Abstract

Unsupported nanoparticles are often less stable, and usually coagulation is unavoidable during the catalytic reactions. To generate stable nanoparticles with good activity, stabilizing the surface is required. Protection has been performed by the addition of polymers or long-chain alkyl surfactants with polar functional groups that attached to the nanoparticle surface via covalent or electrostatic interactions. Alternatively, nanoparticles have been immobilized or grafted onto inorganic supports to improve their stabilization and recycling ability. In this article, the green catalytic processes and recent advances in organic transformations catalyzed by magnetically retrievable catalysts are reviewed. Prior to this, methods for the synthesis of catalysts immobilized on magnetic nanoparticles are addressed briefly.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanosized architecture chemistry is an exponentially growing research field in modern science that involves the synthesis and application of nanoparticles of different sizes and shapes [1]. Nanochemistry offers a possibility to enhance the electrical, optical, magnetic, thermal and mechanical properties of material by controlling its size, shape, porosity and surface functional group [2]. Furthermore, enhancing the percentages of exposed highly reactive facets, at nanoscale, does improve the efficiency of materials in various applications such as photocatalysis and dye-sensitized solar cells [3]. By presenting individual properties, nanoparticles can become a kind of structure unit, in other words, “artificial atoms” to conduct a new type of materials which have difficult in estimating collective properties [4]. Through green nanotechnology, we can get contrivable nanomaterial that contains unique characters which bulk materials never have [5]. This means that we are creating materials with good catalytic activity, stability and more selectivity via changing their forms, sizes and morphologies [6]. Applications of nanoparticles in catalytic reactions are because as size decreases, the surface area-to-volume ratio increases, which enhanced interaction between the reactant and the catalyst, which are needed for high catalytic efficiencies [7]. Unsupported nanoparticles are often less stable, and usually coagulation is inevitable during the catalytic reactions [8]. To generate stable nanoparticles with good activity, stabilizing the surface is required. Protection has been performed by the addition of polymers or long-chain alkyl surfactants with polar functional groups that attached to the nanoparticle surface via covalent or electrostatic interactions [9, 10]. Alternatively, nanoparticles have been immobilized or grafted onto inorganic supports to improve their stabilization and recycling ability [12]. Progress in the discovery of new support materials for the heterogenization of homogeneous catalysts has been periodically reviewed [13]. In this article, the green catalytic processes and recent advances in organic transformations catalyzed by magnetically retrievable catalysts (MRCs) are highlighted. Prior to this, methods for the synthesis of catalysts immobilized on magnetic nanoparticles will be addressed briefly.

Magnetic nanoparticles

Materials have different behavior in the presence of an external magnetic field. Their behavior is dependent on a number of parameters, such as the atomic and molecular structure of the material, and the net magnetic field shared with the atoms. The attractive or repulsive forces between magnetic materials can be explained in terms of magnetic dipoles—tiny bar magnets with opposite poles. Thus, materials can be categorized into diamagnetic, paramagnetic, ferromagnetic, ferrimagnetic, and antiferro-magnetic according to the arrangement of their magnetic dipoles in the absence and presence of an external magnetic field [14]. For a ferromagnetic material, the magnetic dipoles at all times exist in the absence and presence of an external field and exhibit long-range order. This material shows a permanent magnetic moment. Magnetic nanoparticles are used in various applications, such as in biomedical to data storage systems. One of the main applications of magnetic particles is in magnetic separation. In this method, it is possible to separate a specific matter from a mixture of different other materials. The separation time is one of the major factors in the magnetic separation. High magnetic gradient separation (HGMS) is now widely utilized in the fields of medicine, diagnostics and catalysis. In this case, a liquid phase containing magnetic particles is passed by a matrix of wires that are magnetized by applying a magnetic field [15]. Nanoparticles have recently emerged as efficient alternatives for the immobilization of homogeneous catalysts and as catalysts themselves [16]. The high specific surface area of nanoparticles increased catalyst active sites which are required for high catalytic performance. For example, spherical nanoparticles with a diameter of about 10 nm have a calculated surface area of 600 m2 cm−3, which is comparable to many porous supports applied for the stabilization of homogeneous catalysts [17]. So, there is a lot of room on the surface of these materials for the heterogenization of various homogeneous catalysts. In contrast to bulk materials, nanoparticles with diameters of less than 100 nm can be easily dispersed in a liquid medium to form stable suspensions. However, these particles are difficult to separate by filtration. In such cases, ultracentrifugation is usually the only way to separate the product and catalyst. This problem can be solved by using magnetic nanoparticles (MNPs), which can be easily removed from the reaction mixture by magnetic decantation [18].

The special advantages of magnetic nanoparticles in catalysis can be summarized as follows:

-

The particles possess high specific surface areas. The catalytically active sites can be distributed on the outer surface of the support; thus, pore diffusion limitations are avoided.

-

The particles are highly dispersible in solvents; thus, the external active sites are easily accessible to the incoming reactants.

-

Catalyst recovery and reusability are the most important features for many catalytic processes; most heterogeneous catalysts require a filtration or centrifugation step or a tedious workup of the final reaction mixture to recover the catalyst. However, catalysts immobilized on magnetic nanoparticles can be recovered by magnet attraction (Fig. 1) [19].

Developments of magnetic nanoparticles (MNPs) for use as supports and explorations of their applications in aqueous catalysis indicate an important branch of green nanotechnology as they enable environmentally friendly and sustainable catalytic processes. By simple recoverable magnetic nanoparticles from reaction media, different protocols through surface modification, binding and self-assembly offer a broad scope of approaches for preparing magnetically retrievable catalysts.

