Abstract

Heavy metal contamination in polished rice grains collected from Hunan Province, Southern China, has been investigated in this study. The concentrations of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn in rice were determined by microwave-assisted digestion and inductively coupled plasma-mass spectrometry method. In order to evaluate the correlations among heavy metals, statistical analyses including Pearson’s correlation analysis, principal component analysis and hierarchical cluster analysis were performed. Three distinct clusters were classified by the hierarchical cluster analysis approach. In the principal component analysis, three principle components were extracted with the eigenvalue >1.0. The spatial distribution of heavy metals was predicted by the ordinary kriging interpolation. Cu and Ni with similar distribution patterns could be primarily originated from geogenic source. The hot-spot areas in the distribution patterns of Mn, Pb and Zn could be mainly related to mining and smelting activities. Cd and Co might be derived from the combination of natural existence and anthropogenic sources. The chronic non-carcinogenic effect on local rice consumers from exposure to heavy metals was estimated by the target hazard quotient. The average target hazard quotient values of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn were 1.754, 0.367, 0.003, 0.544, 0.165, 0.775, 0.228, 0.049 and 0.481, respectively. The target hazard quotient value of Cd exceeded the threshold value suggesting high potential health risk to residents in Hunan Province through rice consumption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals have attracted considerable attentions in last decades due to their persistent nature and biotoxicity. These pollutants are originated from two sources: natural existence and anthropogenic pollution; the latter one was considered to be the main source accounting for heavy metals in environment (Jia et al. 2017; Karbassi et al. 2014; Ma et al. 2016a; Nasrabadi et al. 2011; Roudposhti et al. 2016). With rapid urbanization and industrialization, the agricultural soils in China have been severely polluted by human activities, such as fuel combustion, mining and smelting processes, waste water irrigation, sewage sludge application, fertilizer usage and solid waste disposal (Fu et al. 2008; Li et al. 2014, 2016; Lu et al. 2012, Wu and Sun 2016). There are several pathways of human exposure to heavy metals in agricultural soil, such as dust inhalation, dermal adsorption, inadvertent soil ingestion and food crops consumption (USEPA 1989). Among them, dietary ingestion of contaminated food was identified to be the most significant pathway (Fu et al. 2008; Liu et al. 2013).

The health risk of heavy metals to human being is not only dependent on the concentration of a particular toxic element, but also relied on the ingestion rate of contaminated food. Long-term exposure to low-level heavy metals might result in malfunction of organs and chronic syndromes due to their long biological half-life (around 15–30 years) and accumulation in human body (Robson et al. 2014). The target hazard quotient (THQ) developed by USEPA (USEPA 1989) is introduced to evaluate chronic non-carcinogenic effect on food consumers. The THQ is defined as a ratio between the estimated intake dose of an investigated contaminant and the reference does (Zheng et al. 2007). As recommended by USEPA, there would be a health risk to local rice consumers if the THQ value is equal or greater than 1.

Paddy rice (Oryza sativa L.) as the staple food of two-thirds of China’s population is considered to be more efficient in accumulating heavy metals than other terrestrial-based foods (Carey et al. 2010). This is due to the cultivated mode of rice plant which increases the bioavailability and mobility of heavy metals in the flooded soils (Williams et al. 2007). Heavy metal accumulations in rice grains have been detected when the rice was cultivated in paddy soils contaminated by heavy metals, such as Cd and Pb (Norton et al. 2014; Wang et al. 2016). The concentrations of Cd and Pb were found up to 0.961 and 0.676 mg/kg, respectively, several times higher than the Chinese maximum contaminant levels (CMCLs) of Cd (0.2 mg/kg) and Pb (0.2 mg/kg) in paddy rice (China Food Standard Agency 2012). Consumption of rice and its product in China, especially in Southern China, is regarded as the main route of the people exposure to heavy metals. Therefore, it is important to ensure rice safety for inhabitants.

