and also to the environment. It was identified a huge potential to valorise these wastes to obtain electricity through gasification, since a significant portion of them are currently disposed of or eliminated in inadequate ways. The economic analysis revealed that it is possible to implement a small-scale gasification plant with financial viability and possible attractive economic results for investors. Construction of these units located in strategic points over the country may contribute for a more sustainable treatment and valorisation of solid wastes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The accelerated growth of industries and the expansion of metropolises have impacted the environment in many ways. Over the past years, a lot of major natural disasters were witnessed. Therefore, it is extremely important to raise awareness in society on the importance of environmental protection. Meanwhile, there are many cities which have found ways in order to be smart/sustainable cities. Smart city is a concept used to define a city which adopts technologies in order to enhance well-being and prevent depletion of natural resources (Snow et al. 2016). Besides, these cities pursue the development of systems that provide energy savings. According to Gutierrez et al. (2015), city managers are working towards the goal of improving both operational efficiency of public municipal services and the quality of people’s life.

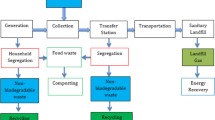

Solid waste management (SWM) is one of the biggest issues that put difficulties to create successful strategic urban plans in cities (Vecchi et al. 2016). The production of waste from human activities is increasing annually and the different types of waste are classified according to their origin, composition and danger, among other criteria. Some of the various classes of solid wastes are municipal solid wastes (MSW), domestic wastes, industrial processing wastes, combustion ash, sewage sludge (SS), commercial wastes, street sweeping, hospital wastes, and construction and demolition wastes (C&DW) (Viegas 2012). Since inadequate waste collection systems along with improper waste disposal can induce great impacts on the environment, SWM is a key factor of successful sustainable development (Cavdar et al. 2016; Vecchi et al. 2016; Alfaia et al. 2017). Some of the main functional elements of SWM are the generation, storage, collection, transportation, processing, recycling, and disposal of wastes (Khan and Samadder 2014).

The European economy conception is largely linear, and this results in negative impacts for the environment and human health, as well as in inefficient use of natural resources. Considering the challenges for waste management, a Circular Economy was developed to integrate both economic activity and environmental well-being in a sustainable way. Moreover, moving to a Circular Economy would deliver benefits at economic, social and environmental levels (European Parliament 2017).

Circular Economy is a strategy developed to integrate both economic activity and environmental well-being in a sustainable way. Basically, its definition is: ‘an economy which balances economic development with environmental and resources protection’ (United Nations 2006). The main goals are to ‘design out’ waste with a view of returning nutrients and recycling durables, and also to make use of renewable energy to power the economy. This idea focuses on optimising entire systems rather than their individual components (Murray et al. 2017). The United Nations Environment Programme report (UNEP) suggests that features of the Circular Economy must include low consumption of energy, low emission of pollutants and high efficiency. It involves the application of Cleaner Production in companies, eco-industrial park development and an integrated resource-based planning for development in industry, agriculture and urban areas (United Nations 2006; Murray et al. 2017).

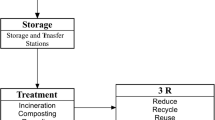

The waste hierarchy aims to improve the sustainability of waste management operations by applying a priority order for them; in this way, this hierarchy prioritizes the prevention, reuse and recycling of wastes over their disposal (Asian Development Bank 2018). Therefore, the 3R strategy (reduce, reuse and recycle) embeds the principles of the circular economy. The European Union Waste Framework Directive 2008/98/EC (European Parliament and Council 2008) sets the basic concepts and definitions related to waste management and introduces recycling and recovery targets to be achieved by 2020 for household waste (50%) and construction and demolition waste (70%). Moreover, the application of 3R aspects on waste management makes it possible to achieve considerable savings on energy and non-renewable natural resources. Studies indicate that depending on the process of recycling, C&DW has potential to increase energy savings in about 20–40% (Dahlbo et al. 2015; Mendoza et al. 2017).

This paper reviews some aspects of the current status of SWM in Portugal, giving special focus on the production and management of MSW, C&DW and SS. The paper also explores the potential of valorisation of these wastes into energy through the use of gasification processes, and at the end, a techno-economic study for a small-scale gasification plant to be integrated in a waste management company is performed, in order to determine its economic feasibility and to define new solutions that can be more environmentally sustainable instead of adopting less advantageous practices like landfilling and incineration. The present study was performed in Polytechnic Institute of Portalegre, Portugal, and was finalised in 2019.

General characteristics of waste management

The amount of generated waste has increased due to the population and urbanisation growth, to the development of manufacturing industries and to the migration of people from rural areas to urban centres. Therefore, an efficient, effective and equitable SWM service plays a key role in the process of sustainable development. This chapter covers the properties, production and management of MSW, SS and C&DW.

Municipal solid waste

MSW is one of the major environmental issues in the world once its inadequate management causes environmental pollution that contributes for the climate change. This pollution is associated with the release of harmful substances during waste treatment and disposal, for example, the generation of dioxins and furans originated from incomplete combustion of wastes. Therefore, MSW management is a basic and fundamental service provided by municipal authorities (Teixeira et al. 2014; Cavdar et al. 2016; Onyanta et al. 2016).

MSW includes domestic waste and waste generated from commercial establishments, services sector and other wastes similar to the domestic ones (Viegas 2012); it contains a variety of materials and end-of-life products. Its physical composition broadly includes organic material, paper and cardboard, plastic, glass, and metals (Vecchi et al. 2016; Alfaia et al. 2017; Martinho et al. 2017).

The European society has grown wealthier with a significant consumerism paradigm, producing more waste than ever before. The average amount of MSW generated by each of about 512 million inhabitants in the European Union (EU) was estimated to be 477 kg per person, during all the year of 2015 (Malinauskaite et al. 2017). The consumption of goods and energy is increasing due to the growth of population and rising standards of living. Therefore, the EU calls for waste management to be transformed into a more sustainable material management which embeds the principles of the circular economy (Malinauskaite et al. 2017).

Due to the rapid depletion of fossil fuel reserves, MSW has been identified as an alternative energy source for mitigating the future energy crisis since it is composed by a high fraction of organic compounds that improve its calorific properties. According to Ng et al. (2014), MSW treatment can reduce environmental impacts and replace a part of primary energy currently supplied by fossil fuels, considering appropriate waste management practices. Within this framework, a variety of processes and technologies promoted the appearance of different solutions for MSW treatment (Magrinho et al. 2006). Therefore, MSW has been studied as a potential energy source that can be used either for electricity or heat generation and has been considered economically viable and environmentally sustainable (Ng et al. 2014; Kumar and Samadder 2017).

Waste-to-energy (WTE) technologies convert waste materials into other types of fuels for energy generation by using thermal or biological processes. However, in many occasions, this conversion is preceded by appropriate pre-treatments like drying, milling and separation, in order to prepare residues for an efficient conversion. There are various technologies which are used to convert solid waste and biomass into useful energy. The major three technologies that can be mentioned are: (1) thermal conversion (incineration, pyrolysis and gasification); (2) biological conversion (anaerobic digestion and composting); and (3) landfilling with gas recovery (Kumar and Samadder 2017). Gasification, for example, is a well-known technology that involves the thermal degradation of biomass and organic solid waste under an oxygen-poor environment, producing a synthesis gas (syngas) which is considered a good source of energy.

Sewage sludge

SS can be included in the MSW category since it is a sub-product obtained during municipal wastewater treatment. Proper management practices applied for this type of waste would prevent pollution and environmental impacts (Cies̈lik et al. 2015; Carrilho and Carvalho 2016). The conventional activated sludge process yields primary sludge in a settling tank, and the excess of activated sludge produced in an aerated tank is commonly referred by sewage sludge (Zhang et al. 2017). In short, every insoluble or absorbed impurities in wastewaters are accumulated in sludge as contaminants. The solid particles are a biologically active mixture of water, organic matter (proteins, carbohydrates, fats and oil), inorganic and organic toxic contaminants (e.g. metallic trace elements and polycyclic aromatic hydrocarbons) and a wide variety of living and dead microorganisms (including pathogens) (Kacprzak et al. 2017; Syed-Hassan et al. 2017).

