Abstract

A new interesting class of linear Schiff-base poly(sulfone-ester)s has been synthesized by polycondensation of (E)-1-(4,4′-(4-hydroxy-3-chlorobenzylidene)thiocarbamoylaminophenyl-sulfonylphenyl)-3-(4-hydroxy-3-chlorobenzylidene)thiourea with 2,6-pyridinedicarbonyl chloride/thiophene-2,5-dicarbonyl dichloride. The enhancement of physical properties (thermal stability, glass transition temperature, mechanical strength, molar mass, electrical conductivity, etc.) of polymeric materials while maintaining their processability was the foremost aspiration of this research work. The pyridine or thiophene-based heteroaromatic poly(sulfone-ester)s (PSEs) showed ample solubility in amide solvents and good yield. PSEs possessed high inherent viscosity of 1.79–1.93 dL/g and molar mass 125 × 103–145 × 103 g mol−1. The polymers were thermally stable with 10 % weight loss in the range 538–547 °C and glass transition temperature between 293 and 296 °C. Further aim was to obtain novel miscible nano-blends exhibiting good electrical conductivity and heat stability. For this purpose, PAN doped with dodecylbenzenesulfonic acid (PAN/DBSA) was prepared by in situ doping polymerization, and then blended in solution/melt with PSEs. The resulting high performance materials potentially combined the fine thermal properties and processability of poly(sulfone-ester)s with electrical characteristics of polyaniline. FESEM of melt-blended PSEs/PAN/DBSA showed nano-level homogeneity of the microstructure liable for better electrical conductivity (2.7–3.2 S cm−1). The azomethine and pyridine moieties introduced in the backbone render these polymers thermally and mechanically stable as well as electrically conducting. The miscible blends, exhibited good heat stability (T 10 520–527 °C, T g 281–285 °C) and mechanical strength (55.20–57.18 MPa) compared with reported azomethine/polyaniline-based structures. New processable and high-performance engineering plastics, attractive for aerospace applications, can be fabricated using novel blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, predominant research activities have been focused on improving the thermal, electrical, and mechanical properties of polymers. There is substantial awareness regarding the polymers consisting of aromatic units linked together directly or via ester, sulfone, thioether, amide, or imide moieties forming the origin of high performance materials [1]. Correspondingly, heat-resistant linear aromatic polyester materials have received great importance owing to their demand in advance applications [2, 3]. However, they stumble upon processing difficulties due to their high glass transition/melting temperature coupled with insolubility in organic solvents. Therefore, development of new processable polymers applicable at high temperature has been a crucial research objective. This problem has occasionally been overcome by using a predecessor monomer synthetic technique. One of such methodologies has involved the introduction of flexible, bulky, or rigid moieties into the polymer backbone, to improve solubility of macromolecules without harming the thermal stability, using substituted monomers [4–6]. If the faction to be introduced is cautiously chosen, this approach may generate a chain separation effect with an increase in free volume, hence it is possible to promote solubility without sacrificing the thermal and mechanical properties. In the same way, several thermally stable polyesters with heteroaromatic groups have been reported [7–9]. Principally, the introduction of imide rings has been well recognized for their high thermoresistance, so improving both the solubility and thermal stability [10].

New type of conducting organic polymers have gained researchers’ interest owing to their excellent electrical properties, superior thermal stability, high surface area, good environmental stability, corrosion resistance along with suitable strength, and fracture toughness [11, 12]. Incidentally, poly(azomethine)s (polyimines/Schiff-base polymers) with a system of conjugated –C=N– bonds have been known to exhibit valuable properties because of the presence of imine sites [13–16]. Although these polymers due to high melting point and low solubility are generally difficult to process. Technical uses of polyimines have also been constrained by their sensitivity to acidic hydrolysis and thermal exchange reactions between the azomethine groups. Several research efforts have been centered on enhancing these characteristics by incorporating flexible or bent substituents into the main chain [17]. Another promising and essentially conducting polymer is polyaniline (PAN). PAN has driven extensive attention, as aniline is rather inexpensive and its polymerization is simple and new applications of PAN are expected in several fields of technology. Good processability, thermal, and mechanical performance of the conventional polymers can be combined with the electrical properties of PAN through the incorporation of PAN into an electrically insulating conventional polymer matrix. These blends are usually produced by in situ polymerization of aniline in the presence of the insulating polymer or by blending soluble or fusible polyaniline with other polymers in solution or melts [18]. Blending has generated original materials with explicit properties for the preferred application at low price. The conducting polyblends produced are stable and retain mechanical properties of the host polymer [19]. Solution processing of PAN with conventional polymers is known as an efficient method when both polymers are soluble in a common solvent. The solubility of PAN in common solvents has been accomplished using a counter ion-induced processability technique, where a specific functionalized protonic acid was used as protonating agent [20]. Thus, doping is the process by which insulator polymers are exposed to dopant (charge transfer agent). For example, dodecylbenzenesulfonic acid (DBSA), having long alkyl chains, is capable of increasing the solubility of PAN/DBSA in different solvents so increase the compatibility with polymer matrices [21]. PAN/DBSA complex has also been utilized in melt blends, owing to its fairly high thermal stability [22, 23]. The electrical conductivity of undoped PAN has reported to be 10−10–10−7 S cm−1, while it increased from 10−2 to 100 S cm−1 upon acid doping. These dopants enhance the solubility of PAN in common organic solvents and facilitate the formulation of conducting blends in which polyaniline and other organic polymers are dissolved and blended in a common solvent.

