Abstract

A surface plasmon resonance (SPR) based fiber optic sensor with cobalt (Co) and nickel (Ni) layers (one layer at a time) is theoretically analyzed. The sensitivity of sensor increases linearly with increase in refractive index of sensing medium for all thicknesses of Co and Ni layers. Besides it, SPR sensor with Co layer has been shown to demonstrate higher sensitivity than that of Ni layer. The usage of Co in place of noble metals (such as gold and silver) curtails the cost of SPR sensor. Optimized thicknesses of Co and Ni layers are found to be 80 nm and 60 nm, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Surface plasmon resonance (SPR) phenomenon has received great attention due to fast and precise optical sensing of various physical, chemical, and biochemical parameters in the last 30 years [1–4]. Surface plasmons are the collective oscillations of free electrons in metal and propagate along the metal-dielectric interface. The surface plasmon is a transverse electromagnetic wave. Being transverse in nature, surface plasmon wave can be excited by exponentially decaying evanescent field of incident p-polarized light. When the wave vector and frequency of incident p-polarized light coincide with those of surface plasmon wave, the p-polarized light resonantly excites the surface plasmon wave. The resonance condition depends on incident angle, wavelength of incident light, and dielectric constants of metal and dielectric. The resonance condition (resonance angle/wavelength) is very sensitive to the variations in refractive index of dielectric adjacent to metal. Thus, the variations in refractive index of sensing medium can be determined by observing the resonance condition. For studying SPR, Kretschmann configuration based on attenuated total internal reflection (ATR) is commonly used [5–7]. In Kretschmann configuration, a high refractive index prism is coated with a thin metal layer. The metal layer touches the sample. Surface plasmon waves are excited by evanescent wave from prism at total reflection condition. Prism based SPR sensing poses many drawbacks such as bulky size of sensor and inapplicability for remote sensing. However, optical fiber based SPR sensing presents numerous benefits over prism based SPR sensing such as simple and flexible optical design, possibility of remote sensing, continuous analysis, and in situ monitoring [8–10]. In optical fiber based SPR sensor, the prism is replaced by core of optical fiber. Optical fiber based SPR sensing has been reported experimentally and theoretically in several research studies [11–15].

Noble metals (such as gold and silver) are generally used for fabrication of SPR sensors because in comparison to other materials, noble metals are less reactive to external medium. However, noble metals are weakly magneto optic and hence, require very high value of magnetic field to express magneto optical activity. On the other hand, ferromagnetic metals show large magneto optical activity and are also appropriate for plasmonics. Recently, ferromagnetic metals like cobalt (Co) and nickel (Ni) have drawn special attention of researchers because of their magnetic properties and magneto optical properties. Though, enough work has not been done on their optical properties [16–20]. In comparison to noble metals, Co is an inexpensive metal and exhibits near-infrared plasmon resonance energy. Therefore, the utilization of Co as a SPR active metal reduces the cost of SPR sensor. Ni is a chemically inert metal, and therefore, its use in SPR sensor is preferred.

In this paper, we have theoretically analyzed the performance of SPR based fiber optic sensor with Co and Ni layers (one layer at a time). SPR produced by coupling of evanescent light to surface plasmons is employed as the sensing scheme, and the wavelength interrogation method is used for the analysis of SPR sensor. In wavelength interrogation method, the wavelength of incident light from the white light source is varied and the corresponding transmitted power through the optical fiber is measured. A sharp dip in transmitted power is emerged at the resonance wavelength. The resonance wavelength depends on the refractive index of sensing medium. The effects of thickness of Co and Ni layers on the sensitivity of SPR sensor have been studied. The sensitivity increases linearly with increase in refractive index of sensing medium for all thicknesses of Co and Ni layers. In addition, SPR sensor with Co layer has been shown to exhibit larger sensitivity than that of Ni layer. The optimized thicknesses of Co and Ni layers are ascertained to be 80 nm and 60 nm, respectively.

2 Theory

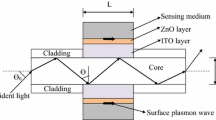

The SPR sensing is based on the principle of attenuated total reflection (ATR) with Kretschmann configuration. In the proposed SPR based fiber optic sensor, the sensing system consisting of a fiber core-metal layer-sensing medium is considered. Two metals; Co and Ni have been worked out in the present study. Schematic diagram of SPR based fiber optic sensor is shown in Fig. 1.

The plastic cladding around the core from the middle portion of a step index multimode plastic clad silica (PCS) fiber (numerical aperture = 0.24 and fiber core diameter = 600 μm) is removed and is coated with a thin metal layer, which is then finally enclosed by the sensing medium. The light from a broadband (polychromatic) source is launched into one of the ends of the optical fiber with suitable optics, and the transmitted light is detected at the other end of the optical fiber.

2.1 Fiber core

The first layer is composed of core of optical fiber. The core of optical fiber is assumed to be made of fused silica. The refractive index of fused silica varies with wavelength according to Sellmeier dispersion relation as,

where λ is the wavelength in micrometers and a 1, a 2, a 3, b 1, b 2, and b 3 are Sellmeier coefficients. The values of these coefficients are given as, a 1 = 0.6961663, a 2 = 0.4079426, a 3 = 0.8974794, b 1 = 0.0684043 μm, b 2 = 0.1162414 μm, and b 3 = 9.896161 μm [21].

2.2 Metal layer

The second layer is made of metal, i.e., Co or Ni (one layer at a time). The dielectric constant of a metal is written according to Drude model as,

Here, λ p and λ c are the plasma wavelength and collision wavelength of metal, respectively. Where, λ p = 3.1215 × 10−7, 2.5381 × 10−7 m and λ c = 3.3578 × 10−5, 2.8409 × 10−5 m for Co and Ni, respectively [20].

2.3 Sensing medium

Layer III is made of sensing medium. The dielectric constant of sensing medium is ε s . If n s is the refractive index of sensing medium, then ε s = n 2 s . The resonance condition for excitation of surface plasmon wave is given as,

Where, \( {K}_{\mathrm{sp}}=\frac{\omega }{c}\sqrt{\frac{\varepsilon_m{\varepsilon}_s}{\varepsilon_m+{\varepsilon}_s}}=\frac{2\pi }{\lambda}\sqrt{\frac{\varepsilon_m{n}_s^2}{\varepsilon_m+{n}_s^2}} \) is the propagation constant of surface plasmon wave and c is the speed of light in vacuum. The left hand side of Eq. 3 denotes the propagation constant of the light incident at an angle θ, and the right hand side shows the real part of propagation constant of surface plasmon wave. If the refractive index of sensing medium is changed, the right hand side of Eq. 3 gets modified, and therefore, the resonance condition will be satisfied at some other value of wavelength. By observing the shift in resonance wavelength, a change in refractive index of sensing medium can be measured.

2.4 Transmitted power

The expression for reflection coefficient (reflectance) of p-polarized incident light can be obtained by using the matrix method for N-layer model [22]. Considering that all the guided rays are launched in the fiber using a collimated source and a microscope objective, the angular power distribution of rays guided in the fiber is given as [23],

Where, θ is angle of the ray with the normal to the core-cladding interface. Also, n 1 is the refractive index of the core of the fiber. To calculate the effective transmitted power, the reflectance (R p ) for a single reflection is raised to the power of number of reflections, the specific propagating angle undergoes with the sensor interface. Hence, for p-polarized light, the generalized expression for normalized transmitted power in an optical fiber based SPR sensor will be given as,

where,

and,

Here, N ref(θ) is total number of reflections performed by a ray making an angle θ with the normal to the core-metal layer interface in the sensing region. L and D are the length of exposed sensing region and the fiber core diameter, respectively. Also, θ cr is critical angle of the fiber and n cl is refractive index of cladding of the fiber.

2.5 Sensitivity

The sensitivity of SPR sensor with wavelength interrogation is defined as change in resonance wavelength per unit change in refractive index of sensing medium [24].

3 Results and discussion

For numerical calculations, the refractive index of sensing medium is varied from 1.30 to 1.37 in steps of 0.01 and the following values of the parameters have been used:

Numerical aperture of the fiber = 0.24, fiber core diameter D = 600 μm, length of the exposed sensing region L = 15 mm. For optimizing the thicknesses of Co and Ni layers, the transmitted output power of SPR based fiber optic sensor has been calculated for various thicknesses (i.e., 20–120 nm) of Co and Ni layers individually.

Figure 2a–b depict the variations of resonance wavelength of SPR sensor with refractive index of sensing medium for 20, 40, 60, 80, 100, and 120 nm thick Co and Ni layers, respectively. Resonance wavelengths of SPR sensor for all thicknesses of Co layer increase with increase in refractive index of sensing medium. The enhancements in resonance wavelengths with increase in refractive index of sensing medium for all thicknesses of Co layer can be explained by Eq. 3. It is evident from Eq. 3 that the real part of propagation constant (K sp) of surface plasmon wave is responsible for the resonance condition. The real part of K sp will be smaller for a small value of refractive index of sensing medium, and hence, its resonance condition is satisfied at a smaller wavelength [22]. Similarly, for high value of refractive index of sensing medium, the resonance condition is satisfied at a larger wavelength due to a large real part of K sp. Likewise, the variations of resonance wavelength with refractive index of sensing medium for all thicknesses of Ni layer follow the same pattern, i.e., the resonance wavelengths for all thicknesses of Ni layer enhance with increase in refractive index of sensing medium. In addition, it can also be viewed that for a given refractive index of sensing medium, the resonance wavelength enhances with increase in thicknesses of Co and Ni layers. However, for any given refractive index of sensing medium, the rise in resonance wavelength with increase in thickness is more for Co than that for Ni.

Figure 3a–b show the plots of sensitivity of SPR sensor with refractive index of sensing medium for 20 to 120 nm thick Co and Ni layers, respectively. Figure 3a–b are obtained from the second order polynomial fit of resonance wavelength versus refractive index curves, plotted in Fig. 2a–b. It can be seen from Fig. 3a–b that the sensitivity of SPR sensor enhances linearly with increase in refractive index of sensing medium for all thicknesses of Co and Ni layers. The slopes of sensitivity of SPR sensor over refractive index of sensing medium are larger for all thicknesses of Co layer than that of Ni layer. The slope of sensitivity over refractive index of sensing medium is highest for 120 nm thick Co layer while it is least for 20 nm thick Co layer. However, the slopes of sensitivity over refractive index of sensing medium for other thicknesses (i.e., 40, 60, 80, and 100 nm) of Co layer are intermediate between those of 120 and 20 nm thick Co layers. In the same way, the slope of sensitivity of SPR sensor over refractive index of sensing medium is large for the 120 nm thick Ni layer while it is small for the 20 nm thick Ni layer. Additionally, the slope of sensitivity over refractive index of sensing medium is greater for 120 nm thick Co layer than that for 120 nm thick Ni layer. For a given refractive index of sensing medium, the sensitivity becomes higher as the thickness of Co layer increases. This occurs due to the real part of K sp , mentioned in Eq. 3. Co layer demonstrates high sensitivity because Co exhibits large value of real part of its dielectric constant at all wavelengths. Hence, Co enhances the shift between resonance wavelengths for a given change of refractive index of sensing medium for each thickness of Co layer. Thus, the sensitivity of SPR sensor increases with increase in thickness of Co layer. Likewise, for a given refractive index of sensing medium, the sensitivity enhances with increase in thickness of Ni layer.

To optimize the thicknesses of Co and Ni layers, the minimum values of transmitted power of SPR based fiber optic sensor are calculated for each thickness of the Co and Ni layers. Figure 4a–b illustrate the variations of minimum transmitted power of SPR sensor with thicknesses of Co and Ni layers, respectively. Energy conservation requires that the sum of reflectance (R), absorbance (A), and transmittance (T) must be equal to unity [25]. As, T = 0 and R = 0 (for a particular thickness of Co layer or Ni layer), A equals to unity i.e. the incident beam is completely absorbed in the medium. Figure 4a–b clearly reveal that the minimum of the curves (for Co and Ni layers) corresponds to the deepest SPR curve with 80 nm thick Co layer and 60 nm thick Ni layer, respectively. Therefore, the optimized thicknesses of Co and Ni layers are obtained to be 80 nm and 60 nm, respectively, because the optimum thickness allows maximum interaction between surface plasmon mode and the fiber mode, resulting in huge absorption of light power by the sensing medium around resonance wavelength. This leads to decrease in normalized transmitted power and hence, results in high sensitivity of the sensor.

Therefore, taking all these facts into consideration, it is concluded that SPR based fiber optic sensor with Co layer demonstrates higher sensitivity than that of Ni layer. Also, the optimized thicknesses of Co and Ni layers are 80 nm and 60 nm, respectively.

4 Conclusions

SPR based fiber optic sensor with Co and Ni layers (one layer at a time) has been theoretically studied. The sensitivity of SPR sensor for various thicknesses (20–120 nm) of Co and Ni layers is calculated. The sensitivity increases linearly with increase in refractive index of sensing medium for all thicknesses of Co and Ni layers. SPR sensor with Co layer possesses higher sensitivity than that with Ni layer. The utilization of Co in place of noble metals curbs the cost of SPR sensor. The optimized thicknesses of Co and Ni layers are 80 nm and 60 nm, respectively.

References

B. Liedberg, C. Nylander, I. Sundstrom, Sens Actuat B 4, 299 (1983)

R.D. Harris, J.S. Wilkinson, Sens Actuat B 29, 261 (1995)

J. Homola, Sens Actuat B 41, 207 (1997)

Z. Salamon, H.A. Macleod, G. Tollin, Biochim Biophys Acta 1331, 117 (1997)

E. Kretschmann, H. Reather, Naturforsch 23, 2135 (1968)

A. Otto, Z Phys 216, 398 (1968)

E. Kretschmann, Z Phys 241, 313 (1971)

J. Homola, Sens Actuat B 29, 401 (1995)

W.B. Lin, N. Jaffrezic-Renault, A. Gagnaire, H. Gagnaire, Sens Actuat A 84, 198 (2000)

A.K. Sharma, B.D. Gupta, Sens Actuat B 100, 423 (2004)

S.K. Srivastava, B.D. Gupta, Sens Actuat B 156, 559 (2011)

S.K. Srivastava, V. Arora, S. Sapra, B.D. Gupta, Plasmon 7, 261 (2012)

M. Rani, N.K. Sharma, V. Sajal, Opt Commun 292, 92 (2013)

N.K. Sharma, M. Rani, V. Sajal, Sens Actuat B 188, 326 (2013)

M. Rani, S. Shukla, N.K. Sharma, V. Sajal, Opt Commun 313, 303 (2014)

A.Y.-C. Yu, T.M. Donovan, W.E. Spicer, Phys Rev 167, 670 (1968)

M. Gilliot, A. En Naciri, L. Johann, J.P. Stoquert, J.J. Grob, D. Muller, M. Stchakovsky, Phys Rev B 74, 045423 (2006)

M. Gilliot, A. En Naciri, L. Johann, J.P. Stoquert, J.J. Grob, D. Muller, J Appl Phys 101, 014319 (2007)

H. Ehrenreich, H.R. Philipp, D.J. Olechna, Phys Rev 131, 2469 (1963)

M.A. Ordal, R.J. Bell, R.W. Alexander Jr., L.L. Long, M.R. Querry, Appl Opt 24, 4493 (1985)

A.K. Ghatak, K. Thyagarajan, An introduction to Fiber optics, 1st edn. (Cambridge University Press, Cambridge, 1999), pp. 82–83

A.K. Sharma, B.D. Gupta, J Appl Phys 101, 093111 (2007)

B.D. Gupta, A. Sharma, C.D. Singh, Int J Optoelectron 8, 409 (1993)

A.K. Sharma, B.D. Gupta, Opt Commun 245, 159 (2005)

R.K. Verma, B.D. Gupta, J Opt Soc Am A 27, 846 (2010)

Acknowledgments

The corresponding author, Navneet K. Sharma, is thankful to Prof. B. D. Gupta for his motivational support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, S., Sharma, N.K. & Sajal, V. Theoretical Study of Surface Plasmon Resonance-based Fiber Optic Sensor Utilizing Cobalt and Nickel Films. Braz J Phys 46, 288–293 (2016). https://doi.org/10.1007/s13538-016-0406-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13538-016-0406-7