Abstract

In the present work, detoxification treatments based on advanced oxidative processes (AOPs) aiming to improve the ethanol production by Pichia stipitis were evaluated. The experimental design was carried out according to a Taguchi L8 orthogonal array in order to evaluate the influences of pH, catalyst type (ZnO or TiO2), UV radiation (UVA or UVC), and oxidant agent (O2 or O3) on aromatic compounds concentration and fermentation performed. The results showed that treatment conditions which most contribute to reducing the toxicity of the hydrolysate in relation to ethanol production were pH 8.0 and the use of O3 as an oxidizing agent. Within the region evaluated, there was no difference between the use of TiO2 or ZnO and or UVA or UVC radiation. The heterogeneous AOPs were able to remove above 49 % of the furan, above 39 % of the total phenolic compounds, and 100 % of the low molecular weight phenolic compounds, without affecting the sugar concentrations in the hydrolysate. Furthermore, heterogeneous processes have provided relevant increases on sugars consumption (148 %) and maximum ethanol concentration (154 %) as compared with untreated hydrolysate. In addition, the AOPs treatment showed advantages such as it does not generate waste, does not degrade hydrolysate sugars, and does not lead to loss of hydrolysate volume due to the treatment. Based on the results, it can be concluded that AOPs are promising processes for application in hydrolysate treatment to reduce toxicity and consequently improve the fermentability of lignocellulosic hydrolysates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hemicellulose is the second major constituent of the lignocellulosic biomass, and its efficient utilization is of fundamental importance for obtaining an economically viable ethanol production from these materials [1]. During the acid hydrolysis process, several toxic compounds including furans (products of sugar degradation) and aromatics compounds (products of lignin degradation) are formed. These compounds can strongly inhibit the microbial metabolism and consequently negatively affect the fermentability of hemicellulosic hydrolysates. Thus, the detoxification step represents an important strategy to improve the fermentation processes from hydrolysates [2].

Many methods of hydrolysate detoxification have been studied with the aim of reducing the concentration of toxic compounds and thus improve the fermentation process in the last decades [3–5]. These methods can be separated into biological, physical, and chemical. The main difference between these methods is the mechanism of action. For example, the biological treatments involve the use of enzymes or microorganisms which act on the hydrolysate toxic compounds, altering their chemical structures [4, 6], whereas the physical methods use adsorbent materials, such as activated charcoal [7], or organic solvents [8], which promote the removal of toxic compounds from the medium, without changing their chemical structures. Regarding the chemical methods, strong alkalis and acids are generally used aiming to modify pH of the medium. These procedures lead to a reduction in hydrolysate toxicity by precipitation and/or decomposition of the toxic compounds due to chemical instability of these inhibitors [9, 10]. Many of the detoxification methods based on physical, chemical, and biological processes may lead to a considerable reduction in sugar concentration; however, these sugar losses are undesirable for fermentation purposes [11–14].

A new alternative for the detoxification of lignocellulosic hydrolysates is the use of advanced oxidative processes (AOPs) [15]. AOPs include a wide range of different processes which in recent decades have been widely studied in the treatment of effluents from various industries. Advanced oxidative processes can be defined as those methods in which hydroxyl radicals (HO•) are produced in sufficient quantities to act as the main oxidizing agent [16]. The hydroxyl radical is a powerful oxidizing agent that is able to mineralize biorecalcitrant organic compounds or convert them into biodegradable compounds [17]. AOPs have been studied for the remediation of wastewater rich in lignin derivatives from pulp and paper industry [18–21]. The hydroxyl radicals have the ability to degrade toxic and recalcitrant compounds, thereby reducing their toxicity and enhancing their susceptibility to biological agents, what increases interest about the possibility of applying AOPs as a method for reducing the toxicity of lignocellulosic hydrolysates.

Due to its high reactivity, the hydroxyl radical must be generated in situ, which may be accomplished with a number of different processes [22]. Hydroxyl radicals can be generated as a result of the combination of strong oxidizing agents, such as hydrogen peroxide and ozone. Ultraviolet (UV) or visible radiation and catalysts such as metal ions and semiconductors can also be used to create hydroxyl radicals [23, 24]. The advanced oxidative processes that use solid catalysts (such as TiO2 and ZnO) are denominated heterogeneous processes, and other processes are known as homogeneous processes [25].

The reaction between the hydroxyl radical and organic molecules present in the environment can be divided into three different classes according to their reaction mechanisms, such as the abstraction of hydrogen atoms, electrophilic addition, and electron transfer (Fig. 1).

Three different kinds of reaction mechanisms between the hydroxyl radical and organic molecules: a the abstraction of hydrogen atoms, b electrophilic addition, and c electron transfer. Figure adapted from Legrini et al. [26]

The abstraction of hydrogen atoms is a reaction that usually occurs with aliphatic hydrocarbons. In this reaction, the hydroxyl radical oxidizes the organic compound by removing a hydrogen atom, resulting in an organic radical which reacts quickly with the oxygen present in the medium, giving rise to organic peroxide radicals, unstable intermediates which initiate subsequent oxidation reactions (Fig. 1, a).

Electrophilic addition reactions usually occur with unsaturated or aromatic hydrocarbons. The hydroxyl radicals attack the organic compounds π bonds resulting in the formation of organic radicals (Fig. 1, b) which reacts quickly with the oxygen present in the medium, originating organic peroxide radicals and initiating the subsequent oxidation reactions.

The reactions of electron transfer occur when the hydrogen abstraction and radical addition reactions are disadvantaged, which may be caused by the presence of the halogen in the molecules or by steric hindrance. In this reaction, the hydroxyl radical is reduced to hydroxyl anion removing electrons from the organic compound oxidized and originating an organic radical (Fig. 1, c).

The chemical structure and reactant concentration are determining factors in the predominance of a particular kind of reaction in the oxidation process of organic compounds [23]. Generally, electrophilic addition reactions tend to occur with higher reaction rate than abstraction of hydrogen or electron transfer reactions, mainly in aromatic and unsaturated compounds. Electrophilic nature of the hydroxyl radical can lead to preferential attack of compounds with aromatic rings and high electron density [27, 28].