Hunan Province, located in Southern China, is one of the largest rice production base in China. Moreover, this province was considered to be the nonferrous center for mining and smelting in Southern China. The agricultural soils in Hunan Province were reported to be remarkably polluted by heavy metals due to long-time mining and smelting activities (Liu et al. 2005; Ma et al. 2015). Heavy metal contents in rice grains from Hunan Province, China, have been investigated in this study. Primarily, the concentrations of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn in the collected rice samples were determined. Secondly, the inter-element relationship and spatial variability of heavy metals in the rice samples were characterized by statistical and geostatistical methods. Furthermore, the non-carcinogenic health risk to local rice consumers from heavy metal exposure was estimated. The research was carried out at Central South University, China, from July 2015 to April 2016.

Materials and methods

Sample collection and preparation

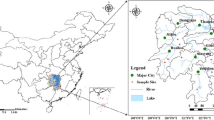

Polished rice grains were collected from 46 sampling sites throughout Hunan Province during July to November, 2015. The detailed sampling information is illustrated in Table S1 and Fig. 1. In each sampling site, 3–5 subsamples were harvested from separated small paddy fields and then mixed thoroughly into one sample. After sent to the laboratory, the rice samples were dried in an oven at 50 °C for 24 h. Then the dried samples were ground thoroughly and passed through a 0.15-mm sieve to obtain homogeneous powders. Before digestion, all the powders were sealed into polyethylene bags and stored in a desiccator.

Heavy metal analysis

The powdered rice sample (0.500 g) was precisely weighed into a polytetrafluoroethylene (PTFE) digestion vessel and was immersed by a mixture of 10 mL of concentrated nitric acid (HNO3, 70%wt, ≥99.999% metal basis, Aladdin Reagent Co. Ltd, China) and 2 mL of hydrogen peroxide (H2O2, 30%wt, guaranteed reagent grade, Aladdin Reagent Co. Ltd, China). A microwave-assisted digestion system (MDS-6G, Sineo Microwave Chemistry Technology Co. Ltd, Shanghai, China) was introduced for sample digestion according to the following program (Ma et al. 2016b): 10 min to 120 °C, 10 min to 190 °C and 30 min at 190 °C. The cooled digested solution was diluted into 25 mL with deionized water (18.2 MΩ cm, Direct-Q 3, Millipore SAS, France) and kept at 4 °C before analysis within 48 h. For each batch of sample preparation, a method blank was performed throughout the whole pretreatment process. The concentrations of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn were determined by inductively coupled plasma-mass spectrometry (ICP-MS, Agilent 7700x, Tokyo, Japan). Due to the interference of carbon (e.g., 40Ar12C+) with 52Cr on m/z 52, a collision/reaction cell was introduced to minimize the influence (Sun et al. 2015). The method detection limits (MDLs) were 0.3, 0.5, 7, 3, 17, 3, 2, 1 and 80 μg/kg for Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn, respectively. Certified reference material (CRM) GBW-10045 rice flour (CRM/RM Information Center, Beijing, China) was employed to verify the digestion efficiency. The recoveries of all the investigated heavy metals were in the range of 88–110%.

Statistical and geostatistical analysis

Statistical analyses including Pearson’s correlation analysis, principal component analysis (PCA) and hierarchical cluster analysis (HCA) were chosen to investigate inter-element relationships and possible origins of heavy metals in the rice grains. The association strength between two sets of heavy metal concentrations was measured by the Pearson’s correlation coefficient. PCA was employed to reduce the dimension of variables and extract a fewer number of principle components (PCs) according to the eigenvalue >1.0 (Lee et al. 2006). The rotation method applied in this study was Varimax with Kaiser Normalization. The purpose of HCA was to categorize heavy metals into different clusters using Ward’s methods. The distance between two clusters was measured by squared Euclidean. The statistical analysis was performed using SPSS software for windows (v.13.0, IBM corp.). Geostatistical analysis performed by geography information system (GIS) software in this study was to investigate spatial distributions of heavy metals in the rice samples. Kriging considered as the best spatial covariance interpolation method is a geostatistical interpolation method using the semivariogram to quantify the spatial variability of regionalized variables (Chen et al. 2014). A suitable theory model and parameters for spatial interpolation were obtained through analysis of the semivariogram (Chen et al. 2008). In this study, the distribution maps were plotted using ordinary kriging interpolation technique to predict heavy metal concentrations at unsampled or unmeasured locations.

