Abstract

The work investigated the efficiency of microbial fuel cells (MFCs) for the treatment of alkaline hexavalent chromium containing wastewater. When lactate was used as the metal chelator in alkaline (pH 8) abiotic cathodes, hexavalent chromium concentration dropped from 10 mg l−1 to undetectable levels within the first 45 h of operation. Power density produced in the pH 8 abiotic cathodes was up to 21.4 mW m−2, and in the pH 9 cathodes up to 2.4 mW m−2; these values were well comparable with other values found in the literature for biologically catalysed cathodes, even at lower pH values. When Shewanella oneidensis MR-1 was present in a hexavalent chromium reducing cathode at pH 8, current production contributed by 26 % to the total hexavalent chromium reduced during the 36 days of operation. On the other hand, when hexavalent chromium (10 mg l−1) was controllably added in the anode where S. oneidensis MR-1 was present, up to 73 % of current decreased immediately after every hexavalent chromium addition; this toxic effect remained even after hexavalent chromium was depleted in the anode and strongly indicates that the presence of hexavalent chromium in the anodes of MFCs must be avoided. Overall, our results indicate that alkaline hexavalent chromium wastewater can be effectively remediated in the cathodes of MFCs, provided that a metal chelator is present in the cathodes and that hexavalent chromium is not present in the anodes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hexavalent chromium (Cr(VI)) has become one of the most abundant inorganic contaminants found in groundwater and has toxic, carcinogenic, and mutagenic effects on the living environment (U.S.E.P.A. 2000). The physicochemical characteristics of Cr(VI) containing wastewater will very much vary from the strongly acidic chrome plating wastewater (Li et al. 2008) to the alkaline chromite ore processing wastewater (Stewart et al. 2007). Various treatment approaches exist but an effective remediation option involves Cr(VI) reduction to the considerably less toxic trivalent form (Cr(III)) (Brandhuber et al. 2004; Palmer and Puls 1994), according to Eq. 1:

Even though it is an effective Cr(VI) remediation method, Cr(VI) reduction strongly depends on the presence of protons and therefore the pH of the wastewater. This can also be seen in the Nernst equation, which relates the concentrations of the reactants in the solution with the redox potential of the Cr(VI)/Cr(III) redox couple:

Where \(E_{0}^{\prime }\) is the potential at standard conditions (1.51 V), R is the molar gas constant (8.31447 J mol−1 K−1), T is the temperature (K), n is the number of electrons exchanged (3), and F is Faraday’s constant (96,485.3 C mol−1). As seen in Eq. 2, the lower the [H+] concentration (higher pH), the lower the redox potential of the Cr(VI)/Cr(III) couple, and therefore the lower the tendency of Cr(VI) for reduction.

Microbial fuel cells (MFCs) are a new technology for Cr(VI) reduction, and their principle is presented in Fig. 1. In the anode, electrons released from organic compounds are transferred to the cathode using bacteria as “catalysts”. In the cathode, which can also utilise bacterial catalysts (biocathode), electrons are received by Cr(VI) as the final step of the process. When a resistor is externally applied to the system, electrical power is generated by the electron movement from the anode to the cathode, which improves the sustainability of the remediation process. To close the electrical circuit and to run Eq. 1, protons are also delivered to the cathode through a proton or a cation exchange membrane.

The concept of Cr(VI) remediation in MFCs: 1 Anodophilic microorganisms break down organic substrates in the anode, releasing protons and electrons; 2 electrical power is generated when protons and electrons are passing to the cathode through a proton-permeable membrane and an external resistor, respectively; 3 Cr(VI) is reduced to Cr(III) in the cathode, where depending on the pH, the exact speciation of the produced Cr(III) will vary

Research on Cr(VI)-reducing cathodes is summarised in Table 1 for abiotic cathodes and in Table 2 for biocathodes. Until now, MFC studies were conducted with either abiotic cathodes mainly operating at acidic pH (Table 1) or with biocathodes mainly operating at near neutral pH (Table 2). In addition, most work on microbial Cr(VI) remediation has been conducted near the physiological pH 7; however, chromium ore processing residue can have typical pH values as high as 8 and 9 (Stewart et al. 2007), and neutral pH will rather be the exception than the rule in this instance.

When at acidic pH, Cr(VI) reduction occurs rather fast due to the abundance of protons (Eqs. 1, 2) and the final product is mainly soluble Cr3+ (Fig. 2). However, protons are not abundant at neutral or alkaline pH, and therefore, the process is very much slowed down. In addition, the charge of the final product of the reduction process (Cr(III)) will vary with varying pH (Fig. 2), and positively charged Cr(III) compounds will be deposited on the negatively charged MFC cathode (Clark and McCreery 2002; Hurley and McCreery 2003). Because Cr(VI) remediation in MFCs relies on electrochemical Cr(VI) reduction, this electrodeposition will result in a self-inhibitory behaviour of the cathode, and finally in a poor ratio of Cr(VI) reduced per electrode surface area.

