Abstract

The aim of this study was the investigation of powder-based formulations for nasal administration of tacrine hydrochloride. The anti-Alzheimer drug was encapsulated in mucoadhesive microparticles based on chitosan/pectin polyelectrolyte complexes. Microparticles were prepared by means of two different technological approaches (direct spray-drying and spray-drying followed by lyophilization) and analysed in terms of size, morphology and physico-chemical characteristics. Moreover, water uptake and mucoadhesion ability were evaluated as well as drug release and permeation behaviour. The results suggest that lyophilization favours the formation of small particle aggregates with a size of 10 μm, instead of single particles (size smaller than 5 μm) such as direct spray-drying. Particles obtained with the two loading methods present different functional properties according to the different physical state of the loaded drug and its possible interaction with chitosan/pectin complex. Moreover, the presence of different amount of chitosan and pectin in the complex influences their ability to hydrate, interact with mucin and favour drug permeation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Powder-based mucoadhesive formulations have been widely studied for nasal drug delivery [1–5]. In fact, the high degree of vascularization and high permeability of the mucosa make the nose an interesting administration site for systemic delivery of drugs and offers an interesting alternative to oral route, especially for the administration of drug with low bioavailability [6, 7].

Microsystem size is one of the most important characteristic for deposition of particles in nasal turbinates and olfactory region, particularly when a possible nose to brain delivery of drugs is aimed. Classically, large particles (>10 μm) are deposited in the nasal cavity after inhalation; the larger the particles, the more anterior the deposition. For smaller particles, the site of deposition depends on the velocity at which the particles are inhaled and the turbulence in the air flow. However, particles of size smaller than 1 μm are not normally deposited in the nasal cavity, but travel down to the trachea to reach the lung [8].

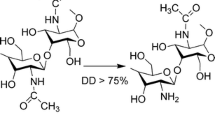

Despite numerous advantages that are associated to intranasal route such as ease of administration, rapid onset of action and avoidance of hepatic first-pass effects, the mucociliary clearance mechanism [9] can seriously impair the effectiveness of administration due to rapid depletion of non-mucoadhesive dosage forms from the absorption site. Mucoadhesive formulations can be used to prevent rapid clearance of the formulation, increasing nasal residence time and thereby allowing longer absorption times. Moreover, an intimate contact with the nasal mucosa provides a higher concentration gradient and thus increased absorption. However, nasal bioavailability differences have been observed for different powder-based mucoadhesive formulations accordingly to their influence on physiological parameters at the site of administration. In particular, some papers focus on the changes of structure and rheology of the mucus caused by mucoadhesive formulations and evaluate how the interaction between the formulation and the mucus influences drug bioavailability [10–12]. In this study, for the preparation of the mucoadhesive formulations, we selected chitosan, the N-deacetylated product of the polysaccharide chitin consisting of glucosamine and N-acetylglucosamine, and pectin, an anionic polysaccharide consisting mainly of d-galacturonic acid and its methyl ester linked via α(1–4) glycosidic bonds. These polymers have proven mucoadhesive properties resulting from the ability to diffuse and engage in entanglements and intramolecular bonding (Van der Waals forces, electrostatic attraction, hydrogen bonding, hydrophobic effects) with mucin [13].

Another interesting property of chitosan is the capacity to interact with high molecular weight molecules with opposite charge-like pectin to form polyelectrolyte complexes stabilised essentially by ionic bounds and able to swell in biological fluid and control drug release [14].

The purpose of this study was the preparation and characterization of microparticles based on chitosan/pectin polyelectrolyte complexes for nasal administration of tacrine (9-amino-1,2,3,4-tetrahydroacridine), the first acetylcholinestearse inhibitor licenced for the treatment of Alzheimer's disease [15]. Despite tacrine is actually marked as oral dosage forms, its administration is associated with low bioavailability due to short elimination half-life, hepatic first-pass effect, gastrointestinal side effect and reversible dose-dependent hepatotoxicity. Hence, the search for alternative routes, as nasal route, has gained interest for this drug.

