Abstract

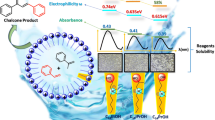

The Knoevenagel condensation between aromatic aldehydes and malononitrile, barbituric acid or 1,3-dimethylbarbituric acid with ethane-1,2-diammonium hydrogen sulfate (EDAHS) in aqueous micellar media, using sodium dodecyl sulfate is described. EDAHS was found to be a highly active and stable Bronsted acidic ionic liquid catalyst under the reaction conditions.

Graphical Abstract

.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Knoevenagel reaction is an important and widely employed method for carbon–carbon bond formation in organic synthesis [1–3]. It is widely used in the synthesis of important intermediates or end-products for perfumes, pharmaceuticals, calcium antagonists, and polymers [4–6].

Traditionally, the Knoevenagel reaction is catalyzed in the presence of base catalyst [1, 7, 8], Lewis acids [9], and zeolites [10]. The use of ionic liquids [11, 12] is applied as a new path for the Knoevenagel condensation. Although other methods are available for this transformation [13–23], attention is moving toward newer and more selective methods for this purpose.

Much work has shown that this condensation is strongly solvent-dependent and benzene, ethanol, and DMF are commonly used. However, toxic reagents, harsh reaction conditions, long reaction time, low yield, and difficult work-up have always posed problems. In addition to, the use of solvents in large scale for the Knoevenagel condensation has led to environmental problems. In view of these limitations, the introduction of efficient and new methods based on green methodology is still in demand.

An area of recent intense synthetic attempt is the use of approaches that are beneficial to industry as well as to the environment. Since green chemistry is mainly concerned with the reduction of chemical hazards and pollution [24], a plausible convention is to use safer solvents that present significantly less threat to ecosystems. Thus, the use of water as solvent in chemical reactions has demonstrated an alternative to organic solvents because water is the most environmentally acceptable, safe and inexpensive solvent [25]. However, organic reactions in water are often limited in scope due to poor solubility of the organic compounds. A possible way to improve the solubility of substrates is the use of surface-active compounds that can form micelles [26–29]. On the basis of previous reports [30], it is likely that micelles act as nanoreactors to bring the reactants together to provide a confined reaction environment.

Ionic liquids have attracted considerable interest as environmentally benign reaction media due to their specific properties such as high thermal and chemical stability, no measurable vapor pressure, no flammability, friction reduction, anti-wearing performance, and high loading capacity [31–34].

Results and discussion

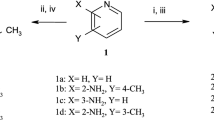

As part of our ongoing efforts to develop environmentally benign processes [20], and in continuation of our research program to develop selective and efficient methods in organic synthesis [35–40], herein, we describe an eco-friendly and economical approach to the Knoevenagel condensation reaction catalyzed by ethane-1,2-diammonium hydrogen sulfate (EDAHS) as a new Bronsted acidic ionic liquid (Scheme 1). The reactions were completed at room temperature with excellent yields of desired products.

Sodium dodecyl sulfate (SDS) was selected because it forms micelles in water, can solubilize organic substrates that are otherwise insoluble in water. We envisioned that the SDS surfactant micelles (SDS micelle diameter about 4 nm [41]) could act as nanoreactors to induce better solubilization of aldehydes and active methylene compounds and ultimately allow these compounds to interact more intimately with the EDAHS. The nonpolar alkyl chains remain in a nonpolar environment and the hydrocarbon chains can dissolve the organic substrate. Thus, there was no requirement to employ water-soluble compounds (Fig. 1).

Our investigations on the Knoevenagel condensation reaction of malononitrile with aryl aldehydes began with the optimization of reaction conditions. Initially, the reaction of 1 mmol of benzaldehyde with 1 mmol of malononitrile in the presence of SDS micellar solution (1 CMC, 5 mL) was tested in the absence of EDAHS at room temperature. The reactants remained unchanged even after 3 h stirring. Upon addition of 0.05, 0.75 and 0.1 mmol of EDAHS, condensation occurred and the reaction led to desired product straightaway in 40, 80, and 94 %, respectively. Further increase in the reaction temperature and the amount of EDAHS did result in no decrease in the reaction time or in no increase in the yield (Table 1, entry 4). Also, using 2 mmol of benzaldehyde (and 1 mmol of malononitrile) showed no change in the final product yield and again, 2-benzylidenemalononitrile was obtained as a final product. Thus, under these optimized conditions, various structurally diverse aromatic aldehydes were reacted with malononitrile, and the corresponding results are listed in Table 2. As shown, the aryl aldehydes bearing electron-releasing and electron-withdrawing groups undergo this reaction with equal efficiency. For example, 2-(4-hydroxybenzylidene)malononitrile (Table 2, entry 6) is produced in 95 % yield, and 2-(3-nitrobenzylidene)malononitrile in 98 % yield (Table 2, entry 4).

Acid-sensitive aryl aldehyde such as 2-furancarboxaldehyde worked well without the formation of any side products, which are normally observed either in the presence of protic or Lewis acids (Table 2, entry 9). Interestingly, the presence of ether (Table 2, entry 7) and amine (Table 2, entry 8) groups did not interfere with the condensation process of the aryl aldehydes, and desired products were obtained in excellent yields. Acid-labile cinnamaldehyde (Table 2, entry 10), also undergoes clean condensation without changing of the double bond.

To demonstrate the efficiency and applicability of the EDAHS further, the Knoevenagel condensation of barbituric acids and various aromatic aldehydes was also investigated (Scheme 1). The same reaction conditions were applied via the condensation of aldehyde (1 mmol) and barbituric acid derivative (1 mmol) in SDS micellar solution (1 CMC, 5 mL) in the presence of EDAHS (0.1 mmol). The reactions were completed within 6–10 min with excellent product yields (Table 2, entries 12–17).

However, as can be seen from the data in Table 2, the chemoselectivity of this process is similar to that of the synthesis of 2-arylidenemalononitrile and the nature of substituent on the aromatic ring does not affect on the yield of the Knoevenagel condensation. However, the reaction failed to proceed with ketones under the same reaction conditions (Table 2, entry 18).

The proposed mechanism for the Knoevenagel condensation is depicted in Scheme 2. It is reasonable to assume that the acidic part of EDAHS (ammonium moiety) protonates the oxygen of carbonyl group of aryl aldehyde and this makes the carbonyl group more electrophilic. On the other side, the anionic part of EDAHS (hydrogen sulfate anion) is basic and deprotonates acidic position of a methylene compounds and causes the formation of nucleophile. Subsequently, the nucleophilic addition to the protonated aryl aldehyde produces an intermediate alcohol. In the end, protonation of this alcohol followed by elimination of water gives the desired products.

A comparison of the catalytic efficiency of EDAHS with selected previously known catalysts is shown in Table 3 to demonstrate that the present method is indeed superior to several of the other methods.

Conclusions

In conclusion, EDAHS is introduced as new and chemoselective Bronsted acidic ionic liquid catalyst for the Knoevenagel condensation of aromatic aldehydes with active methylene compounds in aqueous micellar media, using SDS. The advantages of the present reaction are the elimination of the metals and organic solvents, inexpensive reagents, operational simplicity and excellent yields of products.

Experimental

Materials and techniques

Melting points were taken with an Electrothermal 9100 apparatus and left uncorrected. 1H and 13C NMR spectra were recorded with a Bruker DRX-300 Avance spectrometer at 400/300 and 100/75 MHz. All the chemicals were purchased from Fluka, Merck, and Aldrich, and used without purification.

Preparations of EDAHS

Ethylene diamine (6.67 mL, 0.1 mol) was placed in a two-necked flask equipped with a reflux condenser and a dropping funnel. The flask was fixed in an ice bath. Under vigorous stirring with a magnetic stirring bar (10.7 mL, 0.2 mol) of 98 % H2SO4 was added dropwise to the flask in about 20 min to afford a brown powder as the product (94 % yield), m.p. 85–89 °C. 1H NMR (D2O, 400 MHz) spectrum of EDAHS shows signal at 3.08 ppm (s, 4 H, –CH2–N); 13C NMR (D2O, 100 MHz) spectrum shows a signal at 36.4 ppm. Anal. Calc. for C2H12N2O8S2: 256; C 9.37, H 4.72, N 10.93, S 25.03. Found: C 9.30, H 4.80, N 10.85, S 25.25.

General procedure for the Knoevenagel condensation of active methylene compounds with aryl aldehydes

To a micellar solution of SDS (5 mL, 1 CMC = 8.1 × 10−3 M in H2O), a mixture of aryl aldehyde (1 mmol) and active methylene compound (1 mmol) was added. Then EDAHS (0.026 g, 0.1 mmol) was added and the resulting mixture was stirred at room temperature for the indicated reaction time (Table 2). After the reaction was over as monitored on TLC, The organic material was extracted with ethyl acetate and the surfactant was precipitated by the slow addition of CaCl2 to the vigorously stirred mixture of the micellar solution and ethyl acetate. Upon the evaporation of solvent, the crude product was recrystallized from ethanol and identified by comparison of spectral and physical data with those described in the literature. Spectral data for the selected compound follows.

2-(Furan-2-ylmethylene)malononitrile (Table 2, entry 9)

1H NMR (300 MHz, CDCl3): δ H (ppm): 6.73 (1H, t, J = 1.8 Hz), 7.37 (1H, d, J = 3.6 Hz), 7.52 (1H, d, J = 4.5 Hz), 7.82 (s, 1H); 13C NMR (75 MHz, CDCl3): δ C (ppm): 112.5, 113.8, 114.4, 123.4, 143.0, 148.1, 149.5.

References

G. Jones, Organic reaction, vol. 15 (Wiley, New York, 1967), p. 204

F. Texier-Boullet, A. Foucaud, Tetrahedron Lett. 23, 4927 (1982)

S. Chalais, P. Laszlo, A. Mathy, Tetrahedron Lett. 26, 4453 (1985)

F. Liang, Y.J. Pu, T. Kurata, J. Kido, H. Nishide, Polymer 46, 3767 (2005)

G. Kwak, M. Fujiki, Macromolecules 37, 2021 (2004)

S.M. Lai, C.P. Ng, R. Martin-Arnada, K.L. Yeung, Microporous Mesoporous Mater. 66, 239 (2003)

M.M. Heravi, F. Derikvand, M. Haghighi, Kh Bakhtiari, Lett. Org. Chem. 3, 297 (2006)

J. March, Advanced organic chemistry: reactions, mechanisms, and structure, 4th edn. (Wiley, New York, 1992)

D. Prajapati, K.C. Lekhok, J.S. Sandhu, A.C. Ghosh, J. Chem. Soc. Perkin Trans. 1, 959 (1996)

T.I. Reddy, R.S. Verma, Tetrahedron Lett. 38, 1721 (1997)

J.R. Harjani, S.J. Nara, M.M. Salunkhe, Tetrahedron Lett. 43, 1127 (2002)

F.A. Khan, J. Dash, R. Satapathy, S.K. Upadhyaya, Tetrahedron Lett. 45, 3055 (2004)

Z. Wenfei, L. Jinhua, L. Yanqiu, S. Shoufei, R. Xiaoqian, J. Min, Chin J. Catal. 34, 559 (2013)

A. Rostami, B. Atashkar, H. Gholami, Catal. Commu. 37, 69 (2013)

W. Hu, Z. Guan, X. Deng, Y.-H. He, Biochimie 94, 656 (2012)

J.M. Khurana, K. Vij, Tetrahedron Lett. 52, 3666 (2011)

F.X.L. Xamena, F.G. Cirujano, A. Corma, Microporous Mesoporous Mater. 157, 112 (2012)

K.M. Parida, S. Mallick, P.C. Sahoo, S.K. Rana, Appl. Catal. A Gen. 381, 226 (2010)

A. Modak, J. Mondal, A. Bhaumik, Appl. Catal. A Gen. 459, 41 (2013)

B.A. Robichaud, K.G. Liu, Tetrahedron Lett. 52, 6935 (2011)

