Abstract

Proton-conducting solid oxide fuel cell (H-SOFC) based on layered perovskite type GdBaCuCoO5+x (GBCC) cathode was fabricated with in situ drop-coating BaZr0.1Ce0.7Y0.2O3−δ (BZCY) electrolyte membrane. The influences of Cu doping into Co sites of GdBaCo2O5+x on the electrical conductivity and conduction mechanism, thermal expansion property and electrochemical performance of cathode materials and corresponding single cell were investigated. Results show that the electrical conductivity decreased and the conduction mechanism would gradually transform to the semiconductor-like behavior. A high maximum power density of 480 mW cm−2 was obtained for the anode supported NiO–BZCY/NiO–BZCY/BZCY/GBCC single cells with wet H2 fuel at 700 °C. The corresponding polarization resistance was as low as 0.17 Ω cm2. The excellent electrochemical performance of as-prepared single cell indicates that GBCC is a good candidate of cathode materials for H-SOFCs.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid oxide fuel cell (SOFC), as a kind of green and environment-friendly electrochemical energy device, has attracted intensive attention in the past 20 years, since it can convert the fuel chemical energy into electricity directly with excellent fuel flexibility, very high energy efficiency and wide applications [1,2,3,4,5,6]. To promote the commercial application of SOFCs, lowering the operating temperature to the intermediate-to-low temperature range (400–700 °C) has gradually become one of major research goals [7,8,9,10,11]. Lower operational and system costs, better material and structural stability, ease of sealing can be accomplished for SOFCs run at reduced temperature [9,10,11]. However, this would commonly lead to poor cathode catalytic activity for oxygen reduction reaction [9, 12, 13]. To solve this problem, significant effort has been devoted to explore cathode materials suitable for operation at reduced temperature [9,10,11,12,13,14,15]. Some composite oxides of excellent mixed ionic-electronic conductors (MIECs) are regarded as the most promising cathode materials due to their extended active sites for oxygen reduction reaction in comparison with purely electronic-conducting materials [13]. For example, conventional cathode material La1−xSr x MnO3−δ (LSM) owning negligible oxygen-ion conductivity, has been reported exhibiting relatively high cathode polarization resistance below 700 °C, due to narrow triple phase boundary regions for oxygen reduction reaction [10, 16, 17]. To extend the electrochemically active region, some new cathode materials based on MIECs, such as LnFeO3 (Ln = La, Gd, Sm, Nd), LnCoO3 and doped BaCoO3, have be developed [10, 11, 18,19,20,21]. More recently, Li et al. [9] reported that a Nb and Ta co-substituted perovskite SrCo0.8Nb0.1Ta0.1O3−δ cathode shows high electrocatalysis activity below 500 °C, which is ascribed to an optimal balance of surface electron transfer, oxygen vacancies and ionic mobility.

Compared to simple perovskite cathode materials, layered perovskite cathode materials such as the double perovskite and Ruddlesden–Popper series could improve the oxygen transport properties because of the oxygen diffusion anisotropy and cation ordered structured [22,23,24,25,26]. Among the various layered LnBaCo2O5+x oxides, GdBaCo2O5+x (GBCO) has attracted much attention because of high oxygen self-diffusion coefficient, surface exchange coefficient and low activation energy [27, 28]. However, cobalt-rich cathode materials often show some serious problems such as poor chemical stability in CO2 and high thermal expansion coefficients (TEC) [29]. In our previous studies [30, 31], it is found that partly substitution of Co sites by Cu in cobalt-rich layered perovskite LaBaCoO5+x and YBaCoO5+x cathodes can effectively reduce the thermal expansion coefficients and present super electrochemical performance. Zhou et al. [32]. reported that GdBaCuCoO5+x (GBCC) is a promising cathode candidate for intermediate-temperature SOFCs and the maximal power densities of single cell at 800 °C were 545 and 528 mW cm−2 with LSGM and SDC electrolytes, respectively. Furthermore, substitution of Gd for La in the layered perovskite oxides could lead to reduced TEC, which is beneficial to improve the thermal compatibility of cathode layer.

As well known, SOFCs based on proton conductor electrolytes can be operated at reduced temperatures because of low proton transport activation energy in comparison with oxygen ion-conducting electrolytes [33]. Therefore, in this work, the layered perovskite GdBaCuCoO5+x (GBCC) was applied as the cathode material of proton-conducting SOFC (H-SOFC) with in situ drop-coating BaZr0.1Ce0.7Y0.2O3−δ (BZCY) as the electrolyte.

