Abstract

Butea monosperma leaf powder was used as an adsorbent to remove methylene blue dye from aqueous solution. Different parameters that affect on adsorption such as dye concentration, adsorbent dose, contact time and pH of the solution were analyzed. The suitable dye concentration was found to be 100 mg/l for adsorption experiments. The adsorbent dose and optimum contact time were standardized as 0.5 g/l and 120 min, respectively. The acceptable pH of the medium for adsorption was found as pH = 8. At the standardized environment, the maximum adsorption efficiency of the adsorbent was recorded as 98.70%. The ultra-morphological structure disclosed that the adsorbent had originally rugged surface with empty spaces on it, and after adsorption of the dye, these pores and spaces were filled up with the dye. Fourier transformed infrared spectroscopy chromatogram of the adsorbent shows many downward peaks which can be attributed to the existence of functional groups like C=O, –OH and –NH, etc. The suitably studied isotherm model was the Freundlich model having the correlation coefficient (r2) value of 0.9810. The adsorbent was transferred to the acidic environment (pH 6). At the pH, about 80% adsorbed dye was exuded. The adsorbent can be used for maximum two times for removal of the dye. Therefore, it can be concluded that Butea monosperma leaf powder has potential to remove methylene blue in aqueous solution. The absorbed dye can easily be recovered from adsorbent for reuse purposes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is essential for life. One of the major problems of today is the availability of drinking water (Gupta and Ali 2012). The major cause of water pollution is the anthropogenic activity which includes the discharge of either inadequately or not treated industrial or sewage water to the natural water bodies (Basheer 2018). Besides that the surface runoff water from agriculture field is also a source of water pollution, this water contains a quantifiable amount of pesticides, herbicides and fertilizers. The polluted water degrades aquatic ecosystems and also causes hazardous to public health. The industrial effluents contain both inorganic and organic compounds, even though their ionic forms are depended on the industrial type and utilization of raw material for processing or finishing of their products (Ali and Aboul-Enein 2006). Certain industries release a massive amount of colored water as their effluents, viz. pulp and paper, textile, tannery, plastic, leather, etc. These effluents are being mixed with the natural aquatic system that affect aquatic life and also cause adverse impact to soil micro-flora and micro-fauna. These effluents have also caused toxicological and aesthetical problems. Industries have produced a huge amount of wastewater in their process of production. Therefore, nowadays there is a demand for use of a suitable process or technology to treat the unused water (Ali 2012). Most of the industries use synthetic dyes for coloring their products because these dyes are easily available, low cost and has comparatively high efficiency. The synthetic dyes present in industrial effluents are usually non biodegradable or take a long time for degradation. So synthetic dyes present in effluents must be removed or need to reduce to an acceptable limit before they are discharged to the environment. Today the common methods followed for removal of dyes from industrial effluents are adsorption (Ali et al. 2016a), electro-coagulation (Ali et al. 2012a, b), electro-dialysis (Ali et al. 2011), flocculation (Arami et al. 2006), the ion exchange (Ali and Aboul-Enein 2002), ultra-filtration and reserve osmosis (Chowdhury et al. 2011), but all these methods have their own pitfalls. Though the various water purification and recycling processes are available, use of adsorbent to treat industrial effluents is considered as the quick, less expensive and ubiquitous accepted method (Ali and Gupta 2006; Ali et al. 2018). The effluent of pharmaceutical industries is in general contaminated with drug residues. Some investigators have been reported that iron nano-composite materials can successfully be employed for removal of drugs in aqueous medium (Ali et al. 2016b, c). Moreover, nano-composite materials can also be used as an adsorbent for removal of atrazine pesticide (Ali et al. 2016d), ametryn herbicides (Ali et al. 2016e) and fluoride (Ali et al. 2015) in aqueous medium. Some of the methods have been proven to be an efficient, but limitation is, all these methods are neither economically viable nor feasible for effluent treatment. For example, activated carbon is successfully used for treatment of effluents but the disadvantage of the method is high production cost. Alternately, plant wastes such as banana stalk (Hameed et al. 2008), jack peel waste (Hameed 2009), oil palm trunk fiber (Hameed and El-Khaiary 2008), potato plant waste (Gupta et al. 2016), orange peel (Sivaraj et al. 2001), jute fiber (Senthilkumaar et al. 2005), wheat shells (Bulut and Aydin 2006), soy meal hull (Arami et al. 2006), rice husk (Malik 2003), the activated date pit (Banat et al. 2003), coconut carp (Vieira et al. 2009), bagasse fly ash (Ali et al. 2014) and peanut husk (Song et al. 2011) have been proved as a suitable adsorbent of dyes. Moreover, plants leaves can be used as a suitable adsorbent due to its reproducibility. The adsorbent prepared from plant leaves powder as an adsorbent to remove the dye from industrial effluents has been reported from many plants (Wenga et al. 2009; Sharma and Bhattacharyya 2005; Uddin et al. 2009), but their availability and recovery of the dye are not well studied.

