Abstract

The current research article investigates the remediation of methylene blue (MB), in continuous operation mode, utilizing compost as an adsorbent. The adsorbent was prepared from the water hyacinth plant waste by using effective microorganism (EM) which acts as a decomposer for the materials used. EM contains the various microbes that are responsible for the decomposition and it is available in the dormant liquid form which requires activation. The researcher performed a continuous study in which the following parameters are varied—bed complexity and flow rate. The findings of the study revealed that a maximum uptake of 301.79 mg/g was achieved and the removal efficiency is found to be around 85.44%. The overall sorption time zone, exhaustion time, breakthrough time, and volume of dye treated are also calculated. Modeling of experimental data is performed using bed depth service time (BDST) model and Thomas model. 0.01 M HCL was used as an elutant for the regeneration studies and maximum desorption efficiency of 85.44% was obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Daily, a huge amount of pollutants are produced from industries and that is mixing with the nearby water bodies without pretreatment process which is toxic and poisonous in nature. If these pollutants are not treated properly before disposing it in the environment, it will create numerous effects to human beings and aquatic life. The contamination of water bodies is due to two chief sources namely point and non-point sources [1]. Wastewater generated from the industries that are mixed with nearby water bodies is the common point sources of pollutants, whereas non-point sources are those pollutants like fertilizers, pesticides, and human waste that enter through surface runoff of rainwater.

The textile industry discharges the wastewater containing dyes into the natural watercourses and the environment which may encompass more impurities such as acids, bases, dissolved solids, toxic organic, and inorganic compounds and also colors. These toxic impurities cause major threats to the environment and living entity. Dyes and pigments present in wastewater have high visibility [2]. This dye-contaminated water when consumed will cause ill effects to the liver, kidney, reproductive system, etc. [3, 4]. Even a desirable amount (< 1 mg/L) of this chemical when mixed will change the nature of the water bodies and leads to many side effects [5]. And also, when it was discharged into the water bodies, there is no significant growth of algae. The cationic and basic dyes are most acutely toxic to algae.

The technologies used for the removal of dyes are categorized into three groups—physical, chemical, and biological. Coagulation/flocculation, filtration, reverse osmosis, and adsorption are the frequently utilized physical methods in the removal of dyes. The commonly used chemical methods for dye removal are ion exchange, electro-kinetic coagulation, chemical oxidation, ozonation, and electrolysis. Biological treatment has several advantages when compared to physical and chemical processes. The methods of biodegradation, bioaccumulation, bioremediation, and biosorption are commonly applied to degrade different pollutants using microorganisms.

Biosorption is considered one of the most recent technologies that are used to degrade the pollutants [6,7,8]. In this study, the researchers used compost as a novel sorbent in the biosorption of methylene blue (MB) dye. When the organic matter is biologically degraded under aerobic conditions, it tends to produce compost, an organic-rich compound as a byproduct and this process is called composting. The microbes present in the organic materials are predominantly involved in the decomposition of biodegradable components in waste [9]. Past research proves that compost can be effectively used to improve soil fertility and has a wide application in soil enrichment [10].

Effective microorganism (EM) was developed by Teruo Higa (1970) at the Ryukyus University, Okinawa, Japan [11]. Basically, this is a micro-based solution for natural organic farming systems, and however its results and uses have been expanded for solving some environmental issues. The various studies have suggested that EM may have a number of applications including agriculture, livestock, gardening and landscaping, composting, bioremediation, cleaning septic tanks, algal control, and household uses [12].

EM is a mixture of groups of organisms that has a reviving action on human beings, animals, and the natural environment and has also been described as a multi-culture of coexisting anaerobic and aerobic beneficial microorganisms [13]. EM can ensure high-quality compost as the microbial inoculant increases the production of aerobic bacteria and increases the composting speed. The main species involved in EM include lactic acid bacteria, photosynthetic bacteria, yeasts, Actinomycetes, and fermenting fungi [14]. Ideal composting not only depends on EM but also on other parameters such as moisture, type of bulking agents added, and size, shape, and surface of the organic waste material used [15]. In this study, the organic waste material of water hyacinth plant waste was selected for the aerobic composting process with the application of EM.