Risk assessment

Human exposure to heavy metals from ingestion of rice was assessed by estimated daily ingestion (EDI), which was expressed according to the equation as follows:

where EDI i (mg/BWkg day) is the estimated daily intake of heavy metal i, C i (mg/kg) is the concentration of heavy metal i in rice grains, DI (kg/day) is daily ingestion rate of rice and BW (BWkg) is average body weight of local consumer.

The potential health risk to rice consumer was calculated using the equation as follows (Islam et al. 2014):

where THQ i is the target hazard quotient of heavy metal i, RfDo i (mg/BWkg day) is the oral reference dose for heavy metal i, EF (days/year) is the exposure frequency, ED (year) is the exposure duration and AT (day) is the average exposure time to toxic substances (Ma et al. 2002).

In order to estimate the additive health risk from exposure to all the investigated heavy metals, the hazard index (HI) was employed using the following equation (USEPA 1986):

The average daily ingestion rate and body weight of an adult were 0.425 kg/day and 58.1 kg, respectively, in Hunan Province (Ma et al. 2016c). The EF, ED and AT selected in this study were 365 days/year, 70 years and 25,550 days, respectively. The uncertainty of the index of THQ and HI was conducted through Monte Carlo simulation (Jia et al. 2016; Ma et al. 2017a), which was performed by the Crystal Ball software.

Results and discussion

Heavy metal concentrations in rice grains

The descriptive statistics was applied to summarize the heavy metal concentrations, and the results are profiled in Table 1. The maximum values of Cu, Pb and Zn were 6.292, 0.089 and 31.535 mg/kg, respectively, lower than the CMCLs (10 mg/kg for Cu, 0.2 mg/kg for Pb and 50 mg/kg for Zn) in paddy rice (China Food Standard Agency 2012), which means there was no obvious Cu, Pb or Zn pollution in the study area. Although the mean value of Cr (0.644 mg/kg) in the rice was lower than the CMCLs (1.0 mg/kg), the maximum value of Cr (4.226 mg/kg) was 4 times higher which meant Cr pollution might exist in some subareas. The mean value of Cd (0.240 mg/kg) was higher than the CMCLs (0.2 mg/kg). The Cd level in rice was found to be proportional to the concentration of Cd in the paddy soils (Wang et al. 2016). However, the Cd content in rice grains was also influenced widely by other factors such as rice cultivars, agricultural conditions and soil properties (Li et al. 2012). The normality of heavy metal distributions in the rice was examined by one-sample Kolmogorov–Smirnov (K–S) test. Co, Cu, Mn, Ni, Pb and Zn with p > 0.05 were considered to be normal distributed in the study area. Oppositely, Cd, Cr and Fe with p < 0.05 could not pass the test for normality. The coefficients of variation (CV) were found to be large (>30%) in most of the heavy metals (except Zn) indicating wide variation of concentrations in the locally grown rice.

Statistical analysis

Table 2 shows the Pearson’s correlation matrix with significant level at right upper part and correlation coefficient at left lower part. Co was found to be positive correlated with Cr (r = 0.412), Fe (r = 0.409), Mn (r = 0.522), Ni (r = 0.431) and Zn (r = 0.413) at the p < 0.01 level. Positive significant correlations at the p < 0.01 level were also found between Cd and Ni (r = 0.457), Cr and Fe (r = 0.814), Cu and Ni (r = 0.667), and Mn and Zn (r = 0.609). Positive correlations with significance at 0.05 level were observed between Cd and Cu (r = 0.366), Co and Pb (r = 0.293), and Ni and Pb (r = 0.321). Heavy metals with significant correlations could not always expect to be a common source (Zhou et al. 2014). Nevertheless, useful information on origin and uptake pathway of heavy metals in rice could be derived from the result of relationships.

Before the PCA approach, KMO measure and Bartlett’s test were employed to examine the sampling adequacy and sphericity. The KMO value and Bartlett’s test significance obtained were 0.535 and <0.001, respectively, indicating that the PCA was valid in this study (Ma et al. 2017b). As presented in Table 3, four PCs were extracted from the PCA approach with the eigenvalue >1.0. PC1 with positive and strong loading by Cr (0.919) and Fe (0.949) explained 23.1% of the total variance. PC2 explained 22.8% of the total variance and was characterized by strong loading of Cd, Cu and Ni, whose coefficients were 0.693, 0.860 and 0.863. PC3 explained 21.9% of the total variance and was strongly loaded by Co (0.571), Mn (0.858) and Zn (0.887). PC4 explaining 13.0% of the total variance was strongly loaded by Pb with the coefficient of 0.909.

