Abstract

In order to achieve more rapid response control for integrated helicopter/turboshaft engine system with variable rotor speed, an integrated control method based on the error feedforward between engine required and real output torque is proposed. Firstly, based on the principle of incremental nonlinear dynamic inversion, an online acceleration estimation method of gas turbine speed (Ngdot) is proposed to realize the cascade control for turboshaft engine based on Ngdot. Then, a rotor demanded torque predicted model is developed through min-batch gradient descent-neural network. Meanwhile, a feedforward compensation method based on the error between engine required and real output torque is proposed according to the rotor dynamics characteristics of engine output shaft with variable rotor speed to suppress the interference of the rotor demanded power during variable rotor speed. The simulation results show that under different flight conditions, compared with the collective pitch feedforward and the rotor predicted torque feedforward control, the feedforward control method based on the error between engine required and real output torque can effectively reduce the overshoot of the relative speed of power turbine by about 14%. In addition, the settling time of power turbine speed is shorter, and the dynamic performance is superior, which can realize the rapid response control of turboshaft engine better.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In 2017, the new tiltrotor V-280 attracted the attention of all countries again. The V-280’s first flight broke through the speed limit of the conventional rotorcraft successfully [1], which is likely to replace the Black Hawk in service and to become one of the most widely popular general helicopters in the US Army. Such significant benefits owe to the application of variable rotor speed technology [2, 3]. It can be predicted that variable rotor speed technology will become the core rotorcraft technology for the sustainable development in various countries.

There are three approaches to achieve variable rotor speed. One is to change the output speed by adjusting the fuel flow of the turboshaft engine. The other is to adjust the attack angle of power turbine or other geometric parameters to change the output speed on the premise that the working state of the core engine remains invariant [4]. The third is to alter the gear ratio of transmission system [5]. Among them, the first scheme is limited by the engine efficiency, and the range of speed variation is narrow. The second one needs additional control mechanism, which is difficult and complex, so it is still in the theoretical stage. The last one possesses better prospect and feasibility. NASA and Bell have carried out relevant research on this issue, wherein A-160T unmanned helicopter adopts two-stage transmission mechanism to realize variable rotor speed. Whichever variable rotor speed method is available, it is necessary to overcome the coupling problem between the complex power output of turboshaft engine and the aerodynamic characteristics of main rotor [6] and to design the integrated control method for helicopter/turboshaft engine with variable rotor speed. The conventional design method of flight control system and engine control system can scarcely meet the requirements of the helicopter/engine with variable rotor speed [7, 8]. Developing an aircraft or engine separately without taking into account the coupling among aircraft, engine and control system and then designing a flight control system and engine control system, respectively, usually pay much attention to the stability of subsystems and retain sufficient safety margin, thus sacrificing the overall performance of the whole system.

Currently, the cascade proportion–integration–differentiation (PID) control structure combined with collective pitch feedforward is widely popular in turboshaft engine control [9, 10]. The collective pitch of main rotor is adopted as the cross-linking parameter between helicopter and engine to realize the integrated control for helicopter/turboshaft engine. However, during variable rotor speed, the rotor speed varies in a wide range. It is no longer adequate for collective pitch to represent the required power of main rotor. Therefore, it is urgent to select optimal cross-linking parameters according to the measurable parameters of helicopter and engine and to develop a novel cross-linking scheme to meet the requirements of high-quality control for helicopter/turboshaft engine with variable rotor speed.