2 Experimental Procedure

GBCC, GBCO and BZCY powders were synthesized by an EDTA-citrate complexation method [30]. The anode-supported bi-layer substrate of NiO–BZCY/NiO–BZCY (functional layer) was fabricated by a one-step dry-pressing/co-firing process (800 °C for 2 h). The BZCY suspension was subsequently in situ drop-coated on the surface of anode functional layer, and co-fired at 1400 °C for 5 h to obtain the dense BZCY electrolyte membrane [31]. Finally, the cathode slurry prepared by mixing GBCC powder, terpineol and ethyl cellulose was painted on the BZCY electrolyte and sintered at 950 °C for 3 h in air to form the anode supported single cell of NiO–BZCY/NiO–BZCY/BZCY/GBCC.

Phase structure and chemical compatibility of BZCY, GBCC, GBCC-BZCY and GBCC-SDC were performed by XRD analysis with Cu-Kα radiation at room temperature. The DC four-probe technique was applied to measure the electrical conductivity from 800 to 400 °C in air with a Keithley multimeter (Model 2001). Before measurement, the bar samples (sintered at 1200 °C for 5 h and having a relative density of about 95%) were polished to have a dimension of about 30.1 × 4.9 × 2.1 mm. Thermal expansion performance of similar bar samples was obtained using a dilatometer (Netzsch DIL 402C) from 25 to 800 °C with a heating rate of 5 °C min−1 in air. Electrochemical performance of single cells was tested in a home-developed system, equipped with an electrochemical workstation (Zahner Zennium Pro) to obtain the impedance spectra and current–voltage curves. For this test, the single cell was fixed on the top end of a corundum tube by inorganic glass sealant. Humidified hydrogen (~ 3% H2O) with a flow rate of 35 mL min−1 and ambient static air were applied as the fuel gas and oxidant, respectively. Cell microstructure was observed by field emission scanning electron microscope (SEM, JEOL JSM-6700F).

3 Results and Discussion

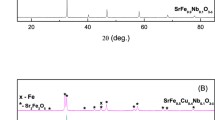

Figure 1a presents the XRD pattern of in situ drop-coated BZCY electrolyte membrane sintered at 1400 °C for 5 h. All the observed diffraction peaks can be indexed to the pure BZCY structure (PDF#35-1318) without any peaks attributable to impurities. To investigate the chemical compatibility, Fig. 1a also shows the XRD patterns of GBCC-BZCY and GBCC-SDC mixtures sintered at 950 °C for 10 h. No new identifiable peaks and shifting of XRD peaks was observed, indicating that no obvious reaction occurred between GBCC and electrolyte materials (Magnified XRD patterns for 20° ≤ 2θ ≤ 35° in Fig. 1b). In view of the good chemical stability, composite cathode consisting of GBCC and sufficient electrolyte material can also be used in future. Actually, composite cathode often results in a better electrochemical performance due to the increased three phase boundary (TPB) length [34].

Figure 2 shows the electrical conductivity of the GBCC sample from 400 to 800 °C. For comparison, the electrical conductivity of GBCO was also included in this figure. As can be observed, the electrical conductivity of GBCC increased gradually with increasing temperature and reached the maximal value of 69.3 S cm−1 at 800 °C, meaning a semiconductor-like behavior. However, the electrical conductivity of un-doped GBCO decreased with increasing temperature, indicating a metallic-like behavior [31, 32, 35]. Cu-doping led to significant decrease of electrical conductivity for GBCO material at all the testing temperatures. This could be interpreted according to the solid defect chemistry analysis of Cu-doped GBCO, similar to Cu-doped YBaCo2O5+x [31]. For GBCO lattice by Cu-doping, the defect reaction can be expressed as following (Eq. 1):

The introduction of Cu into Co sites resulted in the increasing of the oxygen vacancy concentration, and the charge concentration of the hole-type carriers \(\left( {{\text{p}} = \left[ {{\text{Co}}_{\text{Co}}^{ \cdot } } \right]} \right)\) decreased accordingly. So the conduction mechanism transformed from metallic-like behavior of GBCO to the semiconductor-like behavior of GBCC. Similar phenomenon was also observed in YBaCuCoO5+x [31] and LnBaCo2−xCuxO5+d [36] materials. It must be noted that although the measured conductivity of GBCC was lower than those of other cobalt-rich perovskite oxides (including GBCO), it was close to that of well-known Ba0.5Sr0.5Co0.8Fe0.2O3−δ cathode material.

