Abstract

Anaerobic fermentation is an environmentally sustainable technology for converting a variety of feedstocks to biofuels and bioproducts. Considering the complex nature of lignocellulosic hydrolysates, we aimed to investigate product formation from corn stover hydrolysates by using microbial communities under anaerobic conditions. A community developed from lake sediment was able to produce lactic acid from only glucose in the raw or overlimed hydrolysates. Another community from an anaerobic digester, however, was capable of using all hexose and pentose sugars in the raw and undetoxified hydrolysates and released lactic acid at 26.76 g/L. A pure acetogen, Clostridium carboxidivorans P7, was able to grow on the raw and overlimed hydrolysates, too. But the consumption of sugars was minimal and the total released acid concentrations were less than 2 g/L. Next generation sequencing of the enriched community derived from the anaerobic digester revealed the presence of Lactobacillus strains. The predominant species were Lactobacillus parafarraginis (72.6%) and L. buchneri (13.4%). Product titer from using this enriched community can be further enhanced by cultivating at fed-batch or continuous fermentation modes. Results from this study widened the door for producing valuable products from lignocellulosic feedstocks through using mixed cultures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Lignocellulosic materials represent a renewable feedstock for the sustainable production of biofuels and bio-based products. This concept has received unprecedented attention during recent years as a viable alternative for producing fuels and chemicals replacing those from nonrenewable resources [1]. For this purpose, thermochemical conversion, such as gasification [2, 3], pyrolysis [4–6], and hydrothermal liquefaction [7–9], has been studied. To convert biomass feedstocks to the final products of fuels and chemicals biochemically, a three-step approach is commonly adopted [10, 11]. This three-step approach involves pretreatment, enzymatic hydrolysis, and fermentation. In order to release sugars out of cellulosic biomass, successful pretreatment generally requires high temperature, and/or pressure, and/or strong chemicals. These severe and harsh pretreatments result in the formation of a wide variety of compounds that have been proven to be toxic to fermenting microorganisms. To alleviate this issue, pretreatment techniques that are mild but effective have been explored extensively. However, even though some pretreatment methods are better than the others, the resulting hydrolysates still contain hundreds of compounds that are derived from degradation of sugars and lignin during the pretreatment step and are potentially inhibitory to downstream processes [11]. In addition, the toxic effect of individual inhibitors is exacerbated by synergistic effects with other toxic feedstock components as well as fermentation products [12–14]. Certainly, the hydrolysates can be detoxified through various approaches, but this one- or multiple-step detoxification adds cost to the final desired products and decreases the overall energy efficiency.

Besides the presence of inhibitors, such as weak acids (formic acid, acetic acid, levulinic acid), furan derivatives (furfural, 5-hydroxymethyfurfual), and numerous phenolic compounds [15], the hydrolysate is a mixture of hexoses and pentoses. Over the years, a significant effort has been dedicated to identifying microorganisms that can utilize all C5 and C6 sugars and engineering well-studied and well-established microbes to possess this function. Although huge progresses have been made in this field, direct fermentation of lignocellulosic hydrolysates still faces great challenges on achieving product titers that are economically viable.

To address this challenge and consider the complex composition of the biomass hydrolysates, different fermentation schemes, such as using co-cultures or microbial communities, have been on the rise [16]. On the one hand, diverse anaerobic microbiota has been demonstrated to be stable and resilient. The community structure dictates its performance, and the operating conditions affect structure [17]. On the other hand, using mixed microbial cultures may be more favorable than using pure cultures in both economic and environmental terms [18, 19]. In this case, different microorganisms can choose to utilize different compounds and the synergism among them can make the community robust and tolerate the presence of toxic compounds and/or system disruptions. Thus, in the study reported here, we investigated the feasibility of fermenting corn stover hydrolysates through use of two microbial communities. Performances of these two communities were compared to that of a pure acetogen, Clostridium carboxidivorans P7. The reason for studying this P7 strain lies in two facts. First, this acetogen can utilize both glucose and xylose in addition to other simple sugars [20]. Second, to the best of our knowledge, this P7 strain has not been tested on producing acids from lignocellulosic sugars. Among the two communities and the pure acetogen, the enriched community that gave the highest yield of products was sequenced to reveal its microbial structure. Dominant species that may be responsible for the products were identified.

