Abstract

A simple and efficient method has been developed for the synthesis of β-amino alcohols by regioselective ring opening of epoxides with amines in the presence of CuFe2O4 nanoparticles as a heterogeneous recyclable catalyst at room temperature in high yields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

β-Amino alcohols are used as intermediates in the synthesis of wide range of biologically active natural, β-blockers as well as insecticidal agent and synthetic products [1–3] unnatural amino acids [4, 5] and asymmetric synthesis as chiral auxiliaries [6]. The nucleophilic ring opening of epoxides with amines group is a well known route for the synthesis of β-amino alcohols [7–11]. Classical method for the synthesis of β-amino alcohols involves the heating of epoxides with an excess of amines at elevated temperature, which is not only unfavorable to certain functional groups, but also to the control of regioselectivities [12, 13]. This classical method has a number of limitations, such as the requirement of an excess of inorganic base, longer reaction times, low nucleophilicityin the case of deactivated aromatic amines, and in some cases low boiling points when elevated temperature is necessary [12]. Several Lewis acids or Bronsted acids as a useful activator have been reported; that is, high to excellent regioselectivity of aminolysis of epoxides has been observed with Zn(OAc)2 [14], sulfamic acid [15], Al(OTf)3 [16], Er(OTf)3 [17], InCl3 [18], BiCl3 [19], SbCl3 [20], ZnCl2 [21], InBr3 [22], CoCl2 [23], Cu(BF4)2 [24], Al2O3 [25], ionic liquids [26], silica [27, 28], sulfated zirconia [29] and Y(NO3)3·6H2O [30]. However, most of the existing methods involve toxic metal ions and solvent, high cost, high catalyst loading, corrosive reagents and cumbersome work-up procedures. Consequently, new procedures that address these drawbacks are desirable. Magnetic nanoparticles are of great interest for researchers from a wide range of disciplines, including magnetic fluids [31], catalysis [32, 33], data storage, [34] and environmental remediation [35, 36]. Magnetic separation is an attractive alternative to filtration or centrifugation as it prevents the loss of catalyst and enhances reusability, making the catalyst to have beneficial cost and to be promissory for industrial applications. In this work, we have focused our attention to CuFe2O4 nanoparticles [37] as heterogeneous catalysts in the ring opening of epoxides with amines.

Results and discussion

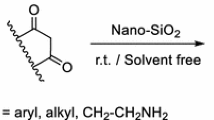

In this letter, we have described a mild and efficient method for the nucleophilic ring opening of epoxides with amines in the presence of CuFe2O4 nanoparticles to afford the corresponding β-amino alcohols in excellent yields (Scheme 1).

Initially, in an effort to develop better reaction conditions, different solvents were screened for the preparation of 1-phenoxy-3-(phenylamino)propan-2-ol 2 from the reaction of glycidyl phenyl ether 1 with aniline in the presence of different amounts of CuFe2O4 nanoparticles under different conditions (Scheme 2) and the results are summarized in Table 1.

Among the different solvents studied, the highest yields were achieved in CH2Cl2 at room temperature (Table 1, entry 3). Other solvents, such as EtOH and CH3CN gave the desired products in low yield (Table 1, entries 1–2). Unfortunately, the corresponding yields were not high with H2O as a solvent (Table 1, entry 6–10).

We have treated the glycidyl phenyl ether with aniline in the presence of catalytic amount of CuFe2O4 nanoparticles, under different conditions. When we used a 1:1 mol ratio of phenyl glycidyl ether and aniline with 10 mol% of catalyst in CH2Cl2 at room temperature after 1.5 h, 95 % yield of the corresponding β-amino alcohol was obtained 3a. This success encouraged us to examine the generality of this reaction with various epoxides and amines (Scheme 1), and the results are summarized in Table 2. The scope of the reaction was explored using a variety of epoxides and amines of diverse structures could be used with the results collected in Table 2. These data indicate that the reaction is highly efficient for all types of substrates. In a similar manner epoxides (1a–d) reacted smoothly with aromatic and aliphatic amines to afford the corresponding β-amino alcohols in very good yields with high regioselectivity. Reaction of phenyl glycidyl ether with p-chloroaniline and p-toluidine lead to regioselective formation of corresponding β-amino alcohols in excellent yields (Table 2, entries 2–3). As seen from the results, a number of aromatic amines have been employed for the cleavage of glycidyl phenyl ether particularly deactivated amines, such as p-nitroaniline (Table 2, entry 4) which showed a limited success for the cleavage of epoxides with other catalysts. In the case of glycidyl phenyl ether, ring opening takes place in a regioselective manner with preferential nucleophilic attack at the less hindered carbon atom of the epoxide (Table 2, entries 1–7), but the reaction of styrene epoxide with aromatic amines ring opening takes place by nucleophilic attack at the benzylic carbon (Table 2, entries 8–11), which could be due to the localized positive charge on the more highly substituted benzylic carbon [43].