The heterogeneous process of generating hydroxyl radicals differ from homogeneous process due to the employment of solid-phase catalysts as used in the heterogeneous photocatalysis processes. The photocatalysts used in these processes are usually metal oxides semiconductors with photosensitive properties [29]. These photocatalysts are usually employed in the form of a fine suspension or immobilized on surfaces, and its photoactivation occurs by light irradiation at wavelengths near UV (300 to 450 nm) [30–33]. The most widely used photocatalysts in advanced oxidative processes are TiO2 (in crystalline form anatase) and ZnO, which present strong photocatalytic activity [34–36].

Semiconductors such as TiO2 and ZnO acting as photocatalysts have two energy regions: a region of higher energy called conduction band (CB) and a region of lower energy called the valence band (VB). The interval between these two regions is called the “band gap,” which represents the minimum energy required to excite the electron, leading to his shift from the valence band to the conduction band. Figure 2 shows a schematic representation of the photoactivation of a semiconductor particle surface on a photocatalytic process with the generation of oxidizing and reducer sites [29, 37].

The generation of the hydroxyl radical in heterogeneous photocatalysis process is described in the literature by various authors such as Hoffmann et al. [29], Spacek et al. [33], Suri et al. [37], Ziolli and Garden [38], and Andreozzi et al. [39], among others. The first step of the hydroxyl radical generation consists in the photons absorption (hν) with same or greater energy of the band gap, which leads to electronic excitation, promoting an electron from the valence band to the conduction band, resulting in the formation of an electron/hole pair (e−/h+), generating oxidants (hole), and reducing sites (electron) on the catalyst surface.

According to Giri et al. [40], the employment of heterogeneous AOPs using semiconductors such as TiO2 combined with ozone, also called catalytic ozonation, may be more efficient than the conventional processes of heterogeneous photocatalysis and ozonation.

For the use of AOPs as a hydrolysate detoxification method, such process should be able to reduce the concentration of inhibitor compounds while providing little or no change in the concentration of sugars present.

Within this perspective, it is important to accentuate that some chemical species present in the lignocellulosic hydrolysate such as phenolic compounds and furans from lignin and carbohydrates degradation, respectively, have aromatic structures as a common characteristic of their molecules, which differs from carbohydrates.

Although most studies on AOPs emphasize the nonselectivity of the hydroxyl radical with organic compounds, currently some authors suggest that molecular structures with high electronic density, as double bonds and aromatic rings, can be oxidized preferentially by such processes [27, 41].

Promising results with the application of homogeneous AOPs on rice straw hemicellulosic hydrolysate detoxification for ethanol production by Pichia stipitis were achieved in an earlier study developed by this research group [15]. The use of homogeneous AOPs for the hydrolysate detoxification resulted in double the increase of the ethanol volumetric productivity in the fermentation step. Because of the promising results achieved with the homogeneous AOPs in previous work, the present study aimed to evaluate the use of heterogeneous AOPs for hydrolysate detoxification aiming at improvements in bioconversion processes using such hydrolysates.

Even under unoptimized treatment conditions, the hydrolysate treatments by AOPs showed results comparable to those obtained by detoxification processes commonly described in the literature about fermentation processes improvement. In addition, the AOPs treatment has other advantage as it does not produce residues, it does not cause degradation of sugars, and there is no loss of hydrolysate volume due to the treatment. These results demonstrate that AOPs are a promising technique for the application on toxicity reduction and consequent improvement in fermentability of lignocellulosic hydrolysates. Within this perspective, in the present study the potential application of the heterogeneous group of advanced oxidative processes as a detoxification method of rice straw hemicellulosic hydrolysate was evaluated. Furthermore, fermentative assays in bench bioreactor were carried out to compare the ethanol production by P. stipitis in fermentations of the treated hydrolysates.

2 Materials and methods

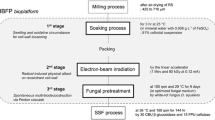

2.1 Preparation of rice straw hemicellulosic hydrolysate

Rice straw was collected from fields near Lorena City, São Paulo State, Brazil. The material was naturally dried by the sun until approximately 10 % moisture content, milled to attain particles of about 1 cm in length and 1 mm in thickness, and stored. Hydrolysate was prepared by dilute acid hydrolysis as described by Mussatto and Roberto [42]. Rice straw hydrolysis was performed in a 50-L reactor, heated by electric resistance and agitated by rotation of the reactor on the own axis. The reaction was performed at 120 °C for 30 min, 3 rpm, and the rice straw was submerged with sulfuric acid solution (100 mg H2SO4/g dry matter) in a 1:10 (grams per milliliter) dry matter–acid solution ratio inside the reactor. After hydrolysis, the residual solid material was separated by centrifugation and the liquid phase (hemicellulosic hydrolysate) was submitted to a vacuum concentration process at 65 °C, in a 30-L stainless steel evaporator, aiming to increase the xylose concentration about 120 g/L. The concentrated hydrolysate was stored at 4 °C for later use.

2.2 Hydrolysate treatment

The rice straw hemicellulosic hydrolysate was submitted to different treatment conditions by heterogeneous AOPs (resulting from combinations among: TiO2 or ZnO/UVA or UVC/O2 or O3). The main characteristic of this group of AOPs is the presence of solid catalysts (like TiO2 and ZnO). Experiments were carried out using a Taguchi L8 array (Table 1), which consisted of eight assays in which the studied variables were type of catalyst (100 mg/L of TiO2 or ZnO), radiation (UVA or UVC), oxidant agent (O2 or O3), and pH (3.0 or 8.0). The levels used at factorial planning were based in previous studies performed by this research group and also in literature. The observed responses were the change in sugar concentration, the decrease in toxic compounds concentration, and the fermentability of the treated hydrolysate.

The treatments were conducted in a glass reactor with a capacity of 150 mL, equipped with water refrigeration and magnetic stirrer. Irradiation was performed using an ultraviolet lamp (UVA or UVC) of 4 W of power, which was submerged in the reaction medium through a quartz bulb (Fig. 3).

Ozone (500 mg/L) was produced by conversion of O2 to O3 by corona effect, by the use of the device Ozone Generator Ozonebras, Z30 model with an output of 60 W, at a flow rate of 1 L/min of oxygen. All treatments were carried out for 30 min at a controlled temperature of 30 °C, under conditions which varied according to experimental design described hereafter. Before conducting the experimental design, the concentrated rice straw hemicellulosic hydrolysate had its pH adjusted to values corresponding to the levels of the experimental design (pH 8 and 3) with NaOH 10 mol/L. The precipitate formed after each pH change was removed by centrifugation (1,000×g for 15 min), and then xylose concentration in the hydrolysate was adjusted to approximately 90 g/L.

