Abstract

Humins are undesired solids formed during the hydrothermal degradation of carbohydrates. In order to reveal the mechanism of formation of humins, we studied the degradation behavior of 11 model compounds including carbohydrates and furfural derivatives, within water and various pure organic solvents as reaction media. All the studied carbohydrates could generate solid humins in both water and studied organic solvents except ethanol, while the furfural derivatives could generate solid humins in only water. The results could be explained by regarding the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes as primary precursors for formation of humins. Furfural derivatives could generate chain α-carbonyl aldehydes (for example, 6-hydroxy-2,5-dioxohexanal from 5-hydroxymethylfurfural and 2-oxopentanedial from furfural) through hydrolytic ring opening reaction; thus, water is essential for these furfural derivatives to generate humins. As for carbohydrates, they could generate α-carbonyl aldehydes and α,β-unsaturated aldehydes through simple step of β-elimination in all solvents; thus, they could form humins in both water and studied organic solvents except ethanol. Ethanol could react with α-carbonyl aldehydes by acetalization; thus, the condensation between α-carbonyl aldehydes was suppressed in ethanol, leading to few humins formation from carbohydrates. Based on the above analysis, we proposed that the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes should be the primary precursor of humins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The depletion of fossil fuels and the increasing demand for fuel, energy, and chemicals have generated interest in alternative, sustainable resources. The abundant and renewable lignocellulosic biomass is one sustainable carbon resources; thus, increasing interest has been paid to transform the raw biomass into valuable chemicals and fuels. Carbohydrate polymers, such as cellulose and hemicellulose, account for about 70% of the lignocellulosic biomass, so conversion of these polysaccharides to bio-based platform chemicals play critical roles for the sustainable development of human society [1, 2]. Catalytic hydrothermal conversion is regarded as one effective method to convert the cellulose and hemicellulose into valuable platform chemicals such as 5-hydroxymethylfurfural (HMF), furfural, levulinic acid, and lactic acid [3,4,5,6]. Unfortunately, the formation of humins, one kind of low-value solid by-product, greatly diminishes the yield of valuable platform chemicals in the hydrothermal treatment of lignocellulosic biomass and reduces the economy of the hydrothermal conversion process [7,8,9,10,11]. Although great amount of work are reported to valorization the solid humins by regarding them as sustainable and harmless carbon resources [12] to produce hydrogen [13], synthesis gas [14], carbon materials [15,16,17,18], adhesive [19], and even thermoset-like resins [10, 20], it seems that suppressing formation of humins could be more favored to improve the economy of the biorefinery process.

Studying the formation of humins mechanism could be helpful to developing efficient method to suppress their formation; thus, great efforts have been devoted to reveal the formation of humins mechanism [21,22,23,24,25]. As has been shown in Fig. 1, different routes are proposed by the previously literatures for formation of humins from carbohydrates: (1) humins are formed by directly polycondensation between the furfural and related derivates through electrophilic substitution [23] (Route 1 in Fig. 1); (2) humins are formed by aldol addition/condensation between furfural derivates and chain aldehydes rich in carbonyl group (2,5-dioxo-6-hydroxyhexanal for example) formed by hydrolytic ring opening of these furfural derivates [24, 25] (Route 2 in Fig. 1); (3) humins are formed by condensation of carbohydrates with the furfural-related derivates through acetalization and etherification [21] (Route 3 in Fig. 1); (4) humins are formed by polymerization of carbohydrates with the furfural-related derivates through aldol condensation [22] (Route 4 in Fig. 1). Although great efforts on the formation of humins mechanism have been devoted, the formation of humins mechanism remains unclear and still needs to be studied in depth.

Identification of the key primary precursors would be very helpful to understand the formation of humins mechanism. Herein, we studied the formation of humins during the degradation of four species of model compounds (furfural derivatives, aldoses, ketoses, and 2-deoxyaldoses) in various solvents and found that the formation of humins from these model compounds could be satisfactorily explained by regarding the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes as the key primary precursor for formation of humins (Route 5 in Fig. 1); thus, we proposed that the humins are formed by aldol addition/condensation of the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes during hydrothermal degradation of carbohydrates.