Materials and methods

Materials

Chitosan (Mw 110,000–150,000; pKa 6.3), pectin from citrus peel (Mw 30,000–100,000; pKa 4.0), tacrine hydrochloride hydrate (MW 234.72), solvents and all other chemicals used for this study were obtained commercially from Sigma-Aldrich (Milan, Italy). Mucin (type II from porcine stomach; bound sialic acid 1 %) was from Sigma-Aldrich (Milan, Italy). Release and permeation studies were carried out in a pH 5.5 buffer solution with the following composition (millimolar): 4.2 Na2HPO4·10H2O, 100.0 KH2PO4, 45.5 NaCl.

Preparation of chitosan/pectin microparticles

Different unloaded microparticles were prepared using various chitosan/pectin molar ratios (1:9, 1:1, 9:1; mol chitosan/mol pectin). Chitosan (1, 5, 9 mmol of monomer) and pectin (9, 5, 1 mmol of monomer) were dissolved respectively in 1 L of aqueous 5 mM HCl and 1 L of aqueous 5 mM NaOH. Pectin solution was slowly added into the chitosan solution and stirred for 24 h at room temperature. The suspension was spray-dried by means of a Mini Spray Dryer B-290 (Buchi, Switzerland), equipped with 1.4 mm diameter nozzle. The drying conditions were set as follows: compressed spray gas flow, 0.75 bar; airflow, 37.5 m3/h; pump rate, 7.5 ml/min; inlet temperature, 140 °C. Previously, different spray-drier settings were tested in order to study the drying effects on the particle size. Three unloaded chitosan/pectin microparticles were obtained (C/P(1:9)SD, C/P(1:1)SD, C/P(9:1)SD).

In order to obtain loaded samples, two different methods were performed: direct spray-drying of drug and excipients or drug soaking on spray-dried microparticles followed by lyophilisation. Loaded spray-dried microparticles were prepared by the same procedure of unloaded samples adding tacrine hydrochloride (1.48 mmol/g of chitosan/pectin total weight) to chitosan solution (C/P/T(1:9)SD, C/P/T(1:1)SD and C/P/T(9:1)SD) before the addition of pectin solution. Lyophilized microparticles were prepared adding 10 mL of a tacrine hydrochloride aqueous solution (55.17 mg/ml) to 1 g of different unloaded spray-dried microparticles. The resultant suspensions were stirred for 2 h and lyophilized (C/P/T(1:9)Lyo, C/P/T(1:1)Lyo and C/P/T(9:1)Lyo).

Microparticle yield and loading efficiency

Spray-dried microparticle yields was calculated as the ratio of final dry weight of each product, with respect to the initial total amount of chitosan, pectin and tacrine hydrochloride used for the preparation.

Encapsulation efficiency was evaluated by tacrine hydrochloride extraction followed by spectrophotometric analysis at 324 nm, performed on a Cary 50 UV-Visible Spectrophotometer (Agilent, CA, USA). A calibration curve was constructed measuring the absorbance of five tacrine hydrochloride standard solutions in the range of 6–30 μg ml−1. About 10 mg of loaded microparticles were added to 100 mL of pH 5.5 phosphate buffer in a Vision Classic 6 dissolution tester (Hanson, CA, USA). The suspension was stirred for 24 h at 37 °C to dissolve tacrine hydrochloride, filtered through a 0.45-μm polytetrafluoroethylene filter (Whatman, USA) and measured in triplicate. Loading efficiency was calculated as the detected amount of tacrine hydrochloride with respect to the theoretical amount of drug loaded in the sample and expressed as a percentage.

Microparticle size and SEM analysis

Particle size distributions were determined by laser diffractometry using a LS100 Q particle size analyser (Beckman Coulter, Miami, FL, USA). Each sample was dispersed in 1-butanol, sonicated for 1 min and then measured in triplicate.

Loaded microparticles were fixed onto the support and coated with gold-palladium under an argon atmosphere, using a gold sputter module in a high-vacuum evaporator. Samples were then observed with LEO 420 (LEO Electron Microscopy Ltd., England), using secondary electron imaging at 15 kV in order to examine the structure of the microparticles.