Aiming a comparison with heterogeneous processes, the detoxification treatment by homogeneous AOPs was performed as described by Silva et al. [15].

2.3 Fermentative process

Fermentations were carried out in semi-synthetic or hydrolysate medium. Before the use of the rice straw hemicellulosic hydrolysate as a fermentation medium, its pH was changed to pH 5.5 with NaOH 10 mol/L or H2SO4 10 mol/L as required. After each change of pH, the hydrolysate was centrifuged at 1,000×g for 15 min to remove solid residue.

2.3.1 Microorganism and inoculum preparation

P. stipitis NRRL Y-7124 was the microorganism used in the experiments. Cultures of this yeast were maintained on malt extract agar slants at 4 °C. For fermentations in semi-synthetic medium, inoculum was prepared by transfer of cells of the yeast from the maintenance medium to 125-mL Erlenmeyer flasks containing 25 mL of the medium composed by (in grams per liter): xylose (20.0), glucose (3.3), arabinose (3.3), urea (2.3), MgSO4·7H2O (1.0), and yeast extract (3.0). For hydrolysate fermentations, the inoculum was also prepared in the hydrolysate, whose sugars concentrations were adjusted by dilution to (in grams per liter): xylose (20.0), glucose (3.3), and arabinose (3.3). The inoculated flasks were incubated in a rotary shaker at 30 °C under stirring at 200 rpm for 24 h. After this time, the cells were recovered by centrifugation (1,100×g for 20 min) and resuspended in sterile distilled water in order to obtain a concentrated suspension of cell which was used as inoculum.

2.3.2 Fermentation medium and conditions

To evaluate the influence of AOPs detoxification treatment on ethanol production, assays were performed in 125-mL Erlenmeyer flasks containing 50 mL of the hydrolysate based medium composed by (in grams per liter): xylose (70.0), glucose (12.0), and arabinose (12.0) with addition of yeast extract (3.0 g/L). The flasks were inoculated with an initial cell concentration of 1 g/L and maintained in a rotary shaker at 30 °C, 200 rpm, during 120 h. Fermentation runs were monitored through periodic sampling to determine the cell growth, xylose consumption, and ethanol production.

Assays were performed in a 2.0-L stirred tank bioreactor (BIOSTAT B, B. Braun), containing 1.2 L of the following fermentation media. Hydrolysates treated by AOPs, untreated hydrolysate, and semi-synthetic media were used as culture medium. The hydrolysate based medium was composed by (in grams per liter): xylose (90.0), glucose (15.0), and arabinose (15.0) with addition of yeast extract (3.0). The semi-synthetic medium was composed by (in grams per liter): xylose (90.0), glucose (15.0), arabinose (15.0), urea (2.3), MgSO4·7H2O (1.0), and yeast extract (3.0). After inoculated with 1 g/L of cells, the fermentation runs were maintained at 30 °C during 96 h. The oxygen transfer condition, kLa close to 5 h−1, was defined in previous work [43]. During the experiments, samples were taken each 12 h for sugars, ethanol, and cell growth determinations.

2.4 Analytical methods

Glucose, xylose, arabinose, acetic acid, and ethanol concentrations were determined by high-performance liquid chromatography (HPLC) in Waters chromatograph equipped with a refractive index detector and a Bio-Rad Aminex HPX-87H column (300 × 7.8 mm). Operation conditions included temperature of 45 °C, 0.005 mol/L sulfuric acid as eluent in a flow of 0.6 mL/min, and sample volume of 20 μL. The cellular growth was determined by measuring the fermentation broth at UV-spectrophotometric absorbance at 600 nm, which was correlated to a calibration curve (dry weight × optical density).

Furfural, hydroxymethylfurfural, vanillic acid, vanillin, p-coumaric acid, and ferulic acid were also determined by HPLC, using an UV detector (at 276 nm) and a ZORBAX Eclipse Plus C18 column (4.6 × 100 mm and 3.5 μm in particle size) at room temperature, acetonitrile/water/acetic acid at a ratio of 88:11:1 as the eluent, a flow rate of 0.8 mL/min, and sample volume of 20 μL. The concentration of total phenolic compounds was estimated by Folin–Ciocalteau method [44] using ferulic acid as standard. Ultraviolet spectrum of the hydrolysate was determined in Hitachi U-2000 spectrophotometer, in the range of 500–200 nm, with a pitch of 5 nm using quartz cuvettes. The determination of the spectrum was made with hydrolysate diluted with alkaline water (pH around 12), and distilled water used as a blank. The differential scanning spectra were obtained by determining the profile scan of the hydrolysate in alkaline media (pH 12), using as zero the same sample, but in acidic media (pH 2). Ethanol yield factor (Y P/S, grams per gram) was defined as the ratio between ethanol concentration (grams per liter) and glucose/xylose consumed (grams per liter). Ethanol volumetric productivity (Q P, grams per liter-hour) was calculated as the ratio between the ethanol concentration (grams per liter) and the fermentation time (hours). Cell yield factor (Y X/S, grams per gram) was defined as the ratio between cell concentration and total substrate consumed (grams per liter).

3 Results and discussion

3.1 Hemicellulosic hydrolysate

The rice straw hemicellulosic hydrolysate was obtained by dilute acid hydrolysis and concentrated by vacuum evaporation. The hydrolysate used in this studied was characterized by Silva et al. [15]. The total sugar concentration was approximately 160 g/L, with a ratio of 6:1:1 of xylose, glucose, and arabinose. In addition to the sugars, potentially harmful compounds to the fermentation process, such as carboxylic acids, furans, and phenolic compounds, were also identified. The hydrolysate contained in (grams per liter): acetic acid 1.96 ± 0.01, total furans (TF) 0.33 ± 0.01, low molecular weight phenolic compounds (LMWPC) 0.50 ± 0.03, and total phenolic compounds (TPC) 12.9 ± 0.8.

The hemicellulosic hydrolysate had a high concentration of phenolic compounds (approximately 12.9 g/L) compared to acetic acid (approximately 2 g/L) and furan (327 mg/L). Among the acid-soluble lignin derivatives compounds, the hydrolysate contained vanillin (28 mg/L), p-coumaric acid (106 mg/L), vanillic acid (32 mg/L), syringic acid (53 mg/L), ferulic acid (270 mg/L), and p-hydroxybenzoic acid (14 mg/L). These compounds have been suggested to be potential inhibitors to microbial metabolism [45].