In order to achieve a greener environment, a suitable technique has to be evolved by combining solid waste management (composting) and wastewater treatment (dye removal) through the adsorption process. The present work deals with the adsorption of MB using effective microorganism (EM)–based water hyacinth waste compost (EMWHC) as a low-cost adsorbent in continuous mode of operation. A very limited study has been carried on the adsorption of dyes in a continuous process. To explore the real-time feasibility of the effluent treatment in industries, a continuous adsorption process will be a real solution [16].

2 Materials and methods

2.1 Collection of materials

The researchers first collected the water hyacinth plant waste from channels and nearby ponds and prepared the EMWHC, i.e., effective microorganism-based water hyacinth plant waste compost along with effective microorganism (EM). To the prepared material, the researchers added sawdust procured from sawmills located nearby as the bulking agent and cow dung from local livestock was used for decomposition. These were added to fasten the composting speed and nutrient content. The dormant EM was procured from Environ biotech, Tamilnadu, India, and this was utilized alike a decomposer for the compost. Prior to use, the EM must be activated since it is sold only in the form of a dormant state. EM activation was done as follows: 1 L of dormant EM was added with 20 L of water and 2 kg of jaggery as per the literature [17]. This mixture was then stored in a clean airtight container under the shade, i.e., without getting exposed to sunlight for 7 days at a suitable temperature. Until the fermentation gets completed, the gas should be let out to escape every day. When getting activated, a white layer can be seen on the top of the mixture with a sweet smell let out by the Actinomycetes. pH seems to be a determining factor for the activated EM which should be maintained below 4.0 [17]. This way, one can acknowledge the activation of effective microorganisms.

2.2 Chemicals used

For the experiment, the researchers procured methylene blue (MB) dye [3,7-bis (dimethylamino) phenothiazine –5-ium ion] from Merck India Ltd. The molecular formula for MB is C16H18ClN3S and the molecular weight is 319.85 g/mol. The wavelength of MB is in the range of 665 nm. Other chemicals used in this study such as HCl, NaOH, H2SO4, HNO3, and CaCl2 were procured from Ranbaxy Fine Chemicals Ltd., India, and are of analytical grade.

2.3 Preparation of EM-based composts

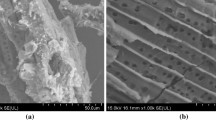

The solid waste materials chosen for the study were first examined, separated based on size less than 5 cm, and dried. The compost bin was prepared and the composting process was initiated. The researchers selected the plastic-made compost bin of 100-cm height. They filled the bottom with crushed stones as well as sand to get rid of leachate in the bed via the holes put in the bottom. Different layers were arranged such as cow-dung, desired solid waste, and sawdust coat, and this was repeated in the same order again until the layers almost filled the bin. In every layer, the activated EM was also sprayed. Until the compost was attained, the complete unit was sprayed with activated EM in regular intervals in order to keep it moist between 45 and 65%. At the starting time of composting, the temperature of the bed is in the range of 25 to 30 °C and after that, the thermophilic condition was retained throughout the process. Regularly, for instance, once every few days, the organic waste was turned in order to aerate the beds and to mix the contents in it. The bed volume reduced significantly at the end of 30 days whereas the top layers of the bin showed the presence of white mold. The end product like humus, which was dark brown in color, was collected. During this phase, the matured EM-based water hyacinth waste compost (EMWHC) was collected at 30 days and sieved as well. Various parameters were analyzed and all are in range for this compost such as electrical conductivity, organic carbon, moisture content, pH, nitrogen (N), potassium (K), C:N ratio, and phosphorus (P). The adsorbent prepared was made to undergo air-drying for about 24 h and oven dried at 70 °C for 2 h and then sieved [2].