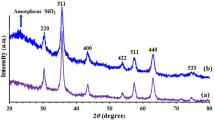

Surface modification of MNPs by organic and inorganic coating

Iron oxides are themselves well known to act as catalysts in some organic reactions [20–22]. However, it is essential to build up a strong barrier between the magnetic core and the catalysts to circumvent unfavorable interactions with molecular catalysts immobilized to the surface of the nanoparticle. Protection of MNPs with silica avoids unwanted contacts with the core and prevents particle aggregation. In addition, the presence of silanol groups allows simple surface functionalization with different functional groups. The MNPs protected with silica is more hydrophilic and more biocompatible than those stabilized by oleic acid. Protection of iron oxides with silica to form core–shell structures due to the presence of surface FeOH groups is quite simple. So, it is needed to apply processes which make the metal surface vitreophilic before starting the coating process [23]. The sol–gel process is the main method for the protection of MNPs with silica [24, 25]. This method basically relies on the well-known Stöber process in which silica is formed over the nanoparticles by the hydrolysis and following condensation of silicon alkoxides (usually, tetraethyl orthosilicate, TEOS) in alcohol/water mixtures under basic conditions. Interestingly, the thickness of the silica shell can easily be manipulated by the reaction conditions. Philipse et al. [26] illustrated that Fe3O4@SiO2 MNPs with a average diameter of 60–120 nm could be achieved by the Stöber process when the bare Fe3O4 MNPs were pretreated with a layer of silicate in aqueous solution. In another research, Deng et al. [27] developed the effect of alcohols (methanol, ethanol, 2-propanol, n-propanol), the ratio of alcohol to water and the amount of aqueous ammonia added through the synthesis on the formation of silica-supported magnetic nanoparticles. It was represented that a pH value between 8 and 10 is ideal for the protection reaction, as it decreases the solubility of the silicate species in solution and also results in a homogeneous coating on the nanoparticle surface without the formation of new silica nuclei. In addition, low concentrations of MNPs and suitable treatment with sonication to separate individual magnetic particles before the protection steps are preferred to achieve typical core–shell nanostructures; otherwise, multi-nuclei iron oxide cores introduced inside silica shells will be produced (Fig. 2) [28]. The presence of multi-nuclei iron oxide cores entered in different shells also allows easy separation of the particles (Fig. 2). An alternative way to increase the magnetism is to produce composite particles by coating of magnetic colloids on a nonmagnetic particle [29]. This will also assist easy and rapid separation because of the high number of superparamagnetic particles. Two methods have generally been applied for the preparation of such composites: the superparamagnetic particles can be embedded on the surface of a preformed nonmagnetic support (typically, a polymer or silica beads) or the superparamagnetic particles can be encapsulated inside a nonmagnetic matrix such as mesoporous silica (Fig. 2). The fabrication of magnetic porous-structured particles has attracted special attention due to their arranged pore channels. They are available in a tunable size range (2–50 nm) for hosting a lot of bio-/catalytic compounds. The silica sites (Si–OH) inside the pores can easily be changed by common reactions of silicon.

Different morphologies of MNPs/nanocomposites: a spherical MNPs, b bimetallic MNPs, c typical core–shell MNPs, d multi-nuclei MNPs embedded in core–shell particles, e MNP–silica nanocomposites, f MNP-decorated silica spheres, g MNP encapsulated in mesoporous materials [11]

Such materials are typically obtained by introducing magnetic particles into the as-synthesized porous matrix or by the synthesis of a porous layer on the surface of premade magnetic nanoparticles [30, 31]. Besides mesoporous silica, porous carbonaceous materials such as mesoporous carbon or carbon nanotubes have been modified with magnetic nanoparticles for applications in catalysis [32, 33]. Although there are more applications for the magnetic core and nonmagnetic shell NPs in the coming future, in this section, the author will focus on applications of the magnetic nanoparticles (MNPs) as a catalyst support in organic synthesis.

Fabrication of catalysts immobilized on magnetic nanoparticles and its applications in organic synthesis

Catalysis is among the most important applications within the field of nanoscience [34]. Catalysts can be involved in some strategies for the fabrication of several nanostructures like quantum dots, nanotubes. Furthermore, some nanostructures themselves can serve as catalysts for certain chemical reactions [35, 36]. Contrary to classic heterogeneous catalysts, [37] nanoparticles (NPs) are synthesized in a bottom-up approach from molecular precursors such as a metal salt, a stabilizer and a reducing agent. When catalytic applications of NPs are discussed, four general strategies can be considered in distinct form as well as in combinations thereof. The first three strategies involve the use of systems where the nanoparticle metal exerts the dominating effect on the catalytic activity (Fig. 3a–c). In all these cases, the catalytic reactions occur on the surface of the nanoparticles, influenced just in one structure by ligands/protecting agents that transmit effect to metal-coordinated substrates in their vicinity (Fig. 3c). Also, nanomaterials can act only as carriers for soluble catalysts (Fig. 3d), a strategy which has been rarely discussed [38]. Herein, the clusters act as a structuring element for an assembly of ligands, which are attached to the core material via an additional function, different from the chelating functional groups defining the catalytic center. The activity arises from a metal different to the core material. Only in the latter case, the core material does not promote the reaction.