In addition, allyl epoxy (Table 2, entries 13–17) and aliphatic alkyl oxirane (Table 2, entries 18–22) reacted with aromatic and aliphatic amines to give the corresponding β-amino alcohols in very good yields in regioselective manner preferentially by terminal attack of the nucleophile (except for deactivated amines).

An interesting feature of this procedure is that all the products were obtained selectively as a single isomer with high purity. All the β-amino alcohols prepared were known compounds and their structures were confirmed by their physical properties and 1H and 13C NMR spectra and comparison with authentic samples. The catalyst was separated from the reaction mixture by applying external magnetic field and reused five times without significant loss of catalytic activity.

Experimental

General procedure for synthesis of nano CuFe2O4

CuFe2O4 nanoparticles were prepared by thermal decomposition of Cu(NO3)2 and Fe(NO3)3 in water in the presence of sodium hydroxide. In brief, to a solution of Fe(NO3)3·9H2O (3.34 g, 8.2 mmol) and Cu(NO3)2·3H2O (1 g, 4.1 mmol) in 75 ml of distilled water, 3 g (75 mmol) of NaOH dissolved in 15 ml of water was added at room temperature over a period of 10 min, during which reddish black precipitate was formed. Then, the reaction mixture was warmed to 90 °C and stirred. After 2 h, it was cooled to room temperature and the magnetic particles so formed were separated by a magnetic separator. It was then washed with water (3 × 30 ml) and catalyst was kept in air oven for overnight at 80 °C. Then, the catalyst was ground in a mortar pestle and kept in a furnace at 700 °C for 5 h (step up temperature 20 °C/min) and then cooled to room temperature slowly. 820 mg of magnetic CuFe2O4 nanoparticles were obtained.

Catalyst characterizations

The systematic characterization of CuFe2O4 catalyst was carried out on X-ray diffraction (XRD), scanning electron microscope (SEM) and transmission electron microscope (TEM). The X-ray diffraction analysis was done in a Philips PW 1830 X-ray diffractometer with CuKα source (λ = 1.5418 Å) in a range of Bragg’s angle (5–60°) at room temperature. The X-ray diffraction pattern of the calcined sample (Fig. 1) perfectly matches with the expected cubic spinel structure of CuFe2O4. The average crystallite size (L) was calculated from X-ray line broadening using (3 1 1) peak and Debye–Sherrer’s equation; L = 0.89λ/βcosθ; β is the FWHF and λ is the wavelength of the radiation and was found to be L = 10.3 nm. Scanning electron micrograph (SEM) pictures were taken using Jeol JSM-5300 microscope (acceleration voltage10 kV). The sample powder was deposited on a carbon tape before mounting on a sample holder. To reduce the charge developed on the sample, gold sputtering was done for 3 min. The SEM of the CuFe2O4 sample is shown in Fig. 2a. As indicated in this figure, small agglomerated nanoparticles of disordered surface morphology are observed. The transmission electron micrographs (TEM) were obtained with a Philips CM-10 microscope. The CuFe2O4 sample for TEM was prepared by dispersing the powdered sample in ethanol by sonication and then drop drying on a copper grid (400 mesh) coated with carbon film. As the TEM figure shows the average size of particles resulted from this method is approximately 5–15 nm. The particle sizes obtained from TEM are in good agreement with XRD measurement (Fig. 2b).

General procedure for the synthesis of β-amino alcohols

To a mixture of epoxide and amine (1 mmol) in (2 mL) CH2Cl2 was added CuFe2O4 nanoparticles (10 mol%) and the resulting mixture was stirred at room temperature for specified period. After completion of the reaction, the catalyst was separated from the reaction mixture with an external magnet and the catalyst was washed several times with Et2O. The reaction mixture was concentrated under reduced pressure to afford the crude product. If necessary, the product was purified by column chromatography over silica gel or by bulb to bulb distillation to afford the corresponding pure β-amino alcohols in excellent yields. The physical data (IR, NMR) of known compounds were found to be identical with reported in the literature. Spectroscopic data for selected examples are shown below.

1-Phenoxy-3-phenylamino-propan-2-ol (3a): IR (KBr): 3,383, 3,254, 3,050, 2,936, 2,861, 1,682, 1,532, 1,525, 1,475, 1,436, 1,336, 1,322, 1,286 cm−1; 1H NMR (CDCl3, 500 MHz): δ 3.22–3.26 (m, 1H), 3.38–3.42 (m, 1H), 3.60–3.65 (m, 2H), 3.98–4.05 (m, 2H), 4.25 (br s, 1H), 6.64–6.68 (m, 2H), 6.70–6.75 (m, 2H), 6.88–6.91 (m, 2H), 7.05–7.25 (m, 2H); 13C NMR (CDCl3, 125 MHz):46.8, 69.7, 70.2, 113.8, 115.8, 117.8, 118.1, 121.3, 129.4, 148.8, 156.6.