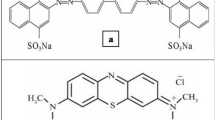

Methylene blue (MB) is a synthetic dye having three benzene rings (Nasuha et al. 2010). It is extensively used in cotton, wood and paper industries for coloring the products. Exposure to high concentration of MB causes burning of eye, sweating, nausea and methemoglobinemia to the human being (Rafatullah et al. 2010). Butea monosperma is a medium-sized dry season deciduous tree, belonging to family fabaceae. It grows to the height of 15 m (Sehrawat and Kumar 2012). The plant has high economic value because of its timber, resin, dye, leaves and medicinal properties (Mishra et al. 2000). The leaves are used for preparation of leaf plates for serving food.

In the current study, an attempt has been made to elucidate the efficiency of Butea monosperma leaf powder (BMLP) as an adsorbent of methylene blue (MB). During the study, various parameters which are affecting on adsorption were standardized.

Materials and methods

Identification and preparation of adsorbents

A full-grown Butea monosperma plant was selected for preparation of adsorbent. Further, the plant was validated at the Department of Botany, Berhampur University, Berhampur. The fresh leaves of the plant were collected for preparation of the adsorbent. The leaves were dried up at 80 °C for 48 h in an oven and then powdered by a domestic mixer and passed through a sieve with 1-mm pores to prepare uniform powder. The leaves powder was cleaned with double distilled water and dried to make them moisture free (Fig. 1). These were kept in a flask for further apply.

Preparation of dye stock solution

Methylene blue (MB) AR grade (chemical formula C16H18N3SCl; FW: 319.86 g/mol; λmax: 620 nm) was obtained from Hi Media Pvt. Ltd., Mumbai. The chemical structure of MB is well established (Chowdhury et al. 2011). The stock solution of the dye was prepared by diluting 1 g of MB in 1 l of double distilled water. Different concentrations of working solutions were prepared by diluting the stock solution with distilled water.

Batch adsorption methods

Parameters affecting on the adsorption process, such as initial dye concentration, absorbent dose, optimum contact time and pH of the solution were investigated. The experiments were conducted in Erlenmeyer flasks (250 ml capacity) with a working volume of 100 ml dye solution. During all the experiments, the flasks were put in a shaker in slow agitation (150 rpm). The adsorption of the dye on the Butea monosperma leaf powder (BMLP) was determined by UV–Vis spectrophotometer at Ao = 620 nm. To determine dye concentration, different dye solutions in a range of 25–200 mg/l were prepared in separate flasks and to each solution 0.5 g/l of adsorbent was added. Other affecting parameters were maintained in optimum condition. The pH of the aqueous solution was maintained in a range of pH 2 to pH 10, and standardized doses (0.5 g/l) of the adsorbents were added to each flask having the standard volume of 100 ml of the aqueous solution. Different doses of BMLP from 0.1 g to 1.0 g/100 ml were added to standardized dye solutions in different containers, and the effect of pH and adsorption of dye were determined. The removal of the dye (in %) by BMLP was calculated by the formula:

Similarly, the adsorption ability of leaf powder was determined by

where \(C_{\text{i}}\) and \(C_{\text{f}}\) are the initial and final concentration of dye, respectively, v = volume of the solution and M = mass of the adsorbent (in g).