Physico-chemical characterization

X-ray powder diffractograms were collected on a Panalytical X’Pert Pro automated diffractometer equipped with X’Celerator, CuKa, using glass sample holder. Tube voltage and amperage were set at 40 kV and 40 mA, respectively. The program used for data collection was set to record only the data points within the range of 3–40 °2θ.

Calorimetric measurements were performed using a DSC 200 F3 Maia® (METZSCH, Germany) differential scanning calorimeter equipped with an intra-cooler. The samples were placed in aluminium pierced pans, and the heating was carried out at 10 °C min−1 in a N2 atmosphere.

Water uptake ability

About 10 mg of loaded microparticles were placed into a DVS Intrinsic instrument (SMS, UK) at 37 °C and dried in a 200 standard cubic centimetres stream of dry nitrogen (<0.1 % relative humidity) for 1 h to establish the dry mass. The sample was then exposed to 90 % relative humidity for several hours in order to measure its kinetic moisture sorption. Results were expressed as percent water uptake as follow: percent water uptake (%WU) = (W H − W D ) × 100/W D , where W H is the mass of hydrated microparticles and W D is the dry mass of the microparticles.

Mucoadhesion properties

Mucoadhesive properties of the microparticles were studied using the periodic acid/Schiff (PAS) colorimetric method for the determination of free mucin concentration in aqueous standard solution after absorption of mucin on the microparticles [16].

Calibration curves were constructed using five mucin standard solutions (1, 2, 3, 4, 5 mg/10 ml). After adding 1 ml of periodic reagent (30 μl of 50 % periodic acid solution in 20 ml of 7 % acetic acid solution, freshly prepared), the solutions were incubated for 2 h at 37 °C. The solutions were cooled to room temperature and 1 ml of Schiff’s reagent (Sigma-Aldrich, Milan, Italy) was added. After 30 min, the absorbance of the solutions was measured by spectrophotometric analysis at 555 nm (UV-1601 spectrophotometer, Shimadzu, Milan, Italy).

Loaded microparticles were analysed adding 10 mg of sample to 40 ml of a mucin standard solution (0.5 mg/ml). The suspension was stirred at 500 rpm for 1 h and centrifuged at 4,000 rpm for 2 min. The supernatant was used for the measurement of free mucin content using the periodic acid/Schiff colorimetric method. The free mucin content was extrapolated from the calibration curve and the resulting bound mucin was plotted as a percentage for each loaded sample.

Release studies

Release studies were performed in a Vision Classic 6 Dissolution Tester (Hanson, CA, USA) using as a dissolution medium a volume of 100 ml of pH 5.5 phosphate buffer stirred at 50 rpm and maintained at 37 °C. After adding 10 mg of microparticles to the dissolution medium, the solution UV absorbance was measured at 324 nm after 2, 4, 6, 8, 10, 20, 30, 40, 50, and 60 min by a Cary 50 UV-Visible Spectrophotometer (Agilent, CA, USA) coupled with optical fibre immersed in the solution. A calibration curve was constructed measuring the absorbance of five tacrine hydrochloride standard solutions in the range of 6–30 μg ml−1; good linearity was found (r 2 = 0.9991).

Permeation studies across sheep nasal mucosa

Permeation studies were performed as previously described [17]. Briefly, sheep nasal mucosa was carefully removed from the underlying bone of turbinates by cutting with haemostatic forceps and pulling the mucosa off. The mucosa was washed with saline solution for 30 min and placed in a Franz-type permeation cell with a diffusional area of 1.5 cm2. Loaded microparticles (15 mg) were placed in the donor compartment in contact with the mucosa. A pH 5.5 phosphate buffer (12 ml), stirred and maintained at 37 °C by the means of a surrounding jacket, was used as receiver phase and every hour samples of 100 μl were taken and replaced by fresh medium. The studies were carried on for 6 h, analysing the samples of receiving phase by high performance liquid chromatography UV. The cumulative amount of tacrine hydrochloride was plotted against the time.