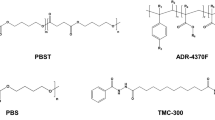

In this article, we wish to report the synthesis and characterization of new poly(sulfone-ester)s (PSEs) and the subsequent development of PSE/PAN/DBSA blends using different techniques. Poly(sulfone-ester)s were prepared from an aromatic Schiff-base diol (E)-1-(4,4′-(4-hydroxy-3-chlorobenzylidene)thiocarbamoylaminophenylsulfonylphenyl)-3-(4-hydroxy-3-chlorobenzylidene)-thiourea (HCBTCAPST) containing preformed sulfone and azomethine linkages. Polysulfones generally own valuable properties such as high strength and stiffness even at elevated temperature, high continuous use and heat deflection temperature, excellent resistance to hydrolysis by acids and bases, and good dimensional stability [24]. Despite these exceptional properties, there is a need to amend the polysulfone structure to obtain several desired features. The polymer modification is usually the one of main routes to achieve such characteristics [25]. We have designed HCBTCAPST in such a way that high molar mass polymers with improved physical properties were obtained. Thermal stability and electrical conductivity of new PSEs were found to increase by the incorporation of sulfone, pyridine/thiophene, and azomethine linkages. The present endeavor also deals with the development of some novel PSE/PAN/DBSA blends by the dispersion of PAN doped with dodecylbenzenesulfonic acid (PAN/DBSA) in poly(sulfone-ester) matrix using solution blending and melt blending methods. Varying PAN/DBSA content and the choice of blending technique were found to significantly affect the thermal stability, mechanical strength, electrical conductivity, and morphology of new blends. Upon melt blending of PSEs with PAN/DBSA miscible nano-blend morphology, representing good compatibility between the two components, was observed. Superior thermal and mechanical stability as well as electrical conductivity were observed in the melt-blended materials compared with those obtained by solution technique. Besides, the novelty of this attempt lies entirely on the unique architecture of poly(sulfone-ester). The prime objective was to enhance the thermal properties, glass transition temperature, molar mass, and conductivity while maintaining the processability of new polymeric material. The thermal stability and electrical conductivity of new PSEs were found to increase by the inclusion of azomethine, pyridine/thiophene moieties in the polymer spine. Similarly, heteroaromatic pyridine-based blends depicted fine properties relative to thiophene-based blends verifying the significance of the unique design of poly(sulfone-ester).

Experimental

Materials

Aniline (analytical grade, Merck) was distilled twice under vacuum and stored under nitrogen in a refrigerator. Ammonium peroxydisulfate (APS) (99 %), N-methylpyrrolidone (NMP) (99 %), dimethyl sulfoxide (DMSO) (99 %) and chloroform (99 %) were also procured from Merck. Dodecylbenzenesulfonic acid (DBSA) (technical grade), 2,6-pyridinedicarbonyl chloride (PDC) (97 %), thiophene-2,5-dicarbonyl dichloride (TDC) (97 %), 4-(4-aminophenylsulfonyl)benzenamine (APSBA) (97 %), 3-chloro-4-hydroxybenzaldehyde (98 %), N,N-dimethylacetamide (DMAc) (99 %), xylene (99 %), and toluene (99.8 %) were provided by Aldrich. Ammonium thiocyanate (98 %), dimethylformamide (DMF) (99 %), and tetrahydrofuran (THF) (99.5 %) were supplied by Fluka.