To improve the thermal stability of cobalt-based cathodes, it is vital to decrease their thermal expansion coefficients (TEC) since too high TEC would lead to delamination at the cathode/electrolyte interface upon heating and cooling. Figure 3 shows the thermal expansion percentage of GBCC and GBCC–BZCY (50:50 in mass ratio) from 25 to 800 °C. The corresponding calculated average TEC values were 15.8 × 10−6 K−1 (15.1 × 10−6 K−1 in Ref. [32]) and 13.6 × 10−6 K−1, respectively, which were much smaller than that of GBCO (20.1 × 10−6 K−1 in Ref. [35]) and close to that of BZCY (10.2 × 10−6 K−1 in Ref. [37]). This implies that GBCC and GBCC-BZCY would be more suitable as a potential cathode material than GBCO in terms of the thermal compatibility with BZCY electrolyte for H-SOFCs.

Figure 4a shows the cross-sectional SEM image of as-prepared anode supported single cells of NiO–BZCY/NiO–BZCY/BZCY/GBCC after testing. It can be found that electrolyte/anode functional layer and cathode/electrolyte interfaces show excellent bonding, and both cathode and anode layers possess a porous structure which would facilitate the gas transportation. The drop-coating BZCY electrolyte membrane (about 20 μm) was completely dense and the grains were quite uniform as shown in Fig. 4b. The results demonstrate that a dense BZCY electrolyte without obvious pores or cracks can be successfully fabricated on the porous anode support via in situ drop coating technique when sintered at 1400 °C for 5 h.

To further evaluate the feasibility of layered perovskite oxide GBCC as the cathode material for H-SOFCs, anode supported NiO–BZCY/NiO–BZCY/BZCY/GBCC single cells were fabricated and analyzed in terms of electrochemical properties. Figure 5 shows the current–voltage (I–V) and current-power density (I–P) curves of single cell at different temperatures from 700 to 550 °C. The maximum power densities of single cell based on GBCC cathode were 480, 343, 217 and 82 mW cm−2 at 700, 650, 600 and 550 °C, respectively, and the corresponding OCV values were 0.99,1.03, 1.04 and 1.04 V. Obviously, the prepared single cell exhibits higher power density than those using other cathodes measured under almost the same conditions, such as: YBaCuCoO5+x (435 mW cm−2 at 700 °C [31]), SrFe0.9Sb0.1O3−δ (428 mW cm−2 at 700 °C [38]), and PrBaFe2O5+δ (452 mW cm−2 at 700 °C [39]) cathodes. In addition, the high open-circuit voltages close to theoretical value also indicate that the in situ drop coating BZCY electrolyte membrane is sufficiently dense, as is in accordance with the SEM observation.

Figure 6 presents the electrochemical impedance spectroscopy analysis results under open-circuit conditions from 700 to 550 °C. As shown in Fig. 6a, the polarization resistance (Rp) increased significantly from 0.17 to 7.0 Ω cm2 with decreasing temperature, while the ohmic resistance (Ro) only increased slightly from 0.25 to 0.84 Ω cm2, which agree well with the change of power densities in Fig. 5. This indicates that the total cell resistance (Rt) is dominated by the polarization resistance (Rp) as shown in Fig. 6b. If assuming that Ro mainly comes from the drop-coated BZCY electrolyte film, the activation energy (Ea) of BZCY with a value of 0.60 eV can be calculated in Fig. 7a, which is similar to those of the proton conducting electrolytes [40]. As shown in Fig. 6a, three depressed arcs including a high frequency arc, a middle frequency arc and a low-frequency arc, can be observed in each spectrum by the fitting of the electrochemical impedance, meaning that there are three rate-limiting steps. Figure 7b shows the temperature dependence of Rp, the simulated RH, RM and RL with relaxation frequency value of about 10 kHz, 100 and 1 Hz, respectively. According to the cathode reaction model for H-SOFCs, RH, RM and RL can be attributed to the proton transfer from the bulk of electrolyte to TPBs during charge transfer process, the reducing of oxygen species, and the oxygen adsorption and desorption on the cathode surface and the diffusion of the oxygen ions, respectively [41]. The excellent electrochemical performance of singe cells at 600–700 °C indicates that the layered perovskite oxide GBCC is a good cathode material in intermediate-to-low temperature range for H-SOFCs.