Biological wastewater treatment plants (WWTP’s) have been employed throughout the world to treat municipal wastewater. Although it is an efficient process to remove organic material, a large amount of sludge is generated. The average annual production of excess sludge is 240 million wet tons in Europe, USA and China when combined together. The main methods for sludge disposal are landfilling, agricultural use and incineration, all incurring in very large costs (e.g. €30–100 per wet ton in Europe) (Wang et al. 2017).

Despite the fact that some quantity of sludge is routinely recycled within the treatment facility process in order to optimise operations, huge quantities of sewage sludge have to be removed from wastewater treatment plants and subsequently have to be correctly managed. In this context, sewage sludge may be a resource to meet the demand for renewable energy due to a rich composition in organic matter, and which gives it interesting calorific properties (Kacprzak et al. 2017).

In order to promote a pro-ecological management of sewage sludge, many directives have been introduced in the European countries which are based on methods leading to waste stabilization and safe recycling, legislation, programs and developmental strategies (Cies̈lik et al. 2015). These methods may consequently lead to the recovery of valuable raw materials from potentially dangerous ones, in order to enable their use in agriculture, industry or heat and energy recovery.

There are two main directions for SS management. In the first one, the organic recycling is associated with the use of this waste as a fertilizer and soil formation, namely in agriculture (direct use as soil fertiliser), reclamation (to restore degraded land), and composting (production of compost for soil fertilisation). On the other hand, SS management may be carried out through the recovery of energy and materials since it presents good fuel properties and mineral fractions for use after thermal transformation. These recovery technologies include incineration (in plants designed only for thermal treatment of sludge as a main feedstock), alternative thermal methods (for solid fuel production) and co-incineration (in cement plants, energy sector and waste incineration plants) (Cies̈lik et al. 2015; Kacprzak et al. 2017).

Construction and demolition waste

The waste originated from the building of new structures, renovation, repair, demolition works, and infrastructure development projects is widely known as C&DW (Marzouk and Azab 2014). This waste is generated worldwide as the result of the increasingly development of the construction industry along with accelerated growth of urbanisation (Li et al. 2017). Therefore, C&DW is becoming a growing concern around the globe once it constitutes a priority waste stream due to the large amounts generated and its high potential for valorisation (Galan et al. 2013; Li et al. 2017).

It is important to examine the interaction among the impacts caused by landfilling and recycling processes for waste disposal aiming to achieve a more sustainable development and a proper C&DW management (Marzouk and Azab 2014). This waste is a highly heterogeneous mixture of materials that typically include metals, concrete, asphalt, mortars, brick, gypsum wallboard, roofing wood, cardboard and plastic (Li et al. 2017). It causes various harmful effects on the environment such as (1) the diminishment of landfill space due to the incremental quantities launched inside them, (2) the increase in contamination caused by landfills that lead to serious negative health effects, and (3) the increase in energy consumption for transportation and manufacturing new materials (Marzouk and Azab 2014). In order to prevent or reduce some of these issues, many techniques of C&DW management and recycling have been studied due to its economic and environmental benefits.

The impact on environment can be minimised by implementing an improvement in the C&DW management and in the related cost during its life cycle. Therefore, the total cost of the process can be composed by five parcels: waste control, collection, transportation, recycling or reuse, and disposal. In this context, the 3R concept is widely employed for C&DW management in order to reduce the impact on the environment. Waste reduction is the optimal management measure which presents the lowest impact on the environment. The latter R-recycling—refers to break down old items to make new materials and objects. The reuse of C&DW is the action of applying building materials again for its original purpose or for a creative reuse, giving it a different function (Huang et al. 2018).

Solid waste management practices

In order to provide a brief framework regarding the current situation of the management of MSW, SS and C&DW, this chapter describes the cases of some developed regions (namely in the EU, United States of America (USA) and Japan), and later focuses on the specific case of Portugal.

Solid waste management in the EU, USA and Japan

Table 1 summarises some relevant data associated with the generation and treatment of MSW, C&DW and SS produced in the regions of EU, USA and Japan.

According to the data that was reported, the USA produced more waste per habitant in the MSW and SS categories, with results of 826 and 24 kg/(hab year), respectively. The generation of C&DW achieved the highest value in the EU [1810 kg/(hab year)], but on the other hand, it was considerably lower in the case of Japan that produced amounts nearly three times smaller.

Regarding the final treatments applied to the waste categories under study, incineration and landfilling still assumed important contributions in the waste management practices, with special focus on MSW and SS. These contributions were greater than 28% when joined together. Since these solutions represent environmental problems and are subjected to legal restrictions that may rise operation costs, there is a possible opportunity to define other waste valorisation solutions with energy production and which have the benefit of being more sustainable (Furness et al. 2000).

The most used waste valorisation practices across all regions were material recycling or reuse (e.g. as fertiliser or for backfilling), and recovery of energy through combustion. For the specific case of MSW, the EU presented the highest material reutilisation ratio through composting, digestion and recycling (46.6%), and also a relevant result for energy recovery through combustion (28%). Landfilling indices were similar to those found in Japan (24.5%) and substantially lower when compared with what happened in the USA (52.3%), despite the fact that this country generated more waste per habitant. Incineration was the most recurring solution to treat MSW in Japan (73%), but it was not clear whether this method was used for energy recovery.

Although the EU exhibited a better performance in terms of waste management when compared with the other regions, it is still far away to achieve the goals stipulated for 2030 (65% for recycling and 10% for landfilling) (European Commission 2019b).

Land fertilisation possessed a strong usage to valorise SS in the EU and USA, contributing with more than 26% in the final destinations applied to this waste. This result is significant, taking into account that legal restrictions, environmental contamination and health problems are connected with the use of SS for fertilisation; therefore, this solution may not be viable in the near future (Furness et al. 2000). In the case of Japan, energy recovery and material recycling through the use of inorganic fractions for construction materials accounted for 24.2% of the final treatments (Ministry of the Environment—Government of Japan 2019). Therefore, the problems caused by the use of SS for fertilisation were minored. Other valorisation alternatives included composting and digestion, as was the case of the EU.

These results suggested that the EU presented better management practices regarding the treatment of SS, especially due to the less significant uses for agriculture fertilisation, incineration and landfilling, which are now considered surpassed and less sustainable.

Analysing the management of C&DW, Japan and the EU exhibited the highest ratios of material recycling (92.8 and 88.4%, respectively); on the contrary, the USA diverted significant amounts of this waste to landfills and combustion (75.4%). While Japan presented the best indicators of waste production per person and management, the USA had a long path to follow towards a more sustainable policy of C&DW management. However, it must be pointed out that data available for the USA are relatively older when compared with the other regions, thus explaining the discrepancies that were observed.

Average compositions of MSW that were generated in the regions under study are pictured in Fig. 1 (for the specific case of Japan, the composition of MSW from Kyoto city was taken as representative).

Composition of MSW varied across the regions and was particularly rich in biodegradable fractions (38.1 wt%), paper/cardboard (29.1 wt%), polymeric materials (15.9 wt%), metallic (5.5 wt%) and other inorganic fractions (5.3 wt%) in average terms. Considering that the organic fractions exhibit potential to be valorised as an energy source, Japan is the region with the best potential to fulfil this purpose since it produced MSW with the greatest fraction of organic materials (93.4 wt%). However, the legislation may restrict this potential as is the situation of the EU, where a waste management hierarchy was established and which prioritises the reutilisation and recycling of materials over energy valorisation processes (European Parliament and Council 2008). Therefore, some of the organic fractions like paper/cardboard and polymeric materials that can be recycled exhibit actually lower amounts available for energetic valorisation.

Figure 2 illustrates the average compositions of C&DW produced in the EU, USA and Japan.

Once again, the composition of this class of waste also varied according to the region under study, and possessed a significant parcel of mineral materials (> 80 wt%). Organic fractions with potential to be energetically valorised constituted a small parcel of C&DW and were mainly composed by wood materials, with fractions ranging from 1 wt% in the EU to 7 wt% in the USA. Thus, the USA showed more resources that can be energetically valorised from C&DW that was produced, in relative terms.