2 Experimental sections

2.1 Experimental materials

Glucose (AR, 99%), fructose (AR, 99%), sorbose (AR, 99%), xylose (AR, 99%), ribose (AR, 99%), 2-deoxyglucose (98%), 2-desoxyribose (98%), 5-hydroxymethylfurfural (98%), 5-methylfurfural (98%), furfural (99%), furfuryl alcohol (97%), ethyl acetate (AR, 99%), tetrahydrofuran (AR, 99%), and ethanol(AR, 99%) were all purchased from Aladdin reagent company (Shanghai, China). All these chemicals were used without further treatment.

2.2 The hydrothermal decomposition of the model compounds

Thirty-milliliter deionized water and model compounds containing 0.12 mol carbon atoms were placed in a Teflon-lined autoclave and kept at 493 K for 5 h to carry out the hydrothermal degradation process. After the hydrothermal degradation process, the solid products were separated by filtering, washed with distilled water and ethanol, and finally dried at 373 K and weighed, while the filtrates were evaporated and dried at 373 K to obtain the involatile products (403 K for conditions with water as reaction media). The carbon yields of the humins were calculated by dividing the total mass of carbon in solid residues (assuming that the carbon content in the solid residues be 65%) by the carbon in the feedstock, while the carbon yields of the involatile products were calculated by dividing the total mass of carbon in the involatile products (assuming that the carbon content in the involatile products to be 60%) by the total mass of carbon in the feedstock. The carbon yield of volatiles was calculated by 100% minus the carbon yield of humins and the carbon yield of non-volatiles [4].

The concentrations of carbohydrates and furfural derivatives were analyzed on an Agilent 1200 series HPLC (Bio-Rad HPX-87H) with a RI and UV detector (210 nm), using a 5 mM aqueous sulfuric acid solution as the eluent at a flow rate of 0.5 mL/min. The column and RI detector temperature were set at 55 °C and 45 °C, respectively [5, 6]. The conversion of the carbohydrates and furfural derivatives is calculated by dividing the model compounds in the filtrate by the feed model compounds.

The volatile products in filtrate were analyzed by gas chromatography with mass spectroscopy detection (GC/MS), which was performed using a Agilent 7890B GC System equipped with Agilent 5977A MSD. The column used was a HP-5 ms Ultra Inert capillary column (30 m × 0.25 mm × 0.25 μm). The oven temperature was programmed to hold at 45 °C, ramp at 10 °C/min to 220 °C, and hold at 220 for 2 min. The flow rate of the He carrier gas was 1.2 mL/min. Experiments were performed in at least duplicate and the results presented an average of two or three measurements.

3 Results and discussion

3.1 Degradation behavior of furfural derivatives in water and ethyl acetate

In the beginning, we compared the degradation behavior of furfural derivatives in water and in pure ethyl acetate. As shown in Table 1, the conversions of all these furfural derivatives in ethyl acetate were always lower than those in water, suggesting that these furfural derivatives were more stable in ethyl acetate than in water. The yields of humins obtained from these furfural derivatives in water were also much different from those in ethyl acetate. The yields of humins from HMF, 5-methylfurfural, furfural, and furfural alcohol in water were 64.6%, 12.1%, 23.4%, and 29.2%, respectively (Table 1, entry 1–4), indicating that these furfural derivatives all could generate humins in water. However, no solid humins were formed when degradation of these furfural derivatives was carried out in ethyl acetate (Table 1, entry 5–8), suggestion that the formations of humins from these furfural derivatives were suppressed. The carbon yield of non-volatiles (1.3–10.5%) generated from these furfural derivatives in ethyl acetate was also much lower than those in water (12–30%), indicating that the condensation/polymerization of these furfural derivatives (or their degradation products) was suppressed. The results confirmed that water is essential for these furfural derivatives to form humins and non-volatiles. It should be note that the conversions of HMF and furfuryl alcohol (both of which contain CH2–OH group linked on the furan ring) in both solvents are higher than 5-methylfurfural and furfural, suggesting that the CH2–OH group is more active than HC=O group under the condition.