Figure 2 shows the dendrogram generated from HCA approach. Four distinct clusters corresponding to four PCs were identified on the basis of Ward’s method and squared Euclidean distance. Cr and Fe classified into Cluster 1 (C1), which corresponded to PC1 and could be primarily associated with the natural origin. Cluster 2 (C2) corresponding to PC3 included Co, Mn and Zn, which could be mainly originated from anthropogenic sources, such as mining and smelting activities. Pb categorized into Cluster 3 (C3) individually was derived from mining activities. Cluster 4 (C4) corresponding to PC 2 consisted of Cd, Cu and Ni, which could be associated with a combination of geogenic and anthropogenic sources.

Spatial distribution and source identification

The spatial distributions of the investigated heavy metals in the rice samples were predicted using ordinary kriging interpolation technique. The contour maps of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn are demonstrated in Fig. 3.

As illustrated in Fig. 3c and e, similar spatial distributions were found for Cr and Fe with concentrations at the northeast corner and low concentrations at other regions of Hunan Province. The result was in agreement with the PCA and HCA approaches. Significant correlation between Cr and Fe was attributed to their similar physical and chemical properties. As trivalent cations in nature, Cr and Fe could be mainly derived from the natural existence and shared same uptake route from soil into rice.

As presented in Fig. 3d and g, the spatial distributions of Cu and Ni showed similar trend with high concentrations at the northeast region and low concentrations at the southwest region. The uptake of heavy metals from soil solution to rice plant is complex, depending on many factors such as soil pH, organic matter, redox potential, hydrological conditions and cation exchange capacity (Zeng et al. 2011). The distribution of Cu and Ni in the collected rice grains could be influenced by soil properties and agricultural conditions. Although Cd was classified into C3 in the HCA and PC3 in the PCA same as Cu and Ni, the counter map of Cd (Fig. 3a) was different from the others. Relatively high concentration of Cd was located at the northwest, middle and east regions, which means human activities made a contribution to the Cd concentration. As mentioned before, the Cd contamination in Hunan Province was mainly derived from nonferrous mining and smelting activities.

The distribution patterns of Mn, Pb and Zn shown in Fig. 3f, h and i, respectively, were similar while high concentrations at the east or southeast region and low concentrations at the west or northwest region. When grown in mine impacted region, the rice plants were observed to be more efficient to accumulate heavy metals in the grains (Williams et al. 2009). The hot-spot areas in the distribution patterns of Mn, Pb and Zn could be mainly related to mining and smelting activities (Liao et al. 2005, Williams et al. 2009). Co was classified into same groups as Mn, Pb and Zn in the HCA approach, whereas the distribution pattern of Co was distinctly different from Mn, Pb and Zn. This result implied that the accumulation and translocation of Co might be affected by various factors. Co should be originated from a combination of geogenic and anthropogenic sources.