Catalysis with a metal nanoparticles, b metal nanoparticles capped with a protective shell, c metal nanoparticles capped with ligands contributing to the catalytic activity and d metal nanoparticles with catalysts supported on the protective shell [39]

Organic catalysts immobilized on magnetic nanoparticles

Organocatalysis is an emerging area of research [40], wherein metal-free approaches accomplish an array of important reactions in an environmentally benign manner [41]. Recently, this approach has been made even greener by grafting the organocatalysts onto solid supports [42]. Organocatalysts functionalized on magnetic supports have a broad range of applications in various organic transformations. Significant advantages of magnetic organocatalysts are their simple recovery and reuse, which results in an environmentally benign catalytic process. Major methods in synthesis of organic molecule-immobilized magnetically retrievable catalysts (MRCs) focus on traditional strategies, in which organic catalysts or ligands are bonded onto the surface of magnetic nanoparticles (MNPs) or SiO2-supported MNPs. Earlier research in supporting of organic molecule onto Fe2O3 MNPs was reported by Gao group [43] at 2006. As shown in Scheme 1, they used dopamine as a linker for immobilization of two amino acid residues (Asp and His residues, which have a carboxylate group and an imidazole molecule on side chains, respectively). They also supported a mixture of two amino acid derivatives of dopamine (1:1 molar ratio of N-Ac-dopamine-Asp and N-Ac-dopamine-His) onto Fe2O3 MNPs (average size of 12 nm), forming the Asp–His-functionalized MNPs. This magnetically retrievable catalyst (MRC) is a magnetic biomimetic nanocatalyst that represented high activity in the hydrolysis of paraoxon (phosphoester) and 4-nitrophenyl acetate (carboxylic ester) in milli-Q water (pH 7.0) at 37 °C. The hydrolyzed amount of paraoxon could be converted to 77 % after 48 h and enhanced to 92 % after 96 h, which is considerably higher than the amount achieved by using the corresponding pair without a nanoparticle support. The increased activity is assigned to synergic effect of the carboxylate–imidazole cooperatives on the surface of the nanoparticle. Moreover, Asp–His-functionalized MNPs could be recovered easily and reused for at least four times without apparent decrease in conversion.

Developments in organic molecule-functionalized MRCs were furthered by Polshettiwar and Varma group [44]. Through a sonochemical strategy, they used glutathione as organocatalyst and anchored it onto the surface of Fe3O4 MNPs via coupling its thiol group with the free hydroxyl groups of Fe3O4 surfaces. The resulting magnetic glutathione-functionalized organocatalyst (nano-FGT) exhibited high efficiency in the Paal–Knorr pyrrole synthesis in water under microwave radiation (Scheme 2). The nano-FGT showed that it could be separated easily and reused at least five times without significant catalytic activity. It also indicated high catalytic performance in aza-Michael reactions and in synthesis of pyrazole. In another study, Leque et al. [45] developed the use of nano-FGT to catalyze homocoupling of several arylboronic acids. In this case, electron-donating or withdrawing substituents at the ortho or para position of aryl groups could be easily converted to products with good yields. Furthermore, the recycled catalyst could be utilized in a repeat reaction without any considerable loss of activity.

Nemati group [46] prepared SiO2-coated sulfonic acid-functionalized MNPs (Fe3O4@SiO2–SO3H). This catalyst was used in the synthesis of pyrimido[4,5-b]quinolines and indeno-fused pyrido[2,3-d]pyrimidines in water under mild conditions (Scheme 3). Results indicate that Fe3O4@SiO2–SO3H possessed good catalytic performance, producing yields of 81–95 %. It could be recovered completely, and its catalytic efficiency remained unaltered after three cycles, giving the one-pot method potential use in large-scale synthesis.

Using alternative methods, Kefayati et al. [47] reported sulfonic acid-functionalized MCM-48 coated on magnetite nanoparticles as a recyclable core–shell solid acid catalyst for three-component condensation of β‐naphthol, aldehydes and barbituric acid. The obtained nanomagnetic catalyst was used in the synthesis of 5‐aryl‐1H-benzo[f]chromeno [2,3‐d]pyrimidine‐2,4(3H,5H)‐diones in good yields under mild reaction conditions. The unique feature of the reaction was the ease of workup and catalyst recovery. The recovered catalyst maintained catalytic activity for five successive runs (Scheme 4).

Recently, Firouzabadi et al. [48] prepared a modified sulfonic acid-functionalized magnetic nanoparticle composite (Fe3O4@γ–Fe2O3–SO3H) using of ultrasonic irradiation. By this method, the size of the nanoparticles was decreased and the magnetization of the material was highly improved. This improvement drastically affected the efficiency and magnetic separation of the material as a catalyst. This new modified nanomagnetic compound was used as a highly efficient and recyclable catalyst for functionalization of indole derivatives via Michael addition and bis indolyl methane synthesis in entirely environmentally friendly media at room temperature. This modified magnetic material can be easily applied for large-scale operations producing the desired products in excellent yields in highly pure states (Scheme 5).

Also, Alizadeh and coworkers developed SiO2-coated metformin-functionalized MNPs (Fe3O4@SiO2-Met) [49] which was used for one-pot synthesis of pyran derivatives in aqueous ethanol. As shown in Scheme 6, the catalytic performance of Fe3O4@SiO2-Met was evaluated by preparation of 2-amino-4-aryl-3-cyano-5-oxo-4H,5H-pyrano[3,2-c]chromene and tetrahydro-benzo[b]pyran derivatives. Synthesis was done by condensing 4-hydroxycoumarin or dimedone, aldehydes, malononitrile in EtOH–H2O mixture (1:1, v/v) under reflux conditions. The Fe3O4@SiO2-Met could be recovered with an external magnet and reused at least six times without obvious loss of activity in a three-component model reaction of 4-nitrobenzaldehyde, malononitrile and 4-hydroxycoumarin.

In another research, Sadeghzadeh formed quinuclidine stabilized on FeNi3 nanoparticles as catalyst for efficient, green and one-pot synthesis of triazolo[1,2-a]indazole-triones at room temperature [50]. The catalyst is readily recovered by simple magnetic decantation and can be recycled at least five times with no significant loss of catalytic activity (Scheme 7).