The pH of the aqueous solution was altered to acidic (pH = 5), and the utilized adsorbent was incubated in an agitation of 150 rpm for 2 h. The desorption of the dye was determined by UV–Vis spectrophotometer.

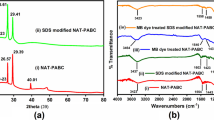

The characterization of BMLP

The ultra-morphology structure of raw and utilized BMLP was analyzed under scanning electron microscopy. The samples were spread in a homogeneous plane and photographed at different magnifications. Similarly, Fourier transmission infrared microscopy (FTIR) study was also made to both leaf powder and adsorbed leaf powder with dye in a range of 400–4000 wavelength cm−1. The chromatogram showing downward peaks was recorded.

Results and discussion

The adsorbent material used to remove methylene blue was Butea monosperma leaf powder (BMLP). Butea is a perennial deciduous tree, native to tropical and subtropical regions of Indian subcontinents. The plant leaves are trifoliate and petiolates. Petioles are long with small stipule. The leaves are leathery; ovoid shaped contains 7–8 pairs of lateral vain (Sumitra et al. 2005). The prepared Butea leaf powder was used for removal of methylene blue from aqueous solution. The repeatedly washing of leaf powder ensured to take out the pigments/metabolites present in it. Thus, the adsorbent at the present contains the hard plant tissues like xylem, phloem and fibers only.

The effect of pH

The adsorption of methylene blue onto the adsorbent was showed low in acidic condition. In the alkaline environment, the adsorption increased and had maximum value at pH 8 (Fig. 2). The acidic solution has a high amount of H+ ions. These ions compete with cationic dye during the adsorption. Thus, the adsorption of the dye was less in acidic solution. Alternately, in the alkaline environment, H+ ions quantity is less and, therefore, there is no hinder for adsorption of the dye onto the adsorbent. Optimum removal of the dye was recorded at pH 8 which was considered as a suitable environment for adsorption. Earlier report indicated that alkaline ambiance also promotes the adsorption of methylene blue onto jack fruit leaves (Hameed and El-Khaiary 2008) and teak leaves (Mishra et al. 2015).

Standardization of the adsorbent dose

To standardize the adsorbent dose for adsorption of the dye, different doses of BMLP such as 0.1–1.0 g were prepared. Each dose was added to 100 mg/l of dye solution in the different flasks. During the investigation, all other factors influencing adsorption were maintained at their optimum condition. The adsorption of dye increased with the increase in adsorbent dose initially, and the values were reached to the maximum at 0.5 g/100 ml. Then they remained constant even though the adsorbent dose increased (Fig. 3). When the BMLP dose was low, all the available spaces were occupied by the dye on BMLP. Thus, the absorption value increased up to saturation of available space on BMLP. Then the value remains constant and, therefore, no further adsorption was increased even though the concentration of dye increased. The optimum adsorbent dose was recorded as 0.5 g/l of BMLP in the 100 ml of methylene blue solution.

Standardization of contact time

To standardize the contact time for maximum adsorption, the mixture of adsorbents and methylene blue solution was kept for the period of 10–200 min. The other factors were maintained at optimum condition during the experiments. The maximum adsorption was achieved at 120 min of incubation (Fig. 4). After due time even though the contact time increased, no further increase in dye adsorption was recorded.

Standardization of dye concentration

Different concentrations of methylene blue in a range of 25–200 mg/l were prepared in different Erlenmeyer flasks, and BMLP of 0.5 g/l of was added to each flask. It was clearly indicated that absorption of the dye increased at lower concentration and at the 100 mg/l of BMLP the adsorption value showed constant (Fig. 5). This is due to limited availability of sites for adsorption of the dye. After saturation attained, no further adsorption was found.