A reversed-phase chromatography was performed using a Thermo Scientific Hypersil GOLD C8 column and a mobile phase composed of pH 3.5, 30 mM potassium phosphate buffer/acetonitrile/methanol/triethylamine (698:100:200:2, v/v/v/v). The chromatographic system was composed of a Shimadzu (Milan, Italy) LC-10ATVP chromatographic pump, Shimadzu SPD-10AVP UV-Vis detector and manual Rheodyne 7125 injector with a 20-μl-sample loop. Using a flow rate of 1 ml/min and UV detection at 240 nm, tacrine hydrochloride was eluted in about 4 min. Data were processed by means of CromatoPlus computerised integration system Shimadzu (Italia, Milan, Italy). A calibration curve with a good linearity (r 2 = 0.9996) was obtained in the range 30–1,000 ng ml−1.

Statistical analysis

ANOVA was used to determine statistical significance. Differences were considered to be significant for values of p < 0.05.

Results

Microparticle yield and loading efficiency

The microparticle yield of spray-dried sample varied from 46 to 66 % (Table 1). Drug loading efficiency was from 66.3 to 79.9 % for the spray-dried formulations and approached 90 % for lyophilized powders.

Microparticle size and SEM analysis

From Table 2, it can be seen that powders of micrometric size were obtained for all samples. In particular, spray-dried microparticle size was lower than lyophilized microparticle size and increasing amounts of pectin increased the size of the microparticles. Microparticles were visualised by SEM studies (Fig. 1). All samples presented dimensions consistent with that measured by laser diffractometry. Spray-dried particles showed similar characteristics: particles had spherical shape, rough surface and heterogeneous size. Drug incorporation did not affect the surface morphology of particles (data not shown). On the contrary, lyophilized particles appeared aggregate and showed an irregular shape.

Physico-chemical characterization

Unloaded microparticles C/P(1:9)SD, C/P(1:1)SD and C/P(9:1)SD showed an amorphous XRPD pattern (Fig. 2) with a peak at about 32 °2θ associable to the presence of NaCl in the complex (Fig. 2d). After loading by lyophilisation, the diffractograms of C/P/T(1:1)Lyo and C/P/T(1:9)Lyo showed that tacrine hydrochloride is present as crystalline form of anhydrous drug (Fig. 3b and c) [18]. In the pattern of C/P/T(1:9)Lyo two peaks with low intensity in the range of 7–9 °2θ were also visible. The XRPD analysis of spray-dried-loaded C/P/T(9:1)SD showed an amorphous profile with some peaks associable to those of anhydrous tacrine hydrochloride (Fig. 3d). C/P/T(1:1)SD e C/P/T(1:9)SD microparticles showed the same diffractogram with crystalline peaks which cannot be related to known crystalline forms of tacrine hydrochloride- or tacrine-free base (Fig. 3e and f).

Figure 4 reports the DSC profiles of drug-loaded microparticles. As reported by Sorrenti et al. [18], anhydrous tacrine hydrochloride shows a melting peak at 284.4 °C. The thermograms of C/P/T(1:1)Lyo and C/P/T(1:9)Lyo showed an endothermic peak at 118.4 and 117.3 °C, respectively. No peaks were observed in the DSC analysis of C/P/T(9:1)SD. Instead, the others spray-dried microparticles C/P/T(1:1)SD and C/P/T(1:9)SD showed an endothermic peak at 182.6 and 177.5 °C, respectively.

Water uptake ability

Figure 5 shows the results of water uptake studies of loaded microparticles under 90 % relative humidity and 37 °C. Water uptake ability was lower for lyophilized microparticles (C/P/T(1:9)Lyo and C/P/T(1:1)Lyo). Moreover, higher amount of pectin in the complexes provided greater water uptake for all the samples analysed.

Mucoadhesion properties

Figure 6 shows mucoadhesive properties of the loaded microparticles studied using the PAS colorimetric method. As can be seen, mucoadhesive properties depend on preparative technique and on complexes composition. In fact, spray-dried microparticles showed higher mucoadhesive ability than lyophilized samples. Moreover, complexes containing high pectin amounts showed greater mucoadhesion capacity.

Release studies

Release profiles from loaded microparticles at pH 5.5 are shown in Fig. 7. Higher drug release can be observed for lyophilized microparticles. A decrease in drug release can be observed in the spray-dried microparticles containing higher pectin amounts.