2.4 Batch studies

From the findings of the batch experiment, it was revealed that a maximum 286.2 mg/g uptake with a removal efficiency of 98.4% is obtained at optimum conditions of pH 8, dosage of 2 g/L, temperature of 30 °C, particle size of 1.18 mm, equilibrium time of 300 min, and initial concentration of 100 mg/L. Five different elutants (HCl, H2SO4, HNO3, NaOH, and CaCl2 with 0.1 M) were used for the regeneration studies and results revealed that 0.01 M HCL showed the maximum removal efficiency of 88.4% with an S/L ratio of 2. These optimized conditions were used for further dye removal in a continuous process [15].

2.5 Continuous mode of studies

The experimental analysis and their results revealed great insights and proved to serve their purpose, i.e., to assess the basic information with regard to the behavior of the biosorbent and its performance in dye biosorption. But there is no accurate scale-up information available for industrial treatment systems, in which the companies installed a continuous flow system. So here arises a need to conduct the biosorption investigations with the help of columns. When it comes to process applications, it is deemed that the packed-bed column is effective and enables the incorporation of cyclic sorption as revealed in the literature studies [18,19,20,21,22,23,24].

Both bed exhaustion time and the breakthrough time were evaluated in order to determine the breakthrough curves. In the case of dye biosorption, such an operating mode is deemed to assure the highest difference in the possible concentration associated with the driving force. With its beginning at the inlet, the researcher witnesses the saturated solid sorbent zone to proceed slowly along the column; as it proceeds, the sorbent is found to break through the column. The breakthrough record generally provides an S-shaped typical breakthrough curve. The shape and slope are the results of the following factors—equilibrium sorption isotherm and mass transfer that is occurring throughout and to the sorbent which is present in the column [25].

The authors conducted a continuous mode of study (column operation) in order to assess the capability of removing industrial effluent dyes and its compatibilities. In the case of a continuous study mode, the researchers considered a glass column with dry adsorbent packed on glass wool with glass beads as the support. The bed was washed thoroughly using deionized water. This process makes sure that there is a close packing of the particles of the adsorbent. Cracks, voids, or channels are also avoided during the transportation of the dye solution that occurs in the column. After the bed drains completely, the EMWHC was loaded with sorbate MB. In a reservoir, fitted with a peristaltic pump at the bottom, the MB dye solution was stored and one can control its flow rate using the pump, into the column packed with the adsorbent. MB aqueous solution as the influent was permitted to get transported via bed by up-flow. The effluent samples were then collected at regular intervals. The researcher noted down the time during every collection and the samples were assessed for the concentration of the remaining dye with the help of a UV-visible spectrophotometer. This experiment was conducted utilizing a wide range of bed heights and flow rates which is a means to understand and analyze column performance.

The column investigations were conducted in a 2-cm diameter as well as a 35-cm-long glass column in an up-flow mechanism. To control the flow rate of the dye solution (Ravel RH-P120VS), the researcher used a peristaltic pump. The channeling effects were negligible as the ratio between the column diameter and particle diameter was witnessed to be high. To adjust the bed height of the column, at the top of the column, an adjustable plunger with a stainless sieve sized 0.5 mm is attached. 1.5-mm diameter glass beads are used to fill the column base as a layer for 2-cm height to ensure a uniform inlet solution flow into the column. Figure 1 represents the experimental setup for the up-flow packed bed column utilized in this study.

2.6 Sorption

The researchers conducted the column sorption investigations by differing the bed heights (10, 15, and 20 cm) and flow rates (10, 15, and 20 mL/min). The biosorbent (of known quantity) was kept in the column in order to attain the required bed height. The concentration-known and pH-adjusted dye solution was pumped in an upward direction via the column in the required flow rate using a peristaltic pump. The samples were fathered from the column exit point at various time periods. These samples were assessed for the concentration of the dye with the help of a UV-visible spectrophotometer. The effluent’s pH was noted down during sample collection at regular intervals. For the operating conditions discussed herewith, the breakthrough curves were plotted.