Measurements

Perkin-Elmer 2400 CHN elemental analyzer was used for the elemental analysis. IR spectra were recorded using FTIR Spectrometer, Model No. FTSW 300 MX, manufactured by BIO-RAD (4 cm−1 resolution). NMR spectra was scanned at room temperature using a Bruker Spectrometer (300.13 MHz for 1H and at 75.47 MHz for 13C NMR) in deutrated THF. Inherent viscosity (ηinh) was measured in THF (30 °C) with an Ubbelohde viscometer for 0.5 g/dL polymer solution. The weight-average molecular weight (M w) was calculated through GPC using THF as an eluent and refractive index (RI) detector. Thermal stability of the polymers was verified by Mettler Toledo TGA/SDTA 851e thermogravimetric analyzer using 1–5 mg of the sample in Al2O3 crucible at a heating rate of 10 °C/min. Differential scanning calorimetry (DSC) was performed by Mettler Toledo DSC 822e differential scanning calorimeter taking 5–10 mg of samples in aluminum pans and heated at a rate of 10 °C/min. X-Ray diffractometer (3040/60 X’pert PRO) with Ni-filtered CuKα radiation (40 kV, 30 mA) was used to obtain X-ray diffractogram of polymers at room temperature. Field emission scanning electron microscope (FE-SEM) of freeze-fractured samples was performed using JSM5910, Jeol, Japan. Electrical conductivities of thin films were measured using a Keithley 614 electrometer and the four-probe method. Stress–strain response of the blend samples was investigated on Universal Testing Machine Instron 4206 according to the ASTM 638 method. A crosshead speed of 100 mm/min was maintained during the test.

Synthesis of 1-(4-thiocarbamoylaminophenylsulfonylphenyl)-thiourea (TCAPST)

On a steam bath, 4-(4-aminophenylsulfonyl)benzenamine (0.2 mol), conc. HCl (16 mL), ammonium thiocyanate (0.2 mol) and de-aerated water (120 mL) were mixed and heated in a porcelain dish for 1 h. The mixture was allowed to cool to room temperature and then gradually evaporated to dryness for 6–7 h. The product obtained was boiled with charcoal in ethanol, filtered, and cooled. 1-(4-thiocarbamoylaminophenylsulfonyl-phenyl)thiourea was recrystallized from ethanol and dried under vacuum at 90 °C (36 h) [26, 27]. Elemental analysis for C14H14N4O2S3: Calculated = %C 45.88, %H 3.85, %N 15.29; Found = %C 43.32, %H 3.69, %N 14.49. FTIR (KBr): 3,365 cm−1, 3,234 cm−1 (N–H stretch), 3,019 cm−1 (aromatic C–H stretch), 2,945 (aliphatic C–H stretch), 1,599 cm−1 (N–H bend), 1,413 cm−1 (C–N stretch), 1,301 and 1,157 (S=O stretch), 1,123 cm−1 (C=S stretch). 1H NMR (300.13 MHz, DMSO-d6, δ ppm): 4.38 (s, 4H, Ha), 9.32 (s, 2H, Hb), 6.65 (d, 4H, Hc), 7.71 (d, 4H, Hd). 13C NMR (75.47 MHz, DMSO-d6, δ ppm): thiocarbonyl C=S 175.1 (C1), 142.4 (C2), 125.3 (C3), 128.1 (C4), 139.9 (C5).

Synthesis of (E)-1-(4,4′-(4-hydroxy-3-chlorobenzylidene)thiocarbamoylaminophenylsulfonylphenyl)-3-(4-hydroxy-3-chlorobenzylidene)thiourea (HCBTCAPST)

TCAPST (0.02 mol), 3-chloro-4-hydroxybenzaldehyde (0.04 mol) and absolute alcohol (250 mL) were agitated in a Dean-Stark apparatus for 30 min (room temperature). The above mixture was refluxed for 1 h after the removal of azeotropic mixture (100 °C). The reaction contents were then cooled to collect the solid and washed with dil. HCl and hot water. The product was recrystallized from ethanol and dried at 80 °C for 36 h to afford HCBTCAPST with 94.9 % yield. Elemental analysis for C28H20Cl2N4O4S3: Calculated = % C 52.25, %H 3.13, %N 8.71; Found = %C 51.82, % H 3.01, % N 8.60. FTIR (KBr) (Fig. 1): 3,409 cm−1 (–OH), 3,387 and 1,598 cm−1 (sec. amine N–H stretch and bend), 3,069 cm−1 (aromatic C–H stretch), 2,931, 2,863 (aliphatic C–H stretch), 1,611 cm−1 (–C=N– stretch), 1,307 and 1,159 (S=O stretch), 1,125 cm−1 (C=S stretch). 1H NMR (300.13 MHz, DMSO-d6, δ ppm) given in Fig. 2: 5.11 (s, 2H, Ha), 6.74 (d, 2H, Hb), 7.31 (d, 2H, Hc), 7.52 (s, 2H, Hd), 8.12 (s, 2H, He), 9.27 (s, 2H, Hf), 6.63 (d, 4H, Hg), 7.65 (d, 4H, Hh). 13C NMR (75.47 MHz, DMSO-d6, δ ppm) presented in Fig. 3: 155.6 (C1), 117.5 (C2), 129.4 (C3), 127.8 (C4), 130.8 (C5), 124.5 (C6), 163.4 (C7), thiocarbonyl C=S 183.7 (C8), 141.4 (C9), 127.1 (C10), 128.9 (C11), 137.4 (C12).