Permeation studies across sheep nasal mucosa

Figure 8 shows that C/P/T(1:1)Lyo favoured the best drug permeation with a percentage of permeated tacrine hydrochloride approaching 100 % in 3 h. At the same time, C/P/T(1:1)SD and C/P/T(9:1)SD allowed great drug permeation. The presence of high amount of pectin in the spray-dried and lyophilized microparticles (C/P/T(1:9)SD C/P/T(1:9)Lyo) provided a sustained drug permeation.

Discussion

Powder-based formulations are widely studied for nasal drug delivery due to their ability to prolong the intimate contact with the nasal mucosa and thus increasing absorption and bioavailability [19]. One of the most important anatomical region of the nose for drug absorption is the respiratory region, which is richly vascularised and contains three nasal turbinates. The deposition of the particles in this region depends on the microsystems size. In this work, we used two different preparative approaches based on spray-drying technique [20]: direct spray-drying of excipients/drug solutions or spray-drying of excipients followed by lyophilyzation in the presence of drug. Yields of production of spray-dried chitosan microparticles are in general quite low [20, 21]. The microparticles prepared using chitosan/pectin complexes in the presence of drug showed nice yield values in the range of 45–65 % (Table 1). The two different loading methods allowed to obtain particles with different size. In particular, lyophilized microparticles presented the best size for nasal administration having a mean diameter ranging from 9 to 19 μm (Table 2). As known, the choice of a suitable actuator influences the plume ability to impact and cover nasal mucosa, but in general, particles with smaller diameter favour a fluffier and larger plume, which can move slowly and cover a higher mucosa surface area [22]. Moreover, improved nasal distribution and limited deposition in the lower airways of smaller particles can be prevent by novel nasal delivery concept such as bi-directional nasal delivery [23]. In this view, particles with 2–5 μm of diameter (spray-dried microparticles) could be evaluated for nasal application (Table 2).

As expected, different preparative methods also influence drug loading capacity. In particular, drug loading efficiency was higher for lyophilized powders (approached 90 %), being lyophilization assurance of minimal loss of drug (Table 1).

As microparticles enter in contact with water molecules, hydration occurs. Figure 5 shows that water uptake ability was particularly high for spray-dried samples, accordingly the lower dimensions of the particles. Moreover, at the experimental conditions (pH 6.0), pectin (pKa 4.0) was highly negative charged and chitosan (pKa 6.3) presented low charge density [24], allowing greater entry of water for the complexes presenting high amount of pectin.

Another important characteristics for nasal powders is their mucoadhesion capacity. In fact, microparticles formed by adhesive materials are retained in the nasal cavity with half-life clearance of 3 h or longer, compared with 15–20 min for usual formulations [25]. Chitosan/pectin microparticles prepared in this study, presented good mucoadhesion ability (Fig. 6). In particular, spray-dried particles showed higher mucoadhesive ability accordingly to their lower dimensions and higher surface to volume ratio, guaranteeing an intimate contact with the mucus layer. Again, at the experimental conditions (mucin solution, pH 5.5) pectin and sialic acid (pKa 2.6) presented negative charges [26], while chitosan chains were positive charged. Despite these conditions which favour chitosan interaction with mucin, greater amount of pectin in the complexes allowed higher mucoadhesion. This behaviour can be explained due to the different water uptake ability of pectin and chitosan, thus providing a more or less efficient chain mobility and physical entanglement with mucus, respectively [27].

Drug release from microparticles (Fig. 7) was higher for lyophilized samples than spray-dried samples. The higher drug availability could be attributed to a lower interaction of chitosan/pectin complex with tacrine hydrochloride. In fact, as can be seen in Fig. 3, C/P/T(1:1)Lyo and C/P/T(1:9)Lyo contained free tacrine hydrochloride in its anhydrous crystalline form. For C/P/T(1:1)SD and C/P/T(1:9)SD, crystalline peaks could not be related to known crystalline forms of tacrine hydrochloride or tacrine-free base, suggesting a possible interaction of the drug with pectin in the complex. This interaction was confirmed also by the appearance, in DSC profiles (Fig. 4), of endothermic peaks at 182.6 and 177.5 °C for C/P/T(1:1)SD e C/P/T(1:9)SD, respectively, corresponding to melting of a new crystalline form of tacrine, different from anhydrous tacrine hydrochloride (T m = 284.4 °C). Finally, C/P/T(9:1)SD presented an intermediate behaviour accordingly to the simultaneous presence of amorphous and crystalline tacrine hydrochloride.