2.7 Desorption

Once the column got exhausted, the authors again generated the dye-loaded biosorbent with the help of an optimized elutant. Once the elution was completed, the bed was cleaned with distilled water until the washed water pH value became 7.0. After this, the dye solution was fed to the column again to perform the sorption-based analysis. Once the bed got exhausted, the optimized elutant was fed into a column wherein the researcher conducted regeneration analysis in batch mode. After several repetitive sorption and desorption cycles, the desorption capacity of the biosorbent was determined.

The process involved in the regeneration of the column was investigated afar the tests of the adsorption was conducted at a desired bed height yield, an optimized flow rate, and MB dye concentration for optimized value at fixed pH. When the experiments of adsorption were completed, the column bed had reached saturation [26]. Thereafter, EMWHC adsorbent was degenerated for regenerating with 0.1 M HCl solution, followed by centrifugation, washing, and drying at (70 °C), and reutilized again in the adsorption test.

2.8 Column data analysis and modeling

The dye quantity retained in the column (mad) is a measure of the product of flow rate and the area above the breakthrough curve. The area above the breakthrough curve is the result of concentration versus time. According to Volesky et al. [27], the dye mass (mad) should be divided by sorbent mass (M) which results in the biosorbent’s uptake capacity (Q).

The time taken when the effluent dye concentration achieve 1 mg/L is known as the breakthrough time (tb). However, the time taken when the effluent dye concentration is equal to inlet concentration is called bed exhaustion time (te). Literature studies have determined the values for the overall sorption zone (Δt) as shown in Eq. (1) [27]:

As per Aksu and Gonen [18], the effluent volume, total percentage of dye removed with respect to the volume of flow, and the overall dye value directed to the column (mtotal) are as follows.

In this equation, Veff denotes the volume of effluent (L), the volumetric flow rate (mL/min) to the bed as f, and C0 as the concentration of influent dye (mg/L).

One can calculate the desorbed dye mass (md) based on the elution curve (C versus t). Furthermore, one can calculate the elution efficiency (E) as given herewith [27]:

Various researchers conducted various investigations in adsorption modeling during the 1960s. Pore surface diffusion, intraparticle pore diffusion, and film diffusion are the few mechanisms which were considered as a trio or on an individual basis. In this study, the column data model is aimed at forecasting the breakthrough curve and adsorption capacity of EM-based compost. This modeling has been investigated and challenged for a long-known period.

2.9 Bed depth service time model

Bed depth service time (BDST) is a model used for analyzing the breakthrough curve. Being a simple model, BDST predicts and enables understanding the relationship that exists between parameters such as service time (denoted as “t”) and bed height (denoted as “Z”) with regard to adsorption parameters and process concentrations [19]. The BDST model works on the basis that the adsorption rate is assumed to be under control by the surface reaction that occurs between the adsorbate and the unused adsorbent capacity [20]. The initial proposition for the BDST theory was to eliminate chlorine gas using a charcoal column. Equation (6) displays the Adams–Bohart model on BDST.

In this equation, the initial concentration (mg/L) is shown as C0, Cb denotes the solute’s desired concentration at breakthrough (mg/L), Ka denotes the adsorption rate constant (L/mg/h) while N0 corresponds to adsorption capacity (mg/L), the bed depth is denoted by Z (cm) while u denotes the linear flow velocity of feed to bed (cm/h), and t denotes the column’s service time. One can determine both model constants Ka and N0 based on the Z plot against t.

Since \( {\mathrm{e}}^{K_{\mathrm{a}}{N}_0Z/u} \)is mostly greater than 1, a linear relationship was proposed by Hutchins in the year 1973 in between service time and bed height. Equation (7) displays the linear relationship.

With Z being the bed depth and t denoting the service time, a plot must draw a straight line with slope equal to (N0/C0u) and intercept of (− (1/KaC0) ln ((C0/Cb) − 1)). One can calculate both N0 and Ka from the slope and the intercept.

