Abstract

[Mn(salen)Cl-cellulose] was synthesized by immobilization of homogeneous Mn(salen)Cl complex on cellulose and characterized by FT-IR, TGA and atomic absorption spectroscopy. The resulted catalyst exhibited moderate to high reactivity in the oxidation of benzylic alcohols into carbonyl compounds using oxone as oxidant in ambient conditions. The catalytic activity of Mn(salen)Cl and [Mn(salen)Cl-cellulose] in this reaction was investigated. The heterogeneous catalyst showed higher catalytic activity with respect to neat Mn(salen)Cl complex.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, science and technology have devoted to the introduction and applications of environmentally friendly and sustainable catalysts. One of the useful strategies for the preparation of such catalysts is the attachment of organic or inorganic materials to different solid supports. The homogeneous catalysts suffer from the drawbacks of poor catalyst recovery and product separation [1]. Low toxicity, moisture resistance, air tolerance, great selectivity, easy handling, and low cost are some of the beneficial features of this method that make it an efficient alternative to homogeneous catalyst.

The field of surface chemistry describes a variety of natural or synthetic materials suitable for chemical surface reactions, with the main objective to improve the overall capacity for applications [2, 3]. A lot of these supports are derived from inorganic compounds, such as silica and other oxides; however, some important reports describe excellent results in which are related to biopolymers [1, 4, 5]. In this sense, the most abundant biopolymer is cellulose. It has excellent thermal, mechanical properties and biocompatibility, also for economic and scientific reasons, is a promising material for biochemical engineering [6, 7]. It was widely applied as an efficient support and/or template for the synthesis of inorganic materials. For example, palladium nanoparticles were synthesized on the cellulose matrix and employed as an active catalyst for the hydrogenation reaction of phenol and the Heck coupling of styrene and iodobenzene [8]. In recent years, cellulose has gained renewed significance as a raw material and still possesses a high potential for future applications [9–12].

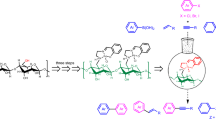

Schiff bases are versatile ligands synthesized from the condensation of an amino compound with carbonyl compounds and these coordinate to metal ions.

Schiff’s base and their complexes possess remarkable properties as catalysts in various biological systems, polymers, dyes, antimicrobial activities, antifungal activities, antiviral activities insecticides, antitumor and cytotoxic activities, plant growth regulator, enzymatic activity and pharmaceutical fields. A variety of schiff’s base and its complexes have been studied extensively. Several model systems, including those with bidentate, tridentate, tetradentate, multidentate Schiff base ligands, and their coordination chemistry of Mn attract much attention because of its biological relevance and its own interesting coordination chemistry such as geometry, flexible redox property, and oxidation state [13].

In this work, [Mn(salen)Cl-cellulose] was synthesized by immobilization of homogeneous Mn(salen)Cl complex on cellulose. We reported comparison of the catalytic activity of homogeneous Mn(salen)Cl complex and heterogeneous Mn(salen)Cl complex in the oxidation reaction. Oxidation reaction carried out using a variety of oxidants. Among these oxygen donors, oxone is the best oxidant [14–20].

Materials and methods

All chemicals and solvents were purchased from Merck or Fluka and were used without purification.

The structure of Mn(salen)-cellulose was obtained by interpretation of the spectra TGA50 (Shimadzu-Japan) on a platinum cell, FT-IR 4300 (Shimadzu-Japan) on a range from 400 to 4,000 cm−1 and atomic absorption spectroscopy (AA-6300 Shimadzu-Japan).

Preparation of catalyst

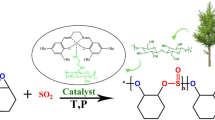

3-Trimethoxysilylpropylamine (10 mmol, 1.76 ml) was added to a suspension of salicylaldehyde (10 mmol, 1.044 ml) in absolute ethanol (10 ml) in ambient temperature. The solution instantly became yellow, indicating the formation of the schiff base. After 30 min, Mn(CH3COO)2 .4H2O (5 mmol, 1.225 g) was added to the solution, and the mixture was further stirred for 2 h to form Mn(salen) complex. LiCl (29.15 mmol, 1.224 g) was then added. After adding 3 gr cellulose and stirring the mixture overnight at room temperature, product was isolated by removing the solvent. The crude product was washed with water, EtOH and ether, respectively. Further drying of the solid product was carried out in an oven at 80 °C for 8 h [21].