When microparticles are placed on nasal mucosal membrane, chitosan/pectin complexes interactions with the biological substrate can strongly influenced drug permeation. In fact, despite all the formulations allowed 100 % of drug release in 1 h (Fig. 7), drug diffusion through sheep nasal mucosa was differently modulated by the different polyelectrolyte complexes. Particularly for the lyophilized samples, the presence of low amount of chitosan in the complex (C/P/T(1:9)Lyo) drastically reduced drug permeation (Fig. 8). This behaviour can be observed also for the spray-dried samples and can be attributed to chitosan ability to enhance drug permeation through mucosal membranes [28]. Moreover, as observed for release studies, the interaction of tacrine with chitosan/pectin complex (spray-dried samples) determined a lower permeation.

This work has contributed to the understanding of chitosan/pectin polyelectrolyte complex formation and interaction with tacrine hydrochloride. The results of this study indicated that chitosan/pectin polyelectrolyte complexes can be employed for the formulation of mucoadhesive microparticles with different functional properties. The selection of suitable chitosan/pectin molar ratio and the technological approach employed for drug loading, allowed to modulate water uptake and mucoadhesion behaviour, as well as tacrine hydrochloride permeation at the administration site. Naturally, after microparticles administration, physiological responses (increased mucous production and blinking of the vibrissae and alteration of rheological parameters of the mucus) can affect in vivo residence time of the applied formulation and consequently drug bioavailability. Moreover, drug bioavailability can be differently influenced by the different mucoadhesion ability of spray-dried and lyophilized microparticles. In fact, the effective residence time of the formulation determines a more or less complete drug permeation. For all these reasons, this work will be furthered by performing rheological studies on microparticles mucoadhesivity in simulated physiological conditions and intranasal absorption studies in animal models.

References

Maurya SK, Pathak K, Bali V. Therapeutic potential of mucoadhesive drug delivery systems—an updated patent review. Recent Patents Drug Deliv Formul. 2010;4(3):256–65. Review.

Alhalaweh A, Vilinska A, Gavini E, Rassu G, Velaga SP. Surface thermodynamics of mucoadhesive dry powder formulation of zolmitriptan. AAPS Pharm Sci Tech. 2011;12(4):1186–92.

Gavini E, Rassu G, Ferraro L, Generosi A, Rau JV, Brunetti A, et al. Influence of chitosan glutamate on the in vivo intranasal absorption of rokitamycin from microspheres. J Pharm Sci. 2010. doi:10.1002/jps.22382.

Bowey K, Neufeld RJ. Systemic and mucosal delivery of drugs within polymeric microparticles produced by spray drying. BioDrugs. 2010;24(6):359–77. Review.

Sollohub K, Cal K. Spray drying technique: II. Current applications in pharmaceutical technology. J Pharm Sci. 2010;99(2):587–97. Review.

Illum L. Nasal drug delivery—recent developments and future prospects. J Control Release. 2012. doi:10.1016/j.jconrel.2012.01.024.

Costantino HR, Illum L, Brandt G, Johnson PH, Quay SC. Intranasal delivery: physicochemical and therapeutic aspects. Int J Pharm. 2007;337(1-2):1–24. Review.

Schroeter JD, Kimbell JS, Asgharian B. Analysis of particle deposition in the turbinate and olfactory region using a human nasal computational fluid dynamic model. J Aerosol Med. 2006;19:301–13.

Merkus FW, Verhoef JC, Schipper NG, Marttin E. Nasal mucociliary clearance as a factor for nasal drug delivery. Adv Drug Deliv Rev. 1998;29:13–38.