Interestingly, a TEMPO-functionalized MNPs (TEMPO: 1-hydroxy-4-oxo-2,2,6,6,-tetra-methylpiperidine) was reported by Karimi group [51]. As shown in Scheme 8, the Fe3O4@SiO2–TEMPO catalyst indicated high sufficiency in the aerial oxidation of acid-sensitive, sterically hindered alcohols. A major benefit of this method was that the products could obtain >99 % purity without any chromatographic purification, which is not usually achievable with most halogen-based TEMPO-catalyzed processes. In addition, this catalytic protocol connects the advantages of heterogeneous strategies, which enable simple separation and high reusability (up to 20 runs), and also homogeneous TEMPO-based processes, which impart good activity and reproducibility. These benefits give potential use of the method in large-scale applications.

Proline is one of the organic compounds widely utilized in catalysis reactions, particularly in asymmetric aldol reactions. Tan et al. [52] synthesized two chiral proline-immobilized MRC-1 and MRC-2 (Scheme 9), which was applied in the asymmetric aldol reaction in water. Unlike MRC-2, MRC-1 could be dispersed more uniformly in water to form a stable suspension. This ability is attributed to the nanoscale size of the supports and the high solubility of imidazolium ion. Moreover, MRC-1 showed high catalytic activity in the aldol reaction of a wide range of ketones and aromatic aldehydes in water.

In another study, Safari and Gandomi-Ravandi [53] have reported that CNTs could be immobilized on Fe3O4 nanoparticles. This catalyst showed good activity in the synthesis of diarylpyrimidinones using grindstone chemistry. The method is efficient, high-yielding, time-saving and environmentally friendly and has simplicity in the experimental procedure (Scheme 10).

Ionic liquids immobilized on magnetic nanoparticles

Ionic liquids (ILs) are increasingly being explored for targeted chemical tasks due to their unique chemical and physical properties of nonvolatility, nonflammability, thermal stability and controlled miscibility [54]. Although ILs possessed several advantages, their widespread practical application was still banned by some disadvantages such as high viscosity, difficult separation and reusability and consequently high cost for the use of ILs in large-scale application [55]. So, in order to reduce these drawbacks, supported IL catalyst as a novel heterogeneous catalyst with the advantageous characteristics of ILs, inorganic acids and solid acids had been designed for catalyzed transformations [56]. Among various applications of ILs in organic chemistry, imidazolium ionic liquid-type catalysts represent one of the most prominent advancements [57]. Recent studies show that magnetic nanoparticles (MNPs) are excellent supports for ILs due to their good stability, simple preparation and functionalization, high surface area, low toxicity and easy separation by magnetic attractions [58]. These attractive features have made MNPs a favorable alternative to catalyst supports. Mokhtary and Azgomi reported a magnetically supported ionic liquid on Fe3O4@SiO2 nanoparticles (MNPs@SiO2-IL) [59]. The MNPs@SiO2-IL was evaluated as a retrievable catalyst for the one-pot synthesis of 1,3-thiazolidin-4-ones in high to excellent yield under solvent-free conditions. The catalyst could be easily recovered by magnetic separation and recycled for 10× without significant loss of its catalytic activity (Scheme 11).

Also, Khosropour et al. [60] immobilized a unique dicationic ionic liquid tethered to superparamagnetic iron oxide nanoparticles (SPION-ACl2) as a green and powerful catalyst for the efficient synthesis of Betti bases in high to excellent yields. The catalyst could then be recycled and reused at least six times without any loss of activity (Scheme 12).

A magnetic nanoparticle-supported polyoxometalate was reported by Kooti et al. [61]. The supported phosphotungstic acid was indicated to be an effective heterogeneous catalyst for the preparation of α-aminophosphonates under solvent-free conditions at ambient temperature. The catalyst is easily recovered by simple magnetic separation and can be recycled several times with no considerable loss of catalytic activity (Scheme 13).

In another research, Khalafi-Nezhad and Mohammadi [62] reported a magnetic-supported acidic ionic liquid-catalyzed one-pot synthesis of spirooxindoles. Operational simplicity, low cost, high yields, wide applicability and reusability and easy recovery of the catalyst using an external magnet are the key features of this methodology (Scheme 14).

Also, Abu-Reziq et al. [63] found that the Pt nanoparticles immobilized on MNPs modified with ionic liquids (ILs) are very efficient and reusable catalyst for the chemoselective hydrogenation of α,β-unsaturated aldehydes and alkynes. The adsorption of Pt nanoparticles on the IL-functionalized MNPs was obtained by ion exchange with K2PtCl4 followed by reduction with hydrazine. This catalyst was used for the hydrogenation of diphenylacetylene in methanol at 90 °C under hydrogen pressure with the selective formation of cis-alkenes (Scheme 15).

Recently, a magnetically ionic liquid supported on γ-Fe2O3 nanocatalyst (AlxCly-IL-SiO2@γ-Fe2O3) was synthesized by Zhang et al. [64]. The catalyst was evaluated for the synthesis of β-ketoenol ethers. The immobilized catalyst proved to be effective and provided the products in high to excellent yield at room temperature. Moreover, the catalyst could be easily recovered by magnetic separation and recycled for six times without significant loss of its catalytic activity (Scheme 16).

Metal complexes immobilized on magnetic nanoparticles

Coating of MNPs with precious metals such as gold, platinum or palladium [65, 66] leads to very useful, bimetallic magnetic nanoparticles. For example, magnetic nanoparticles coated with Au have distinct advantages over its counterpart based on a single-metal component [67]. Generally, protection of magnetic core with relatively non-magnetic inert shell such as silica improves the chemical stability of magnetic nanoparticles. The silica shell can be easily functionalized and good for grafting of several catalytic species containing transition metal complexes. Sardarian et al. [68] reported many different metal ion species of Schiff bases bind on magnetic silica nanoparticles to produce a series of catalysts which can be used for the synthesis of 1,1-diacetals from aldehydes. They reported yields are in excess of 90 % for reactions involving the chromium (IV) catalyst (Scheme 17).