Cai [11] developed a control structure for gas turbine engine, which consists of a controller, an engine estimator and a load estimator. The load estimator can evaluate power turbine speed, torque and rotor load according to the input signals and transmits them to the controller to achieve closed-loop control. HPW3000 engine controller predicts the transient variation of rotor torque through neural network that is accessible as the feedforward compensation loop of turboshaft engine. Meanwhile, it possesses the operation control mode from idle speed to high speed with guide vanes in advance, which further improves the accelerated response ability in acceleration process [12]. Lu [13] designed a speed controller for turboshaft engine based on the internal model principle. Aiming at the disturbance of rotor torque variation on power turbine speed, a torque predicted method based on extreme learning machine (ELM) is proposed, which achieves effective compensation of the engine’s load variation. Sun [14] developed a torque prediction model based on recursive reduced least squares support vector regression (RR-LSSVR) algorithm and model prediction procedure. In addition, the turboshaft engine’s compensator was implemented through the predicted torque information. The simulation results show that the control scheme has better dynamic disturbance rejection ability than traditional system, and it can decrease the sag of power turbine speed more than 10%. The above research results only consider either constant rotor speed operation or the little variation in rotor load, which are difficult to apply to the integrated control for helicopter/turboshaft engine with variable rotor speed. Wang [15] adopted min-batch gradient descent-neural network to obtain the onboard model of turboshaft engine and realized the acceleration optimization control for the integrated helicopter/engine system. So far, the method has not been validated in the full authority digital engine control (FADEC).

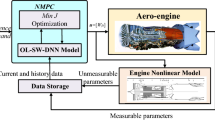

Therefore, in order to compensate for the deficiency of the research on the integrated control method for helicopter/turboshaft engine with variable rotor speed, a novel integrated control method based on the error between engine required and real output torque is proposed. Firstly, based on the principle of incremental nonlinear dynamic inversion (INDI), an online acceleration estimation method of gas turbine speed based on state variable model is developed, which is available to the cascade control for turboshaft engine with variable rotor speed. Then, a rotor demanded torque predicted model is established through min-batch gradient descent-neural network (MGD-NN). According to the rotor dynamics characteristics of engine output shaft with variable rotor speed, a feedforward compensation method based on the error between engine required and real output torque is proposed. Finally, under different flight conditions, the integrated control effect for helicopter/turboshaft engine with variable rotor speed based on engine required and real output torque is validated and compared with the collective pitch feedforward and rotor predicted torque feedforward control.

2 Online Estimation Method of Ngdot Based on Incremental Nonlinear Dynamic Inversion

Based on PID control algorithm, turboshaft engine commonly adopts the cascade control scheme based on power turbine speed and gas turbine speed. Nevertheless, the parameters of speed controller for power turbine and gas turbine influence each other. Meanwhile, turboshaft engine state varies remarkably in the whole flight envelope. Thus, it is difficult to obtain appropriate controller parameters to satisfy the whole flight envelope in practice. On the contrary, the cascade control scheme based on Ngdot is simpler than that based on gas turbine speed. Fortunately, it scarcely affects the natural frequency of the system. Through selecting appropriate damping ratio, the open-loop gain of the system can increase, which is beneficial to improve the dynamic performance of the system. In addition, the integral link in speed regulator of power turbine is removed, which simplifies the parameters tuning accordingly. However, Ngdot is immeasurable. In this case, central difference method is commonly adopted. In order to improve the anti-interference capacity of the control loop for power turbine speed, an online estimation method of Ngdot based on incremental nonlinear dynamic inversion is proposed. The detailed principle is as follows.

Assume that nonlinear system can be expressed in the form of differential equations as follows:

where x(t) ∈ Rn is state vector, y(t) ∈ Rp represents output vector, and u(t) ∈ Rm denotes input vector. According to Eq. (1), Eq. (2) is available:

In order that the output signal can track the reference command as much as possible, it is necessary to construct appropriate control signals to generate the desired dynamic output. The control signal u(t) can be obtained via the inversion of Eq. (3):

where ẏdes(t) is the desired output that is achievable through the linear controller based on the reference command ycom and output signal y, as shown in Fig. 1.

Taking into account the uncertainties and changes of internal parameters, the system can be written as:

where

Here, ν denotes the virtual control signal. Equation (6) is available through substituting Eq. (5) into Eq. (4):

In×n is an n-order identity matrix. According to the above equations, the linear relation ẋ = ν is only valid for Δf = Δg = 0. In this case, the existence of uncertainties degrades the performance of the dynamic inversion controller. Therefore, in order to compensate for the disadvantage, the incremental nonlinear dynamic inversion [16] (INDI) method is proposed.