2 Materials and methods

2.1 Microorganisms and inoculum preparation

Clostridium carboxidivorans

P7 was maintained in DSMZ medium 339a (Wilkins-Chalgren anaerobic broth, referred to as W-C broth in later sections) or ATCC Medium 2713 at 35 °C. The W-C broth contained the following (per liter): tryptone, 10.0 g; gelatin peptone, 10.0 g; yeast extract, 5.0 g; glucose, 1.0 g; sodium chloride, 5.0 g; l-arginine, 1.0 g; sodium pyruvate, 1.0 g; menadione, 0.0005 g; and hemin, 0.005 g. One microbial community was collected from an anaerobic digester at Northwest Wastewater Treatment Plant in Carbondale, IL, USA. The other one was sampled from the lake sediment in Campus Lake of Southern Illinois University, Carbondale, IL, USA. Once samples arrived in the lab anaerobically, an aliquot of 2 g of each was added separately to 50 mL of the W-C broth in a 120-mL sterile serum bottle. The bottles were then capped with butyl rubber stoppers, sealed with aluminum crimp, and left on a shaker at 100 rpm overnight at 25 °C. The resulting microbial communities were used in the studies described below.

2.2 Corn stover pretreatment and enzymatic hydrolysis

Corn stover harvested in Hurley County (South Dakota, USA) was processed for this study. The pretreatment was carried out at the National Renewable Energy Laboratory (NREL) and processed with the deacetylation and disk refining (DDR) process [21]. Initially, the corn stover was knife milled to pass through a 19-mm (0.75-in.) round screen. Deacetylation, for the purpose of removing acetic acid, was then performed in a 1900-L paddle mixer (American Process Systems, Gurnee, Illinois, USA), which contained dry corn stover (100 to 120 dry kg) in a dilute 0.1 M sodium hydroxide solution with a solid to liquid ratio of 1:12 at 80 °C for 2 h. Following deacetylation, washing, and dewatering, the deacetylated corn stover was shipped to the Andritz R&D facility in Springfield, Ohio, and mechanically refined there in a commercial-scale disk refiner (sprout model 401 36-in.). Corn stover particles after the DDR processes were hydrolyzed by commercial cellulase and hemicellulase products at 48 °C for 96 h in a 9-L roller bottle. The liquid supernatant after enzymatic hydrolysis was separated through centrifugation and used in this study as detailed below.

2.3 Corn stover hydrolysates overliming

Overliming the corn stover hydrolysates was conducted similarly to what was reported [22]. Briefly, solid Ca(OH)2 was added to the hydrolysates little by little until the pH reached 10. The whole content was then heated to 50 °C for 30 min followed by centrifugation to separate solids from liquid. The pH of the supernatant was lowered to pH 6.0 by adding concentrated HCl. Following pH adjustment, the liquor was passed through 0.2-μm sterile filters and stored at 4 °C for later use.

2.4 Anaerobic fermentation

Both C. carboxidivorans P7 and the two microbial communities were cultivated on either raw (untreated) or overlimed hydrolysates. Both hydrolysates were tested at either 50 or 25% of the final culture volumes. Each testing condition had three replicates. Thus, a total of 36 reactors were established. Each reactor (120-mL serum bottle) comprised inoculum at 10%, hydrolysates at either 50 or 25%, and 2-bromoethanesulfonate (BES) at 10 mM for inhibiting methanogenic activities. All of these percentages were based on the final total volume of 50 mL which was met by adding different volumes of the W-C broth. Reactors containing C. carboxidivorans were purged with N2 for around 20 min to drive out air. This purging step was not performed for the other reactors. For those that had C. carboxidivorans or the community from the anaerobic digester, a cultivation temperature of 35 °C was used. Regarding those with the community from the lake sediment, all reactors were maintained at 28 °C. All reactors were static without shaking. Once the reactors were set up, 1 mL sample withdrawn from each bottle was subjected to measurement of optical density (OD) at 660 nm. At other time points, the same OD measurement was conducted for each reactor together with measurement of gas produced.

For those reactors that had the highest cell growth based on the OD measurements, a portion of the cultures was further transferred to enrich microorganisms that could grow on raw corn stover hydrolysates without the supplementation of the W-C broth. The anaerobic digester community was transferred four times, but cell growth after the third transfer was not satisfactory. The lake sediment community was transferred three times, but the third time transfer did not lead to much cell growth. Therefore, cultures resulting from the second and first transfer were used to make glycerol stocks (20% glycerol) for long-term storage for the anaerobic digester and the lake sediment community, respectively. Cultures developed from these frozen stocks were used in later studies for identification of the fermentation products. The experimental setups were essentially the same as those for the original communities.