Characterization of BMLP

The ultra-structural morphology and surface topography of BMLP were analyzed by scanning electron microscopy (SEM). The SEM photograph of both raw and the adsorbed BMLP is represented in Fig. 6. The raw BMLP has the heterogeneous surface and considerable number of space for the attachment of the dye. The structure provides a suitable adsorption site for adsorption of methylene blue. The adsorbed BMLP photograph shows that the dye is fully attached to the surface and completely filled up the available surface. The dye was suitably adhered to the surface on BMLP so that the surface of BMLP appeared smooth and shiny.

FTIR analysis

The Fourier transmission infrared (FTIR) analysis of both raw and dye-loaded BMLP is represented (Fig. 7). The FTIR spectrum has a number of downward adsorption peaks, indicating the presence of more number of functional groups (Fuks et al. 2018). The raw adsorbent shows peak at 2916.5 cm−1, 2848.0 cm−1, 1568.3 cm−1, 1338.8 cm−1, 1035.1 cm−1, 884.8 cm−1 and 451.3 cm−1, whereas after adsorption, the BMLP showed the peaks of 2916.8 cm−1, 2848.2 cm−1, 2192.6 cm−1, 1521.7 cm−1, 1054.4 cm−1 and 444.1 cm−1. The peaks of 2916.8 cm−1 and 2848.2 cm−1 wavelength are present in both raw and adsorbed BMLP. It can be interrelated to the existence of the C–O group which has high affinity toward the negative dye. The 1568.3 cm−1 wavelength in raw and 2192.6 cm−1 in adsorbed BMLP can be endorsed to the stretching vibration of the C–O bond. The downshift peak of 1521.7 cm−1 and 1054.4 cm−1 at adsorbed BMLP is due to the presence of –OH group involved in the adsorption of the dye. The downshift of peak 444.1 cm−1 can be accredited to –NH group stretching in the adsorbent.

Adsorption isotherms

To design an adsorption system, the adsorption equilibrium values were analyzed with three popular adsorption isotherm models. The correlation coefficient values (r2) of each model represent the conformity in experimental data. The r2 value of the model close to unity is considered as the most suitable and fitted best model for adsorption.

Langmuir isotherms model

Langmuir proposed that the adsorbent surface contains a number of equivalent sites to which the species are attached either by physisorption or chemisorption. It is assumed that adsorbent surface containing the adsorbing sites is a perfectly flat plane with no corrugations and each site can hold a molecule of adsorbate and there is no interaction between adsorbate molecules on adjacent sites. Adsorbate binding is treated as a chemical reaction between an adsorbate molecules (Am) and an empty site (Es) and the reaction yields an adsorbed complex (Aad) with an associated equilibrium constant Keq. The linear form of the equation is represented as (Dural et al. 2011)

where Qe is the metal ion adsorbed per unit weight of adsorbent (mg/g), Ce is the equilibrium concentration of metal ions in the solution (mg/g), Qm is the monolayer adsorption capacity (mg/g) and KL is the equilibrium constant. The value of Ce/Qe versus Ce for methylene blue is plotted (Fig. 8). From the figure, it is noted that r2 value for methylene blue is 0.8890.

Freundlich isotherms model

The isotherm represents an imperial connection between the solute and adsorbent. The expression is representing the isothermal variation of adsorption of a quantity of material adsorbed by the unit mass of solid adsorbent with pressure. It assumes that the adsorption process takes place on the rough surface and the adsorption ability is related to the concentration of the adsorbate. It is represented as (Hameed 2011).

where kf is a constant which indicates the relative adsorption capacity of the adsorbent (mg/g) and n is an empirical parameter that indicates the intensity of adsorption. The plot of the Freundlich adsorption isotherm model is given in Fig. 9. The plot shows that the correlation coefficient (r2) value of the experiment is 0.9810. The value is nearly to one as compared to other models, and therefore, it is the most favorable model for BMLP as an adsorbent.