The volatiles generated from degradation of all these furfural derivatives in ethyl acetate were much higher than those in water. We employed GC-MS to identify the volatile compounds formed in ethyl acetate. As has been shown in Figs. 2, 5-formylfuran-2-yl)methyl acetate and 5,5′-(oxybis(methylene))bis(furan-2-carbaldehyde) were the main products from HMF, while furfuryl acetate and 2,2′-(oxybis(methylene))difuran were the main products from furfuryl alcohol in ethyl acetate (Fig. 2a and b), suggesting that etherification and transesterification (all of which involves the reaction of CH2–OH group) are the two main reactions for HMF and furfuryl alcohol when ethyl acetate was employed as reaction media [26,27,28]. On the contrary, 5-methylfurfural and furfural were quite stable, and only very little volatile degradation product was detected by GC-MS (Fig. 2c), indicating that the HC=O group is stable in ethyl acetate. Besides, negligible hydrolytic ring opening products (levulinic acid, ethyl levulinate, etc.) were detected by GC-MS analysis from all these furfural derivatives, confirming that ring opening of these furfural derivatives was also suppressed in ethyl acetate [29]. The MS profiles of HMF, 5-formylfuran-2-yl)methyl acetate, 5,5′-(oxybis(methylene))bis(furan-2-carbaldehyde), furfuryl alcohol, furfuryl acetate, 2,2′-(oxybis(methylene))difuran, and furfural are shown in Fig. S1-S7.

Because no humins and hydrolytic ring opening products were generated from furfural derivatives in ethyl acetate, we proposed that the intermediates formed by hydrolytic ring opening of these furfural derivatives, such as 2,5-dioxo-6-hydroxy-hexanal from 5-hydroxymethylfurfural and 2-oxopentanedial from furfural [29], are the key primary precursors for these furfural derivatives to generate the solid humins (Route 2 in Fig. 1), as has been proposed by Patil et al. [24, 25]

3.2 Degradation behavior of carbohydrates in water and ethyl acetate

Above results had confirmed that furfural derivatives could only generate humins in water instead of ethyl acetate. If the furfural derivatives are the only intermediate for these carbohydrates to generate humins, then the degradation behavior of carbohydrates should be consistent with these furfural derivatives. So we further studied the degradation behavior of carbohydrates in water and ethyl acetate.

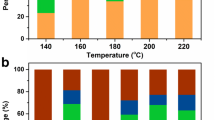

As shown in Table 2, the degradation behaviors of carbohydrates were quite different with these furfural derivatives. The conversion of the studied carbohydrates all reached 100% in both water and ethyl acetate, suggesting that carbohydrates are instable in both solvents. Besides, all these studied carbohydrates could generate solid humins in both water and ethyl acetate, indicating that the formation of humins from these carbohydrates could not be suppressed in ethyl acetate. Degradation of fructose, sorbose, glucose, xylose, and ribose in water could generate humins at yields of 54.1%, 52.8%, 60.7%, 42.5%, and 41.0%, respectively (Table 2, entry 1–5). However, when ethyl acetate was employed as the solvent, the yield of humins from fructose and sorbose (both of which are ketoses) decreased to 33.1% and 35.8%, respectively (Table 2, entry 6–7), while the yield of humins from glucose, xylose, and ribose (all of which are aldoses) increased to 73.1%, 56.6%, and 54.9%, respectively (Table 2, entry 8–10). Obviously, the ketoses yielded less humins in ethyl acetate than in water, while the aldoses are the opposite. The different behavior of ketoses and aldoses could be explained by the different propensity for formation of furfural derivatives. Generally, ketoses such as fructose are presented as furanose form structures in solvents; thus, they could selectively undergo dehydration to form furfural derivatives [30, 31], leading to lower humins and higher volatiles formation in ethyl acetate than in water. On the contrary, the aldoses are generally present as pyranose form structure, so they could not selectively undergo dehydration to generate furfural derivatives [5, 32]. Besides, around 10–20% of non-volatile products were generated from these carbohydrates in both water and ethyl acetate, indicating that the polymerization of the formed intermediates could not be efficiently suppressed in ethyl acetate.

GC-MS analysis also confirmed that fructose can be selectively transformed into furfural derivatives, such as furfural, HMF, (5-formylfuran-2-yl)methyl acetate, and 5,5′-(oxybis(methylene))bis(furan-2-carbaldehyde), while glucose could not be selectively transformed into furfural derivatives (Fig. 2d and e). Except for furfural derivatives, ethyl levulinate, ethyl glucoside, and multiple unidentified by-products were also detected in the degradation products of glucose. It should be noted that ethyl levulinate was not detected from fructose, but it was the main product during the degradation of glucose, suggesting that glucose may generate levulinic acid through a pathway without formation of HMF.