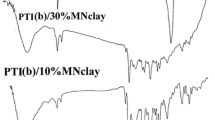

Synthesis of poly(sulfone-ester)s

In a 250 mL round-bottom flask, HCBTCAPST monomer (0.01 mol) and DMF (50 mL) were charged and heated up to 100 °C with vigorous stirring (N2). 0.01 mol diacid chloride (PDC or TDC) dissolved in DMF (20 mL) was added dropwise to the above mixture and heated further at 150–160 °C for 20 h [28]. As the reaction proceeded, the solution became viscous. The viscous liquid was precipitated in methanol. The resultant precipitate was filtered, washed with methanol, and dried at 100 °C under vacuum. The solid residue was dissolved in hot chloroform, again precipitated in methanol and dried. Yield of the obtained polymer was 92–93 %. Spectral data of PSE 1 corroborated the structure of the polymer synthesized (Fig. 4): 3,287 (N–H stretch), 1,599 cm−1 (N–H bend), 3,015 (aromatic C–H stretch), 2,989 (aliphatic C–H stretch), 1,737 (ester C=O stretch), 1,611 cm−1 (–C=N– stretch), 1,301 and 1,160 (S=O stretch), 1,125 cm−1 (C=S stretch). 1H NMR (300.13 MHz, DMSO-d6) (Fig. 5): PSE 1 exhibited doublets nearly 8.41, 8.62 and triplet at 8.29 ppm due to pyridine unit protons. The p-phenylene ring displayed chemical shifts around 6.56 and 7.66 ppm (doublets). A singlet at 8.12 ppm was attributed to the azomethine proton. The aromatic ring protons appeared at about 6.67 and 7.21 ppm as doublet, while singlet was found at 7.54 ppm. Chemical shift of N–H was also observed around 9.32 ppm.

Synthesis of PAN/DBSA

The emulsion polymerization of aniline was performed according to a reported procedure [29, 30]. In this reaction, DBSA (0.075 mol) and aniline (0.051 mol) were dissolved in toluene (250 mL) with continuous stirring at 0 °C. Keeping the above mixture at 0 °C, an aqueous solution of APS (0.021 mol) in water (20 mL) was slowly added. The mixture was allowed to stir for further 6 h to achieve complete polymerization. The reaction content was poured into methanol and the precipitate was filtered, washed with methanol, and dried under vacuum. PAN/DBSA (a dark green powder), prepared by this method, displayed a conductivity up to 1.3 S cm−1.

Poly(sulfone-ester)s/PAN/DBSA blends

Solution blending

Solutions of PAN/DBSA and polyesters in chloroform were individually prepared. The conducting polymer solution was mixed with PSE solution at required proportions. The mixed solutions were ultrasonicated (30 W and 50 Hz) for 5 h. Thin films (~175 μm thickness) were cast by pouring the blend solutions on glass Petri’s, and solvent evaporation at 40 °C for 24 h.

Melt blending

Melt blending of the components was carried out by melt mixing using a Brabender plastograph according to the previously described method [31]. For the conductivity measurement, flat plaques of 2.4 mm thickness were prepared by compression molding.

Results and discussion

Development of poly(sulfone-ester)s and their miscible blends

Preparation of new class of high performance poly(sulfone-ester)s with azomethine-chloro-thiourea-pyridine/thiophene backbone design is not a tried research zone. In most cases, azomethine, pyridine, and thiophene groups render the polymer spine heat stability through decreasing its solubility. On the contrary, sulfone and chloro units may increase the solubility offering lower rotation energy barrier to the polymer chains. Based on these annotations, thermally stable and electrically conducting polymers were intended displaying the communal effect of these functionalities. Scheme 1 represents the synthetic route to high performance polyesters passing through the formation of a new dihydroxy monomer HCBTCAPST. The ensuing poly(sulfone-ester)s had fairly high inherent viscosity up to 1.93 dL/g and molar mass as high as 145 × 103 g mol−1. Thermal and electrical data supported the validity of current approach (structural modification) and the polymers with superior thermal stability, glass transition along with the conductivity were acquired, without affecting their solvent miscibility. Another part of this toil entails the in situ doping polymerization of PAN with dodecylbenzenesulfonic acid yielding PAN/DBSA, which was further employed in the synthesis of few blend systems. The blending of these poly(sulfone-ester)s with PAN/DBSA via solution and melt techniques was an entirely novel tactic to form miscible blends with high electrical conductivity. Unique morphology of compatible nano-blends was supposed to be caused by certain physical interaction between the two matrices (Scheme 2).