General procedure for catalytic oxidation of benzyl alcohol with oxone catalyzed by Mn(salen)Cl-cellulose

In a typical procedure, a suspension of supported Mn catalyst (0.3 gr), oxone (1 mmol, 0.614 g), aromatic alcohols (1 mmol) and ethanol (3 ml) was stirred at room temperature for 30 min. After completion of the reaction (TLC), the catalyst was filtered and the mixture was extracted with diethyl ether (3 × 5 ml), the organic layer was washed with brine (5 ml), dried over MgSO4, and concentrated. Purity determinations of the products were accomplished by TLC on silica-gel polygram SILG/UV 254 plates.

To examine the effect of catalyst, we studied this reaction in the absence of catalyst. Our results showed the oxidation of benzyl alcohol with oxone even in the absence of catalyst also gave benzaldehyde, but in lower yield (8 %). Oxone is a versatile oxidizing agent for the oxidation of alcohols but according to the literature, in the absence of catalyst, its reaction time is too long [22–24].

Results and discussion

Characterization of catalyst

Scheme (1) shows synthesis procedure of [Mn(salen)Cl-cellulose].

Spectroscopic techniques including FT-IR, TGA and atomic absorption analysis were used to study the structure of the manganese(III)-salen complex. The loading of Mn on cellulose was 0.266 mmol/g estimated by AAS.

The derivative TG (DTG) curve of Mn(salen)Cl-cellulose is shown in the Fig. 1. The recorded curve showed weight loss at temperatures ranging from 265 to 575 °C, which corresponds to the loss of salen complex and cellulose [25]. The loading of Mn on cellulose was about 0.255 mmol/g, as determined from the 87.709 % loss in mass between 265 and 575 °C, in accordance with the result obtained from AAS. Covalent bands are responsible for high thermal stability of catalyst and it caused the catalyst stable up to 300 °C.

Figure 2 shows the FT-IR spectra of the cellulose, Mn(salen)Cl and supported complexes of Mn. The spectrum of Mn(salen)Cl shows a band at 1,632 cm−1 due to imine υ(C = N) and another band at 1,596 cm−1 attributed to the aromatic ring vibrations (Fig. 2c). The peak at 646 cm−1 is assigned to the stretching vibrations of the Mn–O bond of the complex. In addition, the observed peaks in the region of 1,300–1,600 cm−1 are due to C–O, C–N and aromatic ring. In Fig. 2b, cellulose exhibited bands at 3,200–3,500 cm−1 and 1,000–1,300 cm−1 that related to OH, C–O and an anomeric carbon. There were some differences between the FT-IR spectra of the pure catalyst (Fig. 2c) and supported catalyst (Fig. 2a). In the spectrum of Mn(salen)Cl-cellulose (Fig. 2a), the vibration intensity of bonds became very weak.

These observations clearly showed the attachment of salen complex onto cellulose.

The effect of solvent on the oxidation of benzyl alcohol with oxone catalyzed by Mn (salen)Cl-cellulose

To find the optimized conditions, benzyl alcohol was used as a model substrate. The oxidation reactions were carried out in various solvents at room temperature. According to the Table 1, n-hexane, chloroform and acetone showed high yield but the time for their reactions is too long. Ethanol (entry 5) shows high yield in the shortest time so it was chosen as reaction medium for the oxidation of benzyl alcohols.

The effect of different oxidants on the oxidation of benzyl alcohol with oxone catalyzed by Mn(salen)Cl-cellulose

The effect of different oxidants on the catalytic activity of Mn(salen)Cl-cellulose in the oxidation of benzyl alcohol was studied. We chose different oxidants such as Oxone, KIO4, UHP and H2O2. The results are summarized in Table 2. When KIO4, UHP and H2O2 were used as the oxygen source in ethanol, Mn(salen)Cl-cellulose, produced low benzaldehyde. Oxone is a strong, cheap and versatile oxidizing agent. The results showed that in the presence of oxone as a oxygen source higher yield was obtained.

Optimization of the oxidant and catalyst amount in the reaction of benzyl alcohol with oxone catalyzed by Mn(salen)Cl-cellulose

To find the optimized conditions, we changed the amount of oxidant and catalyst for the oxidation of benzyl alcohol using oxone in the presence of ethanol at room temperature. Consequently, the best conditions used for the oxidation of benzyl alcohol by this catalytic system were the 0.3 g catalyst and 1 mmol oxidant (Tables 3 and 4). Control experiments indicated that in the absence of the catalyst, the reaction at the same condition gives benzaldehyde in a rather low yield of 8 %.