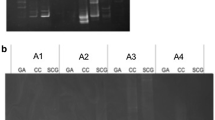

2.5 DNA extraction and sequencing

To understand the microbial composition of the enriched community derived from the anaerobic community, the whole contents in reactors containing this community were subjected to DNA extraction through use of a PowerWater DNA Extraction Kit (Mo Bio, Carlsbad, CA, USA). Following extraction, the DNA samples were quantified and evaluated through use of a NanoDrop spectrophotometer. Three DNA samples with excellent quality (A260/A280 1.8–2.0) and high concentrations (30–50 ng/μL) were sent for sequencing according to procedures reported [23]. In short, to understand the overall diversity of the microbial population, the 16S rRNA gene V4 variable region PCR primers 515/806 [24] were used. Single-step PCR using the HotStarTaq Plus Master Mix Kit (Qiagen, Valencia, CA, USA) was performed under these conditions: 94 °C for 3 min; 28 cycles of 94 °C for 30 s, 53 °C for 40 s, and 72 °C for 1 min; and a final elongation step at 72 °C for 5 min. Sequencing was conducted at Molecular Research (Shallowater, TX, USA) on an Ion Torrent PGM following the manufacturer’s guidelines. Sequence data (15–20,000 reads/assay) were processed using a proprietary analysis pipeline (Molecular Research, Shallowater, TX, USA). In summary, barcodes, primers, sequences <150 bp, and sequences with ambiguous base calls and with homopolymer runs exceeding 6 bp were removed. Following this removal, sequences were denoised, chimeras were removed, and operational taxonomic units (OTUs) were generated. OTUs were defined by clustering at 3% divergence (97% similarity) [25, 26]. Final OTUs were taxonomically classified using BLASTn against a curated Greengenes database [27] and compiled into each taxonomic level into both “counts” and “percentage” files. Counts files contain the actual number of sequences while the percent files contain the relative (proportion) percentage of sequences within each sample that map to the designated taxonomic classification.

2.6 Analytical methods

Concentrations of sugars (glucose, xylose, arabinose) and products (lactic acid, ethanol, formic acid, acetic acid, and butyric acid) in samples were determined by HPLC (Shimadzu Scientific Instrument, Inc. Columbia, MD, USA) through establishing an external calibration curve for each target compound. This HPLC had a refractive index detector and used an Aminex HPX-87 column (5 μm, 30 cm × 4.6 mm, Bio-Rad, CA, USA). This column was installed in an oven set at 35 °C. Sulfuric acid at 0.005 M was used as the mobile phase with a flow rate of 0.6 mL/min. The injection volume was 20 μL.

Newly generated gas volume was measured periodically by inserting a needle to the headspace in each reactor. The needle was connected to a syringe so that the exact volume can be read [28]. Headspace gas content in reactors was analyzed by a 4900 Micro GC (Agilent, Santa Clara, CA, USA), equipped with a M5A molecular sieve column (10 m) and a thermal conductivity detector. The carrier gas was helium. During sampling analysis, the column was maintained at 50 °C.

3 Results

3.1 Corn stover hydrolysates

After deacetylation, disk refining, and enzymatic hydrolysis, the corn stover hydrolysates consisted of glucose, 87.1 ± 4.5 g/L; xylose, 58.3 ± 4.2 g/L; arabinose, 1.8 ± 0.0 g/L; and lactic acid, 9.8 ± 2.5 g/L. Extensive analyses of the hydrolysates by HPLC did not reveal the presence of common fermentation inhibitors, such as furfural, 5-hydroxymethylfurfual, acetic acid, or formic acid. Thus, theoretically, this sugar syrup is readily fermentable. However, considering the possible presence of other compounds that were not detected by HPLC, we tried to use overliming to remove some unknown compounds that might be inhibitory to the tested microbes in this study. After overliming, the hydrolysates contained 81.1 ± 0.04 g/L of glucose, 53.9 ± 0.2 g/L of xylose, 1.8 ± 0.03 g/L of arabinose, and 7.8 ± 0.5 g/L of lactic acid. Thus, this simple treatment did not lead to much concentration decrease for major compounds in the original hydrolysates.

3.2 Anaerobic fermentation: C. carboxidivorans

Although C. carboxidivorans did not grow on the raw hydrolysates without the supplementation of the W-C broth, it did thrive on the untreated and treated hydrolysates when the W-C broth was provided at 50 or 25% (v/v) of the total. Without a lag phase, the cells under different conditions all entered a stationary phase after 2 days (Fig. 1a). This cell growth was supported by glucose and xylose consumption even though the sugar utilization was minimal (Fig. 1b). As a result of cell growth, three products, formic acid, acetic acid, and butyric acid, were observed. The total net acid concentrations on day 8 were 1.39, 1.71, 1.77, and 1.78 g/L for raw hydrolysate at 50%, raw hydrolysate at 25%, overlimed hydrolysate at 50%, and overlimed hydrolysate at 25%, respectively. Among the three acidic products, acetic acid was the dominant one under different cultivation conditions. As a consequence of acid production, the culture pH all decreased in the first 2 days. In light of the fact that there was no difference in product titers in terms of content of raw or treated hydrolysates in the reactors, the hydrolysate itself did not pose any toxic effect to C. carboxidivorans. The low yield of products could be very possibly due to product feedback inhibition or low pH.