Risk assessment

Dietary exposure to heavy metals for local rice consumers was estimated as listed in Table 4. The average EDI from rice consumption was 1.8 × 10−3, 1.1 × 10−4, 4.7 × 10−3, 2.2 × 10−2, 1.2 × 10−1, 1.1 × 10−1, 2.5 × 10−3, 2.0 × 10−4 and 1.4 × 10−1 mg/BWkg day for Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn, respectively. Furthermore, the potential health risk to the rice consumers was evaluated through the index of THQ. The RfDo for heavy metals is listed in Table 4 (USEPA 2015; Yipel and Yarsan 2014). Due to no Cr(VI) species detected in any plant samples (Novotnik et al. 2013), the RfDo for Cr in risk assessment was regarded to be the same as Cr(III) species, 1.5 mg/BWkg day. The average THQ values of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn were 1.754, 1.001, 0.003, 0.544, 0.165, 0.775, 0.228, 0.049 and 0.481, respectively. As recommended by USEPA, the THQ value higher than 1.0 would pose significant chronic health risk to residents consuming the corresponding food (USEPA 1989). For exposure to individual heavy metal, only the mean value of THQ for Cd exceeded the threshold value, suggesting high potential chronic health risk to residents in Hunan Province through rice consumption. The uncertainty of THQs was estimated through Monte Carlo simulation (Table S2). The distribution patterns of THQs are illustrated in Figure S1. The mean, 5th, 50th and 95th percentile values of THQs derived according to the probabilistic modeling are summarized in Table 4. The THQ at the 95th percentile for Cr, Cu, Fe, Ni, Pb and Zn was lower than 1, indicating no particular health risk to over 95% of consumers from exposure to these elements individually. However, the THQ at the 95th percentile for Co and Mn was higher than 1, representing there is a detectable health risk to over 5% of consumers. The HI was calculated as sum of THQs. The uncertainty of HI was evaluated through Monte Carlo simulation as well, and the distribution pattern is demonstrated in Figure S2. The mean, median, 5th and 95th percentile values of HI were 5.160, 4.908, 3.036 and 8.138, respectively, higher than the threshold value. The spatial distribution of HI demonstrated in Fig. 4 was similar with Cu (Fig. 3d) and Ni (Fig. 3g). The pattern showed relatively high potential health risk at northeast region, especially around the Lake Dongting and the Cities of Changsha, Xiangtan and Zhuzhou. The HI value declined from northeast to southwest.

Conclusion

In this study, heavy metal contamination of polished rice grains grown in Hunan Province, Southern China, has been investigated. A total of 46 rice samples were collected throughout the study area. The concentrations of Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn in rice samples were determined by the ICP-MS method. The mean concentration of Cd in the samples was higher than the CMCLs, indicating possible Cd pollution in corresponding paddy soils. As the result of Pearson’s correlation analysis, positive correlations with significance at 0.01 level were observed between Co and Cr (r = 0.412), Co and Fe (r = 0.409), Co and Mn (r = 0.522), Co and Ni (r = 0.431), Co and Zn (r = 0.413), Cd and Ni (r = 0.457), Cr and Fe (r = 0.814), Cu and Ni (r = 0.667), and Mn and Zn (r = 0.609). In the PCA approach, three PCs were extracted according to the eigenvalue >1.0. Co, Mn and Zn were strongly loaded (>0.6) on PC1; Cr and Fe were strongly loaded (>0.9) on PC2; and Cd, Cu and Ni were strongly loaded (>0.65) on PC3. In the HCA approach, three distinct clusters were found while C1 consisted of Cr and Fe, C2 consisted of Co, Mn, Pb and Zn, and C3 consisted of Cd, Cu and Ni. The spatial distributions of heavy metals were predicted by the ordinary kriging interpolation. Cu and Ni with similar distribution patterns could be primarily originated from geogenic source. The hot-spot areas in the distribution patterns of Mn, Pb and Zn could be mainly related to mining and smelting activities. Cd and Co might be derived from the combination of natural existence and anthropogenic sources. The chronic non-carcinogenic effect on local rice consumers from exposure to heavy metals was estimated by the target hazard quotient (THQ). The mean value of THQ for Cd exceeded the threshold value suggesting high potential health risk to residents in Hunan Province through rice consumption.

References

Carey A-M, Scheckel KG, Lombi E, Newville M, Choi Y, Norton GJ, Charnock JM, Feldmann J, Price AH, Meharg AA (2010) Grain unloading of arsenic species in rice. Plant Physiol 152:309–319

Chen T, Liu X, Zhu M, Zhao K, Wu J, Xu J, Huang P (2008) Identification of trace element sources and associated risk assessment in vegetable soils of the urban–rural transitional area of Hangzhou, China. Environ Pollut 151:67–78

Chen H, Lu X, Li LY, Gao T, Chang Y (2014) Metal contamination in campus dust of Xi’an, China: a study based on multivariate statistics and spatial distribution. Sci Total Environ 484:27–35

China Food Standard Agency (2012) Maximum levels of contaminants in foods (GB 2762). Ministry of Health of China, Beijing

Fu J, Zhou Q, Liu J, Liu W, Wang T, Zhang Q, Jiang G (2008) High levels of heavy metals in rice (Oryza sativa L.) from a typical E-waste recycling area in southeast China and its potential risk to human health. Chemosphere 71:1269–1275