Oxidation of alcohols with oxone catalyzed by Mn(salen)Cl-cellulose

Based on the selective conversion of benzyl alcohol to the corresponding aldehyde during the experiments (Table 5, entry 1–6), the oxidation of aliphatic alcohols was investigated at room temperature in the presence of oxone. The oxidation of benzylic alcohols occurred selectively to give the corresponding aldehydes in 30–120 min (Table 5, entries 1–6), while aliphatic alcohol such as ethanol remained unreactive. A possible reason for this is the known reactivity of oxone toward benzylic C–H bonds [22]. As shown in Table 5, the electron-rich groups exhibited high yields and short times, possibly these groups stabilize the intermediates produced along the reaction pathway for the incorporation of oxygen into the molecule. This hypothesis is reinforced by our results for the oxidation reactions of alcohols. For these compounds, the electron-rich groups were directly oxidized, and thus, the appropriate reaction occurs immediately with excellent yield. In aromatic rings containing electron-attraction groups, the yields were lower. The 4-hydroxy benzyl alcohol can be converted to the corresponding aldehyde in high yield, but the time of this reaction is longer than the oxidation of benzyl alcohol (Table 5, entries 1 and 3). For the 2-chloro benzyl alcohols, the yield of the product is moderate (Table 5, entry 5). The best result in the short time was obtained for the oxidation of benzyl alcohol in 85 % yield (Table 5, entry 1). In addition, we observed that the mainly products are the benzaldehyde, not acid.

Comparison of catalytic activity of Mn(salen)Cl and Mn(salen)Cl-cellulose

To show the effect of immobilization on the catalytic activity of Mn(salen)Cl in the alcohol oxidation with oxone, we repeated all reactions under optimization conditions. The results are summarized in Table 5. Our results showed that the turnover frequency (h−1) (TOF) for the Mn(salen)Cl-cellulose catalyst was higher than the Mn(salen)Cl catalyst. One probable explanation is that the ligands of Mn(salen)Cl complex are not oxidized when complex attach to cellulose, and therefore the catalytic activity of Mn(salen)Cl does not reduce. Owing to the abilities of support to highly disperse the active complexes, and to control the local concentrations of the reactant and product around active sites, the immobilization led to an increase in catalytic performance in the oxidation reactions (calculated in terms of TOF). One of the problems of homogeneous catalysis using Mn(III)-salen complexes is the formation of catalytically inactive oxomanganese species that limits recycling of the catalyst. One of the potential advantages of polymer-bound catalysts is the possibility of suppressing this side reaction due to the spatial separation of individual metal complexes on the solid support [26–34]. So the catalytic activity of Mn(salen)Cl complex can be modified by attaching to cellulose through covalent bonding.

Catalyst reusability and stability

It is important to verify the stability of the heterogeneous catalyst since metal leaching from catalyst becomes responsible for decreasing of the catalytic activity in successive cycles. To assess long-term stability and reusability of [Mn(salen)Cl-cellulose], oxidation of benzyl alcohol was chosen as model reaction, and recycling experiments were carried out with a single sample of the catalyst. After each experiment, the catalyst was filtered, washed with H2O, dried and reused. After reusing catalyst for four consecutive times, the yield was 80 %. The results showed that the catalytic activity of Mn(salen)Cl-cellulose is appropriate for more than four-time reuse (Fig. 3).

Conclusions

In this study, we have developed a highly efficient oxidation of benzylic alcohols to carbonyl compounds by oxone in the presence of Mn(salen)Cl-cellulose. Mn(salen)Cl complex was successfully immobilized on to cellulose and this heterogeneous catalyst was used at neutral and mild reaction conditions to convert benzyl alcohols to aldehyde and acid. This catalyst also remarkably alters ratio of aldehyde/acid, which may attributed to the immobilization mode and support effect of heterogeneous catalyst. Mn(salen)Cl-cellulose has received considerable attention as an inexpensive, eco-friendly, highly reactive, easy to handle and non-toxic catalyst for various organic transformations, affording the corresponding products in excellent yields. Moreover, this catalyst as a recoverable catalyst can be easily separated from reaction mixture by a simple filtration and reused repeatedly and can be stored for a long time without any reducing of its reactivity.

References

D. Klemm, B. Heublein, H.P. Fink, A. Bohn, Angew. Chem. Int. Ed. 44(22), 3358–3393 (2005)

S. Babel, T.A. Kurniawan, J. Hazard. Mater. 97, 219–243 (2003)

C. Haensch, S. Hoeppener, U.S. Schubert, Chem. Soc. Rev. 39, 2323–2334 (2010)

M. Kumar, React. Funct. Polym. 46, 1–27 (2000)

R.J. Moon, A. Martini, J. Nairn, J. Simonsen, J. Youngblood, Cellulose nanomaterials review: structure, properties and nanocomposites. Affiliation Information 1. School of Mechanical Engineering, Purdue University, West Lafayette, USA. Chemical Society Review 2011, 40, 3941–3994

