Abstract

Dye-containing wastewaters impose a serious threat to the environment. Adsorption is useful approach for decontamination of contaminated media. In this study, activated carbon prepared from stalk corn (namely SCBAC) was used for removal of Rhodamine B (RhB) from aqueous solution. The effect of pH (3–11), adsorbent dosage (0.5–2.5 g L−1), initial dye concentration (10–50 mg L−1), and contact time (30–110 min) was evaluated for RhB adsorption on SCBAC. In addition, the adsorption equilibrium was demonstrated with Langmuir and Freundlich isotherm models. Obtained results showed that the optimum pH and adsorbent dosage were 3 and 2.5 g L−1, respectively. The Freundlich isotherm model fitted well with the experimental adsorption data. The maximum adsorption capacity attained was 5.6 mg g−1. Adsorption of RhB onto adsorbent followed pseudo-second-order kinetics. Prepared SCBAC showed that can be utilized as economical and effective adsorbent for the adsorption of dyeing pollutants, like RB, from aqueous solutions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Contamination of environment has attracted more attention in recent years [1]. Various studies have been performed to sampling, determination, chemical and electrochemical removal or degradation of environment pollutants for avoiding the irreparable complications of these hazardous materials on the ecosystem cycle [2,3,4,5]. Among the contaminant issue, industrial wastewaters are in great concern [5,6,7,8,9]. Discharge of industrial wastewater without any pretreatment or proper treatment led to the contamination of water body [10, 11]. Among the industrial wastewaters, concerns regarding dye-containing waters were more widespread [12,13,14,15]. It is estimated that about 7 × 105 tons of dyestuff produced annually [16]. Industries such as textiles, pharmaceuticals, foods, pigments, cosmetics, paints, and ceramics used dyes to color their products [17]. Several reports have shown that approximately 15% of the dyes were lost in wastewater during dyeing operation [18]. Due to complex molecular structures, these dyes are considered non-biodegradable, a property makes them more stable and hard to biodegrade [19]. The presence of dyes led to the pollution of water bodies. Along with being aesthetically unpleasing, these compounds also prevent sunlight penetration into water and consequently lead to serious changes in water ecosystems. They are also harmful to living organisms, leading to mutagenic and cancerogenic changes [20]. Several chemical, physical, and biological treatment methods have been considered for the removal of dyes from aqueous solutions. Coagulation-flocculation, precipitation, AOPs (advanced oxidation processes), ion exchanges, electrochemical techniques, adsorption, and membrane separation can be mentioned as treatment approach for removal of dyes [17, 19, 21]. High cost of chemicals and reagents, production of sludge, membrane fouling, and sophisticated operation can be addressed as main drawback of abovementioned approaches [22,23,24,25]. It is thought that adsorption has considerable potential for the removal of synthetic dyes from wastewater. Adsorption was considered to be cost-effective and technically feasible for removal of dyes from wastewaters [17, 26]. Application of adsorption for dye removal has been reported in several studies. For example, in a study conducted by Bentahar et al. [27], natural clay was applied for removal of methylene blue, crystal violet, and Congo red from binary and ternary systems. Mouni et al. [19] reported the application of Kaolin in removal of methylene blue from aqueous solutions. Result of Rajasekhar showed that application of corncob as adsorbent has a good performance in removal of malachite green from aqueous solution [28]. Due to high adsorption capacity, its pore structure and presence of different surface oxygen functional groups at its surface, activated carbon is one of the most widely used groups of adsorbents for the removal of a wide range of pollutants from wastewater [26, 29,30,31,32]. However, the main drawback of activated carbon-based adsorption processes is price of carbon that significantly influences the total cost of an adsorption process system [17, 26]. In recent years, researches have focused on the utilization of available low cost and efficient precursors for the production of activated carbons. In comparison to activated carbon, usage of agricultural by products as low-cost alternative adsorbent has attracted more attention [33]. During the last decade, several types of agricultural waste such as malt bagasse [34], Ficus carica [35], Pterospermum acerifolium shells [36], cashew nut shell [37], almond shell, banana peel [38], sugarcane bagasse [39], cotton wove waste [40], tea factory waste [41], coconut shell [42], and Luffa acutangula [33] have been used for the removal of dyes and heavy metals from waste water.

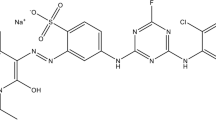

Rhodamine B (RhB) is a basic cationic dye. Transient mucous membrane and skin irritation are likely to occur in long-term exposure to RhB. According to the literature, RhB is a potential mutagen. It could disturb the aquatic life via obstructing light penetration and oxygen transfer [17]. Therefore, there is an urgent need to removal of RhB from aqueous solution.