2.10 Thomas model

In order to design a system, one must definitely know the adsorbent’s maximum adsorption capacity. For a long-known time, this purpose is achieved by the Thomas model, a commonly deployed method in line with the column performance theory [21, 22]. In this model, an assumption is made that the Langmuir adsorption-desorption kinetics and no axial dispersion are derived with adsorption in such a way that its rate-driving force follows the pathway of 2nd order reversible reaction kinetics [23]. According to Yan and Viraraghavan [24], when the column sorption process needs to be successfully designed, the concentration-time profile or otherwise the breakthrough curve should be predicted for the effluent. Literature studies reveal the existence of several mathematical models which are used to elaborate on the concept of fixed-bed adsorption. While a vast number of models exist, the Thomas model is deemed to be a simple yet popular model and is considered by many research scholars and academic investigators [18, 24]. The linearized form of the Thomas model is displayed in Eq. (8).

where C denotes the effluent concentration (mg/L), C0 denoted the influent concentration (mg/L), kTh represents the Thomas rate constant (L/min mg), Q0 corresponds to maximum adsorption capacity (mg/g), M denotes the adsorbent mass (g), V represents effluent volume (mL), and finally the volumetric flow rate (mL/min) is denoted by f. Both kTh and Q0 as constants are calculated based on the plot of ln (C/C0 − 1) against t at a given flow rate.

3 Results and discussion

3.1 Impact of bed height

For assessing the impact of bed height in continuous experiments, variations in bed height were made from 10 to 20 cm wherein EMWHC was used for packing the column. The EMWHC with varying amounts (10.81, 17.5, and 27.18 g) was considered and added to the column with the varying bed heights of 10, 15, and 20 cm. Both the inlet MB concentration (100 mg/L) and the flow rate (10 mL/min) were maintained constantly. In Fig. 2, one can prove that there was an increase in both exhaustion time as well as the breakthrough time when the bed height got increased. This further led to a broadened mass transfer zone. The biomass uptake capacities attained were 213.85, 286.56, and 301.79 mg/g respectively for the bed heights of 10, 15, and 20 cm. The highest bed height recorded the maximum uptake. This is associated with the increased biosorbent surface area which might provide sufficient binding sites for the occurrence of sorption [19]. Furthermore, one can establish the fact that the amount of adsorbent got notably impacted by the uptake capacity of the sorption. In spite of the steep breakthrough curves with a decrease in the bed height, in turn denoted by high dc/dt values, the highest bed height recorded the highest removal percentage as shown in Table 1. As predicted, the increase in the bed result led to the treatment of a high volume of MB dye solution which is witnessed as high removal percentage.

3.1.1 Impact of flow rate

In the assessment of sorbents, the flow rate is considered as an important and significant parameter for continuous treatment of dyestuff effluents that are involved in large-scale operations (industrial scale) [28]. By varying the flow rate from 10 to 20 L/min with an optimized bed height of 20 cm, the impact of the flow rate on the MB biosorption by EMWHC was analyzed. When the flow rate was less, the column excellently performed; however, the performance reduced with the increase in the rate of flow which is displayed in Table 2. This behavior might be attributed to the inadequate time for the solute to remain within the column at high flow rates [29]. When the flow rate was increased, both exhaustion time and breakthrough time got decreased. This behavior may be due to insufficient time for the solute inside the column and the diffusion limitations of the solute into the pores of the sorbent at higher flow rates [30]. As the influent flow continues, there is a gradual saturation of the sites and less effectiveness in the metal ion uptake is reached at a point where the influent concentration equals effluent concentration, implying that the bed is saturated [31]. Figure 3 shows the breakthrough curves of adsorption of MB onto EMWHC at three flow rates.

3.2 BDST modeling

BDST model enables the researcher to measure the bed capacity physically at a wide range of breakthrough values. This simple design model generally does not consider both external film resistance and intraparticle mass transfer resistance due to which the adsorbate gets directly adsorbed only onto the adsorbent surface. According to the assumptions, the BDST model performance is found to be good and provides better equations to model any system parameter changes [29]. Since the BDST model is used to forecast the relationship between service time (t) and bed height (Z), it also serves as a well-accomplished model for dye sorption in systems involving fixed beds [32]. Column service time is taken when the concentration of the effluent dye reaches 1 mg/L.