Solid waste management in Portugal

The total production of combined municipal waste, SS and C&DW generated in Portugal corresponded to 7,308,777 tons in 2016, as shown in Fig. 3. Many residual products were made of components with potential to be used in remanufacturing, through the adoption of reusing or recycling processes. Although wastes may not be useful at the moment, they may be in the future after transformation into new products with the same or different functions. The following topics cover the current solid waste management in Portugal and some recovery and recycling alternatives for waste treatment.

Production of municipal waste, SS and C&DW in Portugal for the year 2016 (Instituto Nacional de Estatística 2019)

Municipal solid waste and sewage sludge management in Portugal

Since the 1970s, a broad range of environmental legislation has been elaborated. Through the last three decades the overall trend of MSW management has become a great global issue. In 1997, a Strategic Plan for Urban Waste (PERSU) was created in Portugal due to the appearance of new EU directives, specifically directives 2004/12/EC and 2006/12/EC. The main goals of this strategic plan were: (1) diverting biodegradable MSW components from landfilling to other processes like composting and incineration; (2) the establishment of a commitment to reduce greenhouse gas emissions; (3) the development of resource recovery technologies, investing in units to produce refuse-derived fuel (RDF) (Teixeira et al. 2014).

Later on, the Decree-Law 73/2011 was created in order to establish MSW management options, with the following goals: (1) to strengthen the prevention of waste production by stimulating waste reuse, recycling and recovery; (2) to encourage the collection of organic waste; (3) to clarify and to review the concepts related with the management of MSW; (4) to approve prevention programs that define goals for waste reuse, recycle and recovery until 2020; among others (Teixeira et al. 2014).

MSW management is a system that covers the entire chain from waste production to its final destination (Viegas 2012). Therefore, an integrated management is a key factor in order to avoid or reduce waste production, as well as its harmfulness to human health and to the environment.

Production of urban waste has been associated with the mass consumption of resources in our society. In Portugal, MSW generation per capita had increased since 2013, but it was still lower than the average result of 649 kg/(hab year) observed in the EU (see Fig. 4).

Production of MSW per capita in mainland Portugal between 2011 and 2016 (Instituto Nacional de Estatística 2019)

The Portuguese integrated MSW management embraces collection, sorting, storage, treatment and disposal steps. Collection system includes the transportation of recyclable and non-recyclable wastes. The latter step does not contain recyclable fractions due to the prior sorting and, therefore, the remaining refuses will end up at the dumping ground to be buried. Usually, non-recyclable waste management is a municipal responsibility. On the other hand, management of recyclable wastes can be carried out by either municipalities or private companies (Magrinho et al. 2006; Teixeira et al. 2014). Collection points (eco-points) are outlets for an effective recyclable waste management. Curbside collection (i.e. identified containers) is designed to facilitate the separation of different types of materials such as glass, paper/cardboard, plastic and metal. These containers are placed on easy access points, near shopping malls, schools, parks, pools, sport complexes, markets and fairs. The waste collection vehicles take the waste from these collection points to a transfer station, known as sorting facility (eco-centres), and where waste will be sent to either an alternative waste treatment facility or a landfill (Teixeira et al. 2014).

Recycling of wastes means that separated materials can replace other primary feedstocks and plays a key role in a sustainable society. In 2012, it accounted for around 30% of the total waste produced (Fig. 5). Textile materials are another fraction that has received more attention and is increasingly collected separately, which represented 9% of the total (Avfall Sverige 2018). About 74% of the total urban waste produced corresponded to materials with potential for recovery or recycling operations (Ministério do Ambiente, Ordenamento do Território e Energia 2014). Components found in the Portuguese MSW exhibited similar proportions when compared with the average values from the EU, except for paper/cardboard that possessed a lower value.

Average physical composition of urban waste produced in mainland Portugal (Ministério do Ambiente, Ordenamento do Território e Energia 2014)

In 2014, a total of 4,710,464 ton of municipal waste was produced. Approximately 49% was sent to landfills, 20% to energy recovery solutions and around 30% to other valorisation operations (Fig. 6). A significant amount of waste was eliminated through the deposition in landfills, therefore wasting resources that could be availed in other ways. This amount was also considerably higher than the average result found for the EU (24.5%), a fact that retards the achievement of the EU goals for 2030. Improper waste management such as its disposal in inadequate places can lead to both soil and air pollution. However, waste valorisation practices have been established as an alternative solution for final disposal of waste over the past decade. Materials that can be energetically recovered like the RDF generated at the end of waste treatment lines may contribute to save energy and natural resources, thereby reducing environmental impact.

Final destinations of municipal waste in Portugal, for the year 2014 (Instituto Nacional de Estatística 2019)

Regarding sewage sludge management, the total production in 2017 was fixed at 642,148 ton and was equivalent to 62 kg/(hab year), a result higher than the average reported for the EU [11 kg/(hab year)]. Treatments applied to SS included a combination of processes for their valorisation and elimination. Around 10% was destined to landfill and incineration. Organic valorisation consists on the use of sludge to treat soils for agricultural benefit or environmental improvement. Multi-material valorisation included recycling and recovery of materials, such as the inorganic fractions (see Fig. 7). Other operations included temporary storage of waste, for which the final destination is defined later. Considering that negligible or no quantity of sewage sludge was destined for energetic recovery purposes, there is an opportunity to produce energy from dehydrated sludge using thermochemical processes, for instance.

Treatments applied to SS in Portugal in 2017 (Instituto Nacional de Estatística 2019)

C&DW management in Portugal

C&DW is typically generated in large quantities. A study from 2002 stated that MSW generation in Portugal was around 4,550,000 ton/year, while C&DW production achieved an even greater amount that was fixed at 6,440,000 ton/year (Coelho and Brito 2013). The construction industry is one of the most important sectors for the Portuguese economic and social development, but its activities have a huge impact on the environment (Viegas 2012). In this context, the decree-law 46/2008 was elaborated and established a system for C&DW management that integrate collection, transport, storage, sorting, treatment, and disposal, as well as prevention and/or alternative reuses. Sorting is an important operation since the recovery capacities of wood, glass, plastic, inert wastes, and other materials depend mainly on this stage (Viegas 2012).

C&DW composition consists of fractions of different sizes and components. This composition depends on many factors such as the location of the processes as well as the construction activities, techniques and materials that were used. Inert materials (e.g. concrete, soils and asphalt) accounted for around 81% of the total C&DW that was generated, a result that was lower than the average detected in the EU (95%, see Fig. 8) (Monteiro 2012; Viegas 2012).

Physical composition of C&DW produced in mainland Portugal (Viegas 2012)

Despite the fact that the major fraction corresponded to inert materials, there is a high potential for recycling and reuse of other C&DW fractions (Viegas 2012). Regarding the treatment of non-hazardous waste materials, 66% are adequate for recovery operations (Agência Portuguesa do Ambiente 2015).

The Portuguese Environment Agency is a public institution within the scope of the Portuguese Ministry of the Environment, Territory Management and Energy. In 2010, the Portuguese Environment Agency carried out a survey in 308 municipalities focusing on C&DW production and management, obtaining at the end a response rate of 34%. This survey covered the following specific matters: characterisation of the current C&DW management, the criticality of improper waste disposal and probable reasons, the applicability of the decree-law 46/2008 which regulates the C&DW issues, the development of preventive and remedial actions by supervisory staff, as well as the identification of good management practices.

One-third of these municipalities claimed that no specific C&DW management was conducted, while the remaining carried out some management plans even before the publication of the preceding law (Agência Portuguesa do Ambiente, 2015). Municipalities that performed any C&DW management activity were distributed geographically according to their Commission for Regional Coordination and Development (CRCD, see Fig. 9). This is a decentralized agency of the national government with the purpose of promoting an integrated and sustainable development of Portuguese regions.

Geographical distribution of municipalities that already defined a C&DW management plan prior to the publication of decree-law 46/2008 (Agência Portuguesa do Ambiente 2015)

Avoiding C&DW generation is an impractical measure; however, there are alternative management approaches which can reduce their negative impacts. The solution based on C&DW recycling is still the most recurrent. The internationally accepted framework based on ‘reduce, reuse and recycle’ is highly accepted for the management of C&DW. Due to the diversity and complexity of the different material fractions, to the underdevelopment and high cost of disposal technologies and equipment, and to the costly environment investments, it can be observed that recycled C&DW products possess high prices and consequently cannot achieve interesting sales (Asian Development Bank 2018).