Cr(III) speciation changes with pH [adapted from Sun et al. (2010), with permissions]. At pH 6, only positively charged Cr(III) species (Cr(OH)2+, Cr(OH) +2 ) are present in solution. At pH 8, mainly positive (Cr(OH) +2 ) species remain in solution, while Cr(OH)3 species are removed from the solution by precipitation. At pH 9, both positively (Cr(OH) +2 ) and negatively (Cr(OH) −4 ) charged dissolved species are present, along with the neutral Cr(OH)3 species that precipitate

A solution to this problem would be to maximise the ratio of electrode surface area used per mass of Cr(VI) available for reduction; however, this option would be impractical for real scale applications where the mass of Cr(VI) that needs to be reduced is high. In a previous study (Xafenias et al. 2013), we demonstrated that lactate can act as a Cr(III)-chelating agent, enhancing the performance of neutral pH cathodes. However, neutral pH will rarely be the case of Cr(VI)-contaminated environments, and therefore, the effectiveness of this approach has to be tested at different pH ranges.

Another important aspect of operating Cr(VI)-reducing MFCs is the toxicity of Cr(VI) that might be present in the anode. Cr(VI) could be transferred to the anode by reactor failure, or by selecting an anion exchange membrane that would allow the negatively charged Cr(VI) oxides to be transferred from the cathode to the anode (Pandit et al. 2011). Therefore, evaluating Cr(VI) toxicity in MFC anodes is essential, and no other work has been published on this issue.

The aim of this study was to study issues related to Cr(VI) wastewater remediation in MFCs, with a focus on the challenging alkaline pH and on Cr(VI) toxicity in the anodes. For this reason, we selected three different pH values (6, 8, and 9) and we studied how changing the cathodic pH from slightly acidic to alkaline affects the MFC performance. We also used a biocathode to test the effect of the biocatalyst present in an alkaline cathode, in order to merge traditional biological remediation with MFC technology. Finally, we tested the effect of Cr(VI) presence in MFC anodes, and we discuss the reasons behind this effect and why Cr(VI) presence in the anodes should be avoided. The work was conducted in 2012, in the Environmental Research laboratories of the Faculty of Engineering and the Environment, University of Southampton, UK.

Materials and methods

Reactor setup

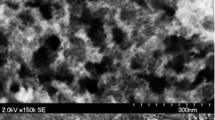

Common dual-chamber electrochemical reactors were used in this study, with 200 ml working volume in each chamber. A Nafion 117 proton exchange membrane that was fixed between the two chambers had a surface area of 4 cm2 and was pretreated as described by Kim et al. (2007). Each chamber was hosting one graphite felt electrode with a 20-cm2 total apparent surface area. One millimetre copper wire was used as the external circuit cable and was connected with the felt through a 3-mm ∅ graphite rod using conductive silver epoxy. Electrodes were cleaned prior to use as described by Chaudhuri and Lovley (2003). To avoid interference with Cr(III) deposits, new electrodes were used for each experiment. Ag/AgCl reference electrodes were used in the MFCs to monitor the potential. All reactors were covered with aluminium foil to exclude light, and experiments were conducted at room temperature (24 ± 2 °C). N2 was flushed at all times in both the anode and the cathode of the Cr(VI)-reducing MFCs except if otherwise indicated. External resistor (R ext.) was 1,000 Ω at all times except if otherwise indicated.

Chemicals

In all cases, anodes were filled up to 200 ml with a pH 7 phosphate buffer minimal medium containing (mM): NaCl (70), KH2PO4 (21), K2HPO4 (29), MgCl2 (1), NH4Cl (28), and CaCl2 (0.7). The medium also contained 0.1 % v/v of a trace elements mixture (Rabaey et al. 2005). A 1.2-M Na-acetate (S2889, Sigma Aldrich) stock solution was prepared in anodic medium and was supplied in the mediatorless MFC anodes operating with anaerobic sludge to increase acetate concentration to around 40 mM before each experiment. When Shewanella oneidensis MR-1 (MR-1) was used, anolyte contained Na-DL-Lactate (F1506, Sigma Aldrich) at the concentrations mentioned.