Organosolubility

Solubility of PSEs at room temperature and heating up to solvent boiling temperature for the samples that remained insoluble at room temperature has been investigated in various solvents. All polymers were soluble in organic polar solvents such as NMP, DMAc, DMF, DMSO, and THF as shown in Table 1. Usually, aromatic polyazomethine, polythiophene, or heteroaromatic polymers possessed low solubility in organic solvents due to their rigid backbone structure. Incidentally, the introduction of flexible substituents in the main chain proffers positive effect on the solubility of these polymers. Higher solubility of PSEs can be interpreted by the effects of sulfone and chloro moieties in polymer chain. These polymers were insoluble in solvents such as toluene and cyclohexane. In chlorinated solvents such as chloroform PSE 1 and 2 dissolved at room temperature, while they were only partially soluble at room temperature in tetrachloroethane. Actually, the presence of pyridine and thiophene moieties and the development of hydrogen bonding between –OCO– and NH or C=S and NH groups were thought to be responsible for the backbone rigidity. However, these polymers were easily soluble in tetrachloroethane on heating. Similar effect was observed when PSEs were dissolved in xylene. The overall fine solubility of polymers, having heteroaromatic and azomethine structure, was due to the presence of flexible Cl and S=O linkages in the main chain creating distance between the macromolecular chains and so the diffusion of solvent was facilitated. The solubility was also found to be superior relative to the previous azomethine or thiophene-based polymers [32, 33].

Molecular weight

Inherent viscosity ηinh and GPC measurements were carried out for the determination of molecular weight of polymers (Table 2). Inherent viscosity (ηinh) of a polymer is generally considered as a measure of its molecular weight. ηinh of PSEs was measured in THF (30 °C) and found to be in the range of 1.79–1.93 dL/g. A relationship between the ηinh of the polymer and its structure can be experiential from this study. The data obtained showed the higher viscosity of PSE 1 derived from HCBTCAPST and PDC (1.93 dL/g), though tended to decrease for the polymer derived from thiophene-based diacid chloride (1.79 dL/g). Thus, the higher ηinh of PSE 1 with pyridine-based structure, –HCBTCAPST–PDC–, was pinpointing the higher chain stacking efficiency due to rigid and symmetrically aligned polymer chains bearing six-membered heteroaromatic rings. GPC analysis also revealed that dihydroxy monomer had fine polymerization potential to yield high molecular weight polyesters. Comparable to the above ηinh assessment, polycondensation of new dihydroxy compound with PDC gave higher molecular weight (Mw 145 × 103) compared with PSE 2 (M w 125 × 103). It is interesting that the higher polymerization capability was obtained for the polymer PSE 1 prepared from the pyridine-based diacid chloride, a segment with high rigidity. A possible explanation can be the more regularly arranged chain segments, which promoted the polymerization in the reaction medium. The relatively lower molar mass was obtained for the polymer PSE 2 prepared from a diacid chloride having thiophene unit. Briefly, new poly(sulfone-ester)s exhibited much higher molar mass relative to the previously synthesized azomethine/thiophene-derived polyesters [32, 33].

Thermal analysis

Thermal stability of the poly(sulfone-ester)s was investigated by means of thermogravimetric analysis (TGA) and DSC. The recorded TGA thermograms (Fig. 6) showed that all investigated copolyesters decomposed through the same process. The degradation started around 520 °C and it was dependent on the polyester composition in diacid chloride units and the temperature of starting decomposition/weight loss increased by varying these moieties (Table 3). Initial decomposition (T 0) of PSE 1 prepared from HCBTCAPST and pyridine-based diacid chloride was 526 °C, 10 % gravimetric loss (T 10) of 547 °C and the decomposition extended up to 588 °C. Whereas, the thiophene-based PSE 2 revealed slightly lower stability as T 0 of 523 °C and T 10 up to 538 °C. The difference in the weight loss of PSE 1 and 2 was understandable due to the discrepancy in the spine structure. Thiophene, a five-membered ring, is thermogravimetrically less stable than six-membered aromatic ring structure and may dissociate easily. The char yield of PSEs was also high 67–69 % at 600 °C. We can also observe that pure poly(sulfone-ester)s were most resistant toward thermo-oxidative degradation relative to the blends system prepared. However, the degradation of PSE 1 and PSE 2/PAN/DBSA (90:10 melt blending) was outset at fairly high temperature (above 500 °C). TGA traces signified high thermal properties (T 0 509–519 °C) and char yield (50–54 %). So, increase in PAN/DBSA loading within the copolymer tended to endow the materials with a slightly lower stability. Figure 7 shows the thermograms obtained during the DSC analysis. Higher T g’s of 296 and 293 °C for PSE 1 and 2 were recorded without any softening or melting transition. The result can be explained by strong interaction of ester and thiourea units with N–Hs, thus lowering the inter-segmental activity. There was a slight displacement of the glass transition to higher temperature in pyridine based-copolyester due to better polymer chain packing. An important decrease in T g (281–285 °C) was noticed in the blends. This was probably due to the disturbance in the order of arrangement of structural segments in regular heteroaromatic copolyesters PSE 1 and 2 with the addition of PAN/DBSA, which enhanced the molecular mobility. New PSEs and their blends, however, revealed much higher thermal stability relative to several reported polyesters with these linkages [32–34].