In addition, the same researchers [69] synthesized a Schiff base complex of Pd(II) supported on superparamagnetic Fe3O4@SiO2 nanoparticles as an efficient copper- and phosphine ligand-free recyclable catalyst for Sonogashira coupling reactions (Scheme 18).

Also, silica-encapsulated magnetic nanoparticles-supported Zn(II) nanocatalyst was prepared by Sharma and Monga [70]. The obtained nanomagnetic catalyst was used in the synthesis of azoxyarenes, combined with facile catalyst recovery and recyclability with excellent reactivity and selectivity (Scheme 19).

It was reported by Tangestaninejad et al. [71] that magnetic nanoparticles with a silica shell can act as a support for a manganese(III) tetrapyridylporphyrin which can act as a catalyst for the epoxidation of alkenes and hydroxylation of alkanes. This new heterogeneous catalyst is of high reusability in the oxidation reactions, in which the catalyst was reused several times without significant loss of its catalytic activity (Scheme 20).

In another study, Wang et al. [72] synthesized a highly efficient, simple, recoverable and reusable Fe3O4 magnetic nanoparticle-immobilized Cu(I) catalyst for the synthesis of quinazolinones and bicyclic pyrimidinones. In this procedure, amidines reacted with substituted 2-halobenzoic acids and 2-bromocycloalk-1-enecarboxylic acids in the presence of catalyst (10 mol%), to generate the corresponding N-heterocycle products in good to excellent yields at ambient temperature in DMF. In addition, the supported Cu(I) catalyst could be recovered at least 10× with little loss of its catalytic activity (Scheme 21).

Recently, Tajbakhsh et al. [73] produced nanomagnetite-functionalized 2,2′-biimidazole complex of metal ion Cu(I) as robust, efficient and recyclable catalysts for green synthesis of propargylamines and 1,4-disubstituted 1,2,3-triazoles in water. The prepared nanocatalyst can be easily recovered and reused many times without a significant decrease in activity and selectivity (Scheme 22).

One of the effective Mizoroki–Heck cross-coupling heterogeneous catalysts was reported by Sobhani and Pakdin-Parizi [74]. In this method, palladium-DABCO complex immobilized on γ-Fe2O3 magnetic nanoparticles (Pd-DABCO-γ-Fe2O3) was prepared as an efficient and recoverable catalyst in Mizoroki–Heck cross-coupling reaction of aryl halides with olefins under solvent-free conditions which was active even after reused five times under solvent-free conditions (Scheme 23).

Dyes are among the most common organic industrial pollutants. Methods applied to dye textiles, paper, plastic, leather, food, and cosmetics are major sources of toxic species in the form of colored wastewater. Nakagaki et al. [75] used recyclable Fe3O4@SiO2–Ag nanospheres as a catalyst for the rapid decolorizing of dye pollutants. The catalytic reaction rate is powerfully dependent on both reaction temperature and Fe3O4@SiO2–Ag amount. Ag nanoparticles immobilized on Fe3O4@SiO2 surfaces serve as an electron relay system and play major role during electron transformation. The catalyst indicates high efficiency for the treatment of some industrial dye pollutants (Scheme 24).

An easy and innovative concept for a micro-aquaponic system (MAS) to valorize residual nitrogen via photocatalytic conversion was also developed by Khakyzadeh et al. [76]. Results confirmed that over 70 % of ammonia could be oxidized to nitrates within 1.5 h under UV irradiation and the remaining taken up by plants which experienced a significantly superior plant growth (with results showing 1.8–1.6× improved petiole growth) with respect to standard grown samples. The proposed strategy may smooth the way to a new eco-farming model aimed to maximize the value of residues to valuable end-products with multidisciplinary efforts and low environmental impact technologies (Fig. 4).

Proposed waste-to-wealth aquaponic concept. From residual nitrogen to plant growth via photoassisted conversion. Reproduced with permission from [76]

Synthesis and applications of dendrimer and polymer immobilized on magnetic nanoparticles

By immobilization of a dendrimers or polymers to the surface of the nanoparticles, the loading with functional groups can be significantly enhanced. By earlier research of Tomalia [77] and Newkome [78], dendrimers have gained remarkable attention as well-defined highly branched structures giving rise to applications in catalysis, sensing, molecular electronics and nanomedicine [79]. One of the interesting properties of the starburst dendritic architecture is the high number of functional end groups contrasting linear polymers. There are generally three methods for modifying solid supports with dendrimers: the divergent preparation of dendrimers on the surface of the support after introducing a linker, the binding of presynthesized dendrimers of various generations and the fabrication of nanoparticles within the boundaries of preformed dendrimers (Fig. 5).

Synthesis of dendrimer-coated magnetic nanoparticles via stepwise divergent synthesis (a), grafting of complete dendrons (b) or synthesis of magnetic nanoparticles (MNPs) inside globular dendrimers (c) [80]

While the solution phase synthesis of dendrimers and following binding might be more easily controlled allowing routine analytics, their generation on the magnetic support can lead to a higher density of functional groups and enables a more suitable workup after each coupling step. Dendrimers are usually immobilized onto magnetic nanoparticles to improve the dispersion of the latter in organic solvents and to multiply functional groups on the surface. For example, poly(amidoamine) (PAMAM) dendrimers on the surface of silica-coated magnetite nanoparticles were reported by Alper et al. [81]. In this procedure, first, magnetic core–shell particles with an approximate size of 60 nm were functionalized with (3-aminopropyl)triethoxysilane (APTMS) to provide an amino group as a initiating point. Then, PAMAM dendrons were synthesized by Michael-type addition of methyl acrylate followed by amide formation with ethylenediamine (Scheme 25).