When studying Cr(VI) reduction at different pH values, the catholyte was a 50-mM phosphate buffer saline (PBS) containing (mM): KH2PO4 (44), K2HPO4 (6) at pH 6, KH2PO4 (3), K2HPO4 (47) at pH 8, and KH2PO4 (0), K2HPO4 (50) at pH 9. When studying Cr(VI) reduction in a pH 8 biocathode, the catholyte was the same as the anodic medium described above, amended to contain (mM): KH2PO4 (3) and K2HPO4 (47). pH in the reactors was corrected using 5 M HCl or 5 M NaOH solutions. Oven-dried potassium dichromate (K2Cr2O7) salt was diluted in ultra-pure water to make a 4-g Cr(VI) l−1 stock solution, which was then spiked in the cathodes to give an initial concentration of 10 mg l−1, except if otherwise indicated. Catholyte also contained 200 mM of Na-dl-Lactate as a chelating agent in all cases.

Start-up and operation

Anaerobic sludge was used as the bacterial catalyst in the anodes of MFCs used to study Cr(VI) reduction at different pH values. The initial seed was obtained from the wastewater treatment plant of Millbrook, Southampton, UK, and was used to inoculate (5 ml) an MFC anode fed with acetate in a fed-batch mode for more than 3 months. About 15 ml of this MFC effluent was then used to inoculate the anodes in each of the three MFCs used, which were initially running with continuous air supply in the cathode and an external resistor. After biofilm formation in the anodes, the catholyte was replaced with anaerobic catholyte-containing Cr(VI) as the final electron acceptor, at the pH values mentioned.

Shewanella oneidensis

MR-1 was used in both the anode and cathode of the biocathode MFC and in the anode of the MFC used to test Cr(VI) toxicity in the anode. MR-1 (NCIMB 14063) was initially grown aerobically on tryptone soya agar (pH 7.3, 30 °C) and then transferred into 200 ml of a Luria–Bertani 50-mM phosphate buffer medium (pH 7.0). After incubation in an orbital-shaking incubator at 30 °C, cells were centrifuged (5,000×g, 4 °C, 20 min), and then, the pellet was rinsed twice using 100 mM NaCl-50 mM phosphate buffer saline (PBS) solution (pH 7.0). Cells were then harvested and resuspended in 200 ml of a minimal medium to achieve an OD600 of 0.7 at the beginning of the experiments. When MR-1 was used in the biocathode MFC, MR-1 was initially inoculated in one chamber of the MFC and was let to produce anodic current for 3 days with lactate as the electron donor and an external resistor. Air was constantly provided in the anodes at 160 ml min−1 using an air pump, in order to form a thick MR-1 biofilm and to sustain bacterial growth. After 3 days, MR-1 was also inoculated in the second chamber of the MFC; N2 was constantly sparged to remove all oxygen present in the ex-anode side; and current was let drop to background levels. Cr(VI) was then added in the ex-anode side, which then started operating as the cathode. When studying the effect of Cr(VI) presence in the anodes, two MFCs were inoculated with the Cr(VI) tolerant strain MR-1 and were let to produce current for around 20 h, with Cr(VI) as the electron acceptor in the cathode ([Cr(VI)]0 = 500 mg l−1, cathode pH 2). Each MFC then had Cr(VI) added under anaerobic conditions (continuous N2 sparging), to give a concentration of around 10 mg l−1 in the anode. Then, current was allowed to stabilise for several hours and further Cr(VI) additions followed similarly. Appropriate sterilisation techniques were applied at all times to avoid contamination of the pure culture.

Analytical methods

Samples were centrifuged at 20,800×g for 3 min, prior to Cr(VI) and acids analyses. The presence of dissolved Cr(VI) was evaluated as described in the Standard Method 3500-Cr B (APHA 2005). Acetate and lactate were measured using Ion Chromatography (882 Compact IC Plus, Metrohm) with an ion-exclusion column (Metrosep Organic Acids, 250/7.8 mm, Metrohm), a 0.5-mM H2SO4 solution as eluent, and flow rate set at 0.6 ml min−1.

Calculations

Voltage drops across an external resistor were recorded every 2 min using a datalogger (DT 505, DataTaker). Current I (A) was calculated according to the Ohm’s law I = E cell/R ext, where E cell (V) is the voltage drop across the external resistor R ext (Ω). Power P was calculated as P = E 2cell /R ext. All current and power densities reported herein were calculated by dividing the current and power by the total apparent surface area of the cathode (20 cm2). Charge transferred from the cathode electrode to the bulk solution was calculated as C 1 = ΣIΔt, where t is the time interval between the two measurements (120 s). The total amount of charge transferred to Cr(VI), assuming a complete Cr(VI) to Cr(III) reduction, was calculated as C 2 = nFvΔ[Cr(VI)]/M, where n is the number of 3 mol of electrons needed to reduce 1 mol of Cr(VI) to Cr(III), F is the Faraday constant (96,485.3 Coulombs/mol of electrons), v is the catholyte volume (200 ml), Δ[Cr(VI)] is the reduction of Cr(VI) at a given time interval (g l−1) and M is the atomic weight of Cr (52 g mol−1). After calculating C 1 and C 2, Coulombic efficiency (CE, %) of the cathode was calculated as CE = C 1/C 2 × 100 %.