3.2 Detoxification treatment

The detoxification process was evaluated in terms of its ability to reduce the concentration of phenolic compounds (total and low molecular weight) and furans and to improve the P. stipitis fermentability of the treated hydrolysates for each condition assessed.

3.2.1 The effect of treatment on sugar concentration

Aiming to reduce the toxicity of this hydrolysate, different conditions of heterogeneous AOPs were evaluated (Table 1). There was no important change in sugars concentration of after the all treatments (less than 1.5 %). This is a positive result as compared to the detoxification methods based on physical, chemical, and biological treatment, which often result in a considerable reduction in sugars concentration [11, 12, 14].

Telli-Okur and Eken-Saraçoglu [11] evaluated the use of different detoxification methods for the treatment of a sunflower seed husk hemicellulose hydrolysate, and they observed significant reductions in sugars concentrations of due to the employed treatments. Reductions up to 12 % in the total sugars were seen after overliming treatment, and reductions up to 20 % when overliming and activated carbon adsorption were combined. Eken-Saraçoglu and Arslan [12] also reported significant decreases in the hydrolysate sugars concentration as result of the overliming treatment and the combination of overliming and zeolite adsorption, 20 and 50 %, respectively. These authors attributed the sugar loss to the decomposition at high pH and the zeolites adsorption. Larsson et al. [14] evaluated various methods of lignocellulosic hydrolysate detoxification, including adsorption, and biological methods such as using fungi. These authors reported reductions of about 26 % adsorption techniques when used in ion exchange resin. However, the biggest loss of sugars, about 35 %, occurred after treating the hydrolysate with the fungus Trichoderma reesei. These studies demonstrate that, unlike AOP, many of the procedures used for the detoxification of lignocellulosic materials hydrolysate may result in the loss of sugar, which to some extent may result in losses to the bioconversion process. Besides not causing degradation of sugars, the AOPs treatment has other advantages such as no waste production and no loss of hydrolysate volume due to the treatment as it occurs with adsorption, overliming, and biological treatments processes.

In the present study, the low influence of the treatments by AOPs on the carbohydrates concentration may be related to the molecular structure of the sugars. The hydroxyl radical, the main oxidizing agent of AOPs, has a higher affinity for compounds with high electron density regions, such as aromatic rings [27, 28], which do not exist in sugar molecules. This behavior was also observed in previous studies that evaluated the hydrolysate detoxification by homogeneous AOPs [15].

3.2.2 The effect of treatment on the concentration of phenolic and furan compounds

In general, the hydrolysate treatments by heterogeneous AOPs were able to reduce or completely eliminate many of furans and LMWPC, and the reduction degree was dependent on the treatment conditions employed (Table 1). For example, the greatest reductions at furans concentrations occurred in trials where ozone was used in the treatment of the hydrolysate (E1, E4, E6, and E7). In these conditions, reductions between 31 and 49 % on furans concentration were observed. Already in assays whose treatments were performed in the absence of ozone (E2, E3, E5, and E8) reductions at furans concentration has achieved 28 %. It was also found that the furans level was not only influenced by the ozone presence but also by the pH value employed during the treatment. Among the treatments performed in the ozone presence, greater reductions in the furans concentration occurred in treatments conducted at pH 3 (E6 and E7), 43 % on average, which corresponds to 7 % more than observed in treatments employing ozone in pH 8 (E1 and E4), 36 % on average.

Similarly to what was observed for furans, ozone was an important factor in reducing the LMWPC concentration. Reductions between 54 and 100 % in LMWPC concentration were achieved in the assays in which ozone was present. Moreover, the removal degree of LMWPC was also influenced by pH value. For example, at pH 3.0 a reduction of 55 % was achieved (assays E6 and E7), whereas at pH 8 the LMWPC were completely degraded (assays E1 and E4), suggesting a possible interaction between ozone and alkaline pH conditions. Such reduction in the LMWPC levels can be attributed to their partial degradation, caused by the action of hydroxyl radicals. Phenolic compounds can be degraded by the action of these radicals. In the first stage, the cleavage of the aromatic ring can generate intermediate oxidation products, such as aliphatic acids, and in some cases reach the complete degradation to form CO2 and H2O [46, 47].

In general, the decreases in LMWPC concentrations observed in the treatments performed in the absence of ozone (assays E2, E3, E5, and E8) were lower than those observed for the treatments in which O3 was used (assays E1, E4, E6, and E7). This behavior is probably due to the nature of the hydroxyl radical generation processes. In the absence of ozone, its generation process occurs exclusively by the interaction of UV radiation on the particles of the catalysts (TiO2 or ZnO) and therefore is strongly linked to the penetration of light in the middle [39], which may have been hampered by high coloring hydrolysate.

The heterogeneous photocatalysis processes carried out in the absence of O3 (tests E2, E3, E5, and E8), even disadvantaged by the high color of the hydrolysate, were able to provide reductions of up to 28 and 43 % in furans and LMWPC, respectively, although these decreases were relatively smaller than those observed in the other treatment conditions evaluated in planning.

Regarding the total phenolic compounds, a similar behavior was observed to those verified with furans and LMWPC. In fact the highest reductions in total phenolic compounds concentration (31 to 39 %) occurred in treatments where ozone was used (E1, E4, E6, and E7). These results confirm the important influence of the ozone on the degradation of such compounds. The decrease of the phenolics by heterogeneous AOPs can be attributed to partial degradation of these compounds, resulting from changes in their chemical structures occasioned by the action of hydroxyl radicals. Phenolic compounds can be degraded by the action of these radicals, resulting in the cleavage of the aromatic ring, what leads in a first stage to the formation of oxidation intermediates, like aliphatic acids and may in some cases come to complete degradation to form CO2 and H2O [46–48].

3.2.3 Differential scanning spectrum analysis

In Fig. 4, the analysis of differential scanning spectrum are shown, as well as the profiles of sugars consumption and ethanol production by P. stipitis for the hydrolysate untreated and treated by AOPs.