Equation (7) is achievable from the first-order terms of Taylor series expansion around the current solution (x0, u0) of the system:

where ẋ0 and u0 are known. In a short timescale, x-x0 is approximately equal to zero. Therefore, instead of computing the total control input directly, only the required increment relative to the previous input is necessary. The corresponding control law is as follows:

The turboshaft engine is a complex nonlinear system, and the expression is shown in Eq. (9); therefore, in order to design the INDI control law, the state variable model shown in Eq. (9) is available through the linearization at the steady-state operating point (x0, u0) of turboshaft engine [13]:

where input signal u is Ngdot. Output signal is engine output torque Tqe, and the state variables are gas turbine speed Ng, relative speed of power turbine Np and Tqe; then, A, B and C are coefficient matrixes with appropriate dimensions and A ∈ R3×3, B ∈ R3, C ∈ R1×3.

According the principle of INDI, INDI control law for turboshaft engine is achievable:

As shown in Fig. 2, the virtual control signal ν required by INDI can be generated by the first-order reference model (RM) with an anti-saturation filter and the output signal.

ΔTqe is the normalized value of the real engine output torque. RM not only is utilized to produce the desired response ΔTqe,rm, but also generates the first-order differential term of the input command, which is adopted as the feedforward νrm of the controller to eliminate the error of state variable model obtained at a single point:

It can be seen that when the proportional gain K is positive (K > 0), the response is always stable. According to above equations, Ngdot estimator can be accessible based on incremental nonlinear dynamic inversion. Figure 3 shows the estimated results of Ngdot based on INDI under different flight conditions.

As shown in Fig. 3, Ngdot estimation method based on INDI can effectively evaluate the acceleration of gas turbine speed. The estimated value is essentially identical with the central difference method. This is because the reference model exists in INDI, which corrects the reference instructions online to compensate for the inaccuracy of the state variable model obtained at a single working point. Figure 3b, d shows that the cascade control based on Ngdot through INDI has better anti-interference ability and superior dynamic control performance, which proves convincing feasibility and benefits of Ngdot estimation method based on INDI.

3 Feedforward Compensation Method Based on the Error Between Engine Required and Real Output Torque

Main rotor is the most important component in a helicopter. The transient torques at the tip of the rotor blades not only contain the pilot information of helicopter, but also represent the power requirement of main rotor. As the external load on turboshaft engine, the transient variation of main rotor torque will inevitably cause the dynamic change of engine output response. Unfortunately, helicopters generally adopt flexible or semirigid and semiflexible blades, resulting in a significant lag in the measurement of main rotor torque [17]. Therefore, it is necessary to predict main rotor torque in advance.

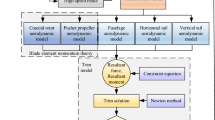

In order to express the dynamic characteristics of the main rotor accurately, min-batch gradient descent-neural network [17] (MGD-NN) is available to obtain the prediction model of rotor demanded torque through offline training. The principle is shown in Fig. 4, and backpropagation is adopted to acquire the gradient of weights and biases.

J(W, b; x, y) denotes the loss function of NN, which is the training objective of the network [15]. Min-batch gradient descent method [18, 19] divides the training data into M groups, and each group has Nb training sets. Then, the loss function of the ith group is as follows:

where i = 1, 2, …,m, ∑bi= N. Loss function is available through computing a subset of training set. Therefore, the calculation cost is less and the gradient direction is better.

Equation (14) shows the derivates δl and the gradient of weights \( \nabla W_{ij}^{l} \) and biases \( \nabla b_{i}^{l} \) at the nodes of the lth layer, wherein \( \otimes \) denotes Hadamard product [20]:

The output of neurons after each iteration is shown in Eq. (15):

where σ(·) is the activation function, and η represents the learning rate [21].

In order to express the dynamic characteristics of the original system more precisely, the structure of nonlinear autoregressive-moving average model is accessible. According to the measureable parameters of helicopter, the prediction model of rotor demanded torque is developed through selecting the historic and current collective pitch of main rotor, flight altitude, forward speed and historic rotor speed as input vector. In addition, the output only consists of rotor demanded torque. The whole model is assumed to a second-order system. Equation (16) summarizes the expression of the whole model, and k denotes the sampling time:

The whole model contains eleven input variables and one output variable. Meanwhile, thirty hidden layer nodes are necessary, and the tansig and purelin function are adopted as the activation functions of hidden layer and output layer separately. The training data are available through normalizing the output data after motivating the integrated helicopter/turboshaft engine system adequately. Figure 5 shows that the relative error of the rotor torque predictive model is less than 0.04%. The precision is high enough to predict rotor demanded torque during variable rotor speed.