Polarisation curves

Polarisation curves were obtained before the Cr(VI) reduction tests, and after a stable open circuit, voltage was recorded under continuous N2 flushing. R ext. from 100,000 to 3 Ω were then applied, and graphs were made after voltage was not substantially changing for each of the R ext. applied.

Results and discussion

Cr(VI) reduction at different pH values

In a preliminary experiment with a poised cathode (−500 mV vs. Ag/AgCl) at pH 8 and in the absence of lactate, electroreduction was minimal (less than 0.5 mg Cr(VI) l−1), and current production reached background levels within 17 h of operation (data not shown). Therefore, in order to study Cr(VI) reduction at different pH values, all catholytes contained 200 mM lactate which is a known metal chelator that can form chelates with Cr(III) (Hamada et al. 2005; Puzon et al. 2005) and thus enhance the Cr(VI) electroreduction process by limiting Cr(III) electrodeposition on the cathode (Xafenias et al. 2013). The reason we used lactate among other metal chelators is that it occurs naturally in the environment, it exhibits low environmental toxicity (Bowmer et al. 1998), it is easily biodegradable by bacteria of environmental interest like Shewanella (Pinchuk et al. 2011) and can be used as an electron donor for Cr(VI) bioremediation (Brodie et al. 2011; Alam et al. 2006).

Polarisation graphs (Fig. 3a) produced at the beginning of the experiments showed that power production at pH 8 was maximum at the current density of 104 mA m−2, when 21 mW m−2 were produced. While power was increased at slightly acidic pH 6 (25 mW m−2 at 112 mA m−2) as can be explained by the Nernst equation, power densities at pH 9 were considerably lower compared with the pH 8 cathodes (2 mW m−2 at 15 mA m−2). Figure 3b demonstrates the higher current production by the MFCs operating with the cathode at pH 8, resulting in faster Cr(VI) reduction compared with other pH values (Fig. 3c). pH 8 cathodes exhibited more efficient Cr(VI) reduction even compared with pH 6 cathodes, regardless of the fact that both systems had an initial current production of around 70 mA m−2. As a result, Cr(VI) levels in pH 8 MFCs fell to less than 0.3 ± 0.3 mg l−1 within the first 43 h of operation, while at pH 6, the same levels of Cr(VI) remaining in solution were only achieved at the end of the 72-h operation period. At pH 9, Cr(VI) was continuously reduced; however, reduction rates were slower, and there were still 6 ± 0.4 mg l−1 available at the end of the operation period.

MFC experiments with anaerobic sludge in the anode and abiotic cathodes with Cr(VI) at three different pH values (200 mM lactate in all cathodes): a polarisation graphs conducted at start; b current evolution through time (R ext. = 1,000 Ω); c Cr(VI) remaining in the solution; d charge produced by the end of the 72-h operation period (charge calculated based on both current production and Cr(VI) reduction). In b–d, values reported are average of triplicate experiments for pH 8 and 9 and duplicate experiments for pH 6. Error bars represent the min and max of the measurements from the reactors running in parallel

Anodic potential under closed circuit conditions did not alter much during operation (pH 6: −531 ± 49 mV, pH 8: −542 ± 21 mV, pH 9: −558 ± 4 mV). Anodic pH did not alter much either and remained around 7.9 throughout operation. Therefore, it should mainly be cathode-related factors that have contributed to the higher current production observed at pH 8. One might assume an increased stability of the Cr(III)–lactate complex with increasing pH, as a result of stronger deprotonation of the lactic ion. Increased stability could limit the electrodeposition of Cr(III) compounds on the cathode electrode and therefore the deactivation of the cathode. However, with a low pK a value for the carboxyl (3.86) and a high pK a value for the hydroxyl (15.1) group (Silva et al. 2009), the protonation state of the lactic ion would not alter much within the pH range studied.