The removal of RhB from aqueous solution has been recently studied by Laysandra et al. for bentonite-titanium dioxide composites [17], Ptaszkowska-Koniarz et al. for modified carbon xerogels [20], Wang et al. for SnS2 nanostructure [43], and Khamparia and Jaspal for Argemone mexicana [12]. In Kermanshah province as study area, corn is cultivated in a large area. However, harvested corn stalks can be considered as the main part of the agricultural waste flow. Recycling this type of waste as low-cost adsorbent in the field of wastewater treatment can be attractive. Regarding the removal of RhB, some previous studies applied corncob activated carbon as adsorbent. To the best of our knowledge, no study has been reported regarding removal of RhB by stalk corn activated carbon (SCBAC).

In the present work, performance of RhB adsorption by SCBAC was investigated. The effect of practical variables such as contact time, pH, initial dye concentrations, and adsorbent dosages on the adsorption of RhB on to the SCBAC was examined. In addition, kinetics, adsorption isotherm models, and thermodynamic studies were carried out to evaluate experimental data.

2 Material and method

2.1 Chemicals and reagents

RhB, sodium hydroxide (NaOH, 96%), sulfuric acid (H2SO4, 98%), and phosphoric acid (H3PO4, 99%) were analytical grade and were purchased from Merck. Stock solution of 1000 mg L−1 of RhB was prepared by dissolving 1.00 g of dye in 1 L distilled water. Solutions of different concentrations were obtained by diluting the stock solution.

2.2 Preparation of adsorbent

The stalk corn was collected from agriculture lands around Kermanshah, Iran, and was washed with distilled water to remove sand and dirt. The material was dried at 100 °C in an oven for 24 h to remove moisture. Then, it was cut into small pieces (2 mm). The activation was performed by mixing of row stalk corn with phosphoric acid (1 N) in a ratio of 1:10 (w/w) for 24 h in laboratory temperature. This mixture was then placed in an oven in 100 °C for 24 h for further drying. The dried mixture was carbonized in a muffle furnace in absence of air firstly in 500 °C for 30 min and after that in 700 °C for 15 min. Nitrogen (N2) was used as a protective gas. The obtained carbon then cooled, pulverized, and sieved to 50-mesh size. Regarding the removal of any impurity, the obtained activated carbon was washed several times with deionized water until the pH of the residual solution reached 6–7 [44].

2.3 Rhodamine B adsorption experiments

Batch adsorption experiments were conducted to evaluate the removal performance of RhB in aqueous solutions. The effect of parameters such as initial solution pH, adsorbent amount, initial RhB concentration, and contact time on the adsorption process was investigated. The experimental studies were perused with 100 mL solution of desired concentration (10–50 mg L−1), contact time of 30–110 min, and adsorbent dosages at the ranges of 0.5–2.5 g L−1 in 250 mL conical flask agitated on a thermostated shaking incubator at 120 rpm. In addition, the effect of pH was studied in the range 3–11 and was adjusted using 0.5 M H2SO4 and NaOH. At the end of mentioned contact times, sampling was done to determine the adsorbate concentration using double beam UV–visible spectrophotometer (Systronics 2203). The concentration of RhB was measured at a wavelength of 554 nm. The amount of adsorbed RhB at equilibrium was calculated by the following equation [45]:

where qe (mg g−1) implies the equilibrium adsorption capacity of RhB adsorbed per gram of the SCBAC, C0 and Ce (mg L−1) the initial and equilibrium RhB concentrations, respectively, V the volume of the RhB solution (L), and m the SCBAC mass (g). The dye removal percentage was calculated using the following relationship:

Each experiment was conducted in duplicate under identical conditions.

2.4 Adsorption equilibrium

An adsorption isotherm is equations for description of adsorbate equilibrium between solid and liquid interfaces [46]. The adsorption isotherm can be useful to illustrate the interaction of the adsorbate with the adsorbent. The adsorption isotherm correlations are important for evaluation of adsorbent distribution on solid/liquid interface and for the estimation of adsorbent uptake capacity. In the present work, Langmuir and Freundlich isotherms were used to identify the mechanisms of adsorption process.

2.4.1 Langmuir model

The Langmuir model, simplest and widely used model, is based on the assumption that adsorption takes place in monolayer form without any interaction between adsorbed molecules. Based on this model, adsorption energies onto the surface are uniform [47,48,49,50]. The Langmuir equation is written as (Eq. 3):

where qm is maximum adsorption capacity (mg g−1) and b is adsorption equilibrium (L mg−1).

RL, can be expressed in terms of separation factor, indicates the adsorption nature to be unfavorable (RL > 1), linear (RL = 1), favorable (0 < RL < 1), or irreversible (RL = 0).

2.4.2 Freundlich isotherm

The Freundlich isotherm assumed that there is no restriction to the formation of a monolayer adsorption and can be used to illustrate heterogeneous adsorbent surface without uniform distribution of the heat of adsorption [51,52,53]. It can be represented by the following equation:

where KF and n are Freundlich constants, which related to the sorption capacity and the sorption intensity of the system. The magnitude of the term (1/n) provides an indication of the favorability of the sorbent/adsorbate systems [35, 54].

2.5 Adsorption kinetic

Batch adsorption experiments were carried out by addition of well-known amount of adsorbent to the liquid solution. The kinetic experiments were conducted by taking the samples from the solution. The kinetic experiments were performed for 10 mg L−1 of RhB and pH of 3. The adsorbent dosage was fixed as 2.5 g L−1. In the present work, two well-known adsorption kinetic models were applied: the pseudo-first-order Lagergren equation and the pseudo-second-order rate equation. The pseudo-first-order equation, proposed by Lagergren, is a method for analyzing the kinetics of adsorption process which can be displayed its linear form as (Eq. 6) [55, 56]:

where qe (mg g−1) and qt (mg g−1) are values of the adsorbed adsorbate at equilibrium and at time t, respectively, and k1 (min−1) is the rate constant of pseudo-first-order adsorption.

The pseudo-second-order kinetics model can be defined as (Eq. 7):

In this regard, k2 (g mg min−1) shows the rate constant of the pseudo-second-order equation rate constant.

3 Result and discussion

3.1 Surface functional group of adsorbent

The SEM micrograph of SCBAC is shown in Fig. 1. The porous surface of activated carbon could be observed by this micrograph. The identification of functional groups on the adsorbent is useful toll in figure out of chemical structures of the adsorbents. FTIR analysis was applied to identify some characteristic functional groups of activated carbon (FCBAC) (Fig. 2). The peak observed in the region around 3450 cm−1 corresponds to O–H stretching of the hydroxyl groups. The distinct peak at 1650 cm−1 is related to C = C stretching vibration in aromatic rings [57]. The peak identified at 1275 cm−1 represents C–N stretching. The presence of C–O groups is indicated by the peak appeared at 1110 cm−1. The peak at 825 cm−1 is due to C–H functional group [58].

3.2 Influence of initial solution pH

One of the most important factors in the adsorption process is solution pH [19, 59]. The effect of solution pH generally depends on the ions present in the reaction mixture as well as electrostatic interactions with the adsorption surface. In the present study, the adsorption of RB was studied as function of pH of 3, 7, and 11.

The obtained results showed that by increasing of pH from 3 to 11, dye removal was decreased (Fig. 3). A possible explanation for this could be the interaction of the positively charged (cationic) RhB molecules with the negatively charged surface of the adsorbent via electrostatic interactions. These results are in agreement with those obtained by others. For example, Mohammadi et al. [60] evaluated the removal of RhB from aqueous solution using palm shell-based activated carbon. Result of their study showed the positive effect of acidic pH on adsorption of RhB. In addition, Cheng et al. investigate the effect of graphene oxide/silicalite-1 composites on adsorption of RhB. They claimed that in acidic environment, the fabricated adsorbent has high performance in removal of RhB [18]. In the point of zero charge (pHzpc), the positive and negative electrical charges found at the adsorbent surface are balanced. The influence of pHzpc on adsorption process is seen in three ways: (1) The adsorbent surface has a negative charge if pHzpc < pH, (2) the adsorbent surface has a positive charge if pHzpc > pH, and (3) if pHzpc = pH, the adsorbent surface has natural [61]. In the present study, the pHpzc was determined via the salt addition method [62]. The pHpzc of the prepared adsorbent was determined 5.9. At pH 3, the surface of prepared activated carbon is positively charged because when the pH < pHpzc, the surface of adsorbent becomes positively charged and therefore attracts the ionic form of RhB dye led to enhanced adsorption at pH lower than pHpzc value [63]. At pH above 3, due to deprotonated form of the COOH groups on the RhB, transformation from a cationic form to a zwitterionic form can occur which in turn leads to an electrostatic repulsion between RhB and the negatively charged SCBAC, thus decreasing its adsorption capacity [18].

3.3 Effect of adsorbent dosage

Effect of adsorbent dosage in removal of RhB from aqueous solution at optimum pH 3 was investigated. The applied adsorbent dosage was varied from 0.5 to 2.5 g L−1 for the dye concentrations from 10 to 50 mg L−1. As depicted in Fig. 4, removal of RhB shows increasing trend by increase of adsorbent dosages. Increase in amount of RhB adsorption by increasing of SCBAC dosage can be related to the increase of surface area and increase of reaction sites. The results obtained in this study are consisted with that obtained by El-Sayed et al. [26], Hayeeye et al. [64], Rangabhashiyam and Balasubramanian [36], and Rajasekhar [28] who reported that increasing of adsorbent dosage led to the increase of adsorbed adsorbate.

3.4 Effect of initial concentration of dye

The effect of initial dye concentration on removal of RhB at various adsorbent dosages and optimum pH of 3 was studied. As shown in Fig. 5, the removal efficiency of RhB was decreased by increasing of dye concentration. The removal of RhB at various dosages of adsorbent was decreased from 38.6 to 24.2%, 57.3 to 5.8%, and 89.6 to 45% respectively by increasing of dye concentration from 10 to 50 mg L−1.

By increasing of initial dye concentration, the active sites of adsorbent were occupied by adsorbate. In addition, the competition of adsorbate molecules for the adsorbent binding sites can be increased [36]. The obtained results are consistent with the previously conducted study [26, 36].

3.5 Effect of contact time

One of the critical parameters that pointedly affect the performance of dye removal is the contact time between adsorbent and adsorbate. Fig. 6 illustrates the effect of contact time on the extent of RhB removal. The percentage removal rate for RhB varied from 65.5 to 62.6%, 41.6 to 36%, and 34.3 to 30.2% for concentrations of 10, 30, and 50 mg L−1, respectively. Looking at Fig. 6, it is apparent that the maximum RhB removal for all the dye concentrations was attained at the first 30 min of experiment. After that time, removal rate was decreased slightly. This can be due to the fact that at the beginning of the experiments, the available vacant adsorption sites are high and by elapsing the time, the amount of vacant sites decreased and thereby it is difficult to occupy these sites [65].

3.6 Adsorption kinetics

In the present work, two adsorption kinetic models were conducted: the pseudo-first-order Lagergren equation and the pseudo-second-order rate equation were both fitted with the experimental data [19]. The pseudo-first-order equation is based on the assumption that physisorption limits the rate of adsorption of the particles onto the adsorbent, while, in the pseudo-second-order model, chemisorption is considered as the rate-limiting mechanism of the process [66]. The result showed that the experimental data is better fitted to a pseudo-second-order model (R2 = 1) than to a pseudo-first-order model (R2 = 0.87), for the adsorption of RhB onto SCBAC (Table 1, Fig. 7).

The obtained data are in line with that obtained by others [18, 19, 55] who reported that the kinetic of adsorbate adsorption on different adsorbent follows the pseudo-second order. Based on the obtained results, it can be concluded that the adsorption of RhB onto SCBAC was a chemisorption process relating valence force through sharing or electron exchange between adsorbate and adsorbent species [55].

3.7 Adsorption isotherm

The Langmuir and Freundlich isotherm models were used to test the equilibrium data of RhB adsorption on SCBAC. The plot for Freundlich and Langmuir isotherm is shown in Fig. 8. The parameters obtained from these isotherm models are illustrated in Table 2. It was found that the “qm,” maximum capacity of the adsorbent and the most significant parameter of the Langmuir isotherm, was 5.3 mg g−1. In the present work, the RL was 0.347 which imply the favorability of the RhB adsorption onto SCBAC (0 < RL < 1). In a study conducted by Nethaji et al. [55], removal of Cr (VI) was investigated by corncob activated carbon coated with nano-sized magnetite particles. Their results showed that the obtained qm was varied from 52.24 to 57.37 mg g−1. Compared to the present work, the difference between the obtained qm can be related to the difference in the nature of the pollutant, different activation method, as well as further modification of the used adsorbent.

The favorability of the adsorption process was also tested by Freundlich equation. In this study, the sorption intensity of the system (n) was 2.63, which confirm the favorability of the process (0 < n < 10). The correlation coefficient of Freundlich model is better than that of Langmuir model, so Freundlich isotherm model was found to be the best fit for the studied system. The obtained results are in contrast with the results found by Kamarehie et al. [67] who showed that Langmuir isotherm provides a better fit for the adsorption of alizarin red S onto the PAC/γ-Fe2O3. According to the assumptions of the Freundlich isotherm, therefore, it can be concluded that the prepared SCBAC had heterogeneous surface.

The sorption capabilities of the prepared activated carbon in this study regarding RhB were compared with some adsorbents reported previously (Table 3). It is obvious that SCBAC has lower removal ability of RhB than other adsorbents previously mentioned.

4 Conclusion

Evaluation of adsorption capacity of SCBAC was done through batch mode studies. The maximum removal of RhB (89.6%) was attained at optimum pH 3 and 2.5 g of adsorbent. The sorption isotherm of RhB by SCBAC was found to be best fitted by the Freundlich model with acceptable R2 = 0.9. Kinetic study showed that adsorption of RhB on SCBAC followed pseudo-second-order model and the maximum adsorption capacity of SCBAC for RhB is 5.3 mg g−1. Based on the results derived from this study, SCBAC has low uptake capacity for higher concentration of RhB. Application of this adsorbent is recommended for low concentration of RhB. Prepared SCBAC showed that can be utilized as economical and effective adsorbent for the adsorption of dyeing pollutants, like RB, from aqueous solutions.

References

Soleimani H, Nasri O, Ghoochani M, Azhdarpoor A, Dehghani M, Radfard M et al (2020) Groundwater quality evaluation and risk assessment of nitrate using Monte Carlo simulation and sensitivity analysis in rural areas of Divandarreh County, Kurdistan province, Iran. Int J Env Anal Chem:1–19

Soury S, Bahrami A, Alizadeh S, Shahna FG, Nematollahi D (2019) Development of a needle trap device packed with zinc based metal-organic framework sorbent for the sampling and analysis of polycyclic aromatic hydrocarbons in the air. Microchem J 148:346–354

Firoozichahak A, Bahrami A, GhorbaniShahna F, Alizadeh S, Nematollahi D, Farhadian M (2020) Development of a needle trap device packed with titanium-based metal-organic framework sorbent for extraction of phenolic derivatives in air. J Sep Sci 43(5):1011–1018

Pirmohammadi Z, Bahrami A, Nematollahi D, Alizadeh S, GhorbaniShahna F, Rahimpoor R (2020) Determination of urinary methylhippuric acids using MIL‐53‐NH 2 (Al) metal–organic framework in microextraction by packed sorbent followed by HPLC–UV analysis. Biomed Chromatogr 34:1-e4725

Asgari G, Seid-Mohammadi A, Rahmani A, Samadi MT, Salari M, Alizadeh S, et al (2021) Diuron degradation using three-dimensional electro-peroxone (3D/E-peroxone) process in the presence of TiO2/GAC: application for real wastewater and optimization using RSM-CCD and ANN-GA approaches. Chemosphere 266:129179

Kamarehie B, Jafari A, Ghaderpoori M, Azimi F, Faridan M, Sharafi K, et al (2020) Qualitative and quantitative analysis of municipal solid waste in Iran for implementation of best waste management practice: a systematic review and meta-analysis. Environmental Science and Pollution Research:1–13

Karami M, Farzadkia M, Jonidi A, Nabizadeh R, Gohari M, Karimaee M (2011) Quantitative and qualitative investigation of industrial solid waste in industrial plants located between Tehran and Karaj. Iran Occupation Health 8(2):12

Mansourian N, Javedan G, Darvishmotevalli M, Sharafi K, Ghaffari H, Sharafi H et al (2016) Efficiency evaluation of zeolite powder, as an adsorbent for the removal of nickel and chromium from aqueous solution: isotherm and kinetic study. Int J Phar Technol 8(2):13891–13907

Taherkhani S, Darvishmotevalli M, Karimyan K, Bina B, Fallahi A, Karimi H (2018) Dataset on photodegradation of tetracycline antibiotic with zinc stannate nanoflower in aqueous solution—application of response surface methodology. Data Brief 19:1997–2007

Motevalli M, Naghan D, Mirzaei N, Haghighi S, Hosseini Z, Sharafi H et al (2015) The reusing feasibility of wastewater treatment plant (conventional activated sludge) effluent of tomato paste factory for agricultural irrigation—a case study. Int J Phar Technol 7(3):9672–9679

Rahmani AR, Navidjouy N, Rahimnejad M, Alizadeh S, Samarghandi MR, Nematollahi D (2020) Effect of different concentrations of substrate in microbial fuel cells toward bioenergy recovery and simultaneous wastewater treatment. Environmental Technology:1–9

Khamparia S, Jaspal D (2016) Investigation of adsorption of Rhodamine B onto a natural adsorbent Argemone mexicana. J Environ Manage 183:786–793

Mohammadi H, Alinejad A, Khajeh M, Darvishmotevalli M, Moradnia M, Tehrani AM et al (2019) Optimization of the 3D electro-Fenton process in removal of acid orange 10 from aqueous solutions by response surface methodology. J Chem Technol Biotechnol 94(10):3158–3171

Fadaei S, Noorisepehr M, Pourzamani H, Salari M, Moradnia M, Darvishmotevalli M et al (2021) Heterogeneous activation of peroxymonosulfate with Fe3O4 magnetic nanoparticles for degradation of Reactive Black 5: batch and column study. J Env Chem Eng 9:4–105414

Shokoohi R, Salari M, Shabanloo A, Shabanloo N, Marofi S, Faraji H, et al (2020) Catalytic activation of persulphate with Mn3O4 nanoparticles for degradation of acid blue 113: process optimisation and degradation pathway. International Journal of Environmental Analytical Chemistry:1–20

AL-Tufaily M, Al-Qadi Z (2016) Preparation and utilization of corncob activated carbon for dyes removal from aqueous solution batch and continuous study. Babylon univ eng scis J 24(3):700–712

Laysandra L, Sari MWMK, Soetaredjo FE, Foe K, Putro JN, Kurniawan A, et al (2017) Adsorption and photocatalytic performance of bentonite-titanium dioxide composites for methylene blue and rhodamine B decoloration. Heliyon 3(12):e00488

Cheng Z-L, Li Y-x, Liu Z (2017) Fabrication of graphene oxide/silicalite-1 composites with hierarchical porous structure and investigation on their adsorption performance for rhodamine B. J Ind Eng Chem 55:234–243

Mouni L, Belkhiri L, Bollinger J-C, Bouzaza A, Assadi A, Tirri A et al (2018) Removal of methylene blue from aqueous solutions by adsorption on Kaolin: kinetic and equilibrium studies. Appl Clay Sci 153:38–45

Ptaszkowska-Koniarz M, Goscianska J, Pietrzak R (2018) Removal of rhodamine B from water by modified carbon xerogels. Colloids Surf, A 543:109–117

Sepehr MN, Allani F, Zarrabi M, Darvishmotevalli M, Vasseghian Y, Fadaei S et al (2019) Dataset for adsorptive removal of tetracycline (TC) from aqueous solution via natural light weight expanded clay aggregate (LECA) and LECA coated with manganese oxide nanoparticles in the presence of H2O2. Data Brief 22:676–686

Karami M, Sharafi K, Asadi A, Bagheri A, Yosefvand F, Charganeh SS, et al (2016) Degradation of reactive red 198 (RR198) from aqueous solutions by advanced oxidation processes (AOPS): O3, H2O2/O3 and H2O2/ultrasonic. Bulgarian Chemical Communications 48(Specia):43–9

Farzadkia M, Karimaee M, Nabizadeh R, Kalantary R, Gohari M, Karami M (2013) Environmental ranking of industries located at west of Tehran based on the quantitative and qualitative characteristics of industrial wastewaters in 2011. Iran Occupational Health 9(4)

Bahram Kamarehie JM, Mousavi SA, Asgari G, Shahamat YD (2017) Aniline degradation from aqueous solution using electro/Fe 2+ /peroxydisulphate process. Desalin Water Treat 80:337–343

Kamarehie B, Ahmadi F, Hafezi F, Abbariki A, Heydari R, Karami MA (2018) Experimental data of electric coagulation and photo-electro-phenton process efficiency in the removal of metronidazole antibiotic from aqueous solution. Data Brief 18:96–101

El-Sayed GO, Yehia MM, Asaad AA (2014) Assessment of activated carbon prepared from corncob by chemical activation with phosphoric acid. Water Resources and Industry 7:66–75

Bentahar S, Dbik A, El Khomri M, El Messaoudi N, Lacherai A (2017) Adsorption of methylene blue, crystal violet and congo red from binary and ternary systems with natural clay: kinetic, isotherm, and thermodynamic. J Environ Chem Eng 5(6):5921–5932

Rajasekhar K (2014) Removal of malachite green from aqueous solution using corn cob as adsorbent. International Journal Of Engineering And Computer Science ISSN:2319–7242

Farnane M, Tounsadi H, Machrouhi A, Elhalil A, Mahjoubi F, Sadiq M et al (2018) Dye removal from aqueous solution by raw maize corncob and H3PO4 activated maize corncob. J Water Reuse Desalin 8(2):214–224

Almasi A, Rostamkhani Z, Mousavi SA (2017) Adsorption of reactive red 2 using activated carbon prepared from walnut shell: batch and fixed bed studies. DESALIN AND WATER TREATMENT 79:356–367

Mousavi SA, Janjani H (2018) Antibiotics adsorption from aqueous solutions using carbon nanotubes: a systematic review. Toxin Reviews:1–12

Kamarehie B, Aghaali E, Musavi S, Hashemi S, Jafari A (2018) Nitrate removal from aqueous solutions using granular activated carbon modified with iron nanoparticles (RESEARCH NOTE). Int J Eng-Transactions A: Basics 31(4):554–563

Siddiqui SH (2017) The removal of Cu 2+, Ni 2+ and methylene blue (MB) from aqueous solution using Luffa Actangula carbon: kinetics, thermodynamic and isotherm and response methodology. Groundwater for Sustainable Development

Lopes GK, Zanella HG, Spessato L, Ronix A, Viero P, Fonseca JM, et al (2021) Steam-activated carbon from malt bagasse: optimization of preparation conditions and adsorption studies of sunset yellow food dye. Arabian Journal of Chemistry:103001

Pathania D, Sharma S, Singh P (2017) Removal of methylene blue by adsorption onto activated carbon developed from Ficus carica bast. Arab J Chem 10:S1445–S1451

Rangabhashiyam S, Balasubramanian P (2018) Adsorption behaviors of hazardous methylene blue and hexavalent chromium on novel materials derived from Pterospermum acerifolium shells. J Mol Liq 254(1):433–445

Kumar PS, Ramalingam S, Kirupha SD, Murugesan A, Vidhyadevi T, Sivanesan S (2011) Adsorption behavior of nickel (II) onto cashew nut shell: equilibrium, thermodynamics, kinetics, mechanism and process design. Chem Eng J 167(1):122–131

Hossain M, Ngo HH, Guo W, Nguyen T (2012) Removal of copper from water by adsorption onto banana peel as bioadsorbent. Int J Geomate 2(2):227–234

Homagai PL, Ghimire KN, Inoue K (2010) Adsorption behavior of heavy metals onto chemically modified sugarcane bagasse. Biores Technol 101(6):2067–2069

Zheng J, Zhao Q, Ye Z (2014) Preparation and characterization of activated carbon fiber (ACF) from cotton woven waste. Appl Surf Sci 299:86–91

Malkoc E, Nuhoglu Y (2005) Investigations of nickel (II) removal from aqueous solutions using tea factory waste. J Hazard Mater 127(1–3):120–128

Zhang Z, Lei Y, Li D, Zhao J, Wang Y, Zhou G et al (2020) Sudden heating of H3PO4-loaded coconut shell in CO2 flow to produce super activated carbon and its application for benzene adsorption. Renewable Energy 153:1091–1099

Wang S, Yang B, Liu Y (2017) Synthesis of a hierarchical SnS2 nanostructure for efficient adsorption of Rhodamine B dye. J Colloid Interface Sci 507:225–233

Bagheri N, Abedi J (2009) Preparation of high surface area activated carbon from corn by chemical activation using potassium hydroxide. Chem Eng Res Des 87(8):1059–1064

Kamarehie B, Noraee Z, Jafari A, Ghaderpoori M, Karami MA, Ghaderpoury A (2018) Data on the fluoride adsorption from aqueous solutions by metal-organic frameworks (ZIF-8 and Uio-66). Data Brief 20:799–804

Yousefi M, Arami SM, Takallo H, Hosseini M, Radfard M, Soleimani H et al (2019) Modification of pumice with HCl and NaOH enhancing its fluoride adsorption capacity: kinetic and isotherm studies. Hum Ecol Risk Assess Int J 25(6):1508–1520

Dehghani MH, Karri RR, Yeganeh ZT, Mahvi AH, Nourmoradi H, Salari M, et al (2020) Statistical modelling of endocrine disrupting compounds adsorption onto activated carbon prepared from wood using CCD-RSM and DE hybrid evolutionary optimization framework: comparison of linear vs non-linear isotherm and kinetic parameters. Journal of Molecular Liquids 302:112526

Samarghandi MR, Zarrabi M, Amrane A, Sepehr MN, Noroozi M, Namdari S et al (2012) Kinetic of degradation of two azo dyes from aqueous solutions by zero iron powder: determination of the optimal conditions. Desalin Water Treat 40(1–3):137–143

Tahmasebi F, Alimohammadi M, Nabizadeh R, Khoobi M, Karimian K, Zarei A (2019) Performance evaluation of graphene oxide coated on cotton fibers in removal of humic acid from aquatic solutions. Korean J Chem Eng 36(6):894–902

Shokoohi R, Salari M, Molla Mahmoudi M, Azizi S, Ghiasian SA, Faradmal J, et al (2020) The sorption of cationic and anionic heavy metal species on the biosorbent of Aspergillus terreus: isotherm, kinetics studies. Environmental Progress & Sustainable Energy 39(2):e13309

Mohammadi AA, Dehghani MH, Mesdaghinia A, Yaghmaian K, Es’ haghi Z, (2020) Adsorptive removal of endocrine disrupting compounds from aqueous solutions using magnetic multi-wall carbon nanotubes modified with chitosan biopolymer based on response surface methodology: functionalization, kinetics, and isotherms studies. Int J Biol Macromol 155:1019–1029

Saleh HN, Dehghani MH, Nabizadeh R, Mahvi AH, Hossein F, Ghaderpoori M et al (2018) Data on the acid black 1 dye adsorbtion from aqueous solutions by low-cost adsorbent-Cerastoderma lamarcki shell collected from the northern coast of Caspian Sea. Data Brief 17:774–780

Eslami F, Nodehi RN, Nasseri S, Salari M, Mahvi AH, Ardejani FD (2020) Optimization of chromium (VI) adsorption by novel nano-pumice modified by cationic surfactant from aqueous media using the response surface method: isotherm and kinetic studies. Desalin Water Treat 177:139–151