Rh complex-immobilized magnetic dendrimer could be formed, and the resulting magnetic catalyst was used in hydroformylations of styrene derivatives leading to high selectivities and reactivities for five runs (Scheme 26) [81].

Although dendrimers can efficiently increase functional groups on the surface of magnetic nanoparticles, polymers present other advantages: They often need less synthetic attempt to achieve at high molecular weight analogues, which accelerate dispersion stabilities of the particles through enhanced steric repulsion. However, polymer coatings deal with an inherent restriction: within dense polymer diffusion, and as a consequence thereof, access to active sites can be hindered. While this is also the case for less common dendrimers with intradendritic active sites, generally they are produced to show well-exposed active sites on their surface. At higher generations, however, steric hindering might also limit the availability to active sites in such cases. Coating of MNPs with polymers is another approach to stabilize MNPs. The typical method of surface-initiated atom transfer radical polymerization has been widely applied in coating of MNPs [82]. As compared to the other shell materials, a polymer shell can serve as a surfactant or stabilizer to prohibit the agglomeration of NPs. Also, it can be applied to prepare the nanocapsulation via the layer-by-layer procedure, and it can be functionalized with other materials by selectively choosing the shell materials such as branched poly(ethylenimine) shell around the poly(methylmethacrylate) (PMMA) core [83]. The preparation of polymer-coated nanoparticles, outlined in Fig. 6, was an adaptation of the method used by Nakatani et al. [84] to prepare polyisobutylene-coated iron nitride nanoparticles. In their work, iron pentacarbonyl was thermally decomposed in the presence of a polymeric dispersant, ammonia and kerosene. Ammonia was provided as the source of nitrogen required for the formation of iron nitride.

Scheme of the polymer shell by the thermal decomposition method. Reproduced with permission from [85]

Emulsion polymerization was examined by Gao and coworkers as an effective route to core–shell polymer-coated iron oxide nanoparticles [86]. γ-Fe2O3 nanocrystals coated with a layer of oleate were trapped in micelles by vigorously stirring with an amphiphilic surfactant in an aqueous medium. 4-Vinylbenzene chloride (VBC) and 1,4-divinylbenzene (DVB) were entered into the hydrophobic micellar cores and polymerized upon addition of a radical initiator forming very thin (about 2 nm) polymer shells around the magnetic nanoparticles. N-heterocyclic carbene ligands (NHC) were afterward introduced subsequently by the formation of Pd-complexes, which were utilized in Suzuki, Heck and Sonogashira coupling reactions (Scheme 27).

Another interesting development is the immobilization of polydentate ligands on magnetic nanoparticles that enable effective removal of toxic transition metal. Recently, Lakouraj et al. [87] reported a magnetic chitosan grafted thiacalix [4] arene (Fe3O4-contained CS-g-TC4A) superparamagnetic nanocomposites via click reaction of freshly prepared magnetic chitosan azide with monopropargyl thiacalix [4] arene. The Fe3O4-contained CS-g-TC4A was evaluated for adsorption of many different metal ion species. The maximal adsorption capacities of Pb(II), Cd(II), Co(II), Ni(II), Cu(II) and Cr(III) by Fe3O4-contained CS-g-TC4A superparamagnetic nanocomposite, as calculated from the Langmuir model, were 23.28, 20.08, 15.89, 16.12, 17.85 and 14.92 mg/g, respectively (Fig. 7).

Proposed ion complexation of Fe3O4-contained CS-g-TC4A super-paramagnetic nanocomposite [87]

Summary and outlook

According to this article, there are some fascinating new developments in catalysts immobilized on magnetic nanoparticles. There is a clear approach involving silica coating of magnetic iron oxide core followed by functionalization using convenient alkoxysilane derivatives. Simple modification of the magnetic nanoparticles surface with organic ligands enhances the adsorption of catalytically active metal nanoparticles, as highlighted with palladium-mediated C–C coupling and Pd-catalyzed hydrogenation reactions. The high dispersity of the MNPs in various solvents is another advantage, since it exposes the surface-bound active reaction sites for the reactants in an optimal way. This lets diffusion limitation to be dominated, which is usually found in microporous or mesoporous heterogenized solids. Obviously, catalysts immobilized on magnetic nanoparticles can be recycled many times by simple magnetic attraction without significant loss in their catalytic activity due to the unique magnetic properties of the superparamagnetic particles. Because metal nanoparticles are highly reactive and possess high specific surface area, the stabilization of such materials during or after catalytic reactions is undoubtedly an important issue. A detailed examination of such issues assists understanding of the mechanism of nanocatalysis and also provides valuable suggestion for the preparation of stable nanoparticles to increase or keep their catalytic activity. The sustainable synthesis of magnetically retrievable catalysts using less toxic and readily available reactants as well as environmentally benign solvents or supports will also make this field of research green. Further interesting development is the stabilization of polymer, dendrimer or polydentate ligands on magnetic nanoparticles that enable effective removal of toxic transition metal ion species. This technique provides appropriate industrial applications in pharmaceutical products, food additives and other sectors [88]. Finally, future endeavors for more efficient protocols will still focus on the stability, sustainability, environmental impact and significant cost and energy savings because of the growing needs of industry. These efforts enable a wide variety of industrial applications for magnetic catalysts in the future.