a Impedance spectra of anode supported singe cells with the GBCC cathode under OCV conditions at 550–700 °C (solid lines are the simulated data). b Total cell resistances (Rt), interfacial polarization resistances (Rp), and ohmic resistances (Ro) obtained from impedance spectra at different temperatures in Fig. 6a

4 Conclusions

In this work, the anode-supported H-SOFC with dense BZCY electrolyte membrane was prepared using Cu-doped layered perovskite GdBaCo2O5+x (GBCO) as the cathode material. The prepared GdBaCuCoO5+x (GBCC) exhibited good chemical compatibility with the SDC and BZCY electrolyte when heat treated at 950 °C for 10 h, and no obvious reaction occurred between GBCC and electrolyte materials. The electrical conductivity of GBCO material decreased significantly after the Cu-doping, and the conduction mechanism transformed from the metallic-like behavior to the semiconductor-like behavior. The GBCC also showed a better thermal compatibility with BZCY electrolyte than GBCO, since its average TEC value of 15.8 × 10−6 K−1 between 25 and 800 °C is much smaller than that of GBCO. The prepared single cell with GBCC cathode demonstrated excellent electrochemical properties. High maximum power densities of 480, 343 and 217 mW cm−2 can be achieved operated at 700, 650 and 600 °C, respectively, and the corresponding interfacial polarization resistance was as low as 0.17 Ω cm2 at 700 °C. The present experimental results have shown that layered perovskite oxide GBCC would be a promising cathode material for H-SOFCs to be applied in the intermediate-to-low temperature range.

References

Sengodan, S., Choi, S., Jun, A., Shin, T.H., Ju, Y.-W., Jeong, H.Y., Shin, J., Irvine, J.T.S., Kim, G.: Layered oxygen-deficient double perovskite as an efficient and stable anode for direct hydrocarbon solid oxide fuel cells. Nat. Mater. 14, 205 (2015)

Wang, W., Su, C., Wu, Y., Ran, R., Shao, Z.: Progress in solid oxide fuel cells with nickel-based anodes operating on methane and related fuels. Chem. Rev. 113, 8104 (2013)

Tao, S.W., Irvine, J.T.S.: A redox-stable efficient anode for solid-oxide fuel cells. Nat. Mater. 2, 320 (2003)

Zhou, Y., Guan, X., Zhou, H., Ramadoss, K., Adam, S., Liu, H., Lee, S., Shi, J., Tsuchiya, M., Fong, D.D., Ramanathan, S.: Strongly correlated perovskite fuel cells. Nature 534, 231 (2016)

Huang, Y.H., Dass, R.I., Xing, Z.L., Goodenough, J.B.: Double perovskites as anode materials for solid-oxide fuel cells. Science 312, 254 (2006)

Yang, C., Yang, Z., Jin, C., Xiao, G., Chen, F., Han, M.: Sulfur-tolerant redox- reversible anode material for direct hydrocarbon solid oxide fuel cells. Adv. Mater. 24, 1439 (2012)

Dusastre, V., Kilner, J.A.: Optimisation of composite cathodes for intermediate temperature SOFC applications. Solid State Ionics 126, 163 (1999)

Murray, E.P., Tsai, T., Barnett, S.A.: Characterization of GdBaCo2O5+δ cathode for IT-SOFCs. Solid State Ionics 110, 235 (1998)

Li, M., Zhao, M., Li, F., Zhou, W., Peterson, V.K., Xu, X., Shao, Z., Gentle, I., Zhu, Z.: A niobium and tantalum co-doped perovskite cathode for solid oxide fuel cells operating below 500 °C. Nat. Commun. 8, 13990 (2017)

Xia, C., Rauch, W., Chen, F., Liu, M.: Sm0.5Sr0.5CoO3 cathodes for low-temperature SOFCs. Solid State Ionics 149, 11 (2002)

Shao, Z.P., Haile, S.M.: A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 431, 170 (2004)