The differential scanning spectrum technique allows to evaluate the presence of phenolic hydroxyl groups. As can be seen, the major changes occurred in the spectrum of the hydrolysates treated in the ozone presence (E1, E4, E6, and E7) in which reductions were observed at 245, 295, and 350–400 nm. In addition, the conditions in which the use of ozone was associated with an alkaline pH, highest decreases in the differential scanning spectrum were attained (E1 and E4), especially in the region of 350–400 nm, which relates to the presence of hydroxyl group conjugated to the carbonyl through the aromatic ring. In general, the observed changes indicate a reduction in the number of phenolic hydroxyl groups present in the hydrolysate as a result of the employed treatments, demonstrating that depending on the treatment conditions AOPs are able to provide changes in phenolic structures, such as the removal of phenolic hydroxyl or aromatic ring cleavage. Such changes were observed only in some treatment conditions evaluated which demonstrates that such conditions have a strong impact on decreasing the concentration of these compounds.

The greatest reductions in the absorbance at the wavelength of 245, 295, and 350–400 nm (E1, E4, E6, and E7) were found in the same assays where the greatest reductions in the concentration of total phenolics occurred (Fig. 4). These results show that the oxidative treatments used have led to changes in chemical structures, such as aromatic ring cleavage. In fact, the cleavage of aromatic structures through the use of advanced oxidative processes are reported in the literature such as the works of Liu et al. [46] and Zhang et al. [49].

3.2.4 Fermentability of treated hydrolysate

The profiles of sugar consumption and ethanol production by P. stipitis in untreated rice straw hemicellulosic hydrolysate and treated by heterogeneous AOPs are shown in Fig. 4. Note that the yeast was unable to consume sugars and produce ethanol in the cultivation carried out in hydrolysate treated under acidic conditions (E5, E6, E7, and E8). These results showed that treatments involving heterogeneous AOPs in acidic conditions were unable to improve the hydrolysate fermentability. Moreover, when the hydrolysate was treated under alkaline conditions in the presence of ozone (test E1 and E4), the substrate consumption and ethanol production by yeast were favored. The maximum ethanol concentration obtained from fermentation of treated hydrolysate in the assays E1 and E4 were about 15 g/L after 72 h of fermentation. This result shows that under these conditions, the hydrolysate detoxification treatment resulted in increase of about 50 % in ethanol production compared to that obtained with untreated hydrolysate, about 10 g/L.

In general, the sugar consumption and ethanol production observed during the fermentations were favored by heterogeneous AOPs when used under alkaline conditions. A similar behavior was also observed in earlier studies for the detoxification treatment of rice straw hemicellulose hydrolysate by homogeneous AOPs [15]. The influence of the treatment pH value on the hydrolysate fermentability is probably related to the different mechanisms of hydroxyl radical attack on inhibitor compounds at different pH values. Phenolic compounds, which can act as inhibitors of microbial metabolism, in alkaline medium form phenolate ions by the dissociation of the hydroxyl proton from the benzene ring, thereby increasing the electron density of the aromatic ring, thus favoring its to oxidation by hydroxyl radical attack, which has electrophilic nature [27, 50].

Regarding ethanol volumetric productivity, higher values, between 0.12 and 0.21 g/L·h, were observed in fermentations of hydrolysates treated under alkaline conditions (E1, E2, E3, E4). In the hydrolysate treated fermentations employing acidic pH (E5, E6, E7, E8), the values achieved were lower than 0.02 g/L·h.

The treatment E4 (pH 8/ZnO/UVA/O3) provided the highest volumetric productivity of ethanol, 0.21 g/L·h. These productivity represents only 60 % of the value achieved in the semi-synthetic medium fermentation (0.36 g/L·h). However, when compared to the Q P value obtained for the untreated hydrolysate, 0.12 g/L·h, this result shows that the treatment was able to provide a 75 % increase in the ethanol volumetric productivity. These results demonstrate that hydrolysate detoxification by heterogeneous photocatalysis improved the hydrolysate fermentability and hence the yield of the bioconversion process under conditions of the assay E4.

3.3 Statistical analysis

We used a statistical analysis to identify the most important factors to influence the detoxification of rice straw hemicellulosic hydrolysates by AOPs. In this analysis, we evaluated the effects of pH (A—pH 3 or 8) and the types of catalyst (B—TiO2 or ZnO), UV radiation (C—UVA and UVC), and the oxidizing agent (D—O2 or O3) (Table 1). The columns AB and AC were used to estimate experimental error. The observed responses were the percent reduction in the furans (furfural and HMF), LMWPC, and total phenolics concentrations, and the changes in the ethanol volumetric productivity were measured for the fermentation of P. stipitis in hydrolysates from each treatment.

The statistical significance of the main effects and their interactions on the different responses were verified using an analysis of variance (ANOVA) test, presented in Table 2. According to the ANOVA, the percentages of variation in the concentrations of furans, total phenolics, LMWPC, and percent of Q P (relative to Q P obtained in the semi-synthetic medium fermentation) showed high correlation coefficients, above 94 %. Thus, the observed variation can be explained by the factors that were evaluated.

For statistical analysis, all terms above 90 % of confidence level were considered significant. Statistical analysis showed that for furan decrease, the type of oxidizing agent (D) and the type of catalysts (B) were significant with confidence level of 95 %, and pH (A) was significant with confidence level of 90 %. For LMWPC reduction, the type of oxidizing agent (D) and pH (A) were considered significant with a confidence level of 99 %, and the combination of oxidizing agent and pH (AD) were significant with a confidence level of 99 %. Regarding the total phenolics, only types of oxidizing agent were significant with a confidence level of 99 %. For ethanol volumetric productivity, type of oxidizing agent (D) and the combination of oxidizing agent and pH (AD) was significant with a confidence level of 90 %. In addition, the pH value (A) was considered significant with a confidence level of 99 %, and this is the very significant variable that can explain about 92 % of all the variation for this response. Except for pH response reduction furans, all these significant variables showed positive effects on observed responses.

The statistical analysis showed that the reduction of the inhibitory compounds concentration and ethanol production increased were favored by use of pH 8 and O3 as an oxidizing agent. In the evaluated range, there was no important difference between the use of TiO2 or ZnO and UVA or UVC radiation.

3.4 Fermentation in bioreactor of the treated hydrolysates

In this step, the hydrolysate treated by heterogeneous AOPs in conditions of assay E4 (ZnO/UVA/O3/pH 8) of this study and the hydrolysate treated in the conditions selected in previous work [15] by homogeneous AOPs (Fe+2/H2O2/O3/pH 8) were used, wherein all the chemical species involved in the hydroxyl radical generation are soluble in the reaction medium. For comparison, fermentations in semi-synthetic medium and untreated hydrolysate were also performed.