Another more likely explanation would involve the speciation of Cr(III)–lactate complexes with varying pH. In an aquatic environment, four Cr(III) species are dominant within the pH range 6–9 (Sun et al. 2010): Cr(OH)2+ and Cr(OH) +2 at pH 6; Cr(OH) +2 at pH 7; Cr(OH) +2 and Cr(OH)3 at pH 8; Cr(OH) +2 , Cr(OH)3 and Cr(OH) −4 at pH 9. Considering a 1:1 lactate–Cr(III) chelation (Hamada et al. 2005), complexes at lower pH might have retained a positive charge, which attracted them on the negatively charged electrode surface. Cr(III) can be deposited on the electrode even after reduction at pH as low as 2 (Zhang et al. 2012); however, the higher H+ availability at lower pH is probably counteracting this inhibition effect (Eq. 1) by increasing the cathode’s reduction potential (Eq. 2).

Another reason for the rather slower electroreduction observed at pH 6 was that at lower pH, partial Cr(VI) reduction by nonelectrochemical pathways was observed. While Coulombic efficiency was close to 100 % at pH 8 and 9, at pH 6, it dropped to only 63 % (Fig. 3d), indicating that another Cr(VI) removal pathway was present at lower pH. With Cr(VI) at the pH range studied being mainly in the negative chromate ion (CrO4 2−) form, Cr(VI) cannot be electrostatically removed by the also negatively charged cathode (Farmer et al. 1997). A more possible mechanism which explains this decrease in Coulombic efficiency would be that of chemical Cr(VI) reduction by lactic acid (Deng and Stone 1996).

Until now, studies on Cr(VI) reduction at neutral–slightly alkaline pH have mainly focused on the use of Cr(VI)-reducing bacterial catalysts in the cathode. Table 3 compares the maximum power densities recorded in the literature, with the ones observed in this study where lactate instead of a bacterial catalyst was used to enhance the process. At pH 6, the power density produced in this study was comparable with previous studies that were performed in the absence of a metal chelator (Wang et al. 2008; Li et al. 2008). However, we only used 1/5 to 1/10 the concentration used elsewhere, and this should have reduced the redox potential of the Cr(VI)/Cr(III) couple, as predicted by the Nernst equation (Eq. 2). At pH 8 and 9, maximum power density produced by 10 mg Cr(VI)/l in the presence of lactate was 31 and 3 times, respectively, the power density produced in a biocathode MFC running with 20 mg Cr(VI)/l at pH 8 (Huang et al. 2011b), indicating that the chelation process is crucial at these pH values.

Our discovery that chelation can enhance Cr(VI) electroremediation can be applied to elucidate the mechanisms via which bacterial catalysts enhance Cr(VI) reduction in MFC biocathodes. These mechanisms are still not clear; however, a possible reason for this enhancement could be because of Cr(III) chelation with organic acids excreted by bacteria (Vollbrecht et al. 1978) present in mixed bacterial biocathodes. In addition, it is of importance whether and how other chelate agents with environmental importance like citrate or EDTA can enhance Cr(VI) electroremediation. Finally, since organic molecules such as lactate can form insoluble complexes with Cr(III) at appropriate pH (Hamada et al. 2005; Puzon et al. 2005), the effluent of the Cr(VI)-reducing cathode could be further environmentally improved by subsequent pH control, which would precipitate and remove total chromium. However, more research is needed on all of these aspects.

Cr(VI) reduction in a pH 8 biocathode

To study whether biological remediation can be applied together with MFC technology at alkaline pH, we tested a lactate-containing cathode in the presence of MR-1, at pH 8. When Cr(VI) was added in the biocathode, the concentration was initially decreased rapidly (Fig. 4a) due to the Cr(VI)-reducing metabolic pathways of MR-1 that did not involve current production. Cathode potential remained at low levels due to the presence of MR-1 (Fig. 4b); however, it was increased by around 50–70 mV after each Cr(VI) addition. The charged produced, calculated both from the total Cr(VI) reduction and the electricity production, showed that the initial rapid Cr(VI) reduction was due to factors other than electricity (e.g. heterotrophic lactate oxidation). During the first 6 days of operation, 89.2 C of charge was produced in the biocathode due to nonelectricity factors, compared with only 4.1 C produced due to electricity (Fig. 4c). However, during the next 30 days of operation, electricity production became the major and more stable Cr(VI) reduction pathway; 23.6 C was bio-electrochemically produced during this time, while only 18.3 C was produced due to other pathways. This finding is important, as it clearly demonstrates that bio-electroreduction can improve the traditional biological Cr(VI) remediation, even at alkaline pH. Finally, the relationship between current produced and Cr(VI) concentration in the biocathode could be represented, with a high coefficient of determination (r 2 = 0.88), by an exponential rise to a maximum equation (Fig. 4d); this indicates that the effect of Cr(VI) concentration on current production in the biocathode was crucial only up to a certain concentration; above that concentration (around 8 mg-Cr(VI)/l), Cr(VI) would not produce considerably higher current density, nor Cr(VI) electroreduction would be considerably faster, given a certain electrode surface area. To overcome this limitation, and depending on the Cr(VI) concentration to be treated, a higher electrode surface area would be beneficial, as it would increase the absolute current value and therefore the Cr(VI) treatment rate.