XRD analysis

Wide angle X-ray diffraction pattern of PSE 1 is presented in Fig. 8. The pyridine-based poly(sulfone-ester) exhibited a broad peak indicating amorphous domains. The heteroaromatic rigid-rod aromatic polymers were anticipated to exhibit crystalline pattern due to better packing of macromolecular backbone. Although, the broad peak with low intensity indicated that the presence of chloro and sulfone moieties tried to obliterate the likelihood of attaining a crystalline order.

Conductivity studies

Pure PSE 1 and 2 showed good electrical conductivity around 1.6 and 1.4 S cm−1, respectively (Table 4). Here, the pyridine moieties were found to increase the conductivity of PSE 1 and its blends significantly. The conductivity of PSE 1/PAN/DBSA with 10 % of PAN/DBSA, obtained via melt blending, was found to be 2.7 S.cm−1. The conductivity reached the highest value 3.2 S.cm−1 at 60 % PAN/DBSA loading. Maximum electrical conductivity was observed for PSE 1 (3.2 S.cm−1), which was an excellent achievement. When comparing the conductivity of blends obtained by two methods, PSEs/PAN/DBSA prepared by melt blending was sufficiently conducting. This may be credited to better interaction between the blend components (Scheme 2) instigating improved combine effect of azomethine/aniline/pyridine or thiophene moieties. The fine electrical conductivity measured indicated the existence of conductive PSEs/PAN network in these nano-blends. The conducting network was very fine and somewhat observable in nano-level compatible blends. Presence of pyridine moieties in PSE 1/PAN system formed better conductive network, thus indicated higher conductivity relative to the PSE 2/PAN. In both blend systems (obtained by either method), the conductivity increased gradually with the increase of PAN content. The higher conductivity of poly(sulfone-ester)s/PAN/DBSA by melt blending suggested the success of method employed. Conductivity of new PSE/PAN/DBSA blends (by solution or melt method) was found to be superior when compared to that of reported poly(azomethine-ester)s/PAN blends and metal doped poly(azomethine-ester)s [35].

Tensile strength of PSE/PAN/DBSA blends

Mechanical behavior of a blend is usually determined by the contribution of each component, the blend morphology and the interfacial adhesion. Table 5 lists the tensile data of new blends with 10 % PAN/DBSA. The maximum stress of PSE 1/PAN/DBSA blend was 57.18 MPa, while PSE 2/PAN/DBSA had slightly lower value 55.20 MPa (Fig. 9). Higher value of the elongation-at-break was also observed for PSE 1-based blend (1.16) relative to that of PSE 2 (1.11). This can be explained on the basis of increased interfacial interactions between the two blend components in pyridine-based poly(sulfone-ester)s and doped polyaniline. Here, the melt blending was again found to be an efficient method to improve the tensile properties of blends. The lower mechanical strength of solution-blended system (maximum stress 22.27–29.13 MPa) suggested that the melt-blending technique was quite successful to obtain high strength materials.

Morphological features

Morphology of both PSE 1/PAN/DBSA and PSE 2/PAN/DBSA films was studied using FESEM. The effect of PAN/DBSA loading on the morphology of PSE 1/PAN/DBSA and PSE 2/PAN/DBSA blends was compared. In PSE 1/PAN/DBSA blend (Fig. 10a), the major component, i.e., functional copolymer formed the matrix whereas the minor component (PAN/DBSA) was the dispersed phase. The microstructures of solution-blended PSE 1/PAN/DBSA revealed some aggregated polymer formation at 1 μm, but no distinct nano-scale morphology was observed. The conducting pathways were also not evident in the solution-processed blends (2.3 S cm−1). With the 10 % addition of conducting polymer in PSE 2, the irregular polymer mass was also visible (Fig. 10c) depicting relatively low conductivity of 1.7 S cm−1. The surface morphology of PSE 1/PAN/DBSA blend obtained by melt blending was considerably changed due to the homogeneous mixing of the two polymers showing nano-level compatibility (Fig. 10b). Nano-blend morphology was, thus, observed owing to the hydrogen bonding between the two fractions (PSE and PAN). To sum up, melt-blended PSE 1/PAN/DBSA (90:10) presented a very homogeneous morphology composed of conducting pathways within dispersed PAN/DBSA particles (2.7 S cm−1). Similarly, Fig. 10d shows fine dispersion of polyaniline in PSE 2 matrix presenting nano-scale compatibility in the melt-processed material, thus, improved the conductivity up to 1.9 S cm−1. The unique morphology appropriately justified the high conductivity achieved by PSE/PAN/DBSA blends.