3.3 Anaerobic fermentation: microbial community derived from the lake sediment

For the microbial community developed from the lake sediment, it did grow on both raw and overlimed hydrolysates at different contents (Fig. 2a). Within the 8-day experimental period, it was apparent that the community with raw hydrolysates at 50% had less cell growth compared with the others. Among the three sets with raw hydrolysates at 25%, with overlimed hydrolysates at either 50 or 25%, the difference on microbial growth was not significant. pH of all reactors decreased with time. For those with overlimed hydrolysates at 50%, their pH dropped from 5.67 to 4.04 (Fig. 2a).

As a result of cell growth, glucose concentration decreased to zero in 8 days for the three reactors with overlimed hydrolysates at 50% (Fig. 2b). This was not the case for xylose and arabinose. Concentrations of these five-carbon sugars remained the same during the experimental period. Two products were observed. Concentration of lactic acid which was initially in the hydrolysates increased from 3.13 to 12.09 g/L in 2 days but basically stayed the same after day 2. Ethanol was not detected until day 5 when its concentration was 7.13 g/L. Within 4 days, its concentration increased to 13.12 g/L. The total product yield was 0.77 g (lactic acid + ethanol) per gram of glucose.

3.4 Anaerobic fermentation: microbial community derived from the anaerobic digester

This microbial community derived from the anaerobic digester grew well on either raw or overlimed hydrolysates at different contents (data not shown). The mixed cells grown on raw hydrolysates at 25% were further transferred to enrich cells that could thrive on raw hydrolysates at 100%. As shown in Fig. 3a, the mixed community did grow on the untreated hydrolysates accompanied by a pH decrease with time. However, the growth was not as good as those when the raw hydrolysates were used at 50% with the W-C broth supplemented.

On raw hydrolysates at 100%, the mixed cells utilized all sugars (Fig. 3b). Glucose concentration decreased mainly during the first 2 days and remained the same in the days after. Arabinose at a day 0 concentration of 1.57 g/L was completely consumed in 2 days. Xylose, however, was utilized steadily. Its concentration decreased from 51.05 to 44.72 g/L in 7 days. Three products were detected. Lactic acid, acetic acid, and ethanol had a final concentration of 16.39, 3.79, and 0.76 g/L, respectively. Adding all products together, the product yield was 1.21 g/g sugars.

The same enriched community was also tested on raw hydrolysates at 50%. Similarly, all three sugars were used by the cells (Fig. 3c). Both glucose and xylose concentrations steadily decreased with time while arabinose was consumed in 2 days. In this experiment, ethanol was not detected. The two products, lactic acid and acetic acid, had a concentration of 26.76 and 1.59 g/L, respectively. Yield of products was calculated as 1.33 g/g sugars.

3.5 Microbial composition of the enriched community from the anaerobic digester

Based on results from the next generation DNA sequencing, the enrich community comprised only bacteria, but no archaeal species. Within the kingdom of bacteria, genera Lactobacillus and Lactococcus were 97.82 ± 2.71% and 1.74 ± 2.11%, respectively. The other genera were all less than 1%. The predominant species were Lactobacillus parafarraginis (72.64%), L. buchneri (13.45%), Lactobacillus spp. (5.83%), and L. lactis (1.74%) (Fig. 4).

4 Discussion

Clostridium carboxidivorans

P7 was initially isolated from an agricultural settling lagoon after enrichment with CO as the substrate [20]. It has been studied intensively regarding syngas fermentation for producing butanol, ethanol, acetate, and butyrate [29–34]. This strain was reported to grow on glucose, xylose, and other sugars, but its growth and performance on lignocellulosic hydrolysates have not been demonstrated to the best of our knowledge. In this study, this strain did grow on the raw hydrolysates and produced acids when the W-C nutrient broth was supplemented. Releasing formic acid by this acetogen has not been reported before. The fact that this strain can utilize both glucose and xylose simultaneously makes it an ideal acetogen for producing acids from sustainable lignocellulosic sugars. In order to improve the product yield, fed-batch or continuous cultivation mode needs to be explored to alleviate negative effects from the acidic products and the low pH.