BET isotherms model

Brunauer–Emmett–Teller (BET) model explains the physical adsorption of gas molecules on a solid surface (Nethaji et al. 2010). The model is relevant to adsorbent having more than one layer, and the absorbing molecule does not react chemically with adsorbent surfaces. It assumes that there will be no lateral affinity between adsorbent molecules and adsorbent surface. The BET model is represented as

where qe is the adsorbed quantity, ce is the volume of monolayer adsorbed quantity, c is a constant related to the ratio of heats of adsorption for the first layer and second layer and x is p/po, p and po are the equilibrium and the saturation pressure of adsorbates at the temperature of adsorption. The correlation coefficient value (r2) for the dye is 0.8860 (Fig. 10). The maximum efficiency of removal of MB onto BMLP was 98.70%. The acidic condition helps the substations of attached dye from the surface of the adsorbent. It was estimated that about 80% dyes had been recovered. The BMLP can be used for maximum two times as an adsorbent for removal of the methylene blue. When the adsorbent was used for the second time, the adsorption efficiency was reduced to 60%. The cause is that during the detachment of the dye from the adsorbent some of the dye was still attached to the adsorbent. Thus, the efficiency of the adsorbent for the second time is less. Therefore, the prepared adsorbents can be used for two times.

Conclusion

Butea monospermous leaf powder (BMLP) was utilized for removal of methylene blue, a frequently used industrial dye, from aqueous solution. The plant is popular for its medicinal and ornamental values. The leaf of the plant is medium sized and is being used by the local people for preparation of different kinds of leaf plates. The parameters like dye concentration, adsorbent dose, contact time and pH of the solution have been standardized. The suitable pH for removal of dye with BMLP was pH = 8. The optimum adsorbent dose and contact time for removal of the dye are 0.5 g/100 ml and 120 min, respectively. The appropriate dye concentration was the 100 mg/l. The maximum removal efficiency was 98.70%. The Freundlich isotherm model was found to be quite suitable for the prepared adsorbent with the correlation coefficient (r2) value of 0.9810. This indicated that dye was attached to the homogeneous surface of adsorbent. Butea is a tree species and is luxuriantly growing in this locality. It is a deciduous plant so a large number of leaves are shed by the plant. The size of the plant leaves is also moderately large. Hence, the plant leaves can be utilized as a sustainable source for preparation of the adsorbent. Though several reports have been available regarding plant parts, powder form can be utilized as an adsorbent to remove different dyes in aqueous medium, but the efficacy of the adsorbents is very few with more than 95%. The prepared adsorbents are able to remove 98.70% of the dye in aqueous medium. Therefore, it can be concluded from the present investigation that BMLP can suitably be used for removal of methylene blue from the industrial effluents. The adsorbent can be used twice for the removal of the dye.

References

Ali I (2012) New generation adsorbents for water treatment. Chem Rev 112(10):5073–5091

Ali I, Aboul-Enein HY (2002) Speciation of arsenic and chromium metal ions by reversed phase high performance liquid chromatography. Chemosphere 48(3):275–278

Ali I, Aboul-Enein HY (2006) Instrumental methods in metal ion speciation, 1st edn. CRC Press, Boca Raton, pp 1–376

Ali I, Gupta VK (2006) Advances in water treatment by adsorption technology. Nat Protoc 1:2661–2667

Ali I, Khan TA, Asim M (2011) Removal of arsenic from water by electro coagulation and electro dialysis techniques. Sep Purif Rev 40:25–42. https://doi.org/10.1080/15422119.2011.542738

Ali I, Gupta VK, Khan TA, Asim M (2012a) Removal of arsenate from aqueous solution by electro coagulation method using Al–Fe electrodes. Int J Electrochem Sci 7:1898–1907

Ali I, Khan TA, Asim M (2012b) Removal of arsenate from ground water by electro coagulation method. Environ Sci Pollut Res 19(5):1668–1676

Ali I, AL-Othman ZA, Alwarthan AR et al (2014) Removal of arsenic species from water by batch and column operations on bagasse fly ash. Environ Sci Pollut Res 21:3218–3229. https://doi.org/10.1007/s11356-013-2235-3