The cell growth (a), sugars consumption (b), and the ethanol production (c) by P. stipitis on cultivations in the hydrolysate treated by heterogeneous and homogeneous AOPs, untreated hydrolysate, and semi-synthetic medium are shown in Fig. 5. As can be seen, the yeast was able to grow in all fermentation media. It was also found that, with the exception of cultivation in semi-synthetic medium, the yeast showed a lag phase. The duration of this phase in the treated hydrolysates was approximately of 12 h, which was lower than that observed in untreated hydrolysate (about 48 h). This result shows a decrease in hydrolysate toxicity as a result of the reduction of inhibitors with the employed treatment. In fact, the effect of inhibitor compounds in the hydrolysate can lead to extension of the lag phase of cell growth in P. stipitis, when compared to the semi-synthetic medium fermentation [51, 52].

Cell growth (a), sugars consumption (b), and ethanol production (c) by yeast P. stipitis NRRL Y-7124, from semi-synthetic medium (line with open circle) rice straw hemicellulosic hydrolysate untreated (line with letter x) and hydrolysate treated by AOPs homogeneous (line with open square) and heterogeneous (line with open triangle)

With respect to sugars consumption (Fig. 5b), in all fermentation media, the yeast completely consumed glucose and partially consumed xylose according to the cultivation medium. Glucose is preferentially consumed, which was expected, since the presence of glucose concentrations in the medium may delay the pentose consumption.

The yeast had higher intakes of sugars in the cultivations performed in the hydrolysate treated by AOPs, compared to untreated hydrolysate. In both hydrolysates treated (by homogeneous and heterogeneous AOPs), the yeast was able to completely consume glucose after 36 h, and about 43 and 74 % of xylose after 96 h, in the cultivations in hydrolysate treated by heterogeneous and homogeneous AOPs, respectively. In untreated hydrolysate cultivation, the yeast showed a lag phase of 48 h, followed by complete consumption of glucose after 72 h and a poor xylose consumption after this period, leaving about 93 % of sugar after 96 h. These results show that the AOPs treatments were able to improve the assimilation of sugars, compared to the untreated hydrolysate cultivation.

Similar to sugars consumption, the ethanol production varied with the culture medium employed. Both types of treatments by AOPs (heterogeneous and homogeneous) resulted in an increase in ethanol production by yeast, when compared to that observed in untreated hydrolysate. However, ethanol concentrations achieved in cultivation carried out in the treated hydrolysate were still inferior to that achieved in semi-synthetic medium. In untreated hydrolysate fermentation, the yeast produced about 5.7 g/L of ethanol after 84 h of fermentation. The treatment by AOPs provided increases in ethanol production to 14.5 g/L after 96 h for the heterogeneous process and 18.5 g/L after 84 h for the homogeneous process (Table 3).

In general, the hydrolysate treatment by AOPs led to increases in the sugar consumption, cell growth, and ethanol production and to a reduction in latency stage. In fact, employment of various types of detoxification treatments, such as adsorption on activated carbon, “overliming,” and sulfite addition, among others, lead to considerable improvements in cell growth, substrate consumption, and ethanol production by P. stipitis; however, even after such treatments, latency periods in cell growth are also observed, which is related to the presence of potentially inhibitory compounds that were not fully removed in treatments [51–54].

By comparing the fermentative behavior of P. stipitis on untreated hydrolysate, it can be seen that homogeneous AOPs was superior to the heterogeneous treatment. Due to the variations observed for Q P and Q S for the different fermentation media, the conversion factor of substrate to product (Y P/S) slightly varied, showing values between 0.28 and 0.31 g/g. On the other hand, the ethanol volumetric productivity was strongly affected by the presence of inhibitors showing values varying from 0.07 to 0.32 g/L·h.

Although better results have been achieved in the fermentation carried out in the semi-synthetic medium, both heterogeneous and homogeneous hydrolysate treatments have provided substantial increases compared to the values observed for cultivation in untreated hydrolysate. Furthermore, the increases in substrate consumption and ethanol volumetric productivity during cultivation on treated hydrolysates by homogeneous AOPs was double that achieved by heterogeneous AOPs treatment.

Among the AOPs evaluated, the homogeneous processes provided the best results in the hydrolysate detoxification. This result may be attributed to the nature of the processes. In the heterogeneous processes, the main mechanism of action is the photocatalysis, wherein the hydroxyl radical is generated by the action of light radiation on the particle surface of the semiconductor, in this way the light penetration is an important factor [39], which probably was strongly affected by the intense color of the hydrolysate.

The use of AOPs as a hydrolysate detoxification treatment showed similar results to those obtained by detoxification processes commonly described in the literature [51–54]. For example, Roberto et al. [52] evaluated the ethanol production by the yeast P. stipitis NRRL-Y-7124 from sugar cane bagasse hemicellulosic hydrolysate treated by adsorption on activated carbon. During fermentation of detoxified hydrolysate, the yeast showed a lag phase of 20 h and a maximum ethanol concentration of 24 g/L after 72 h. The ethanol volumetric productivity was 0.35 g/L·h, which represents about 60 % achieved in the semi-synthetic medium. Despite increased lag phase, and lower productivity, the conversion factor of substrate to product (0.35 g/g) was not affected by the inhibitory effect observed in the treated hydrolysate.

In this study, the detoxification treatment by AOPs allowed to ferment in hydrolysate medium with high concentrations of sugars (about 100 g/L xylose and glucose). Even under these conditions, the fermentative parameters of conversion of substrate to product, ethanol volumetric productivity, were similar to those reported in the literature for usual detoxification processes. However, in the majority of studies on ethanol production by P. stipitis from hemicellulose hydrolysates, total sugars concentrations employed are less than 60 g/L [3, 10, 14, 54–57], which is probably related to effects of inhibition caused by higher concentrations of toxic compounds. It is worth noting that the use of sugars concentrations in the fermentation medium in the range of 80 to 100 g/L is essential for obtaining high concentrations of ethanol from fermented broth and thus for the economic viability of the distillation step [58, 59]. Therefore, in this study, an important improvement was accomplished—the bioconversion process of hemicellulosic hydrolysate to ethanol employing high concentrations of sugars.

