Abstract

In this study, a small vascular graft based on polyurethane (PU) blended with chitosan (Ch) nanoparticles was fabricated using electrospinning technique. Initially, the chitosan nanoparticles were synthesized using ionic gelation method. UV–Vis spectrophotometer confirmed the presence of synthesized Ch nanoparticles by exhibiting absorption peak at 288 nm and the Fourier-transform infrared spectroscopy (FTIR) analysis confirmed the existence of the chitosan. Further, the synthesized Ch nanoparticles showed size diameter in the range of 134 ± 58 nm as measured using ImageJ. In the electrospun PU/chitosan graft, the fiber diameter and pore size diameter was found to be reduced compared to the pure PU owing to incorporation of chitosan into PU matrix. The FTIR spectrum revealed the presence of chitosan in the prepared nanocomposite membrane by the formation of the hydrogen bond and peak shift of CH and NH stretching. Moreover, the contact angle measurements revealed that the prepared graft showed decreased contact angle indicating hydrophilic nature compared to the pristine PU. The cytocompatibility studies revealed the non-toxic behavior of the fabricated graft. Hence, the prepared graft exhibiting significant physiochemical and non-toxic properties may be a plausible candidate for cardiovascular graft applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cardiovascular diseases is considered as a threat to the health of mankind and it claims 17 million lives each year. Coronary heart disease (CHD) which causes the blockage of the coronary arteries and it accounts almost 50% deaths associated with CVD.12,25,29 So there is demand for artificial vascular graft in cardiovascular transplantation to recover from the CVD. The tissue engineered vascular grafts have gained a huge attention toward the fabrication of small arterial substitutes incorporated with endothelial and smooth muscle cells.3,4,10 But the tissue engineered vascular graft possess certain limitations like poor porosity and low infiltrating of cells into the scaffold. Recently, electrospinning technology overcomes the limitations of the tissue engineered graft by producing fibrous matrices in nanoscale dimension which can be substitute for vascular grafts.18 Electrospinning technique is most versatile and cost effective method which applies high voltage to polymer melts which produces the nanofibers at the collector end.23 The nanofibers fabricated thorough electrospun technique were reported to possess high surface area which supports the cell adhesion and high porosity to facilitate nutrients transport and also for waste removal.19 In this research, the tecoflex EG80A polyurethane which is a poly-ether based medical grade PU was used in fabricating the scaffold. Polyurethane is widely used in making tissue engineered scaffolds because the fabrication of nanofibers from PU is easy and also possess biodegradable nature, good barrier properties, oxygen permeability and mechanical properties.17,22,28,34

However, the synthetic polymers provide sufficient mechanical strength but they lack in bio-functionalization due to their hydrophobic nature. So, the combination of synthetic and natural polymer in making the scaffold was gained a huge attention now-a-days.8 Natural polymers provides many advantages like hydrophilicity, cellular affinity and often degrades which gives the spaces for cell migration and proliferation.21 In this work, chitosan a natural polymer was used to enhance the properties of the developed graft. Chitosan (Ch) nanoparticles is widely used in tissue engineering applications such as bone, cartilage and skin due to its hydrophilicity and also it renders sufficient mechanical strength to the product developed.5,6,9,20,26 In the work, a small-diameter vascular graft was fabricated based on PU and Ch nanoparticles by the co-electrospinning technique. Further, the fabricated vascular graft was subjected to physiochemical characterizations.

Materials and Methods

Materials

Tecoflex EG-80A medical-grade thermoplastic polyurethane (PU) was imported from LubriZol. The solvents N,N-dimethylformamide (DMF) was supplied from Merck Millipore, Germany. Glacial acetic acid (100%) was obtained from Darmstadt, Germany. Chitosan powder and sodium tripolyphosphate (TPP) was from Sigma-Aldrich, Canada.

Synthesis of Chitosan (Ch) Nanoparticle

In this study, Ch nanoparticles were synthesized using ionic gelation method. Initially, 1% (v/v) of acetic acid solution was prepared by adding 1 mL of glacial acetic acid into 100 mL of distilled water. Then, the chitosan solution with 0.1 wt% was obtained by adding 20 mg of chitosan powder into 20 mL of prepared 1% acetic acid solution. Similarly, the sodium tripolyphosphate (TPP) solution was prepared for two different weight concentrations (0.1 and 0.2 wt%) by diluting 20 mg and 40 mg of sodium tripolyphosphate (TPP) into 20 mL of distilled water. Finally, two different concentration of Ch nanoparticles were obtained by pipetting 4 mL of prepared sodium tripolyphosphate (TPP) solution into 10 mL of prepared chitosan solution as shown in Table 1. Then, the prepared Ch nanoparticles solution were centrifuged at 12,500 rpm for 25 min. Finally, the obtained Ch nanoparticles were dried under oven at temperature 100 °C for 4 min with intervals until crystal white powder was formed.