The effect of Cr(VI) additions in an MFC cathode operating with S. oneidensis MR-1 as the biocatalyst in both anode and cathode (R ext. = 1,000 Ω): a current production and Cr(VI) reduction through time; b cathode potential through time; c cumulative charge produced, calculated from Cr(VI) reduction (total), electricity production (due to electricity), and the subtraction of the two (due to other than electricity); d current versus Cr(VI) concentration relationship calculated from the last four Cr(VI) additions to the biocathode

Anodic current inhibition by Cr(VI) present in the anode

In the previous paragraph, we demonstrated that sufficient Cr(VI) reduction can take place in MFC cathodes with lactate and MR-1 and that this reduction is the cumulative effect of both biological and electrochemical Cr(VI) reduction. Moving a step forward, it is important to demonstrate the effect that Cr(VI) can have on the activity of MR-1 when the later acts as the anodic biocatalyst.

As seen in Fig. 5a, current increased during the first 20 h of operation when MR-1 was utilising lactate to produce anodic current and Cr(VI) was absent from the anode. However, current density immediately dropped from 0.41 to 0.11 A m−2 after the first Cr(VI) addition (9.8 mg l−1), which corresponds to a 73 % decrease. Current recovered slowly after complete Cr(VI) reduction but did not exceed 0.22 A m−2, even after 2 days of operation. After the second Cr(VI) addition (8.8 mg l−1), the current density dropped from 0.22 to 0.08 A m−2, corresponding to a further 67 % drop. After 2 days of stabilisation, Cr(VI) (10.2 mg l−1) was added for the third time, resulting in a further drop in current density by 67 %, from 0.11 to 0.04 A m−2. After this final drop, current density did not recover but stabilised at around 0.04 A m−2. Cr(VI) concentration in the anode dropped to low levels even after the fourth Cr(VI) addition (10.6 mg l−1); however, current in this instance did not show any clear further response (increase or decrease). As a result of the current density dropping after each Cr(VI) addition, the rates of charge production calculated according to current production and cathodic Cr(VI) reduction also fell (Fig. 5b); this was despite the fact that sufficient amounts of the electron donor (lactate) were present in the anodes at all times (Fig. 5c).

The effect of Cr(VI) additions in an MFC anode operating with S. oneidensis MR-1 as the anodic biocatalyst (R ext. = 1,000 Ω): a current production and Cr(VI) concentration in the anode (arrows indicate Cr(VI) spikes; average values from two reactors are reported, and error bars represent min and max); b on the cumulative charge produced by the MFC, calculated based on both current production and Cr(VI) reduction in the cathode; c lactate and acetate concentrations evolution in the anode

The immediate drop of current as a response to Cr(VI) additions in the anode could be due to the alternative electron acceptor present in the anode, which is being reduced instead of the electrode. However, as demonstrated elsewhere, this was not the case when oxygen was supplied in the MR-1-inoculated anode (Rosenbaum et al. 2010; Xafenias et al. 2013). In addition, this would not explain the slow recovery (or the absence of any recovery) observed after Cr(VI) depletion. Passivation of the electroactive components responsible for anodic current production by Cr(III) precipitates on the bacterial cell surface could be a reason for the reduced electroactivity of MR-1 in the anode. However, recent findings suggesting that MR-1 remained electroactive during Cr(VI) reduction and could utilise the electrode as electron donor during bioelectrochemical Cr(VI) reduction (Xafenias et al. 2013) and could indicate differences between the electron transfer pathways of anodic and cathodic current production. Uncomplexed Cr(III) formed during Cr(VI) reduction is known to have toxic effects on Shewanella, as it accumulates within the cytoplasm and probably binds with the DNA, affecting the cell’s functionality (Bencheikh-Latmani et al. 2007). Therefore, the presence of Cr(VI) in the anodes of MFCs will have severe inhibitory effects on the process and must be avoided. This would be done by separating the anolyte from the catholyte using appropriately selective membranes (e.g. proton or cation exchange membranes and not anion exchange membranes), which would not allow the migration of the negatively charged Cr(VI) ions towards the anode.

Conclusion

Bio-electrochemical Cr(VI) reduction at alkaline cathodic pH is possible when chelating agents such as lactate are present. Current and power produced in the abiotic cathodes with lactate were at the same levels as those of microbially catalysed cathodes, and faster electrochemical reduction was achieved at pH 8, compared with pH 6 and 9. The presence of the cathode electrode in a biological Cr(VI)-reducing system can have a positive cumulative effect, and Cr(VI) will be reduced by both the biocatalyst and the electrode. However, the presence of Cr(VI) in the anodes of bioelectrochemical systems must be prevented as it has been demonstrated to have an irreversible inhibitory effect on anodic current production.