References

C.J. Murphy, J. Mater. Chem. 18, 2173–2176 (2008)

V.F. Puntes, K.M. Krishnan, A.P. Alivisatos, Science 291, 2115–2117 (2001)

H.G. Yang, C.H. Sun, S.Z. Qiao, J. Zou, G. Liu, S.C. Smith, H.M. Cheng, G.Q. Lu, Nature 453, 638–641 (2008)

G.M. Whitesides, B. Grzybowski, Science 295, 2418–2421 (2002)

G.A. Ozin, Adv. Mater. 4, 612–649 (1992)

Y. Gao, Z. Tang, Small 15, 2133–2146 (2011)

G.A. Somorjai, J.Y. Park, Angew. Chem. Int. Ed. 47, 9212–9228 (2008)

C.N.R. Rao, A. Muller, A.K. Cheetham, The Chemistry of Nanomaterials: Synthesis and Applications, vol. 1 (Wiley-VCH, Weinheim, 2004)

Y.W. Jun, J.W. Seo, J. Cheon, Acc. Chem. Res. 41, 179–189 (2008)

I. Washio, Y. Xioung, Y. Yin, Y. Xia, Adv. Mater. 18, 1745–1749 (2006)

S. Shylesh, V. Schünemann, W.R. Thiel, Angew Chem. Int. Ed. 49, 3428–3459 (2010)

R.J. White, R. Luque, V.L. Budarin, J.H. Clark, D.J. Macquarrie, Chem. Soc. Rev. 38, 481–494 (2009)

S. Shylesh, P. Prinson, P. Samuel, S. Sisodia, A.D. Singh, Catal. Surv. Asia 12, 266–282 (2008)

U. Jeong, X. Teng, Y. Wang, Y. Xia, Adv. Mater. 19, 33–60 (2007)

G.A. Mansoori, T. Rohani, A. Ahmadpour, Z. Eshghi, Annu. Rev. Nano Res. 2, 48–50 (2008)

G. Budroni, A. Corma, Angew. Chem. Int. Ed. Engl. 45, 3328–3331 (2006)

A. Hu, G.T. Yee, W. Lin, J. Am. Chem. Soc. 127, 12486–12487 (2005)

N.A. Frey, S. Peng, K. Cheng, S. Sun, Chem. Soc. Rev. 38, 2532–2542 (2009)

R.B. Nasir Baig, R.S. Varma, Chem. Commun. 49, 752–770 (2013)

M. Mokhtary, M. Torabi, J. Saudi Chem. Soc. (2014). doi:10.1016/j.jscs.2014.03.009

M. Nikpassand, L. Zare, T. Shafaati, S. Shariati, Chin. J. Chem. 30, 604–608 (2012)

B. Karimi, S. Nikoseresht, S. Khodabakhshi, Chin. J. Catal. 33, 298–301 (2012)

L.M. Liz-Marzán, M. Giersig, P. Mulvaney, Chem. Commun., 731–732 (1996)

W. Stöber, A. Fink, E.J. Bohn, J. Colloid Interface Sci. 26, 62–69 (1968)

P. Tartaj, C.J. Serna, J. Am. Chem. Soc. 125, 15754–15755 (2003)

A.P. Philipse, M.P.B. van Bruggen, C. Pathmamanoharan, Langmuir 10, 92–99 (1994)

Y.H. Deng, C.C. Wang, J.H. Hu, W.L. Yang, S.K. Fu, Colloid Surface A 262, 87–92 (2005)

L.M. Liz-Marzán, M. Giersig, P. Mulvaney, Langmuir 12, 4329–4335 (1996)

M. Giersig, M. Hilgendorff, Eur. J. Inorg. Chem., 3571–3583 (2005)

R.P. Hodgkins, A. Ahniyaz, K. Parekh, L.M. Belova, L. Bergström, Langmuir 23, 8838–8844 (2007)

N.C. King, R.A. Blackley, M.L. Wears, D.M. Newman, W.Zhou, D.W. Bruce, Chem. Commun., 3414–3416 (2006)

Y. Li, T. Kaneko, T. Ogawa, M. Takahashi, R. Hatakeyama, Chem. Commun., 254–256 (2007)

J. Lee, J. Kim, T. Hyeon, Adv. Mater. 18, 2073–2094 (2006)

J. Grunes, J. Zhu, G.A. Somorjai, Chem. Commun., 2257–2260 (2003)

M. Mokhtary, A. Mossafaii Rad, Int. Nano Lett. 5, 109–123 (2015)

M. Mokhtary, N. Shahrivar Fallah, J. Taibah Univ. Sci. 9, 531–537 (2015)

J.M. Thomas, W.J. Thomas, Principles and Practice of Heterogeneous Catalysis (VCH, Weinheim, 1997)

J. Fan, Y. Gao, J. Exp. Nanosci. 1, 457–475 (2006)

A. Schätz, Dissertation, Universität Regensburg (2009)

D. Enders, O. Niemeier, A. Henseler, Chem. Rev. 107, 5606–5655 (2007)

M. Gruttadauria, F. Giacalone, R. Noto, Chem. Soc. Rev. 37, 1666–1688 (2008)

A. Bruckmann, A. Krebs, C. Bolm, Green Chem. 10, 1131–1141 (2008)

Y. Zheng, C. Duanmu, Y. Gao, Org. Lett. 8, 3215–3217 (2006)

V. Polshettiwar, R.S. Varma, Tetrahedron 66, 1091–1097 (2010)

R. Luque, B. Baruwati, R.S. Varma, Green Chem. 12, 1540–1543 (2010)

F. Nemati, R. Saeedirad, Chin. Chem. Lett. 24, 370–372 (2013)

H. Kefayati, M. Golshekan, S. Shariati, M. Bagheri, Chin. J. Catal. 36, 572–576 (2015)

H. Mahmoudi, A.A. Jafari, S. Saeedi, H. Firouzabadi, RSC Adv. 5, 3023–3030 (2015)

A. Alizadeh, M.M. Khodaei, M. Beygzadeh, D. Kordestani, M. Feyzi, Bull. Korean Chem. Soc. 33, 2546–2552 (2012)

S.M. Sadeghzadeh, Chem. Plus. Chem. 79, 278–283 (2014)