Around 4.53% of the total C&DW produced in 2017 was sent to landfills while almost 93% was destined for valorisation, as shown in Fig. 10. In fact, these results were better than those observed for the EU (11 and 89%, respectively), and almost at the same level of Japan (93% of recycled materials). Other operations were related to temporary storage of waste, for which the final destination is defined later.

Final destinations of C&DW in Portugal, for the year 2017 (Instituto Nacional de Estatística 2019)

Considering that a small fraction of these residues was forwarded to energy generation (0.03%) and that a substantial amount possessed an undefined destiny (c.a. 49%), there is an opportunity to increase the potential of valorisation of C&DW through energy conversion.

Although the management of solid wastes involve government administrative departments, enterprises, construction units, industries, and so forth, some studies have shown that such wastes present potential for energetic recovery, mostly via thermal technologies like gasification (Chiemchaisri et al. 2010; Hwang et al. 2014; Etutu et al. 2016).

Waste-to-energy technologies

A variety of waste conversion processes are available using different WTE technologies. These processes involve the treatment of organic matter present in waste to produce either heat energy, fuel oil or gas (Kumar and Samadder 2017). Anaerobic digestion of sludge is the process by which microorganisms break down biodegradable material without the use of air or elemental oxygen. This process produces two by-products: biogas [mainly composed by methane (55–70%) and carbon dioxide (30–45%)] and a treated effluent that can be used as fertiliser for soils and plants in agriculture. Electricity and heat production from biogas aim to reduce the use of fossil fuels, promoting the generation of a more sustainable energy (Felipe et al. 2018; Tathyana et al. 2018).

Incineration is a treatment process which involves the combustion of waste. Combustion is defined as a highly exothermic chemical reaction, with the occurrence of oxidation of organic substances contained in waste materials at high temperatures (700–1450 °C) and at atmospheric pressure, and with the injection of oxygen. The thermal energy that is produced can be used for electricity generation or to supply heat (Kuo et al. 2008; Lombardi et al. 2015). However, besides the release of typical combustion gases (e.g. H2O, CO2 and N2), other pollutants like volatile heavy metals, organic compounds and particles in the form of ash are also emitted. These must be removed using methodologies and equipment to control air pollution (Kuo et al. 2008; Wu et al. 2014). Due to the fact that pollution control typically represents a significant cost in incineration plants and due to the environmental danger they may represent, incineration presents little society acceptance. Therefore, pyrolysis and gasification are thermal conversion technologies that recently have been widely studied.

Pyrolysis is the thermal decomposition of organic material at high temperatures (300–900 °C) carried out in an oxygen-deficient environment (up to 10% of the stoichiometric amount required for a combustion reaction). The process involves thermal cracking reactions, mass and heat transfer, and leads to the generation of vapours or pyrolytic gases (Teixeira et al. 2014; Raheem et al. 2018). Several solid, liquid and gaseous products are produced and these can be further treated and used as biofuels in processes for obtaining thermal or electric energy. The conversion is essentially effected by endothermic reactions that promote the decomposition of the long molecules of hydrocarbons in the raw materials, and the recombination of simple compounds into the formation of the final products (Manara and Zabaniotou 2012; Chen et al. 2015).

Gasification converts organic compounds into a gas at high temperatures (c.a. 700–900 °C) and with oxygen-deprived environments (typically 25–35% of the stoichiometric ratio for complete combustion). This allows the obtainment of a syngas with suitable properties for energy extraction. This syngas is the main product of gasification and results from incomplete combustion of biomass; it mostly consists of carbon monoxide, hydrogen and traces of methane. This mixture of gases has been successfully applied to run internal combustion engines (compression and spark ignition), or as a substitute for furnace oil in direct heat applications (Monarca et al. 2012; Teixeira et al. 2014; Kumar and Samadder 2017). Many researchers have studied pyrolysis and gasification of wastes (Arena et al. 2010; Chiemchaisri et al. 2010; Luo et al. 2010; Hwang et al. 2014; Teixeira et al. 2014; Hu et al. 2017; Choi et al. 2018).

Gasification has been considered a viable technology due to its greater environmental sustainability. Among all gasification technologies, fluidised-bed reactors are often chosen for their great operating flexibility. Typically, these reactors include a bed of inert materials located at the bottom composed by inert materials (e.g. sand). The bed and wastes are vigorously mixed by a flux of air injected from below, which promotes the turbulent agitation and reaction among the solid and gaseous compounds. The bed may incorporate catalysers like dolomite, olivine and alumina, which improve the gasification efficiency and minimise the generation of undesirable by-products (e.g. tars).

Fluidised-bed reactors possess a series of advantages: the good mixing properties that ensure uniform process conditions, the possibility to utilise various fluidizing agents, and the waste feeding in different positions of the reactor. However, this process also generates other contaminants such as tar, carbonaceous particles and inorganic materials, which lead to an increase in operating costs and efficiency loss (Zaccariello and Mastellone 2015). Typical compositions of the syngas obtained from the gasification of SS and RDF (generated from the last refuses from MSW processing) are shown on Table 2.

Evaluation of the potential of wastes for energy recovery in Portugal

Eliminated solid wastes can be considered an opportunity for energy recovery. Thus, disregarding the inert materials from the total wastes eliminated in Portugal and which were previously described, the remaining fractions have potential for valorisation (Fig. 11).

Both MSW and SS presented a significant fraction which is able to be recovered through a gasification process, and which were fixed around 77% and 63%, respectively. Because SS contained a high moisture content, a drying process is needed before gasification. On the other hand, only 7% of C&DW that was produced was adequate for energy recovery; inert materials represented the majority components in this category of waste.

For the prediction of electric energy produced from these wastes, values of average moisture content, lower heating value (LHV) and yield of syngas were taken into account from some studies regarding gasification. These values are shown in Table 3.

Based on these values, it was possible to estimate the energy which could be generated from gasification, and which resulted from the syngas produced in the process (Fig. 12). It was admitted that the syngas was burnt in an internal combustion engine coupled to an electric generator, with an energy efficiency of 30% (Luz et al. 2015).

The energy production is proportional to the quantity of gasified material, and therefore the highest electric energy production could be obtained from MSW, according to the results (1.504 × 109 kW h). However, SS and C&DW present also considerable values (17.554 × 106 and 3.543 × 106 kW h, respectively). Some variations in the energy production may occur due to the feedstock properties (e.g. amount of moisture) and process performance (e.g. LHV and syngas production); these are more apparent for the situation of SS. There was a significant amount of thermal energy that was generated and not used, and which can be recovered by the gasification process to improve the overall efficiency. This thermal energy may be used, for example, to dry partially the feedstock or to heat the oxidising agent before they enter in the reactor.

It can be concluded that a significant fraction of wastes generated in Portugal can be valorised for energy production through gasification instead of being eliminated by incineration and landfilling, as is the current practice. Gasification of wastes can compensate in certain manner the irregular production from other renewable sources like the sun and the wind, since the availability of wastes does not depend considerably on natural factors.

Case study for a small-scale gasification plant to be implemented in a Portuguese waste management company

Justification for the creation of small-scale gasification units

In spite of generating huge amounts of municipal wastes across the country, the deployment of decentralised small-scale gasification units instead of centralised cores would contribute to evacuate and valorise rapidly and effectively the wastes produced in local areas, as well as to provide energy for small or isolated areas, such as rural communities. In this way, costs associated with the transportation of wastes to gasification facilities may be diminished, as well as the environmental impact caused by the emission of greenhouse gases to the atmosphere. The dependence on the energy supplied by centralised facilities would also be minimised.

Incineration of wastes with energy recovery is viable only for large scale units, apart the environmental and social issues caused by the production of contaminants and odours to the surroundings, and which may increase significantly the expenses required for the implementation and operation of cleaning and decontamination technologies. Stringent regulations in terms of emissions control are being imposed to such facilities (Furness et al. 2000; He et al. 2009). Therefore, small-scale gasification units would overcome problems caused by incineration plants.