3.3 Discussion on the primary precursors and initial reactions for formation of humins

Generally, HMF and furfural are regarded as the primary precursors for formation of humins. Two routes for formation of humins from HMF/furfural are proposed, one route involves the electrophilic substitution of these compounds without ring opening reaction [23, 33] (Route 1 in Figure 1), and the other route involves the aldol condensation of the chain aldehydes rich in carbonyl group formed by hydrolytic ring opening of HMF/furfural [24, 25] (Route 2 in Figure 1). In this study, the formation of humins from these furfural derivates in water but the absence of humins in ethyl acetate indicate that water is essential for these furfural derivates to generate humins, suggesting that the route for formation of humins from furfural derivates via hydrolytic ring opening of the furfural derivates followed by aldol condensation of the formed chain aldehydes rich in carbonyl group seemed to be more feasible (Route 2 in Figure 1). On the other hand, the formation of humins from carbohydrates and the absence of humins from furfural derivates in ethyl acetate suggested that carbohydrates may generate humins with other intermediates in addition to furfural derivates. Some studies also proposed that reaction between carbohydrates and furfural derivates through aldol condensation [22] or acetalization [21] could lead to the formation of humins (Route 3 and 4 in Figure 1). However, the formation of large amounts of humins from solely furfural derivates indicates that those routes could not be main routes for formation of humins. Thus, the results in this study suggested that the proposed routes for formation of humins are incorrect or incomplete, and humins could be formed via other species of primary precursors during the hydrothermal conversion of carbohydrates and furfural derivates.

Identification of the primary precursor of formation of humins during the degradation of carbohydrate is important for revealing the mechanism of formation of humins. Previous reports have confirmed that hydrolytic ring opening of furfural derivatives could generate chain α-carbonyl aldehydes (Fig. 3) [24, 29]. For example, 2,5-dioxo-6-hydroxy-hexanal could be formed by hydrolytic ring opening of HMF, while 2-oxopentanedial could be formed by hydrolytic ring opening of furfural [29] (Table 3). On the other hand, recent research progresses confirmed that the degradation of aldoses (glucose, xylose, erythrose, and glyceraldehyde) could generate a series of C3–C6 α-carbonyl aldehydes, α-hydroxy acids, β,γ-unsaturated-α-carbonyl aldehydes, and β,γ-unsaturated-α-hydroxy acids (Table 3) [34,35,36,37,38,39,40,41,42]. In particular, Tolborg et al. identified the products of 3-deoxyglucosone, 3-deoxy-gluconic acid, trans-2,5,6-trihydroxy-3-hexenoic acid, and 3-deoxy-γ-gluconolactone during the hydrothermal degradation of glucose catalyzed by Sn-β [34]. Elliot et al. reported that catalytic degradation of xylose could generate 3-deoxyxylosone, cis-3,4-dideoxyxylos-3-enone, trans-3,4-dideoxyxylos-3-enone, 2,5-dihydroxy-4-methoxy-pentanoic acid, 3-deoxypentonolactone, and trans-2,5-dihydroxy-3-pentenoic acid [36]. Dusselier et al. reported that catalytic degradation of glucose and erythrose could produce 2-hydroxy butenoic acid, α-hydroxy-γ-butyrolactone, and 2, 4-dihydroxy butyric acid [40, 41]. Among all these identified chemicals, the chain α-carbonyl aldehydes with several adjacent carbonyl groups, such as 3-deoxyglucosone, 3-deoxyxylosone, 4-hydroxy-2-oxobutanal, and pyruvaldehyde, all could be generated from aldoses through β-elimination reaction followed by keto-enol tautomerism [34,35,36,37,38,39,40,41,42]. According to the above analysis, we found that the α-carbonyl aldehydes could be formed both from hydrolytic ring opening of furfural derivates and from β-elimination of carbohydrates. Thus, we suggest that these chain α-carbonyl aldehydes formed during the degradation of carbohydrates may be the primary precursors for formation of humins.