B. Karimi, E. Farhangi, Chem. Eur. J. 17, 6056–6060 (2011)

Y. Kong, L. Zhao, D. Yin, Green Chem. 15, 2422–2433 (2013)

J. Safari, S. Gandomi-Ravandi, RSC Adv. 4, 11486–11492 (2014)

V.I. Parvulescu, C. Hardacre, Chem. Rev. 107, 2615–2665 (2007)

S. Sahoo, P. Coumar, F. Lefebvre, S.B. Halligudi, Appl. Catal. A. Gen. 354, 17–25 (2009)

J. Miao, H. Wan, G. Guan, Catal. Commun. 12, 353–356 (2011)

A. Zarrouk, M. Messali, H. Zarrok, R. Salghi, A.A. Ali, B. Hammouti, S.S. Al-Deyab, F. Bentiss, Int. J. Electrochem. Sci. 7, 6998–7015 (2012)

J. Safari, Z. Zarnegar, C. R. Chim. 16, 920–928 (2013)

N. Azgomi, M. Mokhtary, J. Mol. Catal. A: Chem. 398, 58–64 (2015)

M. Shafiee, A.R. Khosropour, I. Mohammadpoor-Baltork, M. Moghadam, S. Tangestaninejad, V. Mirkhani, Catal. Sci. Technol. 2, 2440–2444 (2012)

H. Hamadi, N. Adibpour, J. Mol. Catal. A: Chem. 373, 25–29 (2013)

A. Khalafi-Nezhad, S. Mohammadi, ACS Comb. Sci. 15, 512–518 (2013)

P.H. Li, B.L. Li, H.C. Hu, Z.H. Zhang, Catal. Commun. 46, 118–122 (2014)

S. Sobhani, Z. Pakdin-Parizi, Appl. Catal. A: Gen. 479, 112–120 (2014)

L. Wang, J. Luo, M.M. Maye, Q. Fan, Q. Rendeng, M.H. Engelhard, C. Wang, Y. Lin, C.J. Zhong, J. Mater. Chem. 15, 1821–1832 (2005)

C.-H. Jun, Y.J. Park, Y.R. Yeon, J.-R. Choi, W.-R. Lee, S.-J. Ko, J. Cheon, Chem. Commun., 1619–1621 (2006)

C. Xu, J. Xie, D. Ho, C. Wang, N. Kohler, E.G. Walsh, J.R. Morgan, Y.E. Chin, S. Sun, Angew. Chem. Int. Ed. 47, 173–176 (2008)

M. Esmaeilpour, A.R. Sardarian, J. Javidi, Appl. Catal. A: Gen. 445–446, 359–367 (2012)

M. Esmaeilpour, A.R. Sardarian, J. Javidi, J. Organomet. Chem. 749, 233–240 (2014)

R.K. Sharma, Y. Monga, Appl. Catal. A: Gen. 454, 1–10 (2013)

M.S. Saeedi, S. Tangestaninejad, M. Moghadam, V. Mirkhani, I. Mohammadpoor-Baltork, A.R. Khosropour, Polyhedron 49, 158–166 (2013)

L. Wang, M. Wang, P. Li, L. Wang, Appl. Organomet. Chem. 26, 576–582 (2012)

M. Tajbakhsh, M. Farhang, S.M. Baghbanian, R. Hosseinzadeh, M. Tajbakhsh, New J. Chem. 39, 1827–1839 (2015)

R. Abu-Reziq, D. Wang, M. Post, H. Alper, Adv. Synth. Catal. 349, 2145–2150 (2007)

S. Lijuan, H. Jin, S. An, D. Ren, Chin. J. Catal. 34, 1378–1385 (2013)

V. Khakyzdeh, R. Luque, M.A. Zolfigol, H.R. Vahidian, H. Salehzadeh, V. Moradi, A.R. Soleymani, A.R. Moosavi-Zare, K. Xu, RSC Adv. 5, 3917–3921 (2015)

D.A. Tomalia, H. Baker, J. Dewald, M. Hall, G. Kallos, S. Martin, J. Roeck, J. Ryder, P. Smith, Poly. J. 17, 117–132 (1985)

G.R. Newkome, Z. Yao, G.R. Baker, V.K. Gupta, J. Org. Chem. 50, 2003–2004 (1985)

D. Astruc, E. Boisselier, C. Ornelas, Chem. Rev. 110, 1857–1959 (2010)

Q.M. Kainz, O. Reiser, Acc. Chem. Res. 47, 667–677 (2014)

R. Abu-Reziq, H. Alper, D. Wang, M.L. Post, J. Am. Chem. Soc. 128, 5279–5282 (2006)

N. Pothayee, S. Balasubramaniam, R.M. Davis, J.S. Riffle, M.R.J. Carroll, R. Woodward, T. St Pierre, Polymer 52, 1356–1366 (2011)

F. Hu, K.G. Neoh, L. Cen, E.T. Kang, Biomacromolecules 7, 809–816 (2006)

I. Nakatani, M. Hijikata, K. Ozawa, J. Magn. Magn. Mater. 122, 10–14 (1993)

N.A.D. Burke, H.D.H. Stöver, F.P. Dawson, Chem. Mater. 14, 4752–4761 (2002)

P.D. Stevens, J. Fan, H.M.R. Gardimalla, M. Yen, Y. Gao, Org. Lett. 7, 2085–2088 (2005)

M.M. Lakouraj, F. Hasanzadeh, E.N. Zare, Iran. Polym. J. 23, 933–945 (2014)

J. Govan, Y.K. Gun’ko, Nanomaterials 4, 222–241 (2014)

Acknowledgments

Financial support by Rasht Branch, Islamic Azad University, Grant No. 4.5830 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mokhtary, M. Recent advances in catalysts immobilized on magnetic nanoparticles. J IRAN CHEM SOC 13, 1827–1845 (2016). https://doi.org/10.1007/s13738-016-0900-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-016-0900-4