References

Alam M, Hossain A, Yonge DR, Peyton BM, Petersen JN (2006) Bioreduction of hexavalent chromium in flow-through quartz sand columns. J Environ Eng 132(3):358–366

APHA (2005) Standard methods for the examination of water and wastewater. Standard Methods for the Examination of Water and Wastewater, 21st-Centennial edn. American Public Health Association (APHA), American Water Works Association (AWWA), Water Environment Federation (WEF), Washington DC

Bencheikh-Latmani R, Obraztsova A, Mackey MR, Ellisman MH, Tebo BM (2007) Toxicity of Cr(III) to Shewanella sp. strain MR-4 during Cr(VI) reduction. Environ Sci Technol 41(1):214–220. doi:10.1021/es0622655

Bowmer CT, Hooftman RN, Hanstveit AO, Venderbosch PWM, van der Hoeven N (1998) The ecotoxicity and the biodegradability of lactic acid, alkyl lactate esters and lactate salts. Chemosphere 37(7):1317–1333. doi:10.1016/s0045-6535(98)00116-7

Brandhuber P, Frey M, McGuire MJ, Chao P, Seidel C, Amy G, Yoon J, McNeill L, Banerjee K (2004) Low-level hexavalent chromium treatment options: bench-scale evaluation. American water works association Research Foundation

Brodie EL, Joyner DC, Faybishenko B, Conrad ME, Rios-Velazquez C, Malave J, Martinez R, Mork B, Willett A, Koenigsberg S, Herman DJ, Firestone MK, Hazen TC (2011) Microbial community response to addition of polylactate compounds to stimulate hexavalent chromium reduction in groundwater. Chemosphere 85(4):660–665. doi:10.1016/j.chemosphere.2011.07.021

Chaudhuri SK, Lovley DR (2003) Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat Biotechnol 21(10):1229–1232

Clark WJ, McCreery RL (2002) Inhibition of corrosion-related reduction processes via chromium monolayer formation. J Electrochem Soc 149(9):B379–B386

Deng B, Stone AT (1996) Surface-catalyzed chromium(VI) reduction: reactivity comparisons of different organic reductants and different oxide surfaces. Environ Sci Technol 30(8):2484–2494. doi:10.1021/es950780p

Farmer JC, Bahowick SM, Harrar JE, Fix DV, Martinelli RE, Vu AK, Carroll KL (1997) Electrosorption of chromium ions on carbon aerogel electrodes as a means of remediating ground water. Energy Fuels 11(2):337–347. doi:10.1021/ef9601374

Hamada YZ, Carlson B, Dangberg J (2005) Interaction of malate and lactate with chromium(III) and iron(III) in aqueous solutions. Synth React Inorg Met-Organ Nan-Met Chem 35(7):515–522. doi:10.1080/15533170500198887

Hsu L, Masuda SA, Nealson KH, Pirbazari M (2012) Evaluation of microbial fuel cell Shewanella biocathodes for treatment of chromate contamination. RSC Adv 2(13):5844–5855

Huang L, Chen J, Quan X, Yang F (2010) Enhancement of hexavalent chromium reduction and electricity production from a biocathode microbial fuel cell. Bioprocess Biosyst Eng 33(8):937–945

Huang L, Chai X, Chen G, Logan BE (2011a) Effect of set potential on hexavalent chromium reduction and electricity generation from biocathode microbial fuel cells. Environ Sci Technol 45(11):5025–5031. doi:10.1021/es103875d

Huang L, Chai X, Cheng S, Chen G (2011b) Evaluation of carbon-based materials in tubular biocathode microbial fuel cells in terms of hexavalent chromium reduction and electricity generation. Chem Eng J 166(2):652–661. doi:10.1016/j.cej.2010.11.042

Hurley BL, McCreery RL (2003) Raman spectroscopy of monolayers formed from chromate corrosion inhibitor on copper surfaces. J Electrochem Soc 150(8):B367–B373

Kim JR, Cheng S, Oh S-E, Logan BE (2007) Power generation using different cation, anion, and ultrafiltration membranes in microbial fuel cells. Environ Sci Technol 41(3):1004–1009. doi:10.1021/es062202m

Li ZJ, Zhang XW, Lei LC (2008) Electricity production during the treatment of real electroplating wastewater containing Cr6+ using microbial fuel cell. Process Biochem 43(12):1352–1358. doi:10.1016/j.procbio.2008.08.005