Compared with the P7 strain, much higher product titers were observed from the two communities. The microbial community derived from the lake sediment did grow on the raw hydrolysate when it was used at 50%. But further enrichment to develop a consortium that can survive on the raw hydrolysate alone was not successful. Use of the overlimed hydrolysates at 50% led to the production of lactic acid followed by ethanol. All of this product release was based on glucose consumption. Since pentose sugars were not consumed, we did not profile the structure of this microbial community.

In contrast to the lake sediment community, the one developed from the anaerobic digester did show good growth on the raw hydrolysate alone at 100% after three transfers. All three sugars were utilized with the appearance of three products. Among the three, lactic acid, acetic acid, and ethanol was 78.25, 18.10, and 3.65%, respectively, of the total final titer of 20.95 g/L at day 7. When the same enriched community was cultivated on raw hydrolysates at 50%, only two products were observed. At day 8, lactic acid and acetic acid were 94.39 and 5.61%, respectively, of the final titer of 28.35 g/L. Thus, the presence of nutrients boosted the metabolic activities of the enriched community and resulted in a simpler product profile.

The enriched community from the anaerobic digester was primarily dominated by lactic acid bacteria (LAB). The top species, L. parafarraginis, is known to have the capability of consuming glucose and xylose and produce lactic acid, ethanol, and acetic acid [35]. But simultaneous utilization of these two sugars has not been demonstrated. The second species, L. buchneri, is reported to possess a relaxed carbon catabolite repression mechanism and has the potential to consume both C5 and C6 sugars simultaneously [36, 37]. Other top species, such as L. lactis and L. brevis, have been shown to be pentose sugar consumers [38–40]. Thus, the enriched community contained a rich group of LAB that can utilize all biomass-derived sugars simultaneously. In addition, the yield (g products/g sugars) of being larger than 1 indicated that this community may possibly be able to utilize other nonsugar compounds in the hydrolysates while tolerating toxicity from a host of unknown toxic chemicals.

The highest concentration of lactic acid detected in this study was 26.76 g/L from the enriched community derived from the anaerobic digester. This titer obtained when the community was cultivated on the raw hydrolysates (50%) with W-C broth (50%) provided was certainly not high when compared with more than 100 g/L obtained from pure glucose and/or xylose mixtures [41]. But considering that (1) the cultural pH was not controlled during batch fermentation and the low pH of around 4.0 certainly affects cellular activities negatively and (2) the presence of unknown fermentation inhibitors from corn stover pretreatment is highly likely, the lactic acid yield we observed from this study is reasonable. This product titer compares well with the most recent reported data obtained from Bacillus coagulans GKN316 on biomass sugars. This mutant was developed through atmospheric and room temperature plasma (ARTP) mutation and evolution [42]. When this engineered strain was cultivated on corn stover prehydrolysates, lactic acid at 23.49 g/L was obtained [43]. When it was grown on condensed corn stover hydrolysates, such as condensed acid-catalyzed steam-exploded hydrolysate (CASEH), condensed acid-catalyzed liquid hot water hydrolysate (CALH), and condensed acid-catalyzed sulfite hydrolysate (CASH), the lactic acid concentration was 45.39, 16.83, and 18.71 g/L respectively. All of these hydroysates were concentrated in a rotary evaporator at 60 °C and 160 mbar. This condensation step might have evaporated some volatile compounds that may be inhibitory to the target strain. However, even without considering this possible detoxification step, the naturally enriched community reported in this study is competitive in converting sugars in untreated hydrolysates directly to commercially valuable compounds. The product yield can be further enhanced by controlling pH at an optimal range and cultivate the community at fed-batch or continuous modes.

Lactic acid is widely used in food, pharmaceutical, cosmetic, and chemical industries [44]. Recently, considering the fact that lactic acid can serve as a precursor for poly-lactic acid which is biodegradable and biocompatible and can replace nondegradable plastics derived from crude oil [45, 46], this compound has attracted renewed interest. Production of lactic acid has generally been achieved by fermentation of starch-based materials and sugars through use of LAB. LAB can release lactic acid from glucose at 100% of theoretical yield through the pentose phosphate pathway. However, most LAB are short of the capability to utilize xylose [41, 47]. The only exceptions are Lactobacillus pentosus [48–50], L. bifermentans DSM 20003 [51], L. brevis [38], L. plantarum [52], Leuconostoc lactis [53], Leuconostoc lactis [54], and Enterococcus mundtii QU 25 [55]. These strains are known to metabolize pentose sugars via the phosphoketolase pathway [50, 53]. Among these known pentose-utilizing strains, only L. brevis was identified in the enriched community. Thus, this community may comprise novel LABs that can grow on xylose. Whether this is true or not, results from this study widened the door for producing lactic acid from renewable lignocellulosic materials through using mixed cultures.