Due to the large inertia of main rotor, the response speed of turboshaft engine is slow relative to the variation of rotor demanded power, resulting in a significant delay in power turbine speed. Nevertheless, the main control loop of turboshaft engine adjusts fuel flow according to the deviation between the reference signal of power turbine speed and feedback value. In this case, the response delay existing in power turbine speed will inevitably cause the engine unable to provide enough rotor demanded power in time. While turboshaft engine can supply adequate power to main rotor, the power turbine speed has deviated from the reference signal far away. Therefore, when loading and unloading, there will be a serious sag or overshoot of power turbine speed.

During variable rotor speed, main rotor speed varies in a wide range, and the response lag of the power turbine speed to rotor demanded power is very serious. Therefore, in order to decrease the overshoot and sag of the power turbine speed in variable rotor speed, a feedforward compensation method based on the error between engine required and real output torque is proposed. As shown in Eq. (17), based on the prediction model of rotor demanded torque, and according to the rotor dynamics characteristics of engine output shaft with variable rotor speed, engine required output torque is available, and the error between engine required and real output torque is selected as feedforward term:

4 Simulation Verification

Figure 6 shows the integrated control structure for helicopter/turboshaft engine with variable rotor speed based on the error between engine required and real output torque. As shown in Fig. 6, engine output torque is normalized and then enters into the Ngdot estimator based on INDI, which generates Ngdot online to realize the cascade PID control of turboshaft engine. The torsional components mixing in the relative speed of power turbine are attenuated by an adaptive torsional filter, which participates in closed-loop control subsequently, so that the relative speed of power turbine can keep around reference speed. The reference speed is generally 100%. Rotor torque predicted module predicts the demanded torque of main rotor online based on the measurable input variables and obtains engine required output torque according to main rotor speed and power turbine speed. Meanwhile, the error between engine required and real output torque is available to compensate for the variation of power turbine speed during variable rotor speed.

Next, at flight altitude H = 600 m and forward speed νc= 118 m/s, the simulation verification of the integrated control for helicopter/turboshaft engine with variable rotor speed based on the error of engine required and real output torque is carried out, which is compared with the collective pitch feedforward and rotor predicted torque feedforward control, wherein triple methods share the identical controller parameters. Figure 7a–g shows the simulation results of the integrated helicopter/turboshaft engine system with variable rotor speed.

As shown in Fig. 7a, b, the relative speed of power turbine generally remains 100%, while main rotor speed varies by 38% with the application of the cascade control structure for turboshaft engine based on Ngdot online estimation method through INDI. Compared with the collective pitch feedforward control, the rotor predicted torque feedforward control method could reduce the overshoot of the relative speed of the power turbine by 7.64% during variable rotor speed. Unfortunately, the static control effect is much worse. On the contrary, the overshoot of Np can decrease by 14% through the feedforward control method of the error between engine required and real output torque. In addition, the relative speed of the power turbine has the shortest settling time, fastest response speed and best dynamic performance. The reason is that during variable rotor speed, the rotor demanded power varies sharply. When main rotor speed decreases, the rotor demanded power decreases as well. Equation (17) summarizes that engine required output torque decreases correspondingly, and the error between engine required and real output torque is negative. This negative error is adopted as feedforward term to modify Ngdot command online, which compensates for fuel flow in advance and reduces engine output torque, which then decreases the overshoot of Np significantly, and vice versa. Figure 7c, g shows that while main rotor speed decreases continuously, to provide adequate thrust, it is necessary to increase the collective pitch. In terms of main rotor, the rotor speed decreases, resulting in the reduction of rotor demanded power, which leads to the rapid decrease in fuel flow and the output power of turboshaft engine. Since the turboshaft engine adopts the constant speed control scheme, that is, the power turbine speed maintains around 100%, the engine output torque decreases accordingly to reduce the output power, as shown in Fig. 7e.