The formation of humins from furfural derivatives and carbohydrates in water and ethyl acetate can be satisfactorily explained by regarding α-carbonyl aldehydes as the primary precursors for formation of humins. As α-carbonyl aldehydes could be formed from dehydration of carbohydrates and hydrolytic ring opening of furfural derivates (Fig. 3), so humins could be formed from furfural derivates solely in hot compressed water, or from carbohydrates in both water and ethyl acetate. On the contrary, when decomposition of these furfural derivatives is carried out in organics such as pure ethyl acetate, the hydrolytic ring opening reaction of these furfural derivatives was suppressed [5, 43, 44], leading to only little α-carbonyl aldehydes and humins being generated. As for the carbohydrates, aldoses (glucose, xylose, and ribose) could easily generate α-carbonyl aldehydes through β-elimination reaction followed by keto-enol tautomerism in both water and ethyl acetate (Fig. 3) [34, 36]; thus, they could yield solid humins in both water and ethyl acetate. As for the ketoses, they could undergo dehydration to form furfural derivatives, thus leading to less formation of humins in ethyl acetate than in water. Because the formation of α-carbonyl aldehydes can explain the formation of humins from all these model compounds, we proposed that α-carbonyl aldehydes are the key primary precursors for formation of humins from furfural derivatives and carbohydrates.

To further confirming that α-carbonyl aldehydes are the key primary precursors for formation of humins, we studied the hydrothermal degradation behavior of glyoxal and pyruvaldehyde, both of which are α-carbonyl aldehydes. The results showed that 21.7% of humins could be formed during the hydrothermal degradation of glyoxal, while pyruvaldehyde could yield 44.2% of humins (Table 2, entry 11–12), further indicating that α-carbonyl aldehydes should be the key primary of formation of humins.

3.4 Degradation behavior of 2-deoxyaldoses in water and ethyl acetate

In the above study, we suggested the humins generated during the degradation of furfural derivatives, ketoses, and aldoses in various solvents with the α-carbonyl aldehydes as the key precursor of humins. Unlike aldoses, 2-deoxyaldoses could hardly generate α-carbonyl aldehydes through the two steps of β-elimination and keto-enol tautomerism during the degradation process (Fig. 4), so we further studied the degradation behavior of 2-deoxyaldoses. However, both of them could generate solid humins in both water and organic solvent, which could not be explained by regarding α-carbonyl aldehydes as the primary precursors of humins (Table 4). Especially, degradation of 2-deoxyglucose and 2-deoxyribose in water can generate as high as 41.2% and 40.6% of humins, respectively. Because these 2-deoxyaldoses all could generate α,β-unsaturated aldehydes with chain structure, we proposed that the α,β-unsaturated aldehydes are also the key precursors of humins production from these 2-deoxyaldoses.

GC-MS analysis confirmed that furfuryl alcohol and furfuryl acetate are the main products formed during 2-deoxyribose degradation in ethyl acetate, indicating that 2-deoxyribose can be easily converted into furfuryl alcohol [45]. Small amounts of 5-(ethoxymethyl)dihydrofuran-2(3H)-one was also detected, which was formed by transesterification of 5-(methyl)dihydrofuran-2(3H)-one with ethyl acetate (Fig. 2(f)). The MS profiles of ethyl levulinate and 5-(ethoxymethyl)dihydrofuran-2(3H)-one are shown in Fig. S8-S9.

The possible formation mechanism of furfuryl alcohol, levulinic acid, and 5-(hydroxymethyl)dihydrofuran-2(3H)-one are shown in Fig. 4. The 2-deoxyribose could undergo β-elimination to generate one α,β-unsaturated aldehyde named 4,5-dihydroxypent-2-enal, which could further undergo acetal cyclization and dehydration to form furfuryl alcohol [45], or undergo Cannizaro reaction to generate 4,5-dihydroxypentanoic acid. The formed 4,5-dihydroxypentanoic acid can further undergo dehydration and keto-enol tautomerism to form levulinic acid, or undergo self-esterification to generate 5-(hydroxymethyl)dihydrofuran-2(3H)-one [46].

3.5 Degradation behavior of carbohydrates in other organic solvents

In order to further verify the previous speculation, we further studied the degradation of these model compounds in two common organic solvent of tetrahydrofuran and ethanol (Table 5). Similar with the condition in ethyl acetate, these furfural derivatives still could not generate humins in tetrahydrofuran and ethanol (Table 5, entry 1–4), which further confirmed that water is essential for these furfural derivatives to generate humins.

The yields of humins formed from carbohydrates were all decreased within tetrahydrofuran as reaction media compared with ethyl acetate and water, but the yield of humins generated from aldoses is always higher than those from ketoses and 2-deoxyaldoses (Table 5, entry 5–11). We propose that the tetrahydrofuran played similar role with ethyl acetate, which could suppress the formation of humins from carbohydrates via suppressing the hydrolytic ring opening of the furfural derivatives, but could not suppress the formation of chain α-carbonyl aldehydes and α,β-unsaturated aldehydes from β-elimination of aldoses. Thus, the carbon yields of humins from carbohydrates were decreased compared with the condition with water as reaction media.