Li Y, Lu AH, Ding HR, Jin S, Yan YH, Wang CQ, Zen CP, Wang X (2009) Cr(VI) reduction at rutile-catalyzed cathode in microbial fuel cells. Electrochem Commun 11(7):1496–1499. doi:10.1016/j.elecom.2009.05.039

Liu L, Yuan Y, Li F-b, Feng C-h (2011) In-situ Cr(VI) reduction with electrogenerated hydrogen peroxide driven by iron-reducing bacteria. Bioresour Technol 102(3):2468–2473. doi:10.1016/j.biortech.2010.11.013

Palmer CD, Puls RW (1994) Natural attenuation of hexavalent chromium in groundwater and soils. EPA Ground Water Issue. U.S. Environmental Protection Agency

Pandit S, Sengupta A, Kale S, Das D (2011) Performance of electron acceptors in catholyte of a two-chambered microbial fuel cell using anion exchange membrane. Bioresour Technol 102(3):2736–2744. doi:10.1016/j.biortech.2010.11.038

Pinchuk GE, Geydebrekht OV, Hill EA, Reed JL, Konopka AE, Beliaev AS, Fredrickson JK (2011) Pyruvate and lactate metabolism by Shewanella oneidensis MR-1 under fermentative, oxygen-limited and fumarate-respiring conditions. Appl Environ Microbiol:AEM.05382-05311. doi:10.1128/aem.05382-11

Puzon GJ, Roberts AG, Kramer DM, Xun L (2005) Formation of soluble organo-chromium(III) complexes after chromate reduction in the presence of cellular organics. Environ Sci Technol 39(8):2811–2817. doi:10.1021/es048967g

Rabaey K, Ossieur W, Verhaege M, Verstraete W (2005) Continuous microbial fuel cells convert carbohydrates to electricity. Water Sci Technol 52(1):515–523

Rosenbaum M, Cotta MA, Angenent LT (2010) Aerated Shewanella oneidensis in continuously fed bioelectrochemical systems for power and hydrogen production. Biotechnol Bioeng 105(5):880–888

Silva A, Kong X, Hider R (2009) Determination of the pKa value of the hydroxyl group in the α-hydroxycarboxylates citrate, malate and lactate by 13C NMR: implications for metal coordination in biological systems. Biometals 22(5):771–778. doi:10.1007/s10534-009-9224-5

Stewart DI, Burke IT, Mortimer RJG (2007) Stimulation of microbially mediated chromate reduction in alkaline soil-water systems. Geomicrobiol J 24(7):655–669

Sun X-F, Ma Y, Liu X-W, Wang S-G, Gao B-Y, Li X-M (2010) Sorption and detoxification of chromium(VI) by aerobic granules functionalized with polyethylenimine. Water Res 44(8):2517–2524

Tandukar M, Huber SJ, Onodera T, Pavlostathis SG (2009) Biological chromium(VI) reduction in the cathode of a microbial fuel cell. Environ Sci Technol 43(21):8159–8165. doi:10.1021/es9014184

U.S.E.P.A. (2000) In situ treatment of soil and groundwater contaminated with chromium-technical resource guide. U.S. Environmental Protection Agency, Office of Research and Development, Washington DC

Vollbrecht D, Nawawy MA, Schlegel HG (1978) Excretion of metabolites by hydrogen bacteria I. Autotrophic and heterotrophic fermentations. Eur J Appl Microbiol Biotechnol 6(2):145–155. doi:10.1007/bf00504426

Wang G, Huang LP, Zhang YF (2008) Cathodic reduction of hexavalent chromium [Cr(VI)] coupled with electricity generation in microbial fuel cells. Biotechnol Lett 30(11):1959–1966. doi:10.1007/s10529-008-9792-4

Xafenias N, Zhang Y, Banks C (2013) Enhanced performance of hexavalent chromium reducing cathodes in the presence of Shewanella oneidensis MR-1 and lactate. Environ Sci Technol 47(9):4512–4520. doi:10.1021/es304606u

Zhang B, Feng C, Ni J, Zhang J, Huang W (2012) Simultaneous reduction of vanadium (V) and chromium (VI) with enhanced energy recovery based on microbial fuel cell technology. J Power Sour. doi:10.1016/j.jpowsour.2012.01.013

Acknowledgments

Funding in support of this work was provided by the Faculty of Engineering and the Environment, University of Southampton, UK.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xafenias, N., Zhang, Y. & Banks, C.J. Evaluating hexavalent chromium reduction and electricity production in microbial fuel cells with alkaline cathodes. Int. J. Environ. Sci. Technol. 12, 2435–2446 (2015). https://doi.org/10.1007/s13762-014-0651-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-014-0651-7