2-Phenyl-2-phenylamino-ethanol (3 h): IR (KBr): 3,321, 3,244, 3,047, 3,031, 2,964, 2,834, 1,615, 1,533, 1,488, 1,351, 1,212; 1H NMR (CDCl3, 500 MHz): δ 3.78 (dd, 1H, J = 5.0, 10.5 Hz), 3.90 (dd, 1H, J = 4.0, 10.5 Hz), 4.55 (dd, 1H, J = 6.5, 10.8 Hz), 6.40 (d, 2H, J = 7.5 Hz), 6.80 (t, 1H, J = 7.8 Hz), 6.95 (d, 2H, J = 8.0 Hz), 7.30–7.45 (m, 5H). 13C NMR (CDCl3, 125 MHz): δ 57.8, 68.5, 112.1, 117.8, 126.4, 127.43, 128.5, 129.7, 136.1, 146.8.

1-Benzylamino-3-phenoxy-propan-2-ol (3 l): IR (KBr): 3,272, 3,012, 2,939, 2,848, 1,618, 1,570, 1,468, 1,360, 1,258, 1,203; 1H NMR (CDCl3, 500 MHz): δ 2.75–2.85 (m, 1H), 2.95 (br s, 1H), 3.80 (d, 2H, J = 2.0 Hz), 3.95 (d, 2H, J = 5.0 Hz), 4.05–4.15 (m, 1H), 6.85–6.95 (m, 3H), 7.30–7.40 (m, 7H); 13C NMR (CDCl3, 500 MHz): 53.8, 55.3, 68.2, 70.5, 114.7, 121.1, 128.1, 128.3, 128.5, 129.2, 140.1, 158.8.

1-Allyloxy-3-morpholin-4-yl-propan-2-ol (3p): IR (KBr): 3,378, 3,259, 2,926, 1,613, 1,523, 1,458, 1,248, 1,237; 1H NMR (CDCl3, 500 MHz): δ 2.1–2.3 (m, 6H), 3.2 (dd, 2H, J = 4.5, 11.2 Hz), 3.45–4.1 (m, 8 H), 4.9–5.1(m, 2H), 5.6–5.7 (m, 1H), 13C NMR (CDCl3, 125 MHz): δ 53.6, 61.2, 66.2, 66.5, 72.5, 116.6, 134.4.

In conclusion, we have demonstrated a highly efficient methodology for the regioselective ring opening of various epoxides with a variety of amines using CuFe2O4 nanoparticles. The notable features of this procedure are mild reaction conditions, excellent regioselectivity, cleaner reactions, improved yields, enhanced reaction rates, reusability of the catalyst and simplicity in operation, which makes it a useful and attractive process for the synthesis of β-amino alcohols.

References

B.M. Teresa, J.C.M. Adilia, C.D. Maycockd, T. Michaud, Tetrahedron 61, 7960–7966 (2005)

E.J. Corey, F. Zhang, Angew. Chem. Int. Ed. Engl. 38, 1931–1934 (1999)

C.W. Johannes, M.S. Visser, G.S. Weatherhead, A.H. Hoveyda, J. Am. Chem. 120, 8340–8347 (1998)

P. O’Brien, Angew. Chem. Int. Ed. Engl. 38, 326–329 (1999)

G. Li, H.T. Chang, K.B. Sharpless, Angew. Chem. Int. Ed. Engl. 35, 451–454 (1996)

D.J. Ager, I. Prakash, S.R. Schaad, Chem. Rev. 96, 835–876 (1996)

G. Huerta, G.C. Ordonez, C. Alvarez-Toledano, V. Santes, E. Gomez, R.A. Toscano, Synth. Commun. 34, 2393–2406 (2004)

S.W. Wei, K.A. Stingl, K.M. Weiss, S.B. Tsogoeva, Synlett 5, 707–711 (2010)

D.M. Hodgson, A.R. Gibbs, G.P. Lee, Tetrahedron 52, 14361–14384 (1996)

R.M. Hanson, Chem. Rev. 91, 437–475 (1991)

A.S. Rao, S.K. Paknikar, J.G. Kirtane, Tetrahedron 39, 2323–2367 (1983)

J.A. Deyrup, C.L. Moyer, J. Org. Chem. 34, 175–179 (1969)

P.A. Crooks, R. Szyudler, Chem. Ind., 1111–1112 (1973)