When ethanol was employed as reaction media, no humins were formed from aldoses, and only very little humins were formed from ketoses (2.1% from fructose and 1.5% from sorbose), which were consisted with the previous reports [47,48,49]. The reduced formation of humins could be due to that the ethanol could react with the formed chain α-carbonyl aldehydes through acetalization [48–50], thus suppressed the aldol addition/condensation of the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes.

4 Conclusion

In summary, we studied the degradation behavior of 11 model compounds including aldoses (glucose, xylose, ribose), ketoses (fructose, sorbose), furfural derivatives (furfural, 5-hydroxymethylfurfural, 5-methylfurfural and furfuryl alcohol), and 2-deoxyaldoses (2-deoxyglucose and 2-desoxyribose) in various solvents (water, ethyl acetate, tetrahydrofuran, and ethanol), and the results suggested that the chain α-carbonyl aldehydes and α,β-unsaturated aldehydes should be the key primary precursors for formation of humins. Carbohydrates could undergo β-elimination to form α,β-unsaturated aldehydes, which can undergo keto-enol tautomerism to generate α-carbonyl aldehydes; the carbohydrates could also undergo dehydration to form furfural and related derivatives, which could undergo hydrolytic ring opening to generate α-carbonyl aldehydes. These formed α,β-unsaturated aldehydes and α-carbonyl aldehydes could undergo aldol addition/condensation to generate solid humins. Thus, we propose that humins are formed by aldol condensation/addition of the formed α-carbonyl aldehydes and α,β-unsaturated aldehydes during the degradation of carbohydrates and furfural derivates.

References

Mika LT, Csefalvay E, Nemeth A (2018) Catalytic conversion of carbohydrates to initial platform chemicals: chemistry and sustainability. Chem Rev 118(2):505–613

Huang YB, Fu Y (2013) Hydrolysis of cellulose to glucose by solid acid catalysts. Green Chem 15(5):1095–1111

Verendel JJ, Church TL, Andersson PG (2011) Catalytic one-pot production of small organics from polysaccharides. Synthesis-Stuttgart 11:1649–1677

Shi N, Liu QY, He X, Cen H, Ju RM, Zhang YL, Ma LL (2019) Production of lactic acid from cellulose catalyzed by easily prepared solid Al2(WO4)3. Bioresource Technol Rep 5:66–73

Shi N, Liu QY, Zhang Q, Wang TJ, Ma LL (2013) High yield production of 5-hydroxymethylfurfural from cellulose by high concentration of sulfates in biphasic system. Green Chem 15(7):1967–1974

Shi N, Liu QY, Wang TJ, Ma LL, Zhang Q, Zhang Q (2014) One-pot degradation of cellulose into furfural compounds in hot compressed steam with dihydric phosphates. ACS Sustain Chem Eng 2(4):637–642

Kang SM, Fu JX, Zhang G (2018) From lignocellulosic biomass to levulinic acid: a review on acid-catalyzed hydrolysis. J Renew Sustain Energy Rev 94:340–362

Van Zandvoort I, Wang YH, Rasrendra CB, Van Eck ERH, Bruijnincx PCA, Heeres HJ, Weckhuysen BM (2013) Formation, molecular structure, and morphology of humins in biomass conversion: influence of feedstock and processing conditions. ChemSusChem 6(9):1745–1758

Van Zandvoort I, Koers EJ, Weingarth M, Bruijnincx PCA, Baldus M, Weckhuysen BM (2015) Structural characterization of 13C-enriched humins and alkali-treated 13C humins by 2D solid-state NMR. Green Chem 17(8):4383–4392

Sangregorio A, Guigo N, Van Der Waal JC, Sbirrazzuoli N (2018) Humins from biorefineries as thermoreactive macromolecular systems. ChemSusChem 11(24):4246–4255

Filiciotto L, Balu AM, Van Der Waal JC, Luque R (2018) Catalytic insights into the production of biomass-derived side products methyl levulinate, furfural and humins. Catal Today 302:2–15

Muralidhara A, Tosi P, Mija A, Sbirrazzuoli N, Len C, Engelen V, De Jong E, Marlair G (2018) Insights on thermal and fire hazards of humins in support of their sustainable use in advanced biorefineries. ACS Sustain Chem Eng 6(12):16692–16701