Zhao, L., He, B.B., Lin, B., Ding, H.P., Wang, S.L., Ling, Y.H., Peng, R.R., Meng, G.Y., Liu, X.Q.: BaZr0.1Ce0.7Y0.1Yb0.1O3−δ electrolyte-based solid oxide fuel cells with cobalt-free PrBaFe2O5+δ layered perovskite cathode. J. Power Sources 194, 835 (2009)

Adler, S.B.: Factors governing oxygen reduction in solid oxide fuel cell cathodes. Chem. Rev. 104, 4791 (2004)

Yoo, S., Jun, A., Ju, Y., Odkhuu, D., Hyodo, J., Jeong, H.Y., Park, N., Shin, J., Ishihara, T., Kim, G.: Development of double-perovskite compounds as cathode materials for low-temperature solid oxide fuel cells. Angew. Chem. Int. Ed. 53, 13064 (2014)

Lee, J.G., Park, J.H., Shul, Y.G.: Tailoring gadolinium-doped ceria-based solid oxide fuel cells to achieve 2 W cm−2 at 550 °C. Nat. Commun. 5, 4050 (2014)

Xia, C., Liu, M.: Novel cathodes for low-temperature solid oxide fuel cells. Adv. Mater. 14, 521 (2002)

Murray, E.P., Barnett, S.A.: (La, Sr) MnO3-(Ce, Gd)O2−x composite cathodes for solid oxide fuel cells. Solid State Ionics 143, 265 (2001)

Zhou, W., Ran, R., Shao, Z.P., Jin, W.Q., Xu, N.P.: Evaluation of A-site cation-deficient (Ba0.5Sr0.5)1−xCo0.8Fe0.2O3−δ (x > 0) perovskite as a solid-oxide fuel cell cathode. J. Power Sources 182, 24 (2008)

Tu, H.Y., Takeda, Y., Imanishi, N., Yamamoto, O.: Ln0.4Sr0.6Co0.8Fe0.2O3−δ (Ln = La, Pr, Nd, Sm, Gd) for the electrode in solid oxide fuel cells. Solid State Ionics 117, 277 (1999)

Hwang, H.J., Moon, J.W., Lee, S., Lee, E.A.: Electrochemical performance of LSCF-based composite cathodes for intermediate temperature SOFCs. J. Power Sources 145, 243 (2005)

Qiu, L., Ichikawa, T., Hirano, A., Imanishi, N., Takeda, Y.: Ln1−xSr x Co1−yFe y O3−δ (Ln = Pr, Nd, Gd; x = 0.2, 0.3) for the electrodes of solid oxide fuel cells. Solid State Ionics 158, 55 (2003)

Yang, Y., Chen, Y., Tian, D., Lu, X., Ding, Y., Yu, W., Lin, B.: A new A-site excessive strategy to improve performance of layered perovskite cathode for intermediate-temperature solid oxide fuel cells. Electrochim. Acta 231, 686 (2017)

Boehm, E., Bassat, J.M., Dordor, P., Mauvy, F., Grenier, J.C., Stevens, P.: Oxygen diffusion and transport properties in non-stoichiometric Ln2−xNiO4+δ oxides. Solid State Ionics 176, 2717 (2005)

Gao, Y., Chen, D.J., Chen, C., Shao, Z.P., Ciucci, F.: Oriented PrBaCo2O5+δ thin films for solid oxide fuel cells. J. Power Sources 278, 623 (2015)

Tarancon, A., Skinner, S.J., Chater, R.J., Hernandez-Ramirez, F., Kilner, J.A.: Layered perovskites as promising cathodes for intermediate temperature solid oxide fuel cells. J. Mater. Chem. 17, 3175 (2007)

Kim, G., Wang, S., Jacobson, A.J., Reimus, L., Brodersen, P., Mims, C.A.: Rapid oxygen ion diffusion and surface exchange kinetics in PrBaCo2O5+x with a perovskite related structure and ordered A cations. J. Mater. Chem. 17, 2500 (2007)

Presti, L.L., Allieta, M., Scavini, M., Ghigna, P., Loconte, L., Scagnoli, V., Brunelli, M.: Crystal structure and structural phase transitions in the GdBaCo2O5.0 cobaltite. Phys. Rev. B 84, 104107 (2011)

Tarancón, A., Burriel, M., Santiso, J., Skinner, S.J., Kilner, J.A.: Advances in layered oxide cathodes for intermediate temperature solid oxide fuel cells. J. Mater. Chem. 20, 3799 (2010)