BDST model’s validity on the basis of the current system was proved by a linear plot (R2 = 1.0) drawn between service time and bed height at 10 mL/min flow rate (Fig. 4). The sorption capacity of the bed per unit bed volume, N0, was determined from the slope of the BDST plot, with assuming initial concentration C0, and linear velocity υ, as constant at the time of operating the column. Ka, the rate constant, was determined from the intercept of the BDST plot and it corresponds to the solute transfer rate from the fluid phase to the solid phase. The constants computed N0 and Ka were found to be 81,592 mg/L and 0.0015 L/mg h respectively. BDST model parameters help increase the process and test it for other rates of flow and there is no need for more experimental runs.

3.3 Thomas modeling

The Thomas model is a popular model used in a packed bed column. In this model, an assumption is made, i.e., Langmuir adsorption-desorption kinetics and no axial dispersion whereas the rate driving force is found to be following the second-order reversible reaction kinetics. In the Thomas model, it is deemed that the separation factor remains to be constant and seems to remain valid for favorable and unfavorable isotherms [18]. This model determines the adsorption rate constant and the solid-phase dye concentration on the adsorbent. It is deemed that analyses using the Thomas model were conducted for a wide range of flow rates at 20-cm optimum bed height. In Table 2, there is a summary of the Thomas model parameters that were attained at a wide range of flow rates. In the results shown, the Thomas model constant kTh was incremented at 15 mL/min flow rate and reduced to 20 mL/min. When the flow rate was increased, the adsorption capacity was also incremented. One can observe that the regression coefficients were 0.98, 0.83, and 0.85 when the flow rates were maintained at 10, 15, and 20 mL/min respectively. Such an outcome reveals the existence of a good fit of the Thomas model. Figure 5 shows the predicted/forecasted breakthrough curves.

Based on the findings displayed in the figures, it is evident that both the Thomas model and the BDST model are found to be fit for column adsorption data. The EM-based water hyacinth plant compost is easily available, cheap, and eco-friendly which makes it the best suitable alternative for dye-bearing wastewater treatment.

3.4 Regeneration

The authors investigated the column regeneration for two sorption-desorption cycles. The authors packed the column with 27.2 g of EMWHC with initial bed height yield up to 20 cm and 62.8 mL bed volume with 432.8 g/L packing density. The flow rate was maintained at optimum 10 mL/min whereas the MB dye solution was taken with 100 mg/L at pH 8. Table 3 shows the dye uptake, exhaustion time, and the breakthrough time for two cycles. By the end of the second cycle, as per the results retrieved, both bed exhaustion time and breakthrough time decreased in an abrupt manner. However, the bed exhaustive limit was chosen to be > 99 mg/L for the dye molecules that generally happens when the full bed got saturated. Figure 6 shows the breakthrough curves for two sorption cycles. The breakthrough curves got flattened in the due course of the cycles. This was also represented through the breakthrough curve slope that decreased with the increase in the number of cycles. The biosorbent’s weight loss post-second cycle was found to be reduced as to 20.9%.

When compared to the second cycle, the dye uptake calculated during the first sorption cycle was found to be high. When the number of cycles was increased, there was a reduction in the uptake too which is associated with prolonged elution which devastated the binding sites. Otherwise, the insufficient elution might have let the molecules in the dye to be retained in the site itself.

In this research, 0.1 M HCl elutant was used by the researchers. The elution curve was acquired for MB desorption and is shown in Fig. 7. The researchers observed the elution curve MB dye molecules wherein it was revealed that there is a steep increase at the initial stages after which it got decreased. The desorption study flow rate was kept under constant at 20 mL/min so as to avoid overcontent of elutant with that of the sorbent. This is also to retrieve the maximum dye concentration in the shortest possible time [27].