Description of the company and relevance of a gasification process integration

A private Portuguese waste management company performed various environmental services by integrating solutions based on the collection and treatment of wastes, as well as on operation and maintenance processes. It carried out services in different environmental areas such as sanitation, washing streets and waste collection, the latter including both SS and C&DW collection.

According to the company records, the total solid wastes that were collected was around 32,513 ton in 2017, and from these an amount of 274 ton (0.8 wt %) incorporated organic fractions that are viable for energy valorisation; these included wood, plastic, paper/card and composite materials that are a mixture of the latter two. Figure 13 illustrates the constitution of this portion of residues.

The company used wood fractions (the major waste material received) in combustion processes to obtain thermal energy for internal activities, and may sell some recyclable fractions (mainly plastics) to other companies specialised in the revitalisation of such materials to generate new feedstocks. The other non-recyclable materials are forwarded to landfills.

These techniques may, however, present some disadvantages: on one hand, the combustion operation may release toxic gases and other sub-products that are harmful for health and environment, and has also a lower efficiency in terms of energy conversion; on the other hand, landfills have high restrictions imposed by local and European laws due to the well-known negative impacts for the environment. In this way, it may be interesting to develop a novel strategy that may replace these practices in order to achieve a higher level of sustainability and competitiveness.

Gasification of the referred combination of residues may be a valid answer since it produces a syngas rich in H2 and CO, which enhance its calorific properties. The syngas can be directly burnt to obtain thermal energy or can be directed to an internal combustion engine coupled to a generator for electricity production. In addition, a gasification unit may be viable for small-scale energy production plant and contaminant emissions are lower when compared with incineration; these advantages may benefit the current company since the amount of residues with potential for energy generation is relatively small.

Before the mixture of wastes is introduced inside the gasifier, it is necessary to prepare them for a correct and efficient process. In this way, milling and drying operations are eligible for this end. A pretreatment of carbonisation at temperatures around 400 °C and employed before those operations may help to obtain a product with a better grindability, homogeneity and interesting fuel properties, thus reducing the premature wear of posterior equipment and eventual costs associated with greater energy consumptions.

However, if a gasification process is selected as a way to valorise the received wastes, it is important to define well the destiny of the generated sub-products, namely tars and chars/ashes. The former can be submitted to biologic or wet oxidation treatments to diminish their toxicity, or even to be directed to a chemical industry in order to extract valuable components such as naphthalene. Chars and ashes may be viable for reuse as adsorption materials for the decontamination of effluents, inhibiting thus their disposal in landfills, as stipulated by European directives.

Economic assessment for the small-scale gasification plant

In order to assess the viability for the construction of a small-scale gasification plant to process the wastes received by the company under analysis, this section is dedicated to perform an economic study for its implementation and to define the optimum conditions of operation. A description of the projected plant, the methodology employed in the study and the main results achieved will be described in the next sections.

Materials and methods

The plant was designed to produce electric energy for sale through the conversion of wastes into syngas considering a downdraft gasifier followed by its burn in an internal combustion engine coupled to an electric generator, with a maximum thermal power production of 1 MW. A downdraft reactor was chosen because it allows the generation of low tar and char amounts, and also due to the shorter duration of start-up (Luz et al. 2015; Molino et al. 2018). Essentially, and as was presumed in the work of (Luz et al. 2015), the plant is composed by six main operating blocks:

A waste separation stage (to remove inert and other strange materials);

A mechanical treatment section (to sieve and grind wastes, and to compact them into briquettes);

A gasification section (to convert briquettes into a product gas inside a downdraft gasifier);

A cleaning section (composed by a cyclone, a filter, a module for thermal cracking and a wet scrubber, to retain fine particulates, tars and gaseous contaminants existing in the product gas);

An electric energy production module (that integrates an internal combustion engine (ICE) connected to an electric generator).

Figure 14 illustrates the connection among all modules and the material fluxes inside the proposed plant.

The plant has capacity to process 250 kg/h of wastes with energetic potential (excluding the major inert fractions), which makes up a total amount of 1850 ton/year of wastes considering a typical operation of 10 month/year. A value of 250 kg/h for waste flow was assumed because it allowed to produce near 1 MW of thermal power inside the reactor; this corresponds to the maximum value that could be chosen in the work of Luz et al. (2015), and in which the current study is based on. As was already mentioned in the previous section, the company received only around 274 ton of wastes during 2017 which is insufficient to ensure the viability of the project. Therefore, it is necessary to acquire other waste fluxes from new sources to make the project economically viable.

Total electric energy generated per year (Eel) was calculated by Eq. 1.

To predict the electric energy available for sale it was necessary to determine the energy consumed for the operation of the plant, which were both calculated through Eqs. 2 and 3.

Determination of the previous variables was done considering the general parameters identified in Table 4.

Economic revenues generated by the plant included the gains with the sale of electric energy to the public grid and the savings achieved by the deviation of waste fluxes to a landfill. The price considered to sell the electric energy was 121.39 €/(MW h), taking into account that this was originated from the conversion of biomass in Portugal (Entidade Reguladora dos Serviços Energéticos 2018). Regarding the charge to deposit wastes in landfills, a value of 9.9 €/ton was used (Agência Portuguesa do Ambiente 2019).

Disbursements that were considered can be divided in capital and operational expenditures (CapEx and OpEx, respectively). CapEx is essentially composed by the investment in the construction and purchase of equipment for the plant.

Table 5 presents the costs associated with the acquisition of equipment for the several sections that compose the facility, already updated to the current year and which were retrieved from Luz et al. (2015).

The updation of costs referred in Table 5 was done through Eq. 4 (Basu 2013).

Iold and Iactual are the values of indexes of producer prices in industry for old (2015) and actual (2018) years, respectively, which were retrieved from Eurostat to perform the conversion of prices among different periods of time (European Commission 2019a). Values considered for both indexes were 100 and 104.8, respectively; in addition, the exchange rate for converting US dollars to Euro was 0.87 €/$US, since the original costs reported by Luz et al. (2015) were expressed in $US.

Costs for the construction of the facility incorporated distinct parcels like installation of equipment, civil works, and engineering, and were estimated by fixed percentages from the total equipment cost. These percentages are mentioned in Table 6.

A working capital cost was also considered for the estimation of CapEx and corresponded to 10% of the sum of equipment and construction costs. Thus, CapEx was estimated by applying Eq. 5, taking into account all the previous data.

For estimating the OpEx, costs associated with personnel, maintenance and operation, and deposition of gasification chars in a landfill were used on a yearly basis. To operate the plant, a team composed by five workers receiving a salary of 600 €/month and working in shifts during approximately 10 month/year was assumed. Maintenance and operation costs were predicted as being equivalent to 5% of CapEx, while costs for forwarding chars to landfills were calculated assuming the waste management tax implemented in Portugal (9.9 €/ton) and a char yield of 0.3 kg/kg of waste after gasification (Luz et al. 2015; You et al. 2016; Agência Portuguesa do Ambiente 2019). OpEx may be therefore calculated using Eq. 6.

Economic indicators that were chosen to evaluate the viability of the project were the net present value (NPV), internal rate of return (IRR) and payback period (PP). The project is considered viable if NPV is greater than zero and the PP has an acceptable lower value compared with the lifetime predicted for the plant, which in the current case was assumed to be t = 20 years (Luz et al. 2015).

NPV was determined through Eq. 7.

In this formula, CFi is the cash flow reported for year i along the lifetime of the plant (i.e. the difference among profits and expenses in year i), and d (discount rate) was assumed to be equal to 15% (Luz et al. 2015).

IRR was calculated taking into account that it is the discount rate that turns NPV equal to zero. When it is necessary to choose the best project among several alternatives considered viable, IRR can help in that decision since higher values indicate that the alternative under analysis generates the best economic results for investors. PP corresponds to the year when the accumulated cash flow for year n (ACFn) is greater than zero, and which by its turn can be found by applying Eq. 8.

For assessing the influence of various operational and economic parameters in the viability of the project, a sensitivity analysis was carried out. The parameters chosen for this analysis were the initial mass of wastes to be processed (kg/year), initial investment or CapEx (€) and price of electricity for sale (€/J), where each one was subjected to a variation in the range of ± 10% relative to the reference values. The viability was studied by examining the results of profits, OpEx, NPV, PP and IRR generated by the different scenarios of parameter variation, in order to determine the best conditions that make the viability optimised.