In order to validate the robustness performance of the feedforward control method based on the error between engine required and real output torque further, the numerical simulation is conducted under variable flight condition. The flight altitude H is 1000 m. Figure 8a shows the forward speed νc. At t = 10 s, νc accelerates linearly from 118 m/s to 123 m/s and remains unchanged between 15 and 45 s. 5 s later, νc decelerates to 118 m/s and stays constant until the end of the simulation. Figure 8b–h shows the simulation results.

As shown in Fig. 8a, c, the forward speed accelerates at t = 10 s, and then, main rotor speed decreases from 176 to 110 rpm. At t = 33 s, the rotor speed increases rapidly to 176 rpm, and the helicopter decelerates 10 s later. During the rotor speed downshift/forward speed acceleration phase, the relative speed of power turbine shown in Fig. 8b is less than 100%. This is because the thrust increases at acceleration and main rotor speed decreases at this time. In order to keep the forward speed constant, the collective pitch needs increase (Fig. 8h). Figure 8b shows that compared with the collective pitch feedforward control method, the feedforward control method based on the error between engine required and real output torque can reduce the overshoot of Np by about 13.8%. The stability and dynamic performance is better than the rotor predicted torque feedforward control. In addition, the feedforward control method designed has satisfactory robustness.

5 Conclusion

The research on the integrated control method for helicopter/turboshaft engine with variable rotor speed has been conducted. A novel feedforward control method based on the error between engine required and real output torque is proposed. Several conclusions can be obtained:

-

1.

Under different flight conditions, Ngdot estimated values through INDI are generally the same as those based on central difference method. In addition, the cascade control based on Ngdot through INDI has superior anti-interference ability of the relative speed of power turbine.

-

2.

Under different flight conditions, compared with the collective pitch feedforward control method, the feedforward control method based on the error between engine required and real output torque can effectively reduce the overshoot of the relative speed of power turbine by about 14%.

-

3.

The feedforward control method based on the error between engine required and real output torque can shorten the settling time of the relative speed of power turbine and improve its response speed, which is beneficial to realize the rapid response control for turboshaft engine with variable rotor speed better.

-

4.

Compared with the collective pitch feedforward and the torque feedforward, the proposed torque error feedforward can achieve superior dynamic control effect without the loss of steady-state control accuracy.

Abbreviations

- N p :

-

Relative speed of power turbine (%)

- N g :

-

Relative speed of gas turbine (%)

- W fb :

-

Fuel flow (kg/s)

- T qe :

-

Engine output torque (kN m)

- T qe,p :

-

Predicted engine output torque (kN m)

- T qr :

-

Main rotor torque (kN m)

- Ω MR :

-

Main rotor speed (rad/s)

- N gdot :

-

Acceleration of gas turbine speed (1/s2)

- θ 0 :

-

Rotor collective pitch (°)

- v c :

-

Forward speed (m/s)

- H :

-

Flight altitude (m)

References

Kalinin, D.V.: Multithreaded continuously variable transmission synthesis for next-generation helicopters. In: St.Petersburg: 29th Congress of International Council of the Aeronautical Science. September 7–12 (2014)

Reddinger, J.P.; Gandhi, F.; Kang, H.: Using control redundancy for power and vibration reduction on a compound helicopter at high speeds. J. Am. Helicopter Soc. 63(3), 1–13 (2018)

Kalinin, D.V.: Multithreaded continuously variable transmission synthesis for next-generation helicopters. In: St. Petersburg: 29th Congress of the International Council of the Aeronautical Sciences, pp. 7–12 (2014)

Snyder, C.A.; Acree Jr, C.W.: Preliminary assessment of variable speed power turbine technology on civil tiltrotor size and performance. In: TX: American Helicopter Society 68th Annual Forum, 1–3 May (2012)

DeSmidt, H.A.; Smith, E.C.; Bill, R.C.; Wang, K.-W.: Comprehensive modeling and analysis of rotorcraft variable speed propulsion system with coupled engine/transmission/rotor dynamics. NASA/CR-2013 -216502.