Conclusion

This paper described the comprehensive outcomes of the direct polycondensation of (E)-1-(4,4′-(4-hydroxy-3-chlorobenzylidene)thiocarbamoylamino-phenylsulfonylphenyl)-3-(4-hydroxy-3-chlorobenzylidene)thiourea with heteroaromatic dicarbonyl dichlorides. In this study, it was aimed to tune the thermal and conducting performance of ensuing poly(sulfone-ester)s via azomethine and pyridine/thiophene links in their structure and sulfone group in order to preserve their solubility. Modification of high performance materials by increasing the solubility while maintaining thermal stability was, therefore, of particular interest. Introducing flexible sulfone linkages into polymer backbone was quite successful in enhancing the solubility, while azomethine and pyridine/thiophene structure render these materials heat stable. We also reported the synthesis of PAN doped with dodecylbenzenesulfonic acid (PAN/DBSA) by in situ doping polymerization, and its blending in solution or melt with PSEs. The heteroaromatic polymer obtained by pyridine-based diacid chloride exhibited higher T g, thermal and electrically conducting properties compared with other poly(sulfone-ester) and the nano-blend systems. The homogeneity of the blends was determined accurately through the use of first step DSC, since a single T g value was detected. It was observed that the PAN has a great potential to be blended with PSEs in order to be used in several industrial applications. The heteroaromatic structure imparted excellent stability to PSE 1 and its blends due to aromaticity and polarizability. Nano-level morphology with conducting pathways was observed in the melt-blended system. Mechanical, thermal, and electrical profiles of the final systems were strongly affected by the choice of blending technique. The results from this study established that conventional melt-blending procedure was predominantly valuable for condensation-type polymers. According to the thermal, electrical, and mechanical properties of the copolymers and nano-blends, they can be well predicted for applications in optoelectronic devices, single layer organic devices, and more complex organic LEDs in future.

References

Uddin R, Hodge P, Chisholm MS, Eustace P (1996) Synthesis of polyesters containing 9,10-diacetoxyanthracene-2,6-diyl moieties via a precursor polymer approach. J Mater Chem 6:527–532

Shenoy MA, Pereira EA, Parikh PF (2005) Aromatic polyester based on bisphenol-A for liquid insulating systems: a synthetic approach. J Appl Polym Sci 95:606–614

Vert M, Li MS, Spenlehauer G, Guerin P (1992) Bioresorbability and biocompatibility of aliphatic polyesters. J Mater Sci Mater Med 3:432–446

Tamami B, Yeganeh H, Kohmareh G-A (2004) Synthesis and characterization of novel polyesters derived from 4-aryl-2,6-bis(4-chlorocarbonyl phenyl) pyridines and various aromatic diols. Eur Polym J 40:1651–1657

Akiba C, Watanabe K, Nagai K, Hirata Y, Nguyen Q-T (2006) Preparation and solubility of water–methanol mixtures in sulfonated poly(etherketone) containing a cardo-ring structure. J Appl Polym Sci 100:1113–1123

Gong C, Guan R, Shu Y-C, Chuang F-S, Tsen W-C (2007) Effect of sulfonic group on solubility parameters and solubility behavior of poly(2,6-dimethyl-1,4-phenylene oxide). Polym Adv Technol 18:44–49

Mallakpour S, Kolahdoozan M (2007) Synthesis and properties of thermally stable and optically active novel wholly aromatic polyesters containing a chiral pendent group. Eur Polym J 43:3344–3354

Kido J, Lizumi Y (1998) Fabrication of highly efficient organic electroluminiscent devices. Appl Phys Lett 73:2721–2723

MacDiarmid AG (2001) Synthetic metals: a novel role for organic polymers (Nobel Lecture). Angew Chem Int Ed 40:2581–2590

Mallakpour S, Rafiee Z (2008) Safe and fast polyamidation of 5-[4-(2-phthalimidiylpropanoylamino)benzoylamino]isophthalic acid with aromatic diamines in ionic liquid under microwave irradiation. Polymer 49:3007–3013

Kimura K, Zhuang J-H, Shirabe K, Yamashita Y (2003) Preparation of needle-like poly(azomethine) crystals by means of reaction-induced crystallization of oligomers. Polymer 44:4761–4764

Yang CJ, Jenekhe SA (1991) Conjugated aromatic poly(azomethines). 1. Characterization of structure, electronic spectra, and processing of thin films from soluble complexes. Chem Mater 3:878–887