Results and discussion

Table 7 presents the main results obtained for the economic study around the implementation of a small-scale gasification unit.

For a facility that receives 1850 ton/year of wastes with energetic potential and operating at 250 kg/h during around 10 month/year, the project presents economic viability with a period of return of all the investment fixed at 7 years. This result may be acceptable since it is much lower than the lifetime presumed for the plant (20 years). The project may generate 208,324 €/year of profits and its expenditures are fixed at 581,615 € for CapEx and at 65,428 €/year for OpEx.

To obtain the present results, it must be emphasised the plant must admit an amount of wastes substantially higher that the value currently received and which is around 274 ton/year. In fact, by using such a low amount the project does not gain any kind of viability. The company must therefore acquire new waste fluxes from other sources in order to achieve the suggested amount of 1850 ton/year, which can be accomplished by establishing partnerships with other waste management entities or by amplifying the actual collection chain of residues.

The economic study employed for this particular company can also be extrapolated for other small-scale units scattered around the country, allowing to evacuate waste fluxes for energetic valorisation. This solution may be relevant not only due to the need of giving value to wastes and avoiding their elimination through landfilling or incineration, but also because these units may admit forest woods and residues responsible for fires during the summer period, causing great catastrophes as was recently reported (Cardoso et al. 2018).

Results for the sensibility analysis of PP and IRR through the variation of initial amount of wastes, CapEx and price of electricity relative to the base values previously exhibited are given in Fig. 15.

As expected, PP decreased with the rise of waste mass and price of electricity and also with the declination of CapEx; in a similar fashion, IRR increased with the same variation of all input parameters. The impact of the three parameters in PP and IRR is almost at the same level since the economic indicators always varied in similar intervals (6–9 years and 5–11%, respectively). However, the best results were obtained when CapEx was reduced − 10% relative with the reference case (final value of 523,454 €), generating a PP period of 6 years and an IRR of 10.99%, with the latter being slightly higher than the other scenarios.

Considering that energetic conversion of wastes are gaining an increasing attention by the scientific community and the society, it is expected that in the next years the economic viability for the construction of small-scale gasification units will be improved due to the increasing production of wastes and the possible reduction of investment costs that accompany the maturity of this technology over time. Thus, the implementation of small-scale gasification units across the country and near waste management entities, as described in the present case study, can be considered a viable option for the valorisation of municipal wastes generated at local levels, and with possible investment returns if it is considered the production and sale of electric energy.

Conclusion

Appropriate waste management practices are increasingly important for a society that is in constant evolution and producing more and more residues. Although the problematic of residues is of a great concern for the environment, it is also true that their production can be seen as an opportunity to minimise the dependence on fossil fuels that are disappearing but still constitute an important energy source around the world; in fact, municipal wastes have a good potential for energetic valorisation and, if managed correctly through the adoption of new WTE technologies, it is possible to guarantee a more sustainable environment.

In the specific case of Portugal, higher amounts of wastes are still directed to landfills or to incineration plants, but these solutions have been shown along the time some drawbacks that force the society to look for other strategies that are more environment friendly. Technologies such as gasification, pyrolysis and bio-digestion present a huge potential for implementation along the country, due to the less harmful effects when compared with conventional technologies. In fact, there is a huge potential to valorise such residues for energy production by adopting gasification.

The economic study for the small-scale gasification unit with electricity production revealed that it is feasible for construction and that the total amount of wastes to be processed, initial investment and electricity price have almost the same impact in the viability. Therefore, construction of these units in different points across the country helps in the valorisation of these residues into useful energy and, at the same time, mitigates environmental problems related with inappropriate management or elimination of resources with value.

Abbreviations

- C char :

-

Cost of deposition of gasification chars in a landfill (€/year)

- C equip :

-

Total cost of equipment (€)

- C i :

-

Cost of equipment in year i (€)

- C M&O :

-

Cost of maintenance and operation (€/year)

- C pers :

-

Costs of personnel (€/year)

- CFi :

-

Cash flow for year i (€/year)

- d :

-

Discount rate

- E el :

-

Annual electric energy produced (J/year)

- E el cons :

-

Annual electric energy consumed by the plant (J/year)

- E el sale :

-

Annual electric energy available for sale (J/year)

- E th :

-

Annual thermal energy produced (J/year)

- I i :

-

Index of producer prices in industry for year i, according to Eurostat

- LHVsyngas :

-

Lower heating value of syngas (J/m3)

- m waste :

-

Total amount of waste processed per year (kg/year)

- \(\dot{m}_{\text{waste}}\) :

-

Mass flux of waste (kg/s)

- P plant :

-

Total electric power consumed by the plant (W)

- t op :

-

Annual operating time of the plant (s/year)

- Y syngas :

-

Syngas yield (m3/kg)

- \(\eta_{\text{ICE}}\) :

-

Conversion efficiency of the internal combustion engine

- \(\eta_{\text{reactor}}\) :

-

Thermal efficiency of the gasifier

- C&DW:

-

Construction and demolition waste

- CapEx:

-

Capital expenditures

- CRCD:

-

Commission for regional coordination and development

- EU:

-

European Union

- ICE:

-

Internal combustion engine

- IRR:

-

Internal rate of return

- LHV:

-

Lower heating value

- MSW:

-

Municipal solid waste

- NPV:

-

Net present value

- OpEx:

-

Operational expenditures

- PP:

-

Payback period

- RDF:

-

Refuse-derived fuel

- SWM:

-

Solid waste management

- SS:

-

Sewage sludge

- UNEP:

-

United Nations Environment Programme

- USA:

-

United States of America

- WTE:

-

Waste to energy

- WWTP:

-

Wastewater treatment plant

References

Agência Portuguesa do Ambiente (2015) Como atingir a meta de 70% de valorização de RCD em 2020? http://www.apambiente.pt/_zdata/destaques/2015/DocSuporteBase_Workshop_Valorizacao_RCD_v2.pdf. Accessed 14 July 2019

Agência Portuguesa do Ambiente (2019) Valor da taxa de gestão de resíduos. https://www.apambiente.pt/index.php?ref=16&subref=84&sub2ref=1118&sub3ref=1119. Accessed 24 Mar 2019

Akhtar A, Sarmah A (2018) Construction and demolition waste generation and properties of recycled aggregate concrete: a global perspective. J Clean Prod 186:262–281. https://doi.org/10.1016/j.jclepro.2018.03.085

Alfaia RGSM, Costa AM, Campos JC (2017) Municipal solid waste in Brazil: a review. Waste Manag Res 35(12):1195–1209. https://doi.org/10.1177/0734242X17735375

Arena U, Zaccariello L, Mastellone ML (2010) Fluidized bed gasification of waste-derived fuels. Waste Manag 30(7):1212–1219. https://doi.org/10.1016/j.wasman.2010.01.038

Arena U, Gregorio F, Troia G, Saponaro A (2015) A techno-economic evaluation of a small-scale fluidized bed gasifier for solid recovered fuel. Fuel Process Technol 131:69–77. https://doi.org/10.1016/j.fuproc.2014.11.003

Asian Development Bank (2018) People’s Republic of China: construction and demolition waste management and recycling. https://www.adb.org/sites/default/files/project-documents/48105/48105-001-tacr-en.pdf. Accessed 18 Jan 2019

Avfall Sverige (2018) Swedish waste management 2018. https://www.avfallsverige.se/fileadmin/user_upload/Publikationer/Avfallshantering_2018_EN.pdf. Accessed 14 July 2019

Basu P (2013) Biomass gasification, pyrolysis and torrefaction—practical design and theory, 2nd edn. Academic Press, New York

Bidlingmaier W, Sidaine JM, Papadimitriou EK (2004) Separate collection and biological waste treatment in the European Community. Rev Environ Sci Bio 3:307–320. https://doi.org/10.1007/s11157-004-2334-1

Cardoso J, Silva V, Eusébio D (2018) Techno-economic analysis of a biomass gasification power plant dealing with forestry residues blends for electricity production in Portugal. J Clean Prod 212:741–753. https://doi.org/10.1016/j.jclepro.2018.12.054