4 Conclusions

The results obtained in this work proved the effectiveness of AOPs as a detoxification method of rice straw hemicellulosic hydrolysate since these treatments were able to provide important improvements on ethanol production by P. stipitis. Additionally, the AOPs treatment did not reduce the sugar concentration or volume of hydrolysate and there was no waste generation during the process, which are important advantages over other traditional methods for hydrolysate detoxification. Under selected conditions for heterogeneous treatment (100 mg/L ZnO; 500 mg/L O3 in the presence of UVA at pH 8.0) and homogeneous treatment (50 mg/L Fe+2; 1000 mg/L H2O2, 500 mg/L O3 at pH 8), the ethanol production increases about 154 and 224 %, respectively, in relation to the fermentation of untreated hemicellulosic hydrolysate. These results support the great potential of this treatment for applications as a detoxification method of lignocellulosic hydrolysates for bioconversion processes.

References

Eliasson A, Christensson C, Wahlbom F, Hahn-Hägerdal B (2000) Anaerobic xylose fermentation by recombinant Saccharomyces cerevisiae carrying XYL1, XYL2, and XYS1 in mineral medium chemostat cultures. Appl Environ Microbiol 66(8):3381–3386

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10

Arslan S, Saraçoglu NE (2010) Effect of pretreatment methods for hazelnut shell hydrolysate fermentation with Pichia stipitis to ethanol. Bioresour Technol 101:8664–8670

Chandel AK, Kapoor RK, Singh A, Kuhad RC (2007) Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresour Technol 98:1947–1950

Villarreal MLM, Prata AMR, Felipe MGA, Silva JBA (2006) Detoxification procedures of eucalyptus hemicellulose hydrolysate for xylitol production by Candida guilliermondii. Enzyme Microb Technol 40:17–24

López MJ, Nichols NN, Dien BS, Moreno J, Bothast RJ (2004) Isolation of microorganisms for biological detoxification of lignocellulosic hydrolysates. Appl Microbiol Biotechnol 64:125–131

Lee JM, Venditti AR, Jameel H, Kenealy WR (2011) Detoxification of woody hydrolyzates with activated carbon for bioconversion to ethanol by the thermophilic anaerobic bacterium Thermoanaerobacterium saccharolyticum. Biomass Bioenergy 35:626–636

Zhu J, Yong Q, Xu Y, Yu S (2011) Detoxification of corn stover prehydrolyzate by trialkylamine extraction to improve the ethanol production with Pichia stipitis CBS 5776. Bioresour Technol 102:1663–1668

Martinez A, Rodrigues ME, Wells ML, York SW, Preston JF, Ingram LO (2001) Detoxification of dilute acid hydrolysates of lignocellulose with lime. Biotechnol Prog 17:287–293. doi:10.1021/bp0001720

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates I: inhibition and detoxification. Bioresour Technol 74:25–33

Telli-Okur M, Eken-Saraçoglu N (2008) Fermentation of sunflower seed hull hydrolysate to ethanol by Pichia stipitis. Bioresour Technol 99:2162–2169

Larsson S, Reimann A, Nilvebrant NO, Jonsson LJ (1999) Comparison of different methods for the detoxification of lignocellulose hydrolyzates of spruce. Appl Biochem Biotechnol 77–79:91–103

Eken-Saraçoglu N, Arslan Y (2000) Comparison of different pretreatments in ethanol fermentation using corn cob hemicellulosic hydrolysate with Pichia stipitis and Candida shehatae. Biotechnol Lett 22:855–858

Mussatto SI, Santos JC, Roberto IC (2004) Effect of pH and activated charcoal adsorption on hemicellulosic hydrolysate detoxification for xylitol production. J Chem Technol Biotechnol 79:590–596

Silva JPA, Carneiro LM, Roberto IC (2013) Treatment of rice straw hemicellulosic hydrolysates with advanced oxidative processes: a new and promising detoxification method to improve the bioconversion process. Biotechnol Biofuels 6(23)

Glaze WH, Kang JW, Chapin DH (1987) The chemistry of water treatment processes involving ozone hydrogen peroxide and ultraviolet radiation. Ozone Sci Eng 9:335–352

Ahmed B, Mohamed H, Limem E, Bensalah N (2009) Degradation and mineralization of organic pollutants contained in actual pulp and paper mill wastewaters by a UV/H2O2 process. Ind Eng Chem 48:3370–3379

Peralta-Zamora Wypych F, Carneiro LM, Vaz SR (2004) Remediation of phenol lignin and paper effluents by advanced oxidative processes. Environ Technol 25:1331–1339

Catalkaya EC, Kargi F (2008) Advanced oxidation treatment of pulp mill effluent for TOC and toxicity removals. J Environ Manage 87:396–404

Torrades F, Perez M, Mansilla H, Peral J (2003) Experimental design of Fenton and photo-Fenton reactions for the treatment of cellulose bleaching effluents. Chemosphere 53:1211–1220

Perez M, Torrades F, Garcia-Hortal JA, Domenech X, Peral J (2001) Removal of organic contaminants in paper pulp treatment effluents under Fenton and photo-Fenton conditions. Appl Catal Environ 36:63–74

Pacheco JR, Peralta-Zamora PG (2004) Integration of physical chemistry and advanced oxidative processes for remediation of landfill leachate. Engenharia Sanitária e Ambiental 9(4):306–311

Nogueira RFP, Trovó AG, Silva MRA, Villa RD, Oliveira MCO (2007) Fundamentos e aplicações ambientais dos processos Fenton e foto-Fenton. Química Nova 30(2):400–408

Freire RS, Pelegrini R, Kubota LT, Durán N (2000) Novas tendências para o tratamento de resíduos industriais contendo espécies organocloradas. Química Nova 23(4):504–511

Huang CP, Dong C, Tang Z (1993) Advanced chemical oxidation: its present role and potential future in hazardous waste treatment. Waste Manag 13:361–377

Legrini O, Oliveros E, Braun AM (1993) Photochemical processes for water treatment. Chem Rev 93:671–698. doi:10.1021/cr00018a003

Lanzalunga O, Bietti M (2000) Photo- and radiation chemical induced degradation of lignin model compounds. J Photochem Photobiol B Biol 56:85–108

Guimarães JR, Almeida Junior RL, Maniero MG, Fadini PS (2010) Ozonização em meio básico para redução de cor do licor negro de indústria de celulose de algodão. Engenharia Sanitária e Ambiental 15(1):93–98

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chemical Review 95:69–96

Khodja AA, Sehili T, Pilichowski JF, Boule P (2001) Photocatalytic degradation of 2-phenylphenol on TiO2 and ZnO in aqueous suspensions. J Photochem Photobiol A Chem 141:231–239