Preparation of Composite Solution

The homogeneous solution PU solution with concentration of 8% (w/v) was obtained by dissolving 800 mg of PU beads in 10 mL of DMF and stirred for 24 h at room temperature. Similarly, the homogeneous solution of Ch solution with 2% (w/w) was prepared by suspending 50 mg of Ch nanoparticles in 2.5 mL of DMF and stirred for 24 h. Finally, PU/chitosan solution with ratio of 8:2 (v/v) and 7:3 (v/v) was prepared by slowly adding the prepared Ch homogeneous solution into the PU solution and stirred for 1 h maximum.

Fabrication of PU and PU/Chitosan Nanocomposites

To fabricate electrospun PU and PU/chitosan membranes, the prepared solution was loaded into a 10 mL plastic syringe attached with 18-G stainless steel needle and fitted to the syringe pump (SP20, NFiber). Then the nanofibers were obtained by applying high voltage to the steel needle was supplied using NFiber high voltage unit. The fabricated polymer was collected on a rotating stainless steel rod with diameter of 0.5 cm at 800 rpm and the collector distance was maintained at 15 cm. For the both PU and PU/chitosan nanocomposites, the flow rate was maintained at 0.50 mL/h with an applied voltage of 10.5 kV. Then the electrospun membranes were carefully detached from the collector and dried under vacuum at room to remove any residual DMF content.

Physicochemical Characterization

UV–Vis Spectrophotometric Absorption

The synthesized chitosan nanoparticles prepared using ionic gelation method was investigated through GENESYS 10S UV–Vis Spectrophotometer to confirm the formation of Ch nanoparticles. To begin, the obtained Ch nanoparticles were diluted with distilled water for 2 h. After, the reaction mixture with 1 mL was pipetted into a 1 cm length plastic cuvette and was scans were performed in the wavelength of 200–500 nm at a resolution of 1 nm. The absorption rate and the peak wave was recorded and then corrected base line using Spekwin software to calculate the wavelength of the samples.

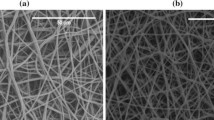

Scanning Electron Microscopy (SEM)

The Hitachi Table Top Microscope (TM3000) was used to investigate the distribution and surface morphology of the fabricated PU and PU/chitosan nanofibers. The electrospun nanofibers were gold plated at 20 mA for 2 min and micrographs was taken at an accelerated voltage of 10 kV with different magnifications. Using Image J software, the fiber diameter was measured at least 50 points randomly in the captured image and the average fiber diameter for both samples were calculated.

Fourier Transform Infrared Spectroscopy (FTIR)

The IR spectrum of the prepared PU and PU/chitosan membranes was obtained through NICOLET IS5 spectrometer unit. For recording the IR spectra of PU and PU/chitosan nanocomposites, a small piece of sample membrane was cut out and placed on the sensor. Meanwhile, the IR spectra of Ch was obtained by placing a small amount of nanoparticles on the sensor. Then, the each samples were recorded over the wavelength of 400–4000 cm−1 at the resolution of 4 cm−1 to investigate the chemical compositions. The obtained IR spectra was base line corrected using Spekwin 32 software to identify the peak shift and differences.

Porosity Diameter Measurement

The Image J software was used to measure the pore size diameter in prepared PU and PU/chitosan composite membrane by measuring 50 points randomly in the scanned SEM image and the graphical representation of pore size distribution was prepared through excel sheet.

Contact Angle Measurement

The VCA Optima contact angle measurement unit was used to calculate for the wettability of PU and the PU/chitosan membranes. Initially, the fabricated membranes were cut into small square shape and placed on the testing stage. Then, syringe loaded with distilled water was fitted to the equipment and a droplet with size of 1 μL was formed and carefully placed on the sample sheets. The static image of the contact angle were captured using a high- resolution video camera after 10 s of droplet deposition. The degree of the angle formed was analyzed using computer integrated software. The experiment was repeated for three separate trials to calculate for the mean contact angle.

Cytocompatibility Studies

HDF cells (Human Skin Fibroblast Cells 1184, ECACC, UK) were cultured and maintained at 37 °C in 5% CO2 in a Dulbecco’s modified Eagle medium supplemented with 10% fetal bovine serum and the medium was refreshed after every 3 days. For in vitro culture adhesion and morphology studies, the fabricated membranes were cut into small diameter circles and placed in the 24 well plates. After, the scaffolds were disinfected by soaking them in 75% alcohol for 3 h and then washed by phosphate buffered saline (PBS). Then, the cultured HDF cells were trypsinized, counted, and seeded on the electrospun membranes at a density of 10 × 103 cells/cm2 and placed in the CO2 incubator. The cell viability was determined after 3 days culture. The nanofibrous scaffolds were added with 20% of MTS (3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-sulfophenyl)-2H tetrazolium, inner salt) and incubated for 4 h. After 4 h, the medium was retrieved and absorbance was recorded at 490 nm in a spectrophotometric plate reader to determine the cell counts in the electrospun membranes.