Carrilho SMAV, Carvalho EH (2016) Avaliação da disposição de lodos de fossa e tanque sépticos em lagoas de estabilização que tratam lixiviados de aterro sanitário. Engenharia Sanitaria e Ambiental 21(1):183–196. https://doi.org/10.1590/S1413-41520201600100136031

Cavdar K, Koroglu M, Akyildiz B (2016) Design and implementation of a smart solid waste collection system. Int J Environ Sci Technol 13(6):1553–1562. https://doi.org/10.1007/s13762-016-0993-4

Chen D, Yin L, Wang H, He P (2015) Reprint of: pyrolysis technologies for municipal solid waste: a review. Waste Manag 37:116–136. https://doi.org/10.1016/j.wasman.2015.01.022

Chiemchaisri C, Charnnok B, Visvanathan C (2010) Recovery of plastic wastes from dumpsite as refuse-derived fuel and its utilization in small gasification system. Bioresour Technol 101(5):1522–1527. https://doi.org/10.1016/j.biortech.2009.08.061

Choi Y, Ko J, Kim J (2018) Gasification of dried sewage sludge using an innovative three-stage gasifier: clean and H2-rich gas production using condensers as the only secondary tar removal apparatus. Fuel 216:810–817. https://doi.org/10.1016/j.fuel.2017.12.068

Cies̈lik BM, Namies̈nik J, Konieczka P (2015) Review of sewage sludge management: standards, regulations and analytical methods. J Clean Prod 90:1–15. https://doi.org/10.1016/j.jclepro.2014.11.031

Coelho A, Brito J (2013) Economic viability analysis of a construction and demolition waste recycling plant in Portugal—part I: location, materials, technology and economic analysis. J Clean Prod 39:338–352. https://doi.org/10.1016/j.jclepro.2012.08.024

Dahlbo H, Bachér J, Lähtinen K, Jouttijärvi T, Suoheimo P, Mattila T, Sironen S, Myllymaa T, Saramäki K (2015) Construction and demolition waste management—a holistic evaluation of environmental performance. J Clean Prod 107:333–341. https://doi.org/10.1016/j.jclepro.2015.02.073

Entidade Reguladora dos Serviços Energéticos (2018) Proveitos permitidos e ajustamentos para 2019 das empresas reguladas do setor elétrico. http://www.erse.pt/pt/electricidade/tarifaseprecos/2019/Documents/Proveitose/Ajustamentos/2019.pdf. Accessed 24 Mar 2019

Etutu TG, Laohalidanond K, Kerdsuwan S (2016) Gasification of municipal solid waste in a downdraft gasifier: analysis of tar formation. Songklanakarin J Sci Technol 38(2):221–228

European Commision (2019b) Review of waste policy and legislation. https://ec.europa.eu/environment/waste/target_review.htm. Accessed Dec 2019

European Commission (2019a) Eurostat—your key to European statistics. http://ec.europa.eu/eurostat. Accessed Dec 2019

European Parliament (2017) Towards a circular economy—waste management in the EU. http://www.europarl.europa.eu/RegData/etudes/STUD/2017/581913/EPRS_STU%282017%29581913_EN.pdf. Accessed 14 July 2019

European Parliament and Council (2008) Directive 2008/98/EC—on waste and repealing certain directives. Off J Eur Un

Felipe I, Tavares A, Gonçalves T, Baptista P, Mambeli R, Lima S (2018) Resources, conservation & recycling combined use of biogas from sanitary landfill and wastewater treatment plants for distributed energy generation in Brazil. Resour Conserv Recycl 136:376–388. https://doi.org/10.1016/j.resconrec.2018.05.011

Furness DT, Hoggett LA, Judd SJ (2000) Thermochemical treatment of sewage sludge. J CIWEM 14:57–65

Galan B, Dosal E, Andrés A, Viguri J (2013) Optimisation of the construction and demolition waste management facilities location in Cantabria (Spain) under economical and environmental criteria. Waste Biomass Valoriz 4(4):797–808. https://doi.org/10.1007/s12649-013-9196-0

Gutierrez J, Jensen M, Henius M, Tahir Riaz (2015) Smart waste collection system based on location intelligence. Proc Comput Sci 61:120–127. https://doi.org/10.1016/j.procs.2015.09.170

He M, Hu Z, Xiao B, Li J, Guo X, Luo S, Yang F, Feng Y, Yang G, Liu S (2009) Hydrogen-rich gas from catalytic steam gasification of municipal solid waste (MSW): influence of catalyst and temperature on yield and product composition. Int J Hydr Energy 34:195–203. https://doi.org/10.1016/j.ijhydene.2008.09.070

Hu B, Huang Q, Buekens A, Chi Y, Yan J (2017) Co-gasification of municipal solid waste with high alkali coal char in a three-stage gasifier. Energy Convers Manag 153:473–481. https://doi.org/10.1016/j.enconman.2017.10.026

Huang B, Wang X, Kua H, Geng Y, Bleischwitz R, Ren J (2018) Construction and demolition waste management in China through the 3R principle. Resour Conserv Recycl 129:36–44. https://doi.org/10.1016/j.resconrec.2017.09.029

Hwang IH, Kobayashi J, Kawamoto K (2014) Characterization of products obtained from pyrolysis and steam gasification of wood waste, RDF, and RPF. Waste Manag 34(2):402–410. https://doi.org/10.1016/j.wasman.2013.10.009

Instituto Nacional de Estatística (2019) Portal do Instituto Nacional de Estatística—Portugal. http://www.ine.pt. Accessed 18 Apr 2019

Kacprzak M, Neczaj E, Fijałkowski K, Grobelak A, Grosser A, Worwag M, Rorat A, Brattebo H, Almås Å, Singh BR (2017) Sewage sludge disposal strategies for sustainable development. Environ Res 156:39–46. https://doi.org/10.1016/j.envres.2017.03.010

Khan D, Samadder SR (2014) Municipal solid waste management using geographical information system aided methods: a mini review. Waste Manag Res 32(11):1049–1062. https://doi.org/10.1177/0734242X14554644

Khoo HH (2009) Life cycle impact assessment of various waste conversion technologies. Waste Manag 29(6):1892–1900. https://doi.org/10.1016/j.wasman.2008.12.020

Kumar A, Samadder SR (2017) A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag 69:407–422. https://doi.org/10.1016/j.wasman.2017.08.046

Kuo JH, Tseng HH, Rao PS, Wey MY (2008) The prospect and development of incinerators for municipal solid waste treatment and characteristics of their pollutants in Taiwan. Appl Therm Eng 28:2305–2314. https://doi.org/10.1016/j.applthermaleng.2008.01.010

Li Y, Zhou H, Su L, Hou H, Dang L (2017) Investigation into the application of construction and demolition waste in urban roads. Adv Mater Sci Eng. https://doi.org/10.1155/2017/9510212

Lombardi L, Carnevale E, Corti A (2015) A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag 37:26–44. https://doi.org/10.1016/j.wasman.2014.11.010

Luo S, Xiao B, Hu Z, Liu S, Guan Y, Cai L (2010) Bioresource Technology Influence of particle size on pyrolysis and gasification performance of municipal solid waste in a fixed bed reactor. Bioresour Technol 101(16):6517–6520. https://doi.org/10.1016/j.biortech.2010.03.060

Luz FC, Rocha MH, Lora EES, Venturini OJ, Andrade RV, Leme MMV, Olmo OA (2015) Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers Manag 103:321–337. https://doi.org/10.1016/j.enconman.2015.06.074

Magrinho A, Didelet F, Semiao V (2006) Municipal solid waste disposal in Portugal. Waste Manag 26(12):1477–1489. https://doi.org/10.1016/j.wasman.2006.03.009

Malinauskaite J, Jouhara H, Czajczyńska D, Stanchev P, Katsou E, Rostkowski P, Thorne RJ, Colón J, Ponsá S, Al-Mansour F, Anguilano L, Krzyżyńska R, López IC, Vlasopoulos A, Spencer N (2017) Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 141:2013–2044. https://doi.org/10.1016/j.energy.2017.11.128