Poulios I, Kositzi M, Kouras A (1998) Photocatalytic decomposition of triclopyr over aqueous semiconductor. J Photochem Photobiol A Chem 115:175–183

Behnajady MA, Modirshahla N, Daneshvar N, Rabbani M (2007) Photocatalytic degradation of C.I. Acid Red 27 by immobilized ZnO on glass plates in continuous-mode. J Hazard Mater 140:257–263

Spacek W, Bauer R, Heisler G (1995) Heterogeneous and homogeneous wastewater treatment comparison between photodegradation with TiO2 and the photo-Fenton reaction. Chemosphere 30:477–484

Selvin R, Hsu HL, Arul NS, Mathew S (2010) Comparison of Photo-Catalytic Efficiency of Various Metal Oxide Photo-Catalysts for the Degradation of Methyl Orange. Sci Adv Mater 2:58–63

Rego E, Marto J, Marcos PS, Labrincha JA (2009) Decolouration of orange II solutions by TiO2 and ZnO active layers screen-printed on ceramic tiles under sunlight irradiation. Appl Catal Gen 355:109–114

Li X, Lv K, Deng K, Tang J, Su R, Sun J, Chen L (2009) Synthesis and characterization of ZnO and TiO2 hollow spheres with enhanced photoreactivity. Mater Sci Eng B 158:40–47

Suri RPS, Liu J, Hand DW, Crittenden JC, Perram DL, Mullins ME (1993) Heterogeneous photocatalytic oxidation of hazardous organic contaminants in water. Water Environ Res 65:665–673

Ziolli RL, Jardim WF (1998) Mecanismo de fotodegradação de compostos orgânicos catalisada por TiO2 Química Nova 21:319–325

Andreozzi R, Caprio V, Insola A, Marotta F (1999) Advanced oxidation processes (AOP) for water purification and recovery. Catal Today 53:51–59

Giri RR, Ozaki H, Taniguchi S, Takanami R (2008) Photocatalytic ozonation of 2,4-dichlorophenoxyacetic acid in water with a new TiO2 fiber. Int J Environ Sci Technol 5(1):17–26

Gernjak W, Krutzler T, Glaser A, Malato S, Caceres J, Bauer R, Fernández-Alba AR (2003) Photo-Fenton treatment of water containing natural phenolic pollutants. Chemosphere 50:71–78

Roberto IC, Mussatto SI, Rodrigues RCLB (2003) Dilute-acid hydrolysis for optmization of xylose recovery from rice straw in a semi-pilot reactor. Ind Crops Prod 17:171–176

Silva JPA, Mussatto SI, Roberto IC, Teixeira JA (2012) Fermentation medium and oxygen transfer conditions that maximize the xylose conversion to ethanol by Pichia stipitis. Renew Energy 37:259–265

Singleton V, Orthofer R, Lamuela-Raventós R (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteus reagent. Methods Enzymol 299:152–178

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Liu L, Liu H, Zhao YP, Wang Y, Duan Y, Gao G, Ge M, Chen W (2008) Directed synthesis of hierarchical nanostructured TiO2 catalysts and their morphology-dependent photocatalysis for phenol degradation. Environ Sci Technol 42(7):2342–2348

Zazo JA, Casas JA, Mohedano AF, Gilarranz MA, Rodriguez JJ (2005) Chemical pathway and kinetics of phenol oxidation by Fenton’s reagent. Environ Sci Technol 39:9295–9302. doi:10.1021/es050452h

Scheck CK, Frimmel FH (1995) Degradation of phenol and salicylic acid by ultraviolet radiation/hydrogen peroxide/oxygen. Water Res 29:2346–2352

Zhanga S, Zhenga Z, Wanga J, Chen J (2006) Heterogeneous photocatalytic decomposition of benzene on lanthanum-doped TiO2film at ambient temperature. Chemosphere 65(11):2282–2288

Machado AEH, Ruggiero R, Neumann MG (1994) Fotodegradação de ligninas acelerada por peróxido de hidrogênio: evidências de participação do 1O2(1Δg) nas reações em meio alcalino. Química Nova 17(2):111–118

Nigam JN (2002) Bioconversion of water-hyacinth (Eichhornia crassipes) hemicellulose acid hydrolysate to motor fuel ethanol by xilose-fermenting yeast. J Biotechnol 97:107–116

Roberto IC, Lacis LS, Barbosa MFS, Mancilha IM (1991) Utilization of sugar cane bagasse hemicellulosic hydrolysate by Pichia stipitis for the production of ethanol. Process Biochem 26:15–21

Nigam JN (2001) Ethanol production from hardwood spent sulfite liquor using an adapted strain of Pichia stipitis. J Ind Microbiol Biotechnol 3:145–150

Van Zyl C, Prior AB, Du-Preez JC (1988) Production of ethanol from sugar cane bagasse hemicelulose hydrolyzate by Pichia stipitis. Appl Biochem Biotechnol 357–369. doi: 10.1007/BF02779170

Nigam JN (2001) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27

Huang CF, Lin TH, Guo GL, Hwang WS (2009) Enhanced ethanol production by fermentation of rice straw hydrolysate without detoxification using a newly adapted strain of Pichia stipitis. Bioresource Technol 100:3914–3920

Chandel AK, Singh OV, Rao LV, Chandrasekhar G, Narasu ML (2011) Bioconversion of novel substrate Saccharum spontaneum a weedy material into ethanol by Pichia stipitis NCIM3498. Bioresour Technol 102(2):1709–1714

Walton S, Heiningen AV, Walsum PV (2010) Inhibition effects on fermentation of hardwood extracted hemicelluloses by acetic acid and sodium. Bioresour Technol 101:935–1940

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Lulasik (2010) Hemicelluloses for fuel ethanol. A review. Bioresour Technol 101:4775–4800

Acknowledgments

The authors gratefully acknowledge financial support from Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP—Proc. 2010/52673-0), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Conselho Nacional de Desenvolvimento Cientifico e tecnológico (CNPq)-Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, J.P.A., Carneiro, L.M. & Roberto, I.C. Assessment of advanced oxidative processes based on heterogeneous catalysis as a detoxification method of rice straw hemicellulose hydrolysate and their effect on ethanol production by Pichia stipitis . Biomass Conv. Bioref. 4, 225–236 (2014). https://doi.org/10.1007/s13399-013-0104-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-013-0104-4