4 Conclusion

Column packed with EMWHC is found to be an effective novel sorbent to remedy the MB in a continuous process. In this research, it was found that the maximum uptake of 301.79 mg/g was obtained. The removal efficiency of 85.44% was attained at 100 mg/L initial concentration with bed depth being 20 cm and flow rate being 10 mL/min. For these optimized conditions, the overall sorption time zone, exhaustion time, breakthrough time, and the volume of treated dye were found to be 105.6, 160, 54.4 h, and 96 L, respectively. The Thomas model predicted a maximum regression of 0.98 at optimized parameters. The desorption studies were carried out with 0.01 M HCL and continuous sorption elution is explored for two cycles.

References

Owa FW (2014) Water pollution: sources, effects, control and management. Int Lett Nat Sci. https://doi.org/10.18052/www.scipress.com/ilns.8.1

Bhagavathi Pushpa T, Vijayaraghavan J, Sardhar Basha SJ, Sekaran V, Vijayaraghavan K, Jegan J (2015) Investigation on removal of malachite green using EM based compost as adsorbent. Ecotoxicol Environ Saf 118:177–182. https://doi.org/10.1016/j.ecoenv.2015.04.033

Srivastava S, Sinha R, Roy D (2004) Toxicological effects of malachite green. Aquat Toxicol 66:319–329. https://doi.org/10.1016/j.aquatox.2003.09.008

Salleh MAM, Mahmoud DK, Karim WAWA, Idris A (2011) Cationic and anionic dye adsorption by agricultural solid wastes: a comprehensive review. Desalination. 280:1–13. https://doi.org/10.1016/j.desal.2011.07.019

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresour Technol 77:247–255. https://doi.org/10.1016/S0960-8524(00)00080-8

Aravindhan R, Rao JR, Nair BU (2007) Removal of basic yellow dye from aqueous solution by sorption on green alga Caulerpa scalpelliformis. J Hazard Mater 142:68–76. https://doi.org/10.1016/j.jhazmat.2006.07.058

Anjaneya O, Santoshkumar M, Anand SN, Karegoudar TB (2009) Biosorption of acid violet dye from aqueous solutions using native biomass of a new isolate of Penicillium sp. Int Biodeterior Biodegrad 63:782–787. https://doi.org/10.1016/j.ibiod.2009.06.005

Pushpa BT, Josephraj J, Saravanan P, Ravindran G (2019) Biodecolorization of Basic Blue 41 using EM based composts: isotherm and kinetics. ChemistrySelect. https://doi.org/10.1002/slct.201901774

Singh RP, Singh P, Araujo ASF, Hakimi Ibrahim M, Sulaiman O (2011) Management of urban solid waste: vermicomposting a sustainable option. Resour Conserv Recycl 55:719–729. https://doi.org/10.1016/j.resconrec.2011.02.005

Anastopoulos I, Massas I, Ehaliotis C (2013) Composting improves biosorption of Pb2+ and Ni2+ by renewable lignocellulosic materials. Characteristics and mechanisms involved. Chem Eng J. https://doi.org/10.1016/j.cej.2013.07.028

Sangakkara UR (2002) The technology of effective microorganisms: case studies of application. Cirencester. UK: Royal Agricultural College. http://www.royagcol.ac.uk/research/conferences/Sangkkara.htm

Higa T, Chinen N (1998) EM treatment of odor, wastewater, and environmental problems. Okinawa. University of Ryukyus. College of agriculture, Japan

Higa T (1995) What is EM Technology? Okinawa. University of Ryukyus. College of Agriculture, Japan

Diver S (2001) Nature farming and effective microorganisms, Retrieved from Rhizosphere II: Publications, Resource Lists and Web Links from Steve Diver http://ncatark.uark.edu/~steved/Nature-Farm-EM.html

Bhagavathi Pushpa T, Vijayaraghavan J, Vijayaraghavan K, Jegan J (2016) Utilization of effective microorganisms based water hyacinth compost as biosorbent for the removal of basic dyes. Desalin Water Treat 57:24368–24377. https://doi.org/10.1080/19443994.2016.1143405