Manara P, Zabaniotou A (2012) Towards sewage sludge based biofuels via thermochemical conversion—a review. Renew Sustain Energy Rev 16(5):2566–2582. https://doi.org/10.1016/j.rser.2012.01.074

Martinho G, Gomes A, Santos P, Ramos M, Cardoso J, Silveira A, Pires A (2017) A case study of packaging waste collection systems in Portugal—part I: performance and operation analysis. Waste Manag 61:96–107. https://doi.org/10.1016/j.wasman.2017.01.030

Marzouk M, Azab S (2014) Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour Conserv Recycl 82:41–49. https://doi.org/10.1016/j.resconrec.2013.10.015

Mendoza FJC, Altabella JE, Izquierdo AG (2017) Application of inert wastes in the construction, operation and closure of landfills: calculation tool. Waste Manag 59:276–285. https://doi.org/10.1016/j.wasman.2016.10.041

Ministério do Ambiente, Ordenamento do Território e Energia (2014) Portaria. no 187-A/2014 (Plano Estratégico para os Resíduos Sólidos Urbanos). Diário da República 1. a Série, no. 179

Ministry of the Environment—Government of Japan (2019) http://www.env.go.jp/en. Accessed Dec 2019

Molino A, Larocca V, Chianese S, Musmarra D (2018) Biofuels production by biomass gasification: a review. Energies 11(4):1–31. https://doi.org/10.3390/en11040811

Monarca D, Colantoni A, Cecchini M, Longo L, Vecchione L, Carlini M, Manzo A (2012) Energy characterization and gasification of biomass derived by hazelnut cultivation: analysis of produced syngas by gas chromatography. Math Probl Eng. https://doi.org/10.1155/2012/102914

Monteiro H (2012) Resíduos de Construção e Demolição—Estado da Arte. Dissertation, Universidade do Porto

Murray A, Skene K, Haynes K (2017) The circular economy: an interdisciplinary exploration of the concept and application in a global context. J Bus Ethics 140(3):369–380. https://doi.org/10.1007/s10551-015-2693-2

Nakajima S, Futaki M (2001) National R&D project to promote recycle and reuse of timber constructions in Japan. In: Chini AR (ed) Deconstruction and materials reuse: Technology, economic, and policy—Proceedings of the CIB task group 39-Deconstruction meeting, 6 April 2001, Wellington, New Zeland, pp 42–54

Ng WPQ, Lam HL, Varbanov PS, Klemeš JJ (2014) Waste-to-energy (WTE) network synthesis for municipal solid waste (MSW). Energ Convers Manag 85:866–874. https://doi.org/10.1016/j.enconman.2014.01.004

Niu M, Huang Y, Jin B, Sun Y, Wang X (2014) Enriched-air gasification of refuse-derived fuel in a fluidized bed: effect of gasifying conditions and bed materials. Chem Eng Technol 37(10):1787–1796. https://doi.org/10.1002/ceat.201400167

Onyanta A (2016) Cities, municipal solid waste management, and climate change: perspectives from the South. Geographys Compass 10(12):499–513. https://doi.org/10.1111/gec3.12299

Raheem A, Sikarwar VS, He J, Dastyar W, Dionysiou DD, Wang W, Zhao M (2018) Opportunities and challenges in sustainable treatment and resource reuse of sewage sludge: a review. Chem Eng J 337:616–641. https://doi.org/10.1016/j.cej.2017.12.149

Snow CC, Håkonsson DD, Obel B (2016) A smart city is a collaborative community: lessons from smart Aarhus. Calif Manag Rev 59(1):92–108. https://doi.org/10.1177/0008125616683954

Syed-Hassan SSA, Wang Y, Hu S, Su S, Xiang J (2017) Thermochemical processing of sewage sludge to energy and fuel: fundamentals, challenges and considerations. Renew Sustain Energy Rev 80:888–913. https://doi.org/10.1016/j.rser.2017.05.262

Tathyana A, Felca A, Mambeli R, Lúcio G, Filho T, Felipe I, Martuscelli E (2018) Analysis of biogas produced by the anaerobic digestion of sludge generated at wastewater treatment plants in the South of Minas Gerais, Brazil as a potential energy source. Sustain Cities Soc 41:139–153. https://doi.org/10.1016/j.scs.2018.04.035

Teixeira S, Monteiro E, Silva V, Rouboa A (2014) Prospective application of municipal solid wastes for energy production in Portugal. Energ Pol 71:159–168. https://doi.org/10.1016/j.enpol.2014.04.002

United Nations (2006) Circular economy: an alternative model for economic development. http://www.unep.fr/scp/publications/details.asp?id=DTI/0919/PA. Accessed 14 July 2019

USEPA—United States Environmental Protection Agency (2019) https://www.epa.gov. Accessed Dec 2019

Vecchi TPB, Surco DF, Constantino AA, Steiner MTA, Jorge LMM, Ravagnani MASS, Paraíso PR (2016) A sequential approach for the optimization of truck routes for solid waste collection. Process Saf Environ 102:238–250. https://doi.org/10.1016/j.psep.2016.03.014

Viegas S (2012) Caracterização e quantificação de resíduos sólidos urbanos (RSU) e resíduos de construção e demolição (RCD). Dissertation, Universidade Católica Portuguesa

Wang Q, Wei W, Gong Y, Yu Q, Li Q, Sun J, Yuan Z (2017) Technologies for reducing sludge production in wastewater treatment plants: state of the art. Sci Total Environ 587–588:510–521. https://doi.org/10.1016/j.scitotenv.2017.02.203

Wu M, Lin C, Zeng W (2014) Effect of waste incineration and gasification processes on heavy metal distribution. Fuel Process Technol 125:67–72. https://doi.org/10.1016/j.fuproc.2014.03.027

Yamada T, Asari M, Miura T, Niijima T, Yano J, Sakai S (2017) Municipal solid waste composition and food loss reduction in Kyoto City. J Mater Cycles Waste Manag 19:1351–1360. https://doi.org/10.1007/s10163-017-0643-z

Yang R, Xu Z, Chai J (2018) A review of characteristics of landfilled municipal solid waste in several countries: Physical composition, unit weight, and permeability coefficient. Pol J Environ Stud 27(6):2425–2435. https://doi.org/10.15244/pjoes/81089

You S, Wang W, Dai Y, Tong YW, Wang CH (2016) Comparison of the co-gasification of sewage sludge and food wastes and cost-benefit analysis of gasification- and incineration-based waste treatment schemes. Bioresour Technol 218:595–605. https://doi.org/10.1016/j.biortech.2016.07.017

Zaccariello L, Mastellone ML (2015) Fluidized-bed gasification of plastic waste, wood, and their blends with coal. Energies 8(8):8052–8068. https://doi.org/10.3390/en8088052

Zhang Q, Hu J, Lee DJ, Chang Y, Lee YJ (2017) Sludge treatment: current research trends. Bioresour Technol 243:1159–1172. https://doi.org/10.1016/j.biortech.2017.07.070

Zhu JG, Yao Y, Lu QG, Gao M, Ouyang ZQ (2015) Experimental investigation of gasification and incineration characteristics of dried sewage sludge in a circulating fluidized bed. Fuel 150:441–447. https://doi.org/10.1016/j.fuel.2015.02.031

Acknowledgements

Authors are grateful for the financial support provided by Fundação para a Ciência e Tecnologia - Ministério da Ciência, Tecnologia e Ensino Superior (grant no. SFRH/BD/111956/2015), co-financed by Programa Operacional Potencial Humano and União Europeia - Fundo Social Europeu, and also provided by project POCI-01-0145-FEDER-024020 (RDFGAS - Aproveitamento energético dos combustíveis derivados de resíduos e lamas secas), co-financed by COMPETE 2020 - Programa Operacional Competitividade e Internacionalização, Portugal 2020 and União Europeia through FEDER.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and animal rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Editorial responsibility: M. Abbaspour.

Rights and permissions

About this article

Cite this article

Passos, J., Alves, O. & Brito, P. Management of municipal and construction and demolition wastes in Portugal: future perspectives through gasification for energetic valorisation. Int. J. Environ. Sci. Technol. 17, 2907–2926 (2020). https://doi.org/10.1007/s13762-020-02656-6

Received:

Revised:

Accepted:

Published: