Abstract

In the past decade, liquid-phase microextraction (LPME), which can also be called solvent microextraction, has emerged as a minimal organic solvent-based sample preparation approach. The main advantages of this method include versatility, simplicity and effectiveness of its extraction procedures at reducing sample complexity, as well as the convenience of liquid sample concentration and injection techniques. LPME is based on the distribution of analytes between the organic solvent and the aqueous solution. Hitherto, several different LPME modes have been developed. Some of the described methodologies usually offer slow extraction kinetics due to the low contact surface between the sample and the extractant phase. Since the introduction of dispersive liquid–liquid microextraction, a number of studies have been focused on the features of emulsification in preconcentration techniques. Emulsification enhances the surface area between the extraction solvent and aqueous sample by the efficient dispersion (chemically assisted or by the use of an external energy source) of the extractant in the sample. In this paper we review the emulsification-based liquid-phase sample preparation techniques. A brief practical and theoretical description of each technique and some applications are given.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sample pre-treatment is the first and possibly the most important step in analysis. The main objectives of sample preparation are removal of potential interferences, analyte preconcentration, conversion (if needed) of the analyte into a more suitable form for detection or separation and providing a robust and reproducible method that is independent of variations in the sample matrix. Liquid–liquid extraction (LLE) is a versatile classical sample preparation technique prescribed in many standard analytical methods. However, conventional LLE uses large amounts of potentially toxic organic solvents which are often hazardous and expensive. LLE is also considered to be a time-consuming, tedious and multi-stage operation [1]. The advent of the concept of “green chemistry” at the beginning of the 1990s emphasized the need for non-toxic and environmentally friendly analytical procedures. The concept also promoted the use of environmentally sustainable sample-preparation methods with the development of solvent-free or miniaturized extraction methods [2].

The development of novel miniaturized techniques derived from conventional LLE is a challenging issue in analytical chemistry. Several works related to the use of microliter volumes of the extractant phase were subsequently carried out at Dasgupta’s laboratory [3, 4]. Jeannot and Cantwell proposed the application of a Teflon rod to expose an 8-μL drop to sample solution [5]. After the microextraction process, the enriched organic phase was withdrawn with a microsyringe for analysis. Employing the microsyringe to expose the microdrop during the extraction process and to retract it back obtained a powerful and simple approach, known currently as single-drop microextraction (SDME) [6, 7]. Since its inception in 1997, SDME has been exploited for hundreds of applications in both organic and inorganic analytes. Although SDME is very simple and efficient, and diminishes the consumption of organic solvents to a few microliters per sample, it suffers from low stability of the hanging drop, which is easily lost in the sample during extraction. In order to improve the stability and reliability of liquid-phase microextraction (LPME), Pedersen-Bjergaard and Rasmussen [8, 9] introduced, in 1999, a new LPME method called hollow fibre-based LPME (HF-LPME). In this method, the extracting phase is placed inside the lumen of a porous hydrophobic hollow fibre that forms a supported liquid membrane (SLM). The extraction is done in two-phase or three-phase sampling modes.

Microextraction time is a key parameter in LPME techniques owing to the time-dependent nature of mass transfer processes [10]. The concentration of analyte in the extractant phase \((C{}^{\text{ext}}(t))\)can be expressed as a function of microextraction time (t), as follows:

wherein, \(C{}_{\text{eq}}^{\text{ext}}\) is the equilibrium concentration in the extractant phase and k is the observed rate constant which is obtained from the equation below:

where A is the interfacial area and β exr is the overall mass transfer coefficient to the extractant phase. Also, V ext and V a are the volumes of extractant phase and aqueous sample, respectively, and K is the distribution coefficient. Thus, for the rapid extraction of an analyte, A and β exr must be maximized and V a should be minimized. The above-mentioned LPME methodologies present slow extraction kinetics because of the low interfacial area between the sample and the extractant phase.

Since the introduction of dispersive liquid–liquid microextraction (DLLME) [11], considerable studies have been conducted focusing on the properties of emulsification-based LPME techniques (EMU-LPME). The interfacial area, A, which defines the available area for the interfacial mass transfer, varies with the square of the droplet diameter. That explains the rapid kinetics of extraction when EMU-LPME is employed in comparison with the other LLE modes described here. In the emulsification-based extraction many tiny drops of organic solvent are formed in the aqueous medium, which provide a larger interface between the two media, hence enhance the extraction rate. Therefore, extraction time is not important in EMU-LPME unlike the other techniques in which equilibrium conditions are not commonly achieved. Consequently, short extraction times are generally gained with EMU-LPME as a result of the infinitely large surface area formed between the extractant phase and the aqueous phase that increases the sample throughput. In fact, this is one of the main advantages of emulsification-based extraction as compared with the rest of preconcentration methodologies.

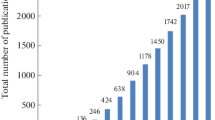

In recent years, the interest in EMU-LPME has increasingly turned towards the refinement of its modes for use in practical sample preparations. In this critical review, first we explore EMU-LPME technique innovations that appeared in the literature (e,g., HLPME, DLLME and supramolecular solvent microextraction) in the period from mid-2006 to mid-2013. After that we investigate hyphenated methods as well as modern phase separation in EMU-LPME. Figure 1 graphically represents the recent relative interest in the three major general EMU-LPME modes using disperser solvent, external force and surfactant.

Homogeneous liquid phase extraction

Homogeneous liquid phase microextraction (HLPME) is a simple and powerful preconcentration method that extracts the solute from a homogeneous solution into a very small organic phase formed from the solution by the phase separation phenomenon. Phase separation phenomenon results in an emulsion of extraction phase in aqueous medium. Several methods such as temperature changing and addition of salt, concentrated acid or an auxiliary solvent have been used for phase separation in HLPME [12].

In LLE, certain solvents such as acetonitrile, acetone, 2-propanol, propylene carbonate, methanol, ethanol and dimethylsulphoxide cannot be used as extracting solvents because they are miscible with water in all proportions. Therefore, they are omitted from use as extractants from aqueous solution although their high dielectric constants, donor numbers and solubility parameters would make them helpful if they could be employed [13]. It is obvious that if some ways could be found to separate these solvents as organic phases from aqueous solutions, the versatility of solvent extraction would be greatly increased.

Temperature dependent homogenous system

These approaches are based on the high solubility of organic solvent in water at higher temperature [14]. At room temperature, the two phases are present heterogeneously, but at the elevated temperature they change into a homogeneous solution, which separates into the two phases again upon cooling. During these sequential procedures, the species in the aqueous phase transfers into the organic phase. The effectiveness of the homogeneous LLE is attributed just to the higher reaction temperature.

Salting out-based homogenous system

Two relatively simple and similar theories have been used to explain salting-out phenomena, one postulating decreased mutual solubility of the solvents and the other postulating removal of one solvent via solvation processes [15]. The former assumes that compounds, not necessarily ionic in nature, are preferentially solvated by one of the solvents, making this solvent unavailable for dissolving the second. The latter theory, which applies only to ionic compounds, assumes that the more polar solvent (e.g., water) in a mixture of two solvents preferentially congregates around the salt because of electrostatic attraction, leading to nonideal behaviour. A combination of these two processes is obviously possible, but the salt effect will probably predominate with ionic salting-out compounds. Three factors should be considered when evaluating a salt and its potential salting-out effect on organic solvent [15]: (1) the solubility of the salt in organic solvent must be negligible; (2) the solubility in water must be large to have maximum interaction with the water molecules; and (3) the ability of ions to precipitate water-loving substances (gels), according the lyotropic series (Mg2+ > Ca2+ > Sr2+ > Ba2+ > Li+ > Na+ > K+ > Rb+ > Cs+). Various salts have been used for acetonitrile phase separation for metal determination, like calcium chloride [16] and sodium nitrate [17].

In case of ternary solvent (water/methanol/chloroform) the phase separation of the extracting solvent (chloroform) from aqueous phase can also be accomplished by salt addition [18]. By this procedure, fine droplets of the extraction phase were sedimented in the bottom of a conical test tube by centrifugation. In this case the volume of the sedimented phase is very small.

Auxiliary solvent-based homogenous system

There is also the procedure [19] that, the addition of a small volume of an auxiliary solvent to promote the separation of an immiscible ternary phase (water/acetonitrile/chloroform), made up almost entirely of the water-miscible solvent. Although such auxiliary solvents need to be found empirically, once a suitable one has been found and the phase diagrams for the ternary system have been constructed, the phases obtainable by use of various ternary solvent compositions can be used for solvent extraction as easily as the solvent pairs in conventional solvent extraction systems.

A similar HLLE method called “single phase” using ternary solvent system (water/ethanol/methylisobutylketone) [20] (acetonitrile/chloroform/HCl aqueous solution) [21] and (water/ethanol/chloroform) [22] has been proposed for metal extraction and determination. After preparing this single-phase solution, the homogeneous three-component solvent system is “broken down” by the addition of an excess of water. By this procedure the homogeneous solution is separated into two liquid layers.

The pH-dependent homogenous system

Another alternative homogeneous LLE method is based on pH-dependent phase separation [23]. Neutralization of perfluorooctanoate ion (PFOA−) in water-miscible organic solvent solution (such as acetone, 1,4-dioxane and tetrahydrofuran) induces phase separation, providing a small volume (down to 0.1 mL, depending on the amount of PFOA− which has been added) of an oily and transparent water-immiscible liquid phase, from a large volume of the aqueous solution. This phase separation was reversible with the pH change in the solution, corresponding to below and above the pKa value of perfluorooctanoic acid (HPFOA).

The PFOA−, pH-dependent, method needs usually strongly acidic condition (pH < 1) and thus is difficult to be applied for the separation and concentration of biologically active substances due to the fact that these substances easily hydrolyse the substituents and cause denaturation of the protein. In order to solve these problems, phase separation in the neutral pH region has been achieved using Zonyl FSA (CF3(CF2) n –CH2CH2–SCH2CH2–COOH, n = 6 ± 8), which induced the methylene group as a spacer of the fluorosurfactant. The pH-dependent phase separation with Zonyl FSA has been applied as a preconcentration step before spectrofluorometric determination of chlorophyll-A [24] and recently for analysis of 14 elements with ICP-AES [25].

Also, recently, a binary system for pH-dependent homogeneous LPME using an organic phase with density lower than water as the extractant was introduced to resolve some problems in pH-dependent systems. Octanoic acid was used as the solvent in acid-induced homogeneous liquid phase microextraction (AI-HLPME). In this method, octanoic acid provides a homogeneous solution in basic mediums (pH ≥ 7.5) and changing in pH was used as emulsification phenomenon for phase separation. Emulsification and phase separation were performed by adding several microliters of concentrated HCl to the homogeneous solution [26].

Moreover, a homogeneous LLE method using the pH-dependent phase separation in the water/acetic acid/chloroform ternary solvent system was reported for copper(II) and palladium(II) determination [27]. It is postulated that the state of the homogeneous solution in water/acetic acid/chloroform dissolved in water is due to the solvation of small amounts of chloroform with acetic acid molecules. When sodium hydroxide is added to this system, acetic acid converts to acetate ion due to the acid–base reaction of acetic acid, and consequently its function as a solvation molecule was absent. Hence, an emulsion of water-immiscible chloroform is formed in the aqueous solution by phase separation. Extracting solvent selection in this case is an important factor and it has to meet the following characteristics: (a) it should be heavier than water, (b) it should form a ternary homogeneous system with water and acetic acid, (c) it should dissolve the analyte more than water and (d) it should be sedimented after adding a phase-separation agent (NaOH solution).

Ion pair-based homogenous system

The ion-pair formation of tetrabutylammonium ion (TBA+) and perfluorooctanoate ion (PFOA−) in a homogeneous solution of water/sodium acetate has been used for extraction and spectrophotometric determination of uranium(VI) [28].

Recently, an ion-pair formation pH-independent phase separation method was established using a homogeneous ternary solvent system (water/TBA+–ClO4−/chloroform) for iron(II), cobalt, copper and nickel extraction, based on ion-pair formation of TBA+ and perchlorate ion (ClO4−) [29].

Dispersion of organic extraction solvent

In 2006, a new mode of LPME namely DLLME, as a high-performance, powerful, rapid and inexpensive microextraction method, was developed for isolation of polyaromatic hydrocarbons (PAHs) from aqueous samples [10]. The basic principle of this method is the dispersion (emulsification) of extraction solvent (immiscible in water), assisted with disperser solvent (miscible in both water and extraction solvent), within the aqueous solution which leads to a very high contact area between the aqueous phase and the extraction solvent. The disperser solvent (e.g. methanol or acetonitrile) reduces the interfacial tension (γ) between organic and aqueous phases, thus making an increase in surface area during fine droplet formation, as explained by the Young–Laplace equation

where R sph is the radius of the spherical droplet and P internal and P external are the internal and external pressures of the droplet, respectively. This simple form of the Young–Laplace equation shows that the interfacial tension decline results in a decrease in the droplet radius and the creation of finer droplets at a constant pressure difference.

In general, several requirements have to be met to perform sample isolation using DLLME. The dispersing solvent must be fully soluble in the water phase. Usually, acetone, acetonitrile and methanol are applied for this purpose. The extracting solvent has to fulfil several requirements. It must have potential for extracting the analytes. Also, it has to be soluble in the dispersing solvent while its solubility in water should be very low. Finally, the density of the extracting solvent should differ greatly from the density of water to enable phase separation. Up to now, three categories of extraction solvents (consisting of organic solvents with higher and lower densities than water, and ionic liquids) have been exploited in DLLME.

Having a look at the literature, it is clear that conventional DLLME covers the utilization of water-immiscible chlorinated solvents as the most common extractants (i.e., chlorobenzene, dichloromethane, carbon tetrachloride, tetrachloroethane, etc.), while disperser solvents include water-miscible solvents, such as acetone, acetonitrile, methanol and ethanol. As a result, in recent years due to the high attractiveness of this technique, several review articles have been published concerning the specific use of DLLME for the extraction of different types of analytes from a wide variety of matrixes [30–33].

Of course, like other analytical methods, DLLME also has drawbacks, that are mainly caused by the requirements for extraction solvent and disperser solvent. One of the most significant disadvantages of this technique is that it is most useful for non-polar analytes. For strong polar and non-volatile samples, which are unsuitable for analysis by gas chromatography (GC), derivatization is necessary to increase the analytes volatility. Application of DLLME coupled with derivatization reaction provides a one-step derivatization and extraction technique, greatly simplifying the operation steps and shortening the analysis time. Simultaneous derivatization and extraction by DLLME combined with GC-electron capture detector (GC-ECD) was developed to determine chlorophenols (CPs) in water samples [34].

On the whole, the technique has been mostly applied in the past few years to the extraction and preconcentration of pesticides [29, 35–37], together with (although to a lesser extent) other organic analytes, such as pharmaceuticals [38, 39], amines [40], parabens [41] and wine compounds like phenols, anisols, etc. [42–46]. All these studies illustrate the use of toxic chlorinated solvents or carbon disulfide as the extracting solvents. GC has been employed in most of these investigations as an analytical technique in which it is natural to utilize DLLME. After that a preliminary study on DLLME conjugated with high-performance liquid chromatography-diode array detection (HPLC–DAD) reported for the analysis of antioxidants in aqueous samples [47]. In propose method, extracted solvent was evaporated before injection to HPLC due to damage possibility to LC columns. The proposed method was very efficient, rapid and repeatable. However, Wei et al. [48] suggested the possibility of direct injection of tetrachloroethane extract in reversed-phase HPLC analysis. In the following years, most researchers used the direct injection of chlorinated solvents in several DLLME techniques to HPLC operating in reversed-phase mode [49, 50] without the tedious solvent evaporation.

Extraction solvents with density higher than water are highly toxic and environmentally-unfriendly. To overcome these problems, researchers have exploited organic solvents with lower densities than water. One probable way of allowing the application of low-density solvents in emulsification-based liquid phase microextraction procedures is the use of special extraction devices [51–54]. All these devices (Fig. 2) work on a single principle: centrifugation of an organic solvent less dense than water after emulsification and extraction procedure, causing its accumulation at the top of the aqueous phase, followed by elevation of the floating film to the narrow part of the device by adding water and withdrawal of the extraction phase for subsequent analysis using a proper analytical method.

Special home-made extraction devices for emulsion-based liquid phase microextraction procedures using extraction solvents lighter than water: a the vessel employed a septum for injecting distilled water in order to elevate the sample surface; b a narrow neck glass tube device; c a centrifuge glass vial with the glass tube fixed on the side of the vial and the capillary tube attached to the top of the vial; d a device for magnetic stirring-assisted liquid-phase microextraction

Room-temperature ionic liquids (ILs) have recently being considered as replacement solvents in sample preparation, because of their unique chemical and physical characteristics such as negligible vapour pressure, non-flammability, good extracting ability for various organic compounds and metal ions as neutral or charged complexes, as well as tunable viscosity and miscibility with water and organic solvents. Besides, the high attention is also due to the capability of ILs to form a wider range of intermolecular interactions than typical volatile organic solvents; these include strong and weak ionic, hydrogen bonding, van der Waals, dispersive, n–π and π–π interactions [55]. Classical DLLME based on ILs as extractant phase (IL-based DLLME) [56, 57] and cold-induced aggregation microextraction (CIAME) [58, 59] have both been proposed as novel ultrasound-assisted emulsification–microextraction (USA-EME) techniques, avoiding many of the problems observed in earlier methods.

In comparison with the conventional DLLME, the performance of the IL-based DLLME decreases significantly as the salt content of sample solution is increased. In the presence of salt, the solubility of ILs increases due to increase in ionic strength of the aqueous solution. Therefore, the volume of the settled phase in IL-based DLLME depends strongly on the salt concentration of samples. Moreover, ILs dissolve completely at high concentration of salt and the cloudy solution is not formed. Consequently, IL-based DLLME cannot be applied for extraction and preconcentration of analyte(s) from samples containing high salt concentration. To overcome to this drawback a novel IL-based DLLME technique that is robust against high salt concentration demonstrated [56] so that a mixture of a water-immiscible ionic liquid (as extraction solvent) and disperser solvent is injected into an aqueous sample solution containing one of the IL’s ions. As an example 1-Hexyl-3-methylimidazolium hexafluorophosphate [Hmim][PF6] (a water-immiscible ionic liquid) and NaPF6 were used as extraction solvent and common ion source, respectively. According to the common-ion effect, the solubility of ionic compounds (such as ILs) decreases in the presence of a common ion, even at high ionic strength. A common ion is any ion in the solution that is common to the ionic compound (IL) being dissolved. In the present work, the \({\text{PF}}_{6}^{\text{ - }}\) ion in NaPF6 is common to the \({\text{PF}}_{6}^{ - }\) in [Hmim][PF6]. In the proposed IL-based DLLME, because of the presence of \({\text{PF}}_{6}^{ - }\) the solubility of [Hmim][PF6] decreases. Therefore, proposed IL-based DLLME can be applied for aqueous samples containing high concentration of salt (up to 40 %, w/v).

As an alternative to IL-based DLLME a new method termed CIAME was developed [58]. In this method, a very small amount of hydrophobic IL as an extractant solvent is dissolved in the sample solution containing Triton X-114. Triton X-114 prevents IL sticking onto the surface of the centrifuge tube wall, so its name is “anti-sticking agent”. One should be aware that there is no interface between the water and the extractant phases; as a result mass transfer from aqueous phase into separated phase has no important effect on the extraction step. After dissolving, the solution is cooled in the ice bath and a cloudy solution is formed due to the solubility reduction of IL and fine droplets are formed. During the formation of fine droplets of the extractant phase, the hydrophobic species are collected by the extractant molecules, and the extraction process is completed after the formation of the droplets. After centrifuging, the fine droplets of extractant phase settle to the bottom of the conical-bottom glass centrifuge tube.

Improvement in DLLME

Emulsification by external force

More recently, by increasing concerns about environmentally friendly chemistry, different external forces were used to eliminate disperser solvent in DLLME. In a heterogeneous system consisting of two immiscible liquid phases, the influence of ultrasound radiation is the result of several concurrent partial phenomena with complex interrelationships and is dependent on a considerable number of variables. The application of ultrasounds in liquids produces cavitations which are related to formation of microbubbles that finally collapse. When the liquid is a mixture of two immiscible phases the result of the formation of cavitations and their collapse is an emulsion of the minority phase in the bulk. The cavitational collapse also produces strong variations of pressure and temperature in the interface which may affect the exchange of analytes between the phases [60]. The application of a miniaturized approach to this technique using a microvolume of extracting organic phase provides the advantages of both DLLME and ultrasound-assisted LLE (USA-LLE) and some more, mainly derived from low concentration of inner phase drops, decrease in the coalescence effect [61], decline in the radiation absorption and then warming and the acoustic flow facilitation leading to increase in homogenization speed. The approach is very efficient for fast preconcentration. After mass transfer, the two phases can be readily separated by centrifugation. In this way, USA-EME has been successfully utilized for the extraction of, amongst others, bisphenol A from beverages [62] and parabens from cosmetics [63]. In addition, the simultaneous performance of derivatization and USA-EME of phenolic compounds in water has been reported [64]. On the other hand, organic extraction solvents tend to volatilize under the ultrasonic radiation. Taking this into account, Liang and co-workers [65] have investigated the application of ILs as extraction solvents instead of organic solvents in USA-EME of four fungicides (azoxystrobin, diethofencarb, pyrimethanil and kresoxim-methyl) from environmental water samples.

Ultrasound energy can be a source of problems [66], since ultrasound irradiation frequently causes the formation of stable emulsions, thus resulting in a prolonged separation. Also, it is often difficult to ensure the uniformity of ultrasound energy among individual samples and experiments, and analyte degradation may occur owing to the influence of ultrasound energy. Hence, the vortex-assisted liquid–liquid microextraction (VA-LLME) technique, in which the dispersion of extraction solvent is enhanced by vortex mixing rather than ultrasound irradiation, was devised. Up to now, low-viscosity organic solvents and high-viscosity ILs were successfully tested for emulsification using VA-DLLME [67–69]. This technique was performed with multiple samples and could conceivably be fully automated.

Emulsification by surfactant

An interesting method for dispersion of extraction solvent in aqueous solution is the use of surfactant-assisted DLLME (SA-DLLME) [70, 71]. This technique needs no ultrasound irradiation or toxic disperser solvent. In the presence of the surfactant a cloudy solution was readily formed as the fine droplets of the immiscible extraction solvent dispersed in the aqueous sample. After centrifugation, the collected phase was injected into HPLC–UV for further analysis. The method exhibited very good results for real water samples, with advantages such as high extraction efficiency and recovery, low cost, low matrix effects and minimum extractant solvent consumption (without the use of dispersive solvent), all of which agreed with green chemistry criteria. There are several reports about the application of surfactant as emulsifier for the microextraction of cannabinoids [72], nitrophenols, chloroanilines [73], fluoroquinolones [74] and some metal ions [75, 76].

Supramolecular solvent-based microextraction

Cloud point extraction

Although cloud point extraction (CPE) method cannot categorize in the microextraction techniques its mechanism is based on emulsion formation of surfactant-rich phase so that firstly a cloudy solution was formed and then analytes were isolated onto non-aqueous phase. Hence, here we introduce extraction mechanism of CPE method which is a promising, environmentally benign extraction technique that was first introduced by Watanabe and coworkers in 1976 [77]. At the beginning, CPE was used for preconcentration of trace-metal ions in the form of their hydrophobic complexes. Later, it was extensively exploited as a primary isolation step in purification of proteins. Since then, analytical chemists throughout the world have been developing its potential and finding different applications. A recent publication by Mishra et al. [78] provides an excellent overview of the fundamentals, methodology and applications of the CPE technique.

Clouding behaviour, also known as lower consolute behaviour or coacervate phase behaviour, is a typical physical change in the homogeneous solutions of amphiphilic substances, due to which the solution separates into a surfactant-rich and a surfactant-poor phase at a definite temperature. The temperature, at which phase separation occurs, i.e. the threshold temperature of clouding, is known as the cloud point (CP) or lower consolute temperature (LCT), as an important character of non-ionic surfactants. Clouding is ascribed to the efficient dehydration of hydrophilic portion of micelles at higher temperature condition. The clouding phenomenon is due to the interaction of non-ionic surfactant micelles via an attractive potential, whose well-depth increases with temperature [79]. These micelles attract each other and form clusters [80] with the approach of the cloud point. However, the mechanism behind the lower consolute behaviour of non-ionic surfactant systems still remains obscure.

CPE consists of three simple steps (Fig. 3): (1) solubilization of the analytes in the micellar aggregates; (2) clouding (or emulsification); and (3) phase separation for analysis. When a surfactant solution is heated over a critical temperature, the solution easily separates into two distinct phases: one aqueous phase contains a surfactant at a concentration below, or equal to, the critical micelle concentration of surfactant, and the other is a surfactant-rich phase. The hydrophobic compounds initially present in the solution and bound to the micelles are extracted to the surfactant-rich phase. This phenomenon is observed, in particular, for polyoxyethylene surfactants and can be attributed to the ethylene oxide segments in the micelle that repel each other at low temperature when they are hydrated and attract each other when the temperature increases owing to the dehydration.

Off-line CPE has been applied to extract and preconcentrate various metal ions from aqueous solutions. It involves a series of fussy procedures including incubation, centrifugation, and separation of the surfactant-rich phase from the bulk aqueous phase and dilution of the surfactant-rich phase. These steps may result in poor reproducibility, a low preconcentration factor, and a time-consuming procedure. In the on-line mode of CPE, some tedious steps that could reduce repeatability of the method, such as heating, centrifugation, cooling in an ice bath, separation of the bulk aqueous phase from the surfactant-rich phase and dilution of the surfactant-rich phase, are omitted. These steps result in a long extraction time, a small preconcentration factor, and poor precision. On-line CPE integrates heating of the sample, trapping of the surfactant-rich phase on a column (emulsion breaking), and elution of the entrapped analytes in one step; therefore, it reduces the analysis time and increases the simplicity, sensitivity, preconcentration factor and precision of the method.

Supramolecular-based microextraction

Recently, Rubio et al. [81] reviewed both theoretical and practical aspects related to the use of supramolecular solvents (SUPRASs) in analytical extractions over the past decade. The term SUPRAS was initially introduced by Pérez-Bendito’s research group. Generally, SUPRAS refers to nano-structured liquids generated from amphiphiles through a sequential, self-assembly process occurring on two molecular and nano scales. Here, the term supramolecular solvent-based extraction is employed for two recent alkyl carboxylic acid aggregate-based extractions (water-induced and tetrabuthylammonium (TBA)-induced coacervation). First, amphiphilic molecules spontaneously form three-dimensional aggregates (e.g. aqueous and reversed micelles or vesicles) above the critical aggregation concentration. Then, the generated nanostructures self-assemble into larger aggregates with a wide size distribution in the nano- and micro-scale regimes by the action of an external stimulus (e.g. water or TBA) and separate from the bulk solution by a mechanism that remains elusive [82].

In 2006, the same research group studied the potential of TBA-induced liquid–liquid phase separation in alkyl carboxylic acid vesicular solutions for the extraction of organic compounds prior to HPLC, for the first time [82]. SUPRASs are water-immiscible liquids made up of supramolecular assemblies dispersed in a continuous phase. Two characteristics make the alkyl carboxylic acid-based coacervates have a high potential for analytical extraction processes. First, the polar region of the molecular aggregates consists of protonated and deprotonated carboxylic and ammonium groups, so a number of interactions (e.g., electrostatic, cation-π, hydrogen bonding, formation of mixed aggregates, etc.) could be established with the analytes, in addition to the hydrophobic interactions in the hydrocarbon region. Second, the vesicles have a number of available solubilization sites; therefore, high concentrations of polar and apolar molecules can be solubilized in each aggregate. In the above work, the creation of vesicles in aqueous solution before adding Bu4N+ ions was not essential to complete liquid–liquid phase separation. The driving forces for the construction of these vesicular aggregates were hydrophobic interactions between the hydrocarbon chains of decanoic acid (DeA) and decanoate (De−), the formation of hydrogen bonds between carboxylic and carboxylate groups, and the electrostatic interactions between carboxylate and quaternary ammonium groups of De− and Bu4N+ ions, respectively.

Normally, pH of sample solution determines the state of DeA in aqueous solution which plays an important role in the stability of vesicles in aqueous samples. It was found that the maximal amount and stability of the vesicles are obtained at pH = 7.0, so it was recommended to work at alkyl carboxylic acid/carboxylate molar ratios around 1.0. On the other hand, vesicular coacervate composition primarily depended on the Bu4N+/DeA + De− molar ratio (w/w) in the bulk solution [83–85].

In another work, SUPRASs made up of reversed micelles of decanoic acid dispersed in THF-water [86]. Analytes with a broad range of polarities were efficiently extracted on the basis of the hydrophobic (e.g., PAHs) and hydrogen bond (e.g., chlorophenols, bisphenols, pesticides, phthalates, non-ionic surfactants, dyes, and photographic developers) interactions of reverse micelles. Decanoic acid dissolves in THF forming reverse micelles according to a sequential-type self-association model with at least three critical aggregation concentrations (4.8 ± 0.2, 7.6 ± 0.4 and 51 ± 2 mmol/L) [87]. The addition of water to this binary system causes partial desolvation of the aggregates, which makes their interactions easier and promotes the construction of larger reverse micelles that separate from the THF:water bulk solution as an immiscible liquid phase. The structure of the coacervates comprised spherical droplets dispersed in a continuous phase. Phase-volume ratios were functions of both alkyl carboxylic acid and THF concentrations. The volume of the solvent produced was linearly and exponentially dependent on the amount of DeA and the percentage of THF, respectively. Recently, the same research group developed SUPRASs-based microextraction of sulfonamides (SAs) from meat samples prior to LC-fluorescence detection [88]. The SUPRAS was prepared within a wide range of THF/water ratios (e.g. from 5:95 to 80:20, v/v) and DeA concentrations below 8.0 % (w/v). Reverse micelles were created only from decanoic acid (pKa = 4.8 ± 0.2), so maximal production of this solvent happened at pHs below 4.0.

The morphology of the nano-sized aggregates of DeA was investigated by dynamic light scattering (DLS). The DLS size distributions of DeA aggregates are shown in Fig. 4 [89]. It is apparent the distributions centred at approximately 1–2 nm correspond to micelles. The actual micelle size is probably larger than the DLS-determined value, because the measured diffusion coefficients are strongly affected by inter-micelle repulsion among the charged micelles. The diffusion coefficient, D, in the Stokes–Einstein equation depends on the nature of interactions between the particles. Because of deprotonated DeA (De−) in the reverse micelle structure the aggregates have a small negative charge, resulting in electrical repulsion between them. When there is a repulsive interaction between particles the diffusion coefficient tends to increase; thus, measured size is slightly smaller than actual size. The larger distributions centred at approximately 100 nm correspond to larger aggregates, which are vesicles. In Fig. 4b, the size distribution is plotted against the number of aggregates. Although the proportion of vesicles is close to 0.0 % (Fig. 4b), because of their large size they scattered 30.0 % of the light (Fig. 4a). It seems that the reverse micelle is the main type of aggregate in the formed SUPRAS.

Dynamic light scattering measurement of size distributions of the supramolecular solvent, including nano-structured DeA aggregates, versus (a) scattered light intensity and (b) number of aggregates. Reprinted with permission from [89]

Hyphenated methods for emulsification-based microextraction

Solid-phase extraction

Solid-phase extraction (SPE) is the most popular clean-up technique, due to factors such as convenience, low cost, and simplicity and also the most accepted sample pretreatment method today. The principal goals of SPE are trace enrichment (concentration), matrix simplification (sample clean-up), and medium exchange. In spite of the fact that SPE methodologies often render high extraction yields, they suffer from two main weaknesses: (i) in the case of commercial sorbents (e.g., C18), selectivity is rather low and many interfering species might be co-eluted [90]; thus, other sorbents or extra-step microextraction methods are required to improve clean-up and selectivity; (ii) the consumption of organic solvents is quite low in SPE compared with LLE, but to attain high extraction efficiency, evaporation of the eluent after extraction is crucial, so extra step and also more time are needed in sample preparation.

For the first time a combination of SPE and DLLME for extraction and determination of chlorophenols (CPs) in complex matrixes (such as highly saline solution) was introduced [91]. This combination leads to a very high concentration factor. In SPE-DLLME, CPs were adsorbed from a large volume of the aqueous samples into functionalized styrene-divinelybenzene polymer sorbent. After elution of the desired compounds from the sorbent by acetone, the DLLME technique was performed on the obtained solution. Besides DLLME, some other EMU-LPME techniques can combine with SPE method. For instance, recently a SPE-SUPRAS for extraction of drugs from urine and water samples was developed [92]. In this study, due to matrix effect, drugs were initially extracted from the samples by SPE. The extracted analytes were subsequently eluted from the sorbent with THF, and the eluate was subjected to SUPRAS formation process. Finally, the analytes in the SUPRAS were separated and determined by HPLC–UV.

Ultrasound-assisted extraction

Ultrasound-assisted solvent extraction (UASE) is considered a good choice for extraction of organic compounds from different matrixes, which provides a more efficient contact between the solid and solvent due to increases in both pressure (that favours penetration and transport) and temperature (that improves solubility and diffusivity). Several extractions can be fulfilled simultaneously and since no specialized laboratory equipment is necessary, the technique is fairly inexpensive compared with most modern extraction methods. In general, UASE method can be used for recovering organic compounds from plant tissues before their preconcentration [93]. Ultrasound is able to break up cell membrane and facilitate the release of analytes from the plant matrix and thus intensify mass transfer. In addition, the above method can be operated at reduced temperatures that are beneficial to the thermally unstable botanical materials. In contrast to other sample preparation methods, this technique requires no cleanup or evaporation of extraction solvent [94].

Supercritical fluid extraction

As a general rule, DLLME is not suitable for extraction of compounds from solid samples since in this case extra steps in sample preparation before DLLME are needed, leading to the consumption of high volumes of toxic organic solvents. The unique properties exhibited by supercritical fluids have already been applied to extract antifungal drugs from solid samples [95]. Supercritical fluid extraction (SFE) is a selective and less solvent-consuming method and thus is environmentally friendly. The most serious problem of off-line SFE methods is evaporation of collecting solvent at the end of extraction to acquire high preconcentration factor. However, this procedure is a time-consuming step which contaminates the environment and the collected analytes may be lost or degraded during it. Meanwhile, sometimes it is impossible to run DLLME for the extraction of analytes from complex matrixes. For this purpose, a combination of SFE and DLLME, as a sample preparation method, for determination of PAHs and OPPs in solid samples was developed [96, 97]. In this SFE-DLLME technique, the collecting solvents, such as methanol and acetonitrile, in SFE were used as disperser solvent in DLLME. After performing SFE and collecting the extracted analytes in the disperser solvent, an appropriate volume of the extracting solvent was added to the collecting solvent. Finally, the mixture was injected into the aqueous sample. The remaining steps were similar to DLLME method.

Modern phase separation in EMU-LPME techniques

In the EMU-LPME techniques, microdroplets of extraction solvents are precipitated from the aqueous bulk usually by centrifuging the oil-in-water (O/W) emulsion. The O/W emulsion is thermodynamically unstable and is separated by centrifugation into its constituent phases at a given sufficient time. The phase separation by centrifugation needs additional instruments and extra time. This time-consuming process leads to low precision and makes the microextraction method difficult to be automated. Moreover, it is not easy to handle large-volume centrifugation. This time-consuming step can be avoided by a recently introduced alternative that is “solvent-based de-emulsification dispersive liquid–liquid microextraction” (SD-DLLME). In this method, methanol and acetonitrile, that typically serve as disperser solvents in DLLME, were established as chemical demulsifiers to break up the dispersed system owing to their characteristics of low surface tension and high surface activity. [98, 99].

An on-line sequential injection DLLME system coupled to atomic absorption spectrometry has been developed in which the organic phase was retained in a microcolumn packed with PTFE-turnings instead of centrifugation, and a portion of several hundred microliters of the eluent (methyl isobutyl ketone) was subsequently used for quantitative elution of the analytes, which were then introduced directly to the atomic absorption spectrometer [100]. The represented method has a number of shortcomings, such as the necessity to apply a microcolumn for the retention of the analytes as well as the use of several hundred microliters of solvent for the elution of the analytes. Additionally, this approach is hardly applicable for the extraction of ion associates with the subsequent UV–vis spectrophotometric detection that is very often employed as a detection technique in sequential injection analysis, since it does not permit the separation of excess dye reagent from the ion associate.

Very recently, an EMU-LPME followed by on-line phase separation coupled to HPLC was described based on a novel idea for the separation of dispersed organic phase from aqueous phase [101]. In this method, the dispersed organic extraction phase was filtered using an in-line filter and separated from the water sample (Fig. 5). The new approach was simple and, in addition to improving some limitations of the conventional EMU-LPME, eliminated the need for centrifugation in the phase separation step. The on-line procedure was performed at two stages: (i) loading step: the emulsion was passed through the in-line filter and the retention and separation of the organic phase from the aqueous solution were carried out based on emulsion filtration and (ii) injection step: by changing the position of the HPLC valve, the in-line filter was located in the pathway of the mobile phase. The organic phase was eluted and introduced into the HPLC column. After separation and detection of the analytes, the filter was washed with acetonitrile and prepared for the next separation. The versatility of different method of EMU-LPME is seen in relation to the variety of applications in many areas, as depicted in Table 1.

Schematic design of on-line microextraction procedure and separation phases using in-line filter. In-line PTFE filter was inserted into its holder and located in the loop position of HPLC valve. In the loading step, extraction phase was trapped in the filter, and after moving the valve to the injection position, the trapped phase was eluted from the inverse direction by the mobile phase and transferred to HPLC column. Reprinted with permission from [101]

Conclusions and future trends

The pressure to decrease organic solvent usage in laboratories is increasing. Thus, miniaturization and improvement of sample handling via the available alternatives is a challenge that has been discussed by several researchers. From this perspective, emulsion-based sample preparation is an educated choice. The following are the main advantages of EMU-LPME methods: (i) the use of only microliter volumes of extraction solvents, which makes the procedure environmentally friendly; (ii) the short extraction time as a result of a rapidly reached equilibrium state; and (iii) the high enrichment factor due to the high phase ratio.

Because of the special benefits of these sample pretreatment techniques, extensive efforts have been made to remove the restrictions of EMU-LPME or to develop and automatize these approaches. For instance, to this aim, researchers have recently attempted to (i) use solvents with densities lower than water, (ii) conduct the extraction without utilizing a disperser solvent and (iii) perform separation phase without centrifugation. Surfactants and external forces, such as ultrasound irradiation and vortex agitation, can disperse the extraction solvent in the aqueous medium in the absence of disperser solvent. With the development of supramolecular solvents for more efficient and selective extraction of analytes, further improvement of EMU-LPME methods has become possible. Besides, there is increasing interest in automating the EMU-LPME, thus speeding up these processes and enhancing their precision and cost-effectiveness.

In the near future, EMU-LPME will certainly be used for solid-state samples and connected to other sample preparation techniques. Usage of EMU-LPME for solid samples has already been reported in some papers. The analytes were extracted from the matrix using solid–liquid extraction, the SFE procedure or microwave irradiation. Then, EMU-LPME was used to concentrate the extracts.

The novel idea for phase separation in EMU-LPME without centrifugation facilitates the automation of these methodologies in further studies. So far, only two papers presented on-line EMU-LPME [100, 101]. One paper reported an on-line sequential injection DLLME system in which the organic phase was retained in a microcolumn packed with PTFE-turnings, and a portion of several hundred microliters of the eluent was subsequently used for quantitative elution of the analytes, [100]. However, the complexity of the procedure presented was far from the simplicity of the EMU-LPME technique. Another paper described use of an EMU-LPME followed by on-line phase separation coupled to HPLC [101]. The dispersed organic extraction phase was filtered using an in-line filter and separated from the water sample. The new approach was simple and improved some limitations of the conventional EMU-LPME.

References

A. Jain, K.K. Verma, Anal. Chim. Acta 706, 37 (2011)

P. Anastas, N. Eghbali, Chem. Soc. Rev. 39, 301 (2010)

A.A. Cardoso, P.K. Dasgupta, Anal. Chem. 67, 2562 (1995)

H. Liu, P.K. Dasgupta, Anal. Chem. 68, 1817 (1996)

M.A. Jeannot, F.F. Cantwell, Anal. Chem. 68, 2236 (1996)

M.A. Jeannot, F.F. Cantwell, Anal. Chem. 69, 235 (1997)

M.A. Jeannot, F.F. Cantwell, Anal. Chem. 69, 2935 (1997)

S. Pedersen-Bjergaard, K.E. Rasmussen, Anal. Chem. 71, 2650 (1999)

S. Pedersen-Bjergaard, K.E. Rasmussen, T.G. Halvorsen, J. Chromatogr. A 902, 91 (2000)

M. Rezaee, Y. Assadi, M.R. Milani Hosseini, E. Aghaee, F. Ahmadi, S. Berijani, J. Chromatogr. A 1116, 1 (2006)

M. Moradi, Y. Yamini, J. Sep. Sci. 35, 2319 (2012)

A.N. Anthemidis, K.I. Ioannou, Talanta 80, 413 (2009)

A.E. Bidari, Z. Jahromi, Y. Assadi, M.R.M. Hosseini, Microchem. J. 87, 6 (2007)

K. Murata, Y. Yokoyama, S. Ikeda, Anal. Chem. 44, 805 (1972)

C.E. Matkovich, G.D. Christian, Anal. Chem. 45, 1915 (1973)

C.E. Matkovich, G.D. Christian, Anal. Chem. 46, 102 (1974)

H. Kawamoto, H. Akaiwa, Chem. Lett. 24, 259 (1973)

L. Tavakoli, Y. Yamini, H. Ebrahimzadeh, S. Shariati, J. Chromatogr. A 1196–1197, 133 (2008)

T. Hori, T. Fujinaga, Talanta 32, 735 (1985)

J.F. da Silva, W. Martins, Talanta 39, 1307 (1992)

Y. Takagai, T. Kubota, R. Akiyama, E. Aoyama, S. Igarashi, Anal. Bioanal. Chem. 380, 351 (2004)

J.C. de Andrade, C.J. Cuelbas, S. de Paula Eiras, Talanta 47, 719 (1998)

S.I. Garashi, T. Yottuyanagi, Mikrochim. Acta 106, 37 (1992)

T. Sudo, S. Igarashi, Talanta 43, 233 (1996)

H. Yamaguchi, S. Itoh, S. Igarashi, T. Kobayashi, Bunseki Kagaku 54, 227 (2005)

B. Ebrahimpour, Y. Yamini, A. Esrafili, J. Sep. Sci. 36, 1493 (2013)

S. Igarashi, N. Ide, Y. Takagai, Anal. Chim. Acta 424, 263 (2000)

A. Takahashi, Y. Ueki, S. Igarashi, Anal. Chim. Acta 387, 71 (1999)

S. Oshite, S. Igarashi, Anal. Sci. 17, i1329 (2001)

A. Zgoła-Grzeskowiak, T. Grzeskowiak, Trends Anal. Chem. 30, 1382 (2011)

M. Rezaee, Y. Yamini, M. Faraji, J. Chromatogr. A 1217, 2342 (2010)

L. Kocúrová, I.S. Balogh, J. Šandrejová, V. Andruch, Microchim. J. 102, 11 (2012)

A.A. Nuhu, C. Basheer, B. Saad, J. Chromatogr. B 879, 1180 (2011)

N. Fattahi, Y. Assadi, M.R. Milani Hosseini, E.Z. Jahromi, J. Chromatogr. A 1157, 23 (2007)

Q. Wu, X. Zhou, Y. Li, X. Zang, C. Wang, Z. Wang, Anal. Bioanal. Chem. 393, 1755 (2009)

J. Xiong, B. Hu, J. Chromatogr. A 1193, 7 (2008)

W.C. Tsai, S.D. Huang, J. Chromatogr. A 1216, 5171 (2009)

M. Saraji, M. Khalili Boroujeni, A.A. Hajialiakbar Bidgoli, Anal. Bioanal. Chem. 400, 2149 (2011)

C. Xiong, J. Ruan, Y. Cai, Y. Tang, J. Pharm. Biomed. Anal. 49, 572 (2009)

C.P. Diao, C.H. Wei, Anal. Bioanal. Chem. 403, 877 (2012)

M.A. Farajzadeh, Dj Djozan, F. Bakhtiyari, Talanta 81, 1360 (2010)

M. Saraji, M. Marzban, Anal. Bioanal. Chem. 396, 2685 (2010)

C. Pizarro, C. Saenz-Gonzalez, N. Perez-del-Notario, J.M. Gonzalez-Saliz, Food Chem. 132, 2202 (2012)

M. Rezaee, Y. Yamini, A. Khanchi, M. Faraji, A. Saleh, J. Hazard. Mater. 178, 766 (2010)

A.N. Anthemidis, K.I.G. Ioannou, Anal. Bioanal. Chem. 404, 685 (2012)

P.X. Baliza, L.S.G. Teixeira, V.A. Lemos, Microchim. J. 93, 220 (2009)

M.A. Farajzadeh, M. Bahram, J.Å. Jonsson, Anal. Chim. Acta 591, 69 (2007)

G. Wei, Y. Li, X. Wang, J. Sep. Sci. 30, 3262 (2007)

W.H. Tsai, H.Y. Chuang, H.H. Chen, J.J. Huang, H.C. Chen, S.H. Cheng, T.C. Huang, Anal. Chim. Acta 656, 56 (2009)

B. Liu, H. Yan, F. Qiao, Y. Geng, J. Chromatogr. B 879, 90 (2011)

A. Saleh, Y. Yamini, M. Faraji, M. Rezaee, M. Ghambarian, J. Chromatogr. A 1216, 6673 (2009)

M.A. Farajzadeh, S.E. Seyedi, M.S. Shalamzari, M. Bamorowat, J. Sep. Sci. 32, 3191 (2009)

Z.H. Yang, P. Wang, W. Zhao, Z.Q. Zhou, D.H. Liu, J. Chromatogr. A 1300, 58 (2013)

P. Hashemi, S. Beyranvand, R.S. Mansur, A.R. Ghiasvand, Anal. Chim. Acta 655, 60 (2009)

J. Łuczak, J. Hupka, J. Thoming, C. Jungnickel, Colloids Surf. A Physicochem. Eng. Aspects 329, 125 (2008)

S.R. Yousefi, F. Shemirani, Anal. Chim. Acta 669, 25 (2010)

R.S. Zhao, X. Wang, J. Sun, S.S. Wang, J.P. Yuan, X.K. Wang, Anal. Bioanal. Chem. 397, 1627 (2010)

M. Baghdadi, F. Shemirani, Anal. Chim. Acta 613, 56 (2008)

H. Zhang, X. Chen, X. Jiang, Anal. Chim. Acta 689, 137 (2011)

J. Regueiro, M. Llompart, C. Garcia-Jares, J.C.G. Garcia-Monteagudo, R. Cela, J. Chromatogr. A 1190, 27 (2008)

M. Moradi, Y. Yamini, S. Seidi, M. Ghambarian, A. Esrafili, Int. J. Environ. Anal. Chem. 93, 199 (2013)

P. Viñas, I. López-García, N. Campillo, R.E. Rivas, M. Hernández-Córdoba, Anal. Bioanal. Chem. 404, 671 (2012)

Y. Yamini, A. Saleh, M. Rezaee, L. Ranjbar, M. Moradi, J. Liq. Chromatogr. Rel. Tech. 35, 2623 (2012)

J. Reueiro, M. Llompart, E. Psillakis, J.C.G. Monteagudo, C. Garcia-Jares, Talanta 79, 1387 (2009)

P. Liang, F. Wang, Q. Wan, Talanta 105, 57 (2013)

L. Sanchez-Prado, R. Barro, C. Garcia-Jares, M. Llompart, M. Lores, C. Petrakis, N. Kalogerakis, D. Mantzavinos, E. Psillakis, Ultrason. Sonochem. 15, 689 (2008)

Z.H. Yang, Y.L. Lu, Y. Liu, T. Wu, Z.Q. Zhou, D.H. Liu, J. Chromatogr. A 1218, 7071 (2011)

M. Chamsaz, A. Atarodi, M. Eftekhari, S. Asadpour, M. Adibi, J. Adv. Res. 4, 35 (2013)

M.C. Breadmore, J. Chromatogr. A 1218, 1347 (2011)

Q. Wu, Q. Chang, C. Wu, H. Rao, X. Zeng, C. Wang, Z. Wang, J. Chromatogr. A 1217, 1773 (2010)

M. Moradi, Y. Yamini, A. Esrafili, S. Seidi, Talanta 82, 1864 (2010)

M. Moradi, Y. Yamini, T. Baheri, J. Sep. Sci. 34, 1722 (2011)

M. Moradi, Y. Yamini, J. Kakehmam, A. Esrafili, M. Ghambarian, J. Chromatogr. A 1218, 3945 (2011)

B. Ebrahimpour, Y. Yamini, M. Moradi, J. Pharm. Biomed. Anal. 66, 264 (2012)

Y. Yamini, M. Moradi, E. Tahmasebi, Anal. Chim. Acta 728, 26 (2012)

S.M. Yousefi, F. Shemirani, J. Hazard. Mater. 254–255, 134 (2013)

H. Watanabe, H. Tanaka, Talanta 25, 585 (1978)

P. Mukherjee, S.K. Padhan, S. Dash, S. Patel, B.K. Mishra, Adv. Colloid Interf. Sci. 162, 59 (2011)

M.S. Cresser, J. Armstrong, J. Cook, J.R. Dean, P. Watkins, M. Cave, J. Anal. At. Spectrom. 9, 25 (1994)

J.R. Dean, O. Butler, A. Fisher, L.M. Garden, M.S. Cresser, P. Watkins, M. Cave, J. Anal. At. Spectrom. 13, 1 (1998)

A. Ballesteros-Gómez, M.D. Sicilia, S. Rubio, Anal. Chim. Acta 677, 108 (2010)

F.J. Ruiz, S. Rubio, D. Pérez-Bendito, Anal. Chem. 78, 7229 (2006)

A. Moral, M.D. Sicilia, S. Rubio, J. Chromatogr. A 1216, 3740 (2009)

M. Moradi, Y. Yamini, J. Chromatogr. A 1229, 30 (2012)

M. Moradi, Y. Yamini, F. Rezaei, E. Tahmasebi, A. Esrafili, Analyst 137, 3549 (2012)

F.J. Ruiz, S. Rubio, D. Pérez-Bendito, Anal. Chem. 79, 7473 (2007)

M. Tayyebi, Y. Yamini, M. Moradi, J. Sep. Sci. 35, 2491 (2012)

E.M. Costi, M.D. Sicilia, S. Rubio, J. Chromatogr. A 1217, 6250 (2010)

M. Moradi, Y. Yamini, M. Tayyebi, H. Asiabi, Anal. Bioanal. Chem. 405, 4235 (2013)

M. Urbanowicz, B. Zabiegała, J. Namieśnik, Anal. Bioanal. Chem. 399, 277 (2011)

N. Fattahi, S. Samadi, Y. Assadi, M.R. Milani Hosseini, J. Chromatogr. A 1169, 63 (2007)

F. Rezaei, Y. Yamini, M. Moradi, B. Ebrahimpour, Talanta 105, 173 (2013)

A. Bidari, M.R. Ganjali, P. Norouzi, M.R. Milani Hosseini, Y. Assadi, Food Chem. 126, 1840 (2011)

H. Sereshti, S. Samadi, M. Jalali-Heravi, J. Chromatogr. A 1280, 1 (2013)

Y. Yamini, M. Moradi, J. Chem. Thermodyn. 43, 1091 (2011)

M. Rezaee, Y. Yamini, M. Moradi, A. Saleh, M. Faraji, M.H. Naeeni, J. Supecrit, Fluids 55, 161 (2010)

M.H. Naeeni, Y. Yamini, M. Rezaee, J. Supercrit. Fluids 57, 219 (2011)

C.K. Zacharis, P.D. Tzanavaras, K. Roubos, K. Dhima, J. Chromatogr. A 1217, 5896 (2010)

B. Majidi, F. Shemirani, Talanta 93, 245 (2012)

A.N. Anthemidis, K.I.G. Ionnou, Talanta 79, 86 (2009)

B. Ebrahimpour, Y. Yamini, A. Esrafili, Anal. Chim. Acta 751, 79 (2012)

S. Berijani, Y. Assadi, M. Anbia, M.R. Milani Hosseini, E. Aghaee, J. Chromatogr. A 1123, 1 (2006)

R.S. Zhao, L.L. Zhang, X. Wang, Anal. Bioanal. Chem. 399, 1287 (2011)

J. Chen, Y. Xia, Y. Zhou, F. Guo, G. Chen, Anal. Chim. Acta 701, 86 (2011)

M. Shamsipur, N. Fattahi, J. Chromatogr. B 879, 2978 (2011)

M. Shamsipur, N. Fattahi, M. Sadeghi, M. Pirsaheb, J. Iran Chem. Soc. doi:10.1007/s13738-013-0294-5

G. Khayatian, S. Hassanpoor, J. Iran Chem. Soc. doi:10.1007/s13738-012-0131-2

G. Khayatian, S.S. Hosseini, S. Hassanpoor, J. Iran Chem. Soc. doi:10.1007/s13738-013-0258-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moradi, M., Yamini, Y. & Ebrahimpour, B. Emulsion-based liquid-phase microextraction: a review. J IRAN CHEM SOC 11, 1087–1101 (2014). https://doi.org/10.1007/s13738-013-0376-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-013-0376-4