Ali I, AL-Othman ZA, Sanagi MM (2015) Green synthesis of iron nano-impregnated adsorbent for fast removal of fluoride from water. J Mol Liq 211:457–465. https://doi.org/10.1016/j.molliq.2015.07.034

Ali I, AL-Othman ZA, Alharbi OML (2016a) Uptake of pantoprazole drug residue from water using novel synthesized composite iron nano adsorbent. J Mol Liq 218:465–472. https://doi.org/10.1016/j.molliq.2016.02.088

Ali I, AL-Othman ZA, Alwarthan AR (2016b) Synthesis of composite iron nano adsorbent and removal of ibuprofen drug residue from water. J Mol Liq 219:858–864. https://doi.org/10.1016/j.molliq.2016.04.031

Ali I, AL-Othman ZA, Al-Warthan A (2016c) Sorption, kinetics and thermodynamics studies of atrazine herbicide removal from water using iron nano composite material. Int J Environ Sci Technol 13:733. https://doi.org/10.1007/s13762-015-0919-6

Ali I, AL-Othman ZA, Alwarthan AR (2016d) Green synthesis of functionalized iron nano particles and molecular liquid phase adsorption of ametryn from water. J Mol Liq 221:1168–1174

Ali I, AL-Othman ZA, Alwarthan AR (2016e) Molecular uptake of congo red dye from water on iron composite nano particles. J Mol Liq 224:171–176

Ali I, Alharbi Omar OML, Alothman ZA, Badjah AY, Alwarthan AR, Basheer AA (2018) Artificial neural network modelling of amido black dye sorption on iron composite nano material: kinetics and thermodynamics studies. J Mol Liq 250:1–8. https://doi.org/10.1016/j.molliq.2017.11.163

Arami M, Limaee NY, Mahmoodi NM, Tabrizi NS (2006) Equilibrium and kinetics for the adsorption of direct acid dyes from aqueous solution by soy meal hull. J Hazard Mater 135:171–179

Banat F, Al-Asheh S, Al-Makhadmeh L (2003) Evaluation of the use of raw and activated date pits as potential adsorbents for dye containing waters. Process Biochem 39:193–202

Basheer AA (2018) Chemical chiral pollution: impact on the society and science and need of the regulations in the twenty-first century. Chirality 30(4):402–406. https://doi.org/10.1002/chir.22808

Bulut Y, Aydin H (2006) A kinetics and thermodynamics study of methylene blue adsorption on wheat shells. Desalination 194:259–267

Chowdhury S, Mishra R, Saha P, Kushwaha P (2011) Adsorption thermodynamics, kinetics and isosteric heat of adsorption of malachite green onto chemically modified rice husk. Desalination 265:159–168

Dural MU, Cavas L, Papageorgiou SK, Katsaros FK (2011) Methylene blue adsorption on activated carbon prepared from Posidonia oceanica (L.) dead leaves: kinetics and equilibrium studies. Chem Eng J 168:77–85

Fuks L, Herdzik-Koniecko I, Maskalchuk L, Leontieva T (2018) Clay-salt slimes of the JSC “Belaruskali” as potential engineering barriers in the radioactive waste repositories: sorption of Cs(I), Sr(II), Eu(III) and Am(III). Int J Environ Sci Technol 15:2047–2058

Gupta VK, Ali I (2012) Environmental water—advances in treatment, remediation and recycling, vol 1, 1st edn. Elsevier, Amsterdam, p 232

Gupta N, Kushwaha AK, Chattopadhyaya MC (2016) Application of potato (Solanum tuberosum) plant wastes for the removal of methylene blue and malachite green dye from aqueous solution. Arab J Chem 9(1):S707–S716. https://doi.org/10.1016/j.arabjc.2011.07.021

Hameed BH (2009) Removal of cationic dye from aqueous solution using jackfruit peel as non-conventional low-cost adsorbent. J Hazard Mater 162:344–350

Hameed BH (2011) Grass waste: a novel sorbent for the removal of basic dye from aqueous solution. Desalination 265:159–168