Hoang TM, Lefferts L, Seshan K (2013) Valorization of humin-based byproducts from biomass processing-a route to sustainable hydrogen. ChemSusChem 6(9):1651–1658

Hoang TMC, Van Eck ERH, Bula WP, Gardeniers JGE, Lefferts L, Seshan K (2015) Humin based by-products from biomass processing as a potential carbonaceous source for synthesis gas production. Green Chem 17(2):959–972

Wang K, Jiang J, Liang X, Wu H, Xu J (2018) Direct conversion of cellulose to levulinic acid over multifunctional sulfonated humins in sulfolane–water solution. ACS Sustain Chem Eng 6(11):15092–15099

Björnerbäck F, Hedin N (2018) Microporous humins prepared from sugars and bio-based polymers in concentrated sulfuric acid. ACS Sustain Chem Eng 7(1):1018–1027

Kang S, Fu J, Deng Z, Jiang S, Zhong G, Xu Y, Guo J, Zhou J (2018) Valorization of biomass hydrolysis waste: activated carbon from humins as exceptional sorbent for wastewater treatment. Sustainability 10(6):1795

Kang S, Jiang S, Peng Z, Lu Y, Guo J, Li J, Zeng W, Lin X (2018) Valorization of humins by phosphoric acid activation for activated carbon production. Biomass Convers Bior 8(4):889–897

Kang S, Fu J, Zhang G, Zhang W, Yin H, Xu Y (2017) Synthesis of humin-phenol-formaldehyde adhesive. Polymers 9(8):373–382

Sangregorio A, Guigo N, Van Der Waal JC, Sbirrazzuoli N (2019) All ‘green’ composites comprising flax fibres and humins’ resins. Compos Sci Technol 171:70–77

Dee SJ, Bell AT (2011) A study of the acid-catalyzed hydrolysis of cellulose dissolved in ionic liquids and the factors influencing the dehydration of glucose and the formation of humins. ChemSusChem 4(8):1166–1173

Cheng BG, Wang XH, Lin QX, Zhang X, Meng L, Sun RC, Xin FX, Ren JL (2018) New understandings of the relationship and initial formation mechanism for pseudo-lignin, humins, and acid-induced hydrothermal carbon. J Agric Food Chem 66(45):11981–11989

Sumerskii IV, Krutov SM, Zarubin MY (2010) Humin-like substances formed under the conditions of industrial hydrolysis of wood. Russ J Appl Chem 83(2):320–327

Patil SKR, Lund CRF (2011) Formation and growth of humins via aldol addition and condensation during acid-catalyzed conversion of 5-hydroxymethylfurfural. EnergyFuel 25(10):4745–4755

Patil SKR, Heltzel J, Lund CRF (2012) Comparison of structural features of humins formed catalytically from glucose, fructose, and 5-hydroxymethylfurfuraldehyde. Energy Fuel 26(8):5281–5293

Krystof M, Perez-Sanchez M, De Maria PD (2013) Lipase-catalyzed (trans)esterification of 5-hydroxymethylfurfural and separation from HMF esters using deep-eutectic solvents. ChemSusChem 6(4):630–634

Shi N, Liu QY, Wang TJ, Zhang Q, Tu JL, Ma LL (2014) Conversion of cellulose to 5-hydroxymethylfurfural in water-tetrahydrofuran and byproducts identification. Chin J Chem Phys 27(6):711–717

Wang H, Wang Y, Deng T, Chen C, Zhu Y, Hou X (2015) Carbocatalyst in biorefinery: selective etherification of 5-hydroxymethylfurfural to 5,5’(oxy-bis(methylene))bis-2-furfural over graphene oxide. Catal Commun 59:127–130

Horvat J, Klaic B, Metelko B, Sunjic V (1985) Mechanism of levulinic acid formation. Tetrahedron Lett 26(17):2111–2114

Akien GR, Qi L, Horvath IT (2012) Molecular mapping of the acid catalysed dehydration of fructose. Chem Commun 48(47):5850–5852

Yong G, Zhang YG, Ying JY (2008) Efficient catalytic system for the selective production of 5-hydroxymethylfurfural from glucose and fructose. Angew Chem Int Ed 47(48):9345–9348

Zhao HB, Holladay JE, Brown H, Zhang ZC (2007) Metal chlorides in ionic liquid solvents convert sugars to 5-hydroxymethylfurfural. Science 316(5831):1597–1600