Amri, H.; Feil, R.; Hajek, M.; et al.: Possibilities and difficulties for rotorcraft using variable transmission drive trains. CEAS Aeronaut. J. 7(2), 333–344 (2016)

Hua, W.; Miao, L.; Zhang, H.; et al.: A new turbo-shaft engine control law during variable rotor speed transient process. Int. J. Turbo Jet-Engines 32(4), 325–340 (2015)

Krantz, T.L.; Handschuh, R.F.; Roberts, G.D.: Results of NASA technical challenge to demonstrate two-speed drive for vertical lift vehicle. GRC-E-DAA-TN54203. May 14 (2018)

Kuantama, E.; Vesselenyi, T.; Dzitac, S.; et al.: PID and fuzzy-PID control model for quadcopter attitude with disturbance parameter. Int. J. Comput. Commun. Control 12(4), 519–532 (2017)

Min, W.X.Y.H.: Multivariate chaotic time series prediction based on extreme learning machine. Acta Phys. Sin. 8, 80507 (2012)

Cai, C.; Crowley, T.J.; Meisner, R.P.: Load estimation for a twin-engine helicopter. U.S. Patent Application 10/036,331[P]. 2018-7-31

Smith, B.J; Zagranski, R.D.: Next generation control system for helicopter engines. In: 57th Annual Forum of AHS, Washington, DC, May 9–11, pp. 1617–1626 (2001)

Lu, C.; Li, Q.; Jiang, J.; et al.: Internal model control method based on predicted torque feed-forward for turbo-shaft engine. J. Aerospace Power 5, 1166–1172 (2013)

Sun, L.; Sun, J.; Zhang, H.; et al.: Torque feed-forward control of engine/helicopter system based on support vector regression. J. Aerospace Power 3, 680–686 (2011)

Wang, Y.; Zheng, Q.; Zhang, H.; et al.: A study on the acceleration optimization control method for the integrated helicopter/engine system based on torsional vibration suppression. IEEE Access 7, 1182–1194 (2019)

Simplício, P.; Pavel, M.D.; Van Kampen, E.; et al.: An acceleration measurements-based approach for helicopter nonlinear flight control using incremental nonlinear dynamic inversion. Control Eng. Pract. 21(8), 1065–1077 (2013)

Zheng, Q.; Xu, Z.; Zhang, H.; et al.: A turboshaft engine NMPC scheme for helicopter autorotation recovery maneuver. Aerosp. Sci. Technol. 76, 421–432 (2018)

Ioffe, S.; Szegedy, C.: Batch normalization: accelerating deep network training by reducing internal covariate shift. arXiv preprint arXiv:1502.03167 (2015).

Pennington, J.; Socher, R.; Manning, C.: Glove: global vectors for word representation. In: Proceedings of the 2014 Conference on Empirical Methods in Natural Language Processing (EMNLP), pp. 1532–1543 (2014)

Schmidhuber, J.: Deep learning in neural networks: an overview. Neural Netw. 61, 85–117 (2015)

Smith, L.N.: Cyclical learning rates for training neural networks. In: 2017 IEEE Winter Conference on Applications of Computer Vision (WACV), pp. 464–472. IEEE (2017)

Acknowledgements

The work has been co-supported by National Science and Technology Major Project under Grant 2017-V-0004-0054, Research on the Basic Problem of Intelligent Aero-engine under Grant 2017-JCJQ-ZD-047-21, National Natural Science Foundation of China under Grant 51906102, China Postdoctoral Science Foundation Funded Project under Grant 2019M661835 and Aeronautics Power Foundation under Grant 6141B09050385.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Rights and permissions

About this article

Cite this article

Wang, Y., Zheng, Q., Zhang, H. et al. Research on Integrated Control Method for Helicopter/Turboshaft Engine with Variable Rotor Speed Based on the Error Between Engine Required and Real Output Torque. Arab J Sci Eng 45, 6529–6540 (2020). https://doi.org/10.1007/s13369-020-04533-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04533-3