Islam MS, Ahmed MK, Habibullah-Al-Mamun M (2014) Heavy metals in cereals and pulses: health implications in bangladesh. J Agric Food Chem 62:10828–10835

Jia Y, Kong Q, Yang Z, Wang L (2016) Accumulation behavior and risk assessment of heavy metals and arsenic in tissues of white bream (Parabramis pekinensis) from the Xiang River, southern China. Environ Sci Pollut Res 23:25056–25064

Jia Y, Wang L, Qu Z, Wang C, Yang Z (2017) Effects on heavy metal accumulation in freshwater fishes: species, tissues, and sizes. Environ Sci Pollut Res 24:9379–9386

Karbassi A, Nasrabadi T, Rezai M, Modabberi S (2014) Pollution with metals (As, Sb, Hg, Zn) in agricultural soil located close to zarshuran gold mine, iran. Environ Eng Manag J 13:115–120

Lee CS, Li XD, Shi WZ, Cheung SC, Thornton I (2006) Metal contamination in urban, suburban, and country park soils of Hong Kong: a study based on GIS and multivariate statistics. Sci Total Environ 356:45–61

Li Q, Chen Y, Fu H, Cui Z, Shi L, Wang L, Liu Z (2012) Health risk of heavy metals in food crops grown on reclaimed tidal flat soil in the Pearl River Estuary, China. J Hazard Mater 227–228:148–154

Li W, Xu B, Song Q, Liu X, Xu J, Brookes PC (2014) The identification of ‘hotspots’ of heavy metal pollution in soil–rice systems at a regional scale in eastern China. Sci Total Environ 472:407–420

Li PY, Li XY, Meng XY, Li MN, Zhang YT (2016) Appraising groundwater quality and health risks from contamination in a semiarid region of northwest China. Expo Health 8:361–379

Liao X-Y, Chen T-B, Xie H, Liu Y-R (2005) Soil As contamination and its risk assessment in areas near the industrial districts of Chenzhou City, Southern China. Environ Int 31:791–798

Liu H, Probst A, Liao B (2005) Metal contamination of soils and crops affected by the Chenzhou lead/zinc mine spill (Hunan, China). Sci Total Environ 339:153–166

Liu X, Song Q, Tang Y, Li W, Xu J, Wu J, Wang F, Brookes PC (2013) Human health risk assessment of heavy metals in soil–vegetable system: a multi-medium analysis. Sci Total Environ 463–464:530–540

Lu A, Wang J, Qin X, Wang K, Han P, Zhang S (2012) Multivariate and geostatistical analyses of the spatial distribution and origin of heavy metals in the agricultural soils in Shunyi, Beijing, China. Sci Total Environ 425:66–74

Ma H-w, Lai Y-L, Chan C-C (2002) Transfer of dioxin risk between nine major municipal waste incinerators in Taiwan. Environ Int 28:103–110

Ma L, Sun J, Yang Z, Wang L (2015) Heavy metal contamination of agricultural soils affected by mining activities around the Ganxi River in Chenzhou, Southern China. Environ Monit Assess 187:731–740

Ma L, Yang Z, Li L, Wang L (2016a) Source identification and risk assessment of heavy metal contaminations in urban soils of Changsha, a mine-impacted city in Southern China. Environ Sci Pollut Res 23:17058–17066

Ma L, Wang L, Tang J, Yang Z (2016b) Optimization of arsenic extraction in rice samples by Plackett–Burman design and response surface methodology. Food Chem 204:283–288

Ma L, Wang L, Jia Y, Yang Z (2016c) Arsenic speciation in locally grown rice grains from Hunan Province, China: spatial distribution and potential health risk. Sci Total Environ 557–558:438–444

Ma L, Yang Z, Kong Q, Wang L (2017a) Extraction and determination of arsenic species in leafy vegetables: method development and application. Food Chem 217:524–530

Ma L, Wang L, Tang J, Yang Z (2017b) Arsenic speciation and heavy metal distribution in polished rice grown in Guangdong Province, Southern China. Food Chem 233:110–116