Gokulan R, Ganesh Prabhu G, Jegan J (2019) A novel sorbent Ulva lactuca-derived biochar for remediation of Remazol Brilliant Orange 3R in packed column. Water Environ Res 91:642–649. https://doi.org/10.1002/wer.1092

Sekeran V, Balaji C, Pushpa TB (2005) Evaluation of effective microorganisms (EM) in solid waste management. Electron Green J 1. https://doi.org/10.5070/G312110589

Aksu Z, Gönen F (2004) Biosorption of phenol by immobilized activated sludge in a continuous packed bed: prediction of breakthrough curves. Process Biochem 39:599–613. https://doi.org/10.1016/S0032-9592(03)00132-8

Zulfadhly Z, Mashitah MD, Bhatia S (2001) Heavy metals removal in fixed-bed column by the macro fungus Pycnoporus sanguineus. Environ Pollut 112:463–470. https://doi.org/10.1016/S0269-7491(00)00136-6

Hutchins RA (1973) New method simplifies design of activated carbon systems. Chem Eng 80:133–138

Thomas HC (1944) Heterogeneous ion exchange in a flowing system. J Am Chem Soc 66:1664–1666. https://doi.org/10.1021/ja01238a017

Han R, Wang Y, Zhao X, Wang Y, Xie F, Cheng J, Tang M (2009) Adsorption of methylene blue by phoenix tree leaf powder in a fixed-bed column: experiments and prediction of breakthrough curves. Desalination. 245:284–297. https://doi.org/10.1016/j.desal.2008.07.013

Suksabye P, Thiravetyan P, Nakbanpote W (2008) Column study of chromium (VI) adsorption from electroplating industry by coconut coir pith. J Hazard Mater 160:56–62. https://doi.org/10.1016/j.jhazmat.2008.02.083

Yan G, Viraraghavan T et al (2001) Bioresour Technol 78:243–249. https://doi.org/10.1016/S0960-8524(01)00020-7

Da Silva EA, Cossich ES, Tavares CRG, Filho LC, Guirardello R (2002) Modeling of copper(II) biosorption by marine alga Sargassum sp. in fixed-bed column. Process Biochem. https://doi.org/10.1016/S0032-9592(02)00231-5

Alardhi MS, Albayati TM, Alrubaye JM (2020) Adsorption of the methyl green dye pollutant from aqueous solution using mesoporous materials MCM-41 in a fixed-bed column. Heliyon. https://doi.org/10.1016/j.heliyan.2020.e03253

Volesky B (2003) Sorption and Biosorption. BV-Sorbex, Inc. St. Lambert (Montreal), Quebec (ISBN 0-9732983-0-8)

Zhao M, Duncan JR, Van Hille RP (1999) Removal and recovery of zinc from solution and electroplating effluent using Azolla filiculoides. Water Res 33:1516–1522. https://doi.org/10.1016/S0043-1354(98)00338-8

Ko DCK, Porter JF, McKay G (2000) Optimized correlations for the fixed-bed adsorption of metal ions on bone char. Chem Eng Sci 55:5819–5829. https://doi.org/10.1016/S0009-2509(00)00416-4

Ko DCK, Porter JF, McKay G (2000) Optimised correlations for the fixed-bed adsorption of metal ions on bone char. Chem Eng Sci 55:5819–5829

Yahya MD, Aliyu AS, Obayomi KS, Olugbenga AG, Abdullahi UB (2020) Column adsorption study for the removal of chromium and manganese ions from electroplating wastewater using cashew nut shell adsorbent. Cogent Eng. https://doi.org/10.1080/23311916.2020.1748470

Walker GM, Weatherley LR (2000) Biodegradation and biosorption of acid anthraquinone dye. Environ Pollut 108:219–223. https://doi.org/10.1016/S0269-7491(99)00187-6

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thillainayagam, B.P., Saravanan, P., Ravindiran, G. et al. Continuous sorption of methylene blue dye from aqueous solution using effective microorganisms-based water hyacinth waste compost in a packed column. Biomass Conv. Bioref. 13, 1189–1198 (2023). https://doi.org/10.1007/s13399-020-01208-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01208-9