In summary, this is the first study to demonstrate that C. carboxidivorans P7 can utilize biomass sugars and release acids. It is also the first study of its kind to use microbial communities for converting biomass hydrolysates to products to the best of our knowledge. In particular, the combination of the pretreatment scheme described here and the microbial community developed from the anaerobic digester addressed two bottlenecks that persist in converting lignocellulose to commodities. These two challenges are how to efficiently release fermentable sugars and how to utilize pentose sugars effectively. As discussed above, product titers from either the pure acetogen or the microbial community can be further improved by adopting fed-batch or continuous cultivation modes.

5 Conclusion

Clostridium carboxidivorans

P7 was able to grow on corn stover hydrolysates when the W-C broth was supplemented. Limited growth on glucose and xylose led to release of formic acid, acetic acid, and butyric acid. The microbial community derived from the lake sediment was able to grow on only glucose in the raw or overlimed hydrolysates and resulted in the formation of lactic acid and ethanol. The enriched community from an anaerobic digester utilized glucose, xylose, and arabinose in the raw hydrolysates and gave mainly lactic acid as the final product. This enriched community is primarily dominated by Lactobacillus parafarraginis.

References

Wierckx N, Koopman F, Bandounas L, De Winde JH, Ruijssenaars HJ (2010) Isolation and characterization of Cupriavidus basilensis HMF14 for biological removal of inhibitors from lignocellulosic hydrolysate. Microb Biotechnol 3:336–343

Iribarren D, Susmozas A, Petrakopoulou F, Dufour J (2014) Environmental and exergetic evaluation of hydrogen production via lignocellulosic biomass gasification. J Clean Prod 69:165–175

Zhang K, Chang J, Guan Y, Chen H, Yang Y, Jiang J (2013) Lignocellulosic biomass gasification technology in China. Renew Energy 49:175–184

Xiong Q, Aramideh S, Kong SC (2014) Assessment of devolatilization schemes in predicting product yields of biomass fast pyrolysis. Environmental Progress & Sustainable Energy 33:756–761

Xiong Q, Kong S-C (2014) Modeling effects of interphase transport coefficients on biomass pyrolysis in fluidized beds. Powder Technol 262:96–105

Xiong Q, Zhang J, Xu F, Wiggins G, Daw CS (2016) Coupling DAEM and CFD for simulating biomass fast pyrolysis in fluidized beds. J Anal Appl Pyrolysis 117:176–181

Bi Z, Zhang J, Peterson E, Zhu Z, Xia C, Liang Y et al (2017) Biocrude from pretreated sorghum bagasse through catalytic hydrothermal liquefaction. Fuel 188:112–120

Zhang B, von Keitz M, Valentas K (2009) Thermochemical liquefaction of high-diversity grassland perennials. J Anal Appl Pyrolysis 84:18–24

Budhavaram NK, Fan Z (2009) Production of lactic acid from paper sludge using acid-tolerant, thermophilic Bacillus coagulan strains. Bioresour Technol 100:5966–5972

Liang Y, Jarosz K, Wardlow AT, Zhang J, Cui Y (2014) Lipid production by Cryptococcus curvatus on hydrolysates derived from corn fiber and sweet sorghum bagasse following dilute acid pretreatment. Appl Biochem Biotechnol 173:2086–2098

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Palmqvist E (2000) Hahn-Hägerdal Br. Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24

Nigam J (2001) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27

Chandel AK, Da Silva SS, Singh OV (2013) Detoxification of lignocellulose hydrolysates: biochemical and metabolic engineering toward white biotechnology. BioEnergy Research 6:388–401

Taniguchi M, Tokunaga T, Horiuchi K, Hoshino K, Sakai K, Tanaka T (2004) Production of L-lactic acid from a mixture of xylose and glucose by co-cultivation of lactic acid bacteria. Appl Microbiol Biotechnol 66:160–165

Werner JJ, Knights D, Garcia ML, Scalfone NB, Smith S, Yarasheski K et al (2011) Bacterial community structures are unique and resilient in full-scale bioenergy systems. Proc Natl Acad Sci 108:4158–4163

Gurieff N, Lant P (2007) Comparative life cycle assessment and financial analysis of mixed culture polyhydroxyalkanoate production. Bioresour Technol 98:3393–3403

Nikodinovic-Runic J, Guzik M, Kenny ST, Babu R, Werker A, O'Connor KE (2013) Carbon-rich wastes as feedstocks for biodegradable polymer (polyhydroxyalkanoate) production using bacteria. Adv Appl Microbiol:139–200