H. Eshghi, M. Rahimizadeh, A. Shoryabi, J. Iran. Chem. Soc. 2, 155–160 (2005)

M. Hosseini-Sarvari, H. Sharghi, J. Iran. Chem. Soc. 5, 384–393 (2008)

D.B.G. Williams, M. Lawton, Tetrahedron Lett. 47, 6557–6560 (2006)

A. Procopio, M. Gaspari, M. Nardi, M. Oliverio, O. Rosati, Tetrahedron Lett. 49, 2289–2293 (2008)

L.R. Reddy, M.A. Reddy, N. Bhanumathi, K.R. Rao, New J. Chem. 25, 221–222 (2001)

T. Ollevier, G. Lavie-Compin, Tetrahedron Lett. 43, 7891–7893 (2002)

M.C. Singh, R.K. Peddinti, Tetrahedron Lett. 48, 7354–7357 (2007)

A.K. Chakraborti, A. Kondaskar, Tetrahedron Lett. 44, 8315–8319 (2003)

J.R. Rodriguez, A. Navarro, Tetrahedron Lett. 45, 7495–7498 (2004)

G. Sundararajan, K. Vijayakrishna, B. Varghese, Tetrahedron Lett. 45, 8253–8256 (2004)

A. Kamal, R.R. Ramu, M.A. Azhar, G.B.R. Khanna, Tetrahedron Lett. 46, 2675–2677 (2005)

M. Maheswara, K.S.V.K. Rao, J.Y. Do, Tetrahedron Lett. 49, 1795–1800 (2008)

J.S. Yadav, B.V.S. Reddy, A.K. Basak, A.V. Narasaiah, Tetrahedron Lett. 44, 1047–1050 (2003)

H. Kotsuki, T. Shimanouchi, M. Teraguchi, M. Kataoka, A. Tatsukawa, H. Nishizawa, Chem. Lett., 2159–2162 (1994)

A.K. Chakraborti, S. Rudrawar, A. Kondaskar, Org. Biomol. Chem. 2, 1277–1280 (2004)

B.M. Reddy, K.M. Patil, B.T. Reddy, S.E. Park, Catal. Commun. 9, 950–954 (2008)

M.J. Bhanushali, N.S. Nandurkar, M.D. Bhor, B.M. Bhanage, Tetrahedron Lett. 49, 3672–3676 (2008)

S. Chikazumi, S. Taketomi, M. Ukita, M. Mizukami, H. Miyajima, M. Setogawa, Y. Kurihara, J. Magn. Magn. Mater. 65, 245–251 (1987)

A.H. Lu, W. Schmidt, N. Matoussevitch, H. Pnnermann, B. Spliethoff, B. Tesche, E. Bill, W. Kiefer, F. Schüth, Angew. Chem. 116, 4403–4410 (2004)

S.C. Tsang, V. Caps, I. Paraskevas, D. Chadwick, D. Thompsett, Angew. Chem. 116, 5763–5767 (2004)

T. Hyeon, Chem. Commun., 927–934 (2003)

D.W. Elliott, W.X. Zhang, Environ. Sci. Technol. 35, 4922–4926 (2001)

M. Takafuji, S. Ide, H. Ihara, Z. Xu, Chem. Mater. 16, 1977–1983 (2004)

I. Nedkov, R.E. Vandenberghe, T. Marinova, Ph. Thailhades, T. Merodiiska, I. Avramova, Magnetic CuFe2O4 nanoparticles were prepared according to literature. Appl. Surf. Sci. 253, 2589–2596 (2006)

I. Cepanec, M. Litvic, H. Mikuldas, A. Bartolinčić, V. Vinković, Tetrahedron 59, 2435–2439 (2003)

H. Danafar, B. Yadollahi, Catal. Commun. 10, 842–847 (2009)

A.T. Placzek, J.L. Donelson, R. Trivedi, R.A. Gibbs, S.K. De, Tetrahedron Lett. 46, 9029–9034 (2005)

N. Azizi, M.R. Saidi, Org. Lett. 7, 3649–3651 (2005)

M.M. Mojtahedi, M.S. Abaee, V. Hamidi, Catal. Commun. 8, 1671–1674 (2007)

A.T. Placzek, J.L. Donelson, R. Trivedi, A.R. Gibbs, S.K. De, Tetrahedron Lett. 46, 9029–9034 (2005)

Acknowledgments

We would like to thank the Islamic Azad University; Ayatollah Amoli Branch for generous financial support of the research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baghbanian, S.M., Farhang, M. Efficient synthesis of β-amino alcohols by regioselective ring opening of epoxides with amines catalyzed by CuFe2O4 nanoparticles. J IRAN CHEM SOC 10, 1033–1037 (2013). https://doi.org/10.1007/s13738-013-0241-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-013-0241-5