D.H.R. Barton, A.E. Martell, D.T. Sawyer, The activation of dioxygen and homogeneous catalytic oxidation (Plenum, New York, 1993)

J.P. Collman, V.J. Lee, C.J. Kellen-Yuen, X. Zhang, J. Am. Chem. Soc. 117, 692 (1995)

K. Srinivasan, P. Michaud, J.K. Kochi, J. Am. Chem. Soc. 108, 2309 (1986)

R.L. Hammonds, M.S. Harrison, T.C. Cravanas, W.H. Gazzola, C.P. Stephens, R.S. Benson, Cellulose 19, 1923–1932 (2012)

R.J. Maurer, A.F. Sax, V. Ribitsch, Cellulose 20, 25–42 (2012)

B. Duchemin, A. Thuault, A. Vicente, B. Rigaud, C. Fernandez, S. Eve, Cellulose 19, 1837–1854 (2012)

R. Katwal, H. Kaur, B.K. Kapur, Sci. Revs. Chem. Commun. 3(1), 1–15 (2013)

P. Malik, D. Chakraborty, Tetrahedron Lett. 53, 5652–5655 (2012)

S.P. Das, J.J. Boruah, H. Chetry, N.S. Islam, Tetrahedron Lett. 53, 1163–1168 (2012)

V. Mirkhani, M. Moghadam, S. Tangestaninejad, I. Mohammad poor-Baltork, N. Rasouli, Catal. Commun. 9, 2411–2416 (2008)

B.R. Travis, M. Sivakumar, G.O. Hollist, B. Borhan, Org. Lett. 5, 1031–1034 (2003)

T.W. Bell, Y.M. Cho, Al. Firestone, K. Healy, J. Liu, R. Ludwig, S.D. Rothenberger, Org. Syn. 69, 226–237 (1990)

M. Uyanik, M. Akakura, K. Ishihara, J. Am. Chem. Soc. 131, 251–262 (2009)

C. Bolm, A.S. Magnus, J.P. Hildebrand, Org. Lett. 2, 1173–1175 (2000)

A.P. Thottumkara, M.S. Bowsher, T.K. Vinod, Org. Lett. 7, 2933–2936 (2005)

X.G. Zhou, X.Q. Yu, J.S. Huang, C.M. Che, Chem. Commun. 23, 2377–2378 (1999)

K.N. Parida, S. Jhulki, S. Mandal, J.N. Moorthy, Tetrahedron 68, 9763–9768 (2012)

B.S. Koo, C.K. Lee, K.J. Lee, Synth. Commun. 32(14), 2115–2123 (2002)

S. Seth, S. Jhulki, J.N. Moorthy, Eur. J. Org. Chem. 12, 2445–2452 (2013)

Y.P. Chauhan, R.S. Sapkal, V.S. Sapkal, G.S. Zamre, Int. J. Chem. Sci. 7(2), 681–688 (2009)

K.D. Pradeep, B.D. Binod, S.J. Swaminathan, Mol. Catal. A Chem. 177, 71–87 (2001)

V.D. Chaube, S. Shylesh, A.P. Singh, J. Mol. Catal. A Chem. 241, 79–87 (2005)

S. Shylesh, A.P. Singh, J. Catal. 228, 333 (2004)

S. Shylesh, S. Sharma, S.P. Mirajkar, A.P. Singh, J. Mol. Catal. A Chem. 212, 219 (2004)

P. Karandikar, M. Agashe, K. Vijaymohanam, A.J. Chandwadkar, Appl. Catal. A Gen 257, 133 (2004)

X.G. Zhou, X.Q. Yu, J.S. Huang, S.G. Li, L.-S. Li, C.M. Che, Chem. Commun. 18, 1789–1790 (1999)

T. Joseph, S.B. Halligudi, C.V.V. Satyanarayana, D.P. Sawant, S. Gopinathan, J. Mol. Catal. A Chem. 168, 8797 (2001)

S.B. Halligudi, K.N. Kalaraj, S.S. Despande, S. Gopinathan, J. Mol. Catal. 154, 25 (2000)

T. Joseph, D.P. Sawant, C.S. Gopinath, S.B. Halligudi, J. Mol. Catal. A Chem. 184, 289 (2002)

Acknowledgments

The authors are thankful to the University of Birjand Research Council for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nasseri, M.A., Mohammadinezhad, A. & Salimi, M. A cellulose-supported Mn(salen)Cl complex as an efficient heterogeneous catalyst for the selective oxidation of benzylic alcohols. J IRAN CHEM SOC 12, 81–86 (2015). https://doi.org/10.1007/s13738-014-0457-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-014-0457-z