Liou JS-C, Balkwill DL, Drake GR, Tanner RS (2005) Clostridium carboxidivorans sp. nov., a solvent-producing clostridium isolated from an agricultural settling lagoon, and reclassification of the acetogen Clostridium scatologenes strain SL1 as Clostridium drakei sp. nov. Int J Syst Evol Microbiol 55:2085–2091

Chen X, Shekiro J, Pschorn T, Sabourin M, Tao L, Elander R et al (2014) A highly efficient dilute alkali deacetylation and mechanical (disc) refining process for the conversion of renewable biomass to lower cost sugars. Biotechnology for Biofuels 7:98

Pan W, Perrotta JA, Stipanovic AJ, Nomura CT, Nakas JP (2012) Production of polyhydroxyalkanoates by Burkholderia cepacia ATCC 17759 using a detoxified sugar maple hemicellulosic hydrolysate. J Ind Microbiol Biotechnol 39:459–469

Zhang J, Liang Y, Pandey R, Harpalani S (2015) Characterizing microbial communities dedicated for conversion of coal to methane in situ and ex situ. Int J Coal Geol 146:145–154

Caporaso JG, Lauber CL, Walters WA, Berg-Lyons D, Lozupone CA, Turnbaugh PJ et al (2011) Global patterns of 16S rRNA diversity at a depth of millions of sequences per sample. Proc Natl Acad Sci 108:4516–4522

Edgar RC (2010) Search and clustering orders of magnitude faster than BLAST. Bioinformatics 26:2460–2461

Dowd SE, Callaway TR, Wolcott RD, Sun Y, McKeehan T, Hagevoort RG et al (2008) Evaluation of the bacterial diversity in the feces of cattle using 16S rDNA bacterial tag-encoded FLX amplicon pyrosequencing (bTEFAP). BMC Microbiol 8:125

DeSantis TZ, Hugenholtz P, Larsen N, Rojas M, Brodie EL, Keller K et al (2006) Greengenes, a chimera-checked 16S rRNA gene database and workbench compatible with ARB. Appl Environ Microbiol 72:5069–5072

Zhang J, Park SY, Liang Y, Harpalani S (2016) Finding cost-effective nutrient solutions and evaluating environmental conditions for biogasifying bituminous coal to methane ex situ. Appl Energy 165:559–568

Fernández-Naveira Á, Abubackar HN, Veiga MC, Kennes C (2016) Efficient butanol-ethanol (B-E) production from carbon monoxide fermentation by Clostridium carboxidivorans. Appl Microbiol Biotechnol 1-10

Li N, Yang J, Chai C, Yang S, Jiang W, Gu Y (2015) Complete genome sequence of Clostridium carboxidivorans P7T, a syngas-fermenting bacterium capable of producing long-chain alcohols. J Biotechnol 211:44–45

Phillips JR, Atiyeh HK, Tanner RS, Torres JR, Saxena J, Wilkins MR et al (2015) Butanol and hexanol production in Clostridium carboxidivorans syngas fermentation: medium development and culture techniques. Bioresour Technol 190:114–121

Shen Y, Brown R, Wen Z (2014) Syngas fermentation of Clostridium carboxidivoran P7 in a hollow fiber membrane biofilm reactor: evaluating the mass transfer coefficient and ethanol production performance. Biochem Eng J 85:21–29

Ahmed A, Cateni BG, Huhnke RL, Lewis RS (2006) Effects of biomass-generated producer gas constituents on cell growth, product distribution and hydrogenase activity of Clostridium carboxidivorans P7T. Biomass Bioenergy 30:665–672

Bruant G, Lévesque M-J, Peter C, Guiot SR, Masson L (2010) Genomic analysis of carbon monoxide utilization and butanol production by Clostridium carboxidivorans strain P7 T. PLoS One 5:e13033

Endo A, Okada S (2007) Lactobacillus farraginis sp. nov. and Lactobacillus parafarraginis sp. nov., heterofermentative lactobacilli isolated from a compost of distilled shochu residue. Int J Syst Evol Microbiol 57:708–712

Kim J-H, Block DE, Mills DA (2010) Simultaneous consumption of pentose and hexose sugars: an optimal microbial phenotype for efficient fermentation of lignocellulosic biomass. Appl Microbiol Biotechnol 88:1077–1085

Liu S, Skinner-Nemec KA, Leathers TD (2008) Lactobacillus buchneri strain NRRL B-30929 converts a concentrated mixture of xylose and glucose into ethanol and other products. J Ind Microbiol Biotechnol 35:75–81