Wei, B., Lu, Z., Huang, X.Q., Liu, M.L., Li, N., Su, W.H.: Synthesis, electrical and electrochemical properties of Ba0.5Sr0.5Zn0.2Fe0.8O3−δ perovskite oxide for IT-SOFC cathode. J. Power Sources 176, 1 (2008)

Ling, Y.H., Zhao, L., Lin, B., Dong, Y.C., Zhang, X.Z., Meng, G.Y., Liu, X.Q.: Layered perovskite LaBaCuMO5+x (M = Fe, Co) cathodes for intermediate-temperature protonic ceramic membrane fuel cells. J. Alloys Compd. 493, 252 (2010)

Ling, Y.H., Zhao, L., Liu, X.Q., Lin, B.: Tailoring electrochemical property of layered perovskite cathode by Cu-doping for proton-conducting IT-SOFCs. Fuel Cells 15, 384 (2015)

Zhou, Q.J., Zhang, Y.C., Shen, Y., He, T.M.: Layered perovskite GdBaCuCoO5+x cathode material for intermediate-temperature solid oxide fuel cells. J. Electrochem. Soc. 157, B628 (2010)

Bi, L., Zhang, S., Lin, B., Fang, S., Xia, C., Liu, W.: Screen-printed BaCe0.8Sm0.2O3−δ thin membrane solid oxide fuel cells with surface modification by spray coating. J. Alloys Compd. 473, 48 (2009)

Ling, Y.H., Chen, H., Niu, J.N., Wang, F., Zhao, L., Ou, X.M., Nakamura, T., Amezawa, K.: Bismuth and indium co-doping strategy for developing stable and efficient barium zirconate-based proton conductors for high-performance H-SOFCs. J. Eur. Ceram. Soc. 36, 3423 (2016)

Li, N., Lu, Z., Wei, B., Huang, X.Q., Chen, K.F., Zhang, Y.H., Su, W.H.: Characterization of GdBaCo2O5+δ cathode for IT-SOFCs. J. Alloys Compd. 454, 274 (2008)

Kim, Y.N., Manthiram, A.: Layered LnBaCo2−xCuxO5+δ (0 ≤ x ≤ 1.0) perovskite cathodes for intermediate-temperature solid oxide fuel cells. J. Electrochem. Soc. 158, B276 (2011)

Zhu, Z.W., Tao, Z.T., Bi, L., Liu, W.: Investigation of SmBaCuCoO5+δ double-perovskite as cathode for proton-conducting solid oxide fuel cells. Mater. Res. Bull. 45, 1771 (2010)

Ling, Y.H., Zhang, X.Z., Wang, S.L., Zhao, L., Lin, B., Liu, X.Q.: A cobalt-free SrFe0.9Sb0.1O3−δ cathode material for proton-conducting solid oxide fuel cells with stable BaZr0.1Ce0.7Y0.1Yb0.1O3−δ electrolyte. J. Power Sources 195, 7042 (2010)

Ping, H.P., Xue, X.J.: BaZr0.1Ce0.7Y0.1Yb0.1O3−δ electrolyte-based solid oxide fuel cells with cobalt-free PrBaFe2O5+δ layered perovskite cathode. J. Power Sources 195, 7038 (2010)

Fabbri, E., Bi, L., Tanaka, H., Pergolesi, D., Traversa, E.: Chemically stable Pr and Y Co-doped barium zirconate electrolytes with high proton conductivity for intermediate-temperature solid oxide fuel cells. Adv. Funct. Mater. 21, 158 (2011)

Zhao, L., He, B.B., Gu, J.Q., Liu, F., Chu, X.F., Xia, C.R.: Reaction model for cathodes cooperated with oxygen-ion conductors for solid oxide fuel cells using proton-conducting electrolytes. Int. J. Hydrogen Energy 37, 548 (2012)

Acknowledgements

The authors would like to thank the financial support from the National Natural Science Foundation of China (Nos. 51462012 and 51462011) and Jiangxi Provincial Department of Education, China (KJLD14076).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, X., Jiang, Y., Hu, X. et al. High Performance Proton-Conducting Solid Oxide Fuel Cells with a Layered Perovskite GdBaCuCoO5+x Cathode. Electron. Mater. Lett. 14, 147–153 (2018). https://doi.org/10.1007/s13391-018-0023-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-018-0023-4