Sharifi S, Nabizadeh R, Akbarpour B, Azari A, Ghaffari HR, Nazmara S et al (2019) Modeling and optimizing parameters affecting hexavalent chromium adsorption from aqueous solutions using Ti-XAD7 nanocomposite: RSM-CCD approach, kinetic, and isotherm studies. J Environ Health Sci Eng 17(2):873–888

Nethaji S, Sivasamy A, Mandal A (2013) Preparation and characterization of corn cob activated carbon coated with nano-sized magnetite particles for the removal of Cr (VI). Biores Technol 134:94–100

Dehghan A, Mohammadi AA, Yousefi M, Najafpoor AA, Shams M, Rezania S (2019) Enhanced kinetic removal of ciprofloxacin onto metal-organic frameworks by sonication, process optimization and metal leaching study. Nanomaterials 9(10):1422

Marković S, Stanković A, Lopičić Z, Lazarević S, Stojanović M, Uskoković D (2015) Application of raw peach shell particles for removal of methylene blue. J Environ Chem Eng 3(2):716–724

Song M, Jin B, Xiao R, Yang L, Wu Y, Zhong Z et al (2013) The comparison of two activation techniques to prepare activated carbon from corn cob. Biomass Bioenerg 48:250–256

Moghaddam MH, Nabizadeh R, Dehghani MH, Akbarpour B, Azari A, Yousefi M (2019) Performance investigation of Zeolitic imidazolate framework–8 (ZIF-8) in the removal of trichloroethylene from aqueous solutions. Microchemical Journal 150:104185

Mohammadi M, Hassani AJ, Mohamed AR, Najafpour GD (2010) Removal of rhodamine B from aqueous solution using palm shell-based activated carbon: adsorption and kinetic studies. J Chem Eng Data 55(12):5777–5785

Kamarehie B, Jafari A, Ghaderpoori M, Amin Karami M, Mousavi K, Ghaderpoury A (2019) Catalytic ozonation process using PAC/γ-Fe2O3 to Alizarin Red S degradation from aqueous solutions: a batch study. Chem Eng Commun 206(7):898–908

Mahmood T, Saddique MT, Naeem A, Westerhoff P, Mustafa S, Alum A (2011) Comparison of different methods for the point of zero charge determination of NiO. Ind Eng Chem Res 50(17):10017–10023

Abia Daouda ATH, Noumi Guy Bertrand, Richard aD (2019) Adsorption of Rhodamine B onto orange peel powder American Journal of Chemistry 9(5):142–9

Hayeeye F, Sattar M, Chinpa W, Sirichote O (2017) Kinetics and thermodynamics of Rhodamine B adsorption by gelatin/activated carbon composite beads. Colloids Surf, A 513:259–266

Oveisi M, Asli MA, Mahmoodi NM (2017) MIL-Ti metal-organic frameworks (MOFs) nanomaterials as superior adsorbents: synthesis and ultrasound-aided dye adsorption from multicomponent wastewater systems. Journal of hazardous materials

Sumalinog DAG, Capareda SC, de Luna MDG (2018) Evaluation of the effectiveness and mechanisms of acetaminophen and methylene blue dye adsorption on activated biochar derived from municipal solid wastes. J Environ Manage 210:255–262

Kamarehie B, Jafari A, Ghaderpoori M, Karami MA, Mousavi K, Ghaderpoury A (2018) Data on the alizarin red S adsorption from aqueous solutions on PAC, treated PAC, and PAC/γ≈ Fe2O3. Data Brief 20:903–908

Cheng Z-L, Li Y-x, Liu Z (2018) Study on adsorption of rhodamine B onto Beta zeolites by tuning SiO 2/Al 2 O 3 ratio. Ecotoxicol Environ Saf 148:585–592

Motahari F, Mozdianfard MR, Salavati-Niasari M (2015) Synthesis and adsorption studies of NiO nanoparticles in the presence of H2acacen ligand, for removing Rhodamine B in wastewater treatment. Process Saf Environ Prot 93:282–292

Khan TA, Dahiya S, Ali I (2012) Use of kaolinite as adsorbent: equilibrium, dynamics and thermodynamic studies on the adsorption of Rhodamine B from aqueous solution. Appl Clay Sci 69:58–66

Acknowledgements

The authors would like to thank the Kermanshah and Lorestan University of Medical Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mousavi, S.A., Kamarehie, B., Almasi, A. et al. Removal of Rhodamine B from aqueous solution by stalk corn activated carbon: adsorption and kinetic study. Biomass Conv. Bioref. 13, 7927–7936 (2023). https://doi.org/10.1007/s13399-021-01628-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01628-1