Chaillou S, Bor Y-C, Batt CA, Postma PW, Pouwels PH (1998) Molecular cloning and functional expression in Lactobacillus plantarum 80 of xylT, encoding thed-xylose–H+ symporter of Lactobacillus brevis. Appl Environ Microbiol 64:4720–4728

Kato H, Shiwa Y, Oshima K, Machii M, Araya-Kojima T, Zendo T et al (2012) Complete genome sequence of Lactococcus lactis IO-1, a lactic acid bacterium that utilizes xylose and produces high levels of L-lactic acid. J Bacteriol 194:2102–2103

Ishizaki A, Ueda T, Tanaka K, Stanbury PF (1993) The kinetics of end-product inhibition of l-lactate production from xylose and glucose by Lactococcus lactis IO-1. Biotechnol Lett 15:489–494

Abdel-Rahman MA, Tashiro Y, Sonomoto K (2011) Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: overview and limits. J Biotechnol 156:286–301

Jiang T, Qiao H, Zheng Z, Chu Q, Li X, Yong Q et al (2016) Lactic acid production from pretreated hydrolysates of corn stover by a newly developed Bacillus coagulans strain. PLoS One 11:e0149101

Zheng Z, Cai C, Jiang T, Zhao M, Ouyang J (2014) Enhanced l-lactic acid production from biomass-derived xylose by a mutant Bacillus coagulans. Appl Biochem Biotechnol 173:1896–1906

Ouyang J, Cai C, Chen H, Jiang T, Zheng Z (2012) Efficient non-sterilized fermentation of biomass-derived xylose to lactic acid by a thermotolerant Bacillus coagulans NL01. Appl Biochem Biotechnol 168:2387–2397

Lasprilla AJ, Martinez GA, Lunelli BH, Jardini AL, Maciel FR (2012) Poly-lactic acid synthesis for application in biomedical devices—a review. Biotechnol Adv 30:321–328

Jem KJ, van der Pol JF, de Vos S (2010) Microbial lactic acid, its polymer poly (lactic acid), and their industrial applications. Plastics from bacteria: Springer:323–346

Abdel-Rahman MA, Xiao Y, Tashiro Y, Wang Y, Zendo T, Sakai K et al (2015) Fed-batch fermentation for enhanced lactic acid production from glucose/xylose mixture without carbon catabolite repression. J Biosci Bioeng 119:153–158

Bustos G, De la Torre N, Moldes A, Cruz J, Domínguez J (2007) Revalorization of hemicellulosic trimming vine shoots hydrolyzates trough continuous production of lactic acid and biosurfactants by L. pentosus. J Food Eng 78:405–412

Zhu Y, Lee Y, Elander RT (2007) Conversion of aqueous ammonia-treated corn stover to lactic acid by simultaneous saccharification and cofermentation. Appl Biochem Biotechnol 137:721–738

Moldes A, Torrado A, Converti A, Dominguez J (2006) Complete bioconversion of hemicellulosic sugars from agricultural residues into lactic acid by Lactobacillus pentosus. Appl Biochem Biotechnol 135:219–227

Givry S, Prevot V, Duchiron F (2008) Lactic acid production from hemicellulosic hydrolyzate by cells of Lactobacillus bifermentans immobilized in Ca-alginate using response surface methodology. World J Microbiol Biotechnol 24:745–752

Helanto M, Kiviharju K, Leisola M, Nyyssölä A (2007) Metabolic engineering of Lactobacillus plantarum for production of L-ribulose. Appl Environ Microbiol 73:7083–7091

Ohara H, Owaki M, Sonomoto K (2006) Xylooligosaccharide fermentation with Leuconostoc lactis. J Biosci Bioeng 101:415–420

Tanaka K, Komiyama A, Sonomoto K, Ishizaki A, Hall S, Stanbury P (2002) Two different pathways for D-xylose metabolism and the effect of xylose concentration on the yield coefficient of L-lactate in mixed-acid fermentation by the lactic acid bacterium Lactococcus lactis IO-1. Appl Microbiol Biotechnol 60:160–167

Abdel-Rahman MA, Tashiro Y, Zendo T, Hanada K, Shibata K, Sonomoto K (2011) Efficient homofermentative L-(+)-lactic acid production from xylose by a novel lactic acid bacterium, Enterococcus mundtii QU 25. Appl Environ Microbiol 77:1892–1895

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, C., Kumar, A., Chen, X. et al. Conversion of corn stover hydrolysates to acids: comparison between Clostridium carboxidivorans P7 and microbial communities developed from lake sediment and an anaerobic digester. Biomass Conv. Bioref. 8, 169–178 (2018). https://doi.org/10.1007/s13399-017-0239-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0239-9