S. Ghosh, J. Das, S. Chattopadhyay, Tetrahedron Lett. 52, 2869 (2011)

Y. Zhang, Y. Zhao, C. Xia, J. Mol. Catal. A Chem. 306, 107 (2009)

J. Xu, K. Shen, B. Xue, Y.-X. Li, J. Mol. Catal. A Chem. 372, 105 (2013)

C. Pellerin, Chemistry goes green. Ejournal USA Global Issues. (2005)

C.-J. Li, Chem. Rev. 93, 2023 (1993)

J.H. Fendler, E.J. Fendler, Catalysis in micellar and macromolecular systems (Academic Press, London, 1975)

Mixed Surfactant Systems, ed. by P. M. Holland, D. N. Rubingh (American Chemical Society, Washington, 1992)

Structure and Reactivity in Aqueous Solution, ed. by C. J. Cramer, D. G. Truhlar (American Chemical Society, Washington, 1994)

Surfactant-Enhanced Subsurface Remediation, ed. by D. A. Sabatini, R. C. Knox, J. H. Harwell (American Chemical Society, Washington, 1994)

D.M. Vriezema, M.C. Aragonés, J.A.A.W. Elemans, J.J.L.M. Cornelissen, A.E. Rowan, R. Nolte, J.M. Chem. Rev. 105, 1445 (2005)

L. Chen, M. Zheng, Y. Zhou, H. Liu, H. Jiang, Synth. Commun. 38, 239 (2008)

J.C. Legeay, J.Y. Goujon, J.J. Vanden Eynde, L. Toupet, J.P. Bazureau, J. Comb. Chem. 8, 829 (2006)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, H.G. Kruger, Z. Asgari, V. Khakyzadeh, M. Kazem-Rostami, J. Org. Chem. 77, 3640 (2012)

M. Ali Zolfigol, V. Khakyzadeh, A.R. Moosavi-Zare, A. Zare, S.B. Azimi, Z. Asgari, A. Hasaninejad, C. R. Chimie. 15, 719 (2012)

K. Bahrami, M.M. Khodaei, A. Nejati, Green Chem. 12, 1237 (2010)

M.M. Khodaei, K. Bahrami, A. Farrokhi, Synth. Commun. 40, 1492 (2010)

K. Bahrami, M.M. Khodaei, F. Naali, J. Org. Chem. 73, 6835 (2008)

K. Bahrami, M.M. Khodaei, M. Soheilizad, J. Org. Chem. 74, 9287 (2009)

K. Bahrami, M.M. Khodaei, M. Sheikh Arabi, J. Org. Chem. 75, 6208 (2010)

K. Bahrami, M.M. Khodaei, P. Fattahpour, Catal Sci. Technol. 1, 389 (2011)

P.A. Hassan, S.R. Raghavan, E.W. Kaler, Langmuir 18, 2543 (2002)

M.L. Deb, P.J. Bhuyan, Tetrahedron Lett. 46, 6453 (2005)

Q. Liu, H. Ai, Z. Li, Ultrason. Sonochem. 18, 477 (2011)

M. Gupta, R. Gupta, M. Anand, Beilstein J. Org. Chem. 5, 1 (2009)

D.Q. Shi, J. Chen, Q.Y. Zhuang, X.S. Wang, H.W. Hu, Chin. Chem. Lett. 14, 1242 (2003)

C. Zhuo, D. Xian, W. Jian-Wei, X. Hui, ISRN Org. Chem. 2011, 1 (2011)

M.M. Heravi, K. Bakhtiari, S. Taheri, H.A. Oskooie, J. Chin. Chem. Soc. 54, 1557 (2007)

Acknowledgments

We are thankful to the Razi University Research Council for partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bahrami, K., Khodaei, M.M., Babajani, N. et al. Knoevenagel condensation in aqueous micellar media using EDAHS as a new Bronsted acidic ionic liquid. J IRAN CHEM SOC 11, 1675–1680 (2014). https://doi.org/10.1007/s13738-014-0440-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-014-0440-8