Tsilomelekis G, Orella MJ, Lin Z, Cheng Z, Zheng W, Nikolakis V, Vlachos DG (2016) Molecular structure, morphology and growth mechanisms and rates of 5-hydroxymethyl furfural (HMF) derived humins. Green Chem 18(7):1983–1993

Tolborg S, Meier S, Sadaba I, Elliot SG, Kristensen SK, Saravanamurugan S, Riisager A, Fristrup P, Skrydstrup T, Taarning E (2016) Tin-containing silicates: identification of a glycolytic pathway via 3-deoxyglucosone. Green Chem 18(11):3360–3369

Chen HS, Wang A, Sorek H, Lewis JD, Roman-Leshkov Y, Bell AT (2016) Production of hydroxyl-rich acids from xylose and glucose using Sn-BEA zeolite. Chemistryselect 1(14):4167–4172

Elliot SG, Andersen C, Tolborg S, Meier S, Sádaba I, Daugaard AE, Taarning E (2017) Synthesis of a novel polyester building block from pentoses by tin-containing silicates. RSC Adv 7(2):985–996

Sølvhøj A, Taarning E, Madsen R (2016) Methyl vinyl glycolate as a diverse platform molecule. Green Chem 18(20):5448–5455

Holm MS, Saravanamurugan S, Taarning E (2010) Conversion of sugars to lactic acid derivatives using heterogeneous zeotype catalysts. Science 328(5978):602–605

Holm MS, Pagán-Torres YJ, Saravanamurugan S, Riisager A, Dumesic JA, Taarning E (2012) Sn-Beta catalysed conversion of hemicellulosic sugars. Green Chem 14:702

Dusselier M, Van Wouwe P, De Clippel F, Dijkmans J, Gammon DW, Sels BF (2013) Mechanistic insight into the conversion of tetrose sugars to novel α-hydroxy acid platform molecules. Chemcatchem 5(2):569–575

Dusselier M, De Clercq R, Cornelis R, Sels BF (2017) Tin triflate-catalyzed conversion of cellulose to valuable (alpha-hydroxy-)esters. Catal Today 279:339–344

Clercq RD, Dusselier M, Christiaens C, Dijkmans J, Iacobescu RI, Pontikes Y, Sels BF (2015) Confinement effects in Lewis acid-catalyzed sugar conversion: steering toward functional polyester building blocks. ACS Catal 5(10):5803–5811

Nikolla E, Roman-Leshkov Y, Moliner M, Davis ME (2011) “One-pot” synthesis of 5-(hydroxymethyl)furfural from carbohydrates using tin-Beta zeolite. ACS Catal 1(4):408–410

Roman-Leshkov Y, Chheda JN, Dumesic JA (2006) Phase modifiers promote efficient production of hydroxymethylfurfural from fructose. Science 312(5782):1933–1937

Herzfeld J, Rand D, Matsuki Y, Daviso E, Mak-Jurkauskas M, Mamajanov I (2011) Molecular structure of humin and melanoidin via solid state NMR. J Phys Chem B 115(19):5741–5745

Wondrak GT, Tressl R (1997) Maillard reaction of free and nucleic acid-bound 2-deoxy-D-ribose and D-ribose with ö-amino acids. J Agric Food Chem 45:321–327

Hu X, Li CZ (2011) Levulinic esters from the acid-catalysed reactions of sugars and alcohols as part of a bio-refinery. Green Chem 13(7):1676–1679

Hu X, Lievens C, Larcher A, Li CZ (2011) Reaction pathways of glucose during esterification: effects of reaction parameters on the formation of humin type polymers. Bioresour Technol 102(21):10104–10113

Huang YB, Yang T, Lin YT, Zhu YZ, Li LC, Pan H (2018) Facile and high-yield synthesis of methyl levulinate from cellulose. Green Chem 20:1323–1334

Funding

This research received support from the Guizhou province science and technology plan project ([2017]5789-08), the National Natural Science Foundation of China (51576199), and the Natural Science Foundation of Guangdong Province (2017A030308010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 8197 kb)

Rights and permissions

About this article

Cite this article

Shi, N., Liu, Q., Cen, H. et al. Formation of humins during degradation of carbohydrates and furfural derivatives in various solvents. Biomass Conv. Bioref. 10, 277–287 (2020). https://doi.org/10.1007/s13399-019-00414-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00414-4