Hoppe H, Sariciftci NS (2004) Organic solar cells: an overview. J Mater Res 19:1924–1945

Stutzmann N, Friend RH, Sirringhaus H (2003) Self-aligned, vertical-channel, polymer field- effect transistors. Science 299:1881–1884

He F, Tian L, Xie W, Li M, Gao Q, Hanif M, Zhang Y, Cheng G, Yang B, Ma Y, Liu S, Shen J (2008) Highly efficient blue organic light-emitting devices based on improved guest/host combination. J Phys Chem C 112:12024–12029

Grigoras M, Catanescu CO (2004) Imine oligomers and polymers. J Macromol Sci Part C Polym Rev C 44:1–37

Arnand J, Palaniappan S, Sathyanarayana DN (1998) Conducting polyaniline blends and composites. Prog Polym Sci 23:993–1018

De Paoli M-A (1997) In: Nalwa HS (ed) Handbook of organic conductive molecules and polymers, Vol. 2, Chapter 18, Wiley, New York

Mitzakoff S, De Paoli MA (1999) Blends of polyaniline and engineering plastics. Eur Polym J 35:1791–1798

Cao Y, Smith P, Hegger AJ (1992) Counter-ion induced processibility of conducting polyaniline and of conducting polyblends of polyaniline in bulk polymer. Synth Met 48:91–97

Cao Y, Smith P (1993) Liquid-crystalline solutions of electrically conducting polyaniline. Polymer 34:3139–3143

Zilberman M, Titelman GI, Siegmann A, Haba Y, Narkis M, Alperstein D (1997) Conductive blends of thermally dodecylbenzene sulfonic acid-doped polyaniline with thermoplastic polymers. J Appl Polym Sci 66:243–253

Shacklette LW, Han CC, Luly MH (1993) Polyaniline blends in thermoplastics. Synth Met 57:3532–3537

Olabisi O (1997) Handbook of thermoplastics. Marcel and Dekker, New York

Jouanneau J, Mercier R, Gonon L, Gebel G (2007) Synthesis of sulfonated polybenzimidazoles from functionalized monomers: preparation of ionic conducting membranes. Macromolecules 40:983–990

Kausar A, Zulfiqar S, Ali L, Ishaq M, Sarwar MI (2011) Novel poly(thiourea-ether-imide)s derived from 4,4′-oxydiphenyl-bis(thiourea): probing the possibility for high-temperature applications. Polym Int 60:564–570

Vasanthi BJ, Ravikumar L (2007) Number-average molecular weight of radiation-degraded poly(tetrafluoroethylene). An end group analysis based on solid-state NMR and IR spectroscopy. Eur Polym J 43:4325–4330

Petreus O, Vlad-Bubulac T, Hamciuc C (2008) New polyesterimides containing bulky, cyclic phosphorus groups. High Perform Polym 20:588–600

Osterholm JE, Cao Y, Klavetter F, Smith P (1994) Emulsion polymerization of aniline. Polymer 35:2902–2906

Barra GMO, Leyva ME, Gorelova MM, Soares BG, Sens M (2001) X-Ray photoelectron spectroscopy and electrical conductivity of polyaniline doped with dodecylbenzenesulfonic acid as a function of the synthetic method. J Appl Polym Sci 80:556–565

Zilberman M, Titelman GI, Siegmann A, Haba Y, Narkis M, Alperstein D (1997) Conductive blends of thermally dodecylbenzene sulfonic acid-doped polyaniline with thermoplastic polymers. J Appl Polym Sci 66:243–253

Ubale VP, Patil AS, Maldar NN (2007) Polyhydrazides based on 2,5-bis(4-carboxymethylene phenyl)-3,4-diphenyl thiophene. Eur Polym J 43:1038–1045

Vlase T, Vlase G, Doca N, Ilia G (2010) Thermo-oxidative degradation of polymers containing phosphorus in the main chain. High Perform Polym 22:863–875

Thaker BT, Chothani NJ, Dhimmar YT, Patel BS, Solanki DB, Patel NB, Kanojiya JB, Tandel RS (2010) Synthesis, characterization and liquid crystalline properties of some Schiff base-ester central linkage involving 2,6-disubstituted naphthalene ring system. Liq Cryst 39:551–569

Cristovan FH, Lemos SG, Pereira EC (2010) Systematic evaluation of the preparation of conducting PANI/ABS blends. J Appl Polym Sci 116:825–831

Acknowledgments

For financial support in the research work, A. Kausar expresses thanks to Higher Education Commission of Pakistan (HEC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kausar, A., Hussain, S.T. Processing and properties of new heteroaromatic Schiff-base poly(sulfone-ester)s and their blends. Iran Polym J 22, 175–185 (2013). https://doi.org/10.1007/s13726-012-0116-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-012-0116-0