Callens C, Ceulemans J, Ludwig A, Foreman P, Remon JP. Rheological study on mucoadhesivity of some nasal powder formulations. Eur J Pharm Biopharm. 2003;55(3):323–8.

Hägerström H, Paulsson M, Edsman K. Evaluation of mucoadhesion for two polyelectrolyte gels in simulated physiological conditions using a rheological method. Eur J Pharm Biopharm. 2000;9(3):301–9.

Lai SK, Wang Y-Y, Wirtz D, Hanes J. Micro- and macrorheology of mucus. Adv Drug Deliv Rev. 2009;61(2):86–100.

Morris G, Kök S, Harding S, Adams G. Polysaccharide drug delivery systems based on pectin and chitosan. Biotechnol Genet Eng Rev. 2010;27:257–84. Review.

Hamman JH. Chitosan based polyelectrolyte complexes as potential carrier materials in drug delivery systems. Mar Drugs. 2010;8(4):1305–22. Review.

Freeman SE, Dawson RM. Tacrine: a pharmacological review. Prog Neurobiol. 1991;36:257–77.

Ping H, Davis SS, Illum L. In vitro evaluation of the mucoadhesive properties of chitosan microspheres. Int J Pharm. 1998;166:75–88.

Luppi B, Bigucci F, Abruzzo A, Corace G, Cerchiara T, Zecchi V. Freeze-dried chitosan/pectin nasal inserts for antipsychotic drug delivery. Eur J Pharm Biopharm. 2010;75:381–7.

Sorrenti M, Catenacci L, Bruni G, Luppi B, Bigucci F, Bettinetti G. Solid-state characterization of tacrine hydrochloride. J Pharm Biomed Anal. 2012;63:53–61.

Björk E, Isaksson U, Edman P, Artursson P. Starch microspheres induce pulsatile delivery of drugs and peptides across the epithelial barrier by reversible separation of the tight junctions. J Drug Target. 1995;2(6):501–7.

Cal K, Sollohub K. Spray drying technique. I: Hardware and process parameters. J Pharm Sci. 2010;99(2):575–86. Review.

Gavini E, Hegge AB, Rassu G, Sanna V, Testa C, Pirisino G, et al. Nasal administration of carbamazepine using chitosan microspheres: in vitro/in vivo studies. Int J Pharm. 2006;307(1):9–15.

Colombo P, Buttini F, Sonvico F, Colombo G, Russo P, Scatturin A, et al. Respiratory drug delivery. Proc Int Sch Adv Mater Sci Technol. 2005; 91–110.

Djupesland PG, Skretting A, Winderen M, Holand T. Bi-directional nasal delivery of aerosols can prevent lung deposition. J Aerosol Med. 2004;17(3):249–59.

Bigucci F, Luppi B, Monaco L, Cerchiara T, Zecchi V. Pectin-based microspheres for colon-specific delivery of vancomycin. J Pharm Pharmacol. 2009;61(1):41–6.

Luppi B, Bigucci F, Cerchiara T, Zecchi V. Chitosan-based hydrogels for nasal drug delivery: from inserts to nanoparticles. Expert Opin Drug Deliv. 2010;7(7):811–28.

Peppas NA, Sahlin JJ. Hydrogels as mucoadhesive and bioadhesive materials: a review. Biomaterials. 1996;17:1553–61.

Peppas NA, Buri PA. Surface, interfacial and molecular aspects of polymer bioadhesion on soft tissues. J Control Release. 1985;2:257–75.

Davis SS, Illum L. Absorption enhancers for nasal drug delivery. Clin Pharmacokinet. 2003;42(13):1107–28. Review.

Acknowledgments

This work was supported by a grant received from the Fondazione Cassa di Risparmio di Imola. The authors would like to thank Giulia Nerina Nardone for her contribution to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saladini, B., Bigucci, F., Cerchiara, T. et al. Microparticles based on chitosan/pectin polyelectrolyte complexes for nasal delivery of tacrine hydrochloride. Drug Deliv. and Transl. Res. 3, 33–41 (2013). https://doi.org/10.1007/s13346-012-0086-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-012-0086-y