Hameed BH, El-Khaiary MI (2008) Batch removal of malachite green from aqueous solutions by adsorption on oil palm trunk fibre: equilibrium isotherms and kinetic studies. J Hazard Mater 154:237–244

Hameed BH, Mahmoud DK, Ahmad AL (2008) Sorption equilibrium and kinetics of basic dye from aqueous solution using banana stalk waste. J Hazard Mater 158:499–506

Malik PK (2003) Use of activated carbons prepared from sawdust and rice-husk for adsoprtion of acid dyes: a case study of acid yellow. Dyes Pigm 56:239–249

Mishra M, Shukla YN, Kumar S (2000) Euphane triterpenoid and lipid constituents from Butea monosperma. Phytochemistry 54:835–848

Mishra Y, Sowmya V, Shanthakumar S (2015) Adsorption studies of basic dyes onto Teak (Tectona grandis) leaf powder. J Urban Environ Eng 9:102–108

Nasuha N, Hameed BH, Mohddin AT (2010) Rejected tea as a potential low-cost adsorbent for the removal of methylene blue. J Hazard Mater 175:126–132

Nethaji S, Sivasamy A, Thennarasu G, Saravanan S (2010) Adsorption of Malachite Green dye onto activated carbon derived from Borassus aethiopum flower biomass. J Hazard Mater 181:271–280

Rafatullah M, Sulaiman O, Hashim R, Ahmad A (2010) Adsorption of methylene blue on low-cost adsorbents: a review. J Hazard Mater 177:70–80

Sehrawat A, Kumar V (2012) Butein imparts free radical scavenging, anti-oxidative and pro apoptotic properties in the flower extracts of Butea monosperma. Biocell 36:63–71

Senthilkumaar S, Varadarajan PR, Porkodi K, Subbhuraam CV (2005) Adsorption of methylene blue onto jute fiber carbon: kinetics and equilibrium studies. J Colloid Interface Sci 284:78–82

Sharma A, Bhattacharyya KG (2005) Utilization of a biosorbent based on Azadirachta indica neem leaves for removal of water-soluble dyes. Indian J Chem Technol 12:285–295

Sivaraj R, Namasivayam C, Kadirvelu K (2001) Orange peels an adsorbent in the removal of acid violet 17 (acid dye) from aqueous solutions. Waste Manag 21:105–110

Song J, Zou W, Bian Y, Su F, Han R (2011) Adsorption characteristics of methylene blue by peanut husk in batch and column modes. Desalination 265:119–125

Sumitra M, Manikandan P, Suguna L (2005) Efficacy of Butea monosperma on dermal wound healing in rats. Int J Biochem Cell Biol 37(3):566–573

Uddin MT, Rukanuzzaman M, Khan MMR, Islam MA (2009) Jackfruit (Artocarpus heterophyllus) leaf powder: an effective adsorbent for removal of methylene blue from aqueous solutions. Indian J Chem Technol 16:142–149

Vieira AP, Santana SAA, Bezerra CWB, Silva HAS, Chaves JAP, Melo JCP, Filho ECS, Airoldi C (2009) Kinetics and thermodynamics of textile dye adsorption from aqueous solutions using Babassu coconut mesocarp. J Hazard Mater 166:1272–1278

Wenga CH, Linb YT, Tzeng TW (2009) Removal of methylene blue from aqueous solution by adsorption onto pineapple leaf powder. J Hazard Mater 170:417–424

Acknowledgements

The authors wish to thank management of GIET University, Gunupur, for providing laboratory facilities to carry out the investigation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest

Additional information

Editorial responsibility: Necip Atar.

Rights and permissions

About this article

Cite this article

Das, M., Samal, A.K. & Mehar, N. Butea monosperma leaf as an adsorbent of methylene blue: recovery of the dye and reuse of the adsorbent. Int. J. Environ. Sci. Technol. 17, 2105–2112 (2020). https://doi.org/10.1007/s13762-019-02480-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02480-7