Statistical Analysis

All experiments involved in this study was carried out thrice independently. One way ANOVA followed by dunnett post hoc test was utilized to analyze the statistical significance (p < 0.05). The results attained from all experiments are expressed as mean ± SD and for qualitative experiments, a representative of three images is indicated.

Results and Discussion

UV/VIS Spectrum of Synthesized Ch Nanoparticles

Figure 1 depicts the UV/VIS absorption spectrum of Ch nanoparticles obtained from the different concentrations (Set A and Set B). From results obtained, it was observed that the Set A showed absorption peak at 288 nm while the Set B exhibited absorption peak at 289 nm respectively. Sathiyabama et al. synthesized chitosan nanoparticles which exhibited the absorption peak at 285 nm and confirmed the formation of the chitosan nanoparticles.27 In our study, the absorption peaks was measured at similar range which correlates with their findings and confirmed the formation of Ch nanoparticles.

Morphology of Synthesized Ch Nanoparticles

Figures 2a and 2b shows the SEM images of synthesized Ch nanoparticles. The average diameter of Set A was found to be 143 ± 68 nm and for Set B it was observed to be 124 ± 47 nm. The corresponding particle size distribution curves for the synthesized nanoparticles were shown in Figs. 2c and 2d. The obtained results showed that the nanoparticles had average diameter around 134 ± 58 nm with spherical shape and scattered distribution. The particle size diameter was found to be decreased with the increase in the concentration of the TPP. Esquivel et al. synthesized chitosan nanoparticles using ionic gelation method. It was observed that the diameter of synthesized chitosan nanoparticles was observed to be in the range of 120–150 nm. Further, the increase in the concentration of TPP resulted in the decrease in the particle size diameter7 and the obtained results correlates with their findings. In the another study, Sathiyabama et al. reported that the synthesized chitosan nanoparticles which exhibited the absorption peak at 285 nm and showed nanoparticles in the range of 10 and 30 nm.27 In this study, size of the synthesized chitosan nanoparticles (134 ± 58 nm) exhibited absorption peak in the similar range but the calculated particle size using Image J does not correlates with the above findings. The reason for the increase in the chitosan nanoparticle size was might be due to the agglomeration masses of the particles.7,15

Infrared Spectrum of Synthesized Ch Nanoparticles

Figure 3 represents the FTIR spectrum of synthesized Ch nanoparticles. The Ch nanoparticles exhibited dominant peak at 3327, 2943, 2854, 1731.42, 1541.15, 1412.79, 1328.63, 1154.23, 1090.34, 1036.23 and 852.01 cm−1 respectively. The broad peak at 3327 cm−1 indicates the amine N–H symmetrical vibration and the sharp peaks at 2943 and 2854 cm−1 represents the CH stretch vibrations. The peak observed at 1731.42 cm−1 indicates the amide I group and the vibrations of CO group were seen at peak at 1090.34, 1036.23 cm−1 respectively. The peak at 1541.15 cm−1 indicates the amino group of chitosan and the peak at 1412.79 and 1328.63 cm−1 indicates the CH3 symmetrical deformation mode. The peaks at 1154.23 and 852.01 cm−1 observed indicates the saccharide structure of chitosan.1,2 In Set B, the characteristics peaks were observed at 3327, 2943, 2854, 1731.35, 1548.54, 1409.95, 1328.23, 1154.09, 1090.12, 1039.22, and 811.94 cm−1. It was observed that the peak at 1541.15 cm−1 corresponding to amino group in set A was shifted to 1548.54 cm−1 in set B which clearly indicates the decrease in the particle size and correlates with the SEM observations.

Characterization of Electrospun Nanofiber

Morphology of Electrospun PU and Composite Nanofibers

The morphology of electrospun PU and PU/chitosan nanofibers [8:2 (v/v) and 7:3 (v/v)] were shown in SEM images as indicated in Figs. 4a–4c. It was observed that the incorporation of Ch nanoparticles into the PU matrix reduced the fiber diameter. It was observed that the fiber diameter of PU was found to be 995 ± 112 nm and for PU/chitosan nanofibers electrospun at ratio 8:2 (v/v) and 7:3 (v/v) was found to be 848 ± 192 nm and 493 ± 186 nm respectively as shown in Figs. 5a–5c. Ishii et al. utilized polycaprolactone (PCL) for fabricating the vascular graft and reported that the smaller fiber diameters favors enhanced cell attachment and cell proliferation owing to its high specific area and porosity.11 