Nasrabadi T, Bidhendi GN, Karbassi AR, Grathwohl P, Mehrdadi N (2011) Impact of major organophosphate pesticides used in agriculture to surface water and sediment quality (Southern Caspian Sea basin, Haraz River). Environ Earth Sci 63:873–883

Norton GJ, Williams PN, Adomako EE, Price AH, Zhu Y, Zhao F-J, McGrath S, Deacon CM, Villada A, Sommella A, Lu Y, Ming L, De Silva PMCS, Brammer H, Dasgupta T, Islam MR, Meharg AA (2014) Lead in rice: analysis of baseline lead levels in market and field collected rice grains. Sci Total Environ 485–486:428–434

Novotnik B, Zuliani T, Scancar J, Milacic R (2013) Chromate in food samples: an artefact of wrongly applied analytical methodology? J Anal At Spectrom 28:558–566

Robson TC, Braungardt CB, Rieuwerts J, Worsfold P (2014) Cadmium contamination of agricultural soils and crops resulting from sphalerite weathering. Environ Pollut 184:283–289

Roudposhti GM, Karbassi A, Baghvand A (2016) A pollution index for agricultural soils. Arch Agron Soil Sci 62:1411–1424

Sun J, Yang Z, Lee H, Wang L (2015) Simultaneous speciation and determination of arsenic, chromium and cadmium in water samples by high performance liquid chromatography with inductively coupled plasma mass spectrometry. Anal Methods 7:2653–2658

USEPA (1986) Guidelines for the health risk assessment of chemical mixtures. United States Environmental Protection Agency, Washington

USEPA (1989) Risk assessment guidance for superfund: volume I-human health evaluation manual (Part A). United State Environmental Protection Agency, Washington

USEPA (2015) Regional screening level (RSL) summary table. United States Environmental Protection Agency, Washington

Wang M, Chen W, Peng C (2016) Risk assessment of Cd polluted paddy soils in the industrial and township areas in Hunan, Southern China. Chemosphere 144:346–351

Williams PN, Villada A, Deacon C, Raab A, Figuerola J, Green AJ, Feldmann J, Meharg AA (2007) Greatly enhanced arsenic shoot assimilation in rice leads to elevated grain levels compared to wheat and barley. Environ Sci Technol 41:6854–6859

Williams PN, Lei M, Sun G, Huang Q, Lu Y, Deacon C, Meharg AA, Zhu Y-G (2009) Occurrence and partitioning of cadmium, arsenic and lead in mine impacted paddy rice: Hunan, China. Environ Sci Technol 43:637–642

Wu JH, Sun ZC (2016) Evaluation of shallow groundwater contamination and associated human health risk in an alluvial plain impacted by agricultural and industrial activities, mid-west China. Expo Health 8:311–329

Yipel M, Yarsan E (2014) A risk assessment of heavy metal concentrations in fish and an invertebrate from the Gulf of Antalya. Bull Environ Contam Toxicol 93:542–548

Zeng F, Ali S, Zhang H, Ouyang Y, Qiu B, Wu F, Zhang G (2011) The influence of pH and organic matter content in paddy soil on heavy metal availability and their uptake by rice plants. Environ Pollut 159:84–91

Zheng N, Wang Q, Zhang X, Zheng D, Zhang Z, Zhang S (2007) Population health risk due to dietary intake of heavy metals in the industrial area of Huludao city, China. Sci Total Environ 387:96–104

Zhou LL, Yang B, Xue ND, Li FS, Seip HM, Cong X, Yan YZ, Liu B, Han BL, Li HY (2014) Ecological risks and potential sources of heavy metals in agricultural soils from Huanghuai Plain, China. Environ Sci Pollut Res 21:1360–1369

Acknowledgement

This work was financially supported by the Natural Science Foundation of China (Grant No. 21607175), Special Fund for Agro-scientific Research in the Public Interest of China (Grant No. 201503108), and the Hunan Provincial Science and Technology Plan Project, China (No. 2016TP1007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Q. Aguilar-Virgen, Ph.D.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, L., Ma, L. & Yang, Z. Spatial variation and risk assessment of heavy metals in paddy rice from Hunan Province, Southern China. Int. J. Environ. Sci. Technol. 15, 1561–1572 (2018). https://doi.org/10.1007/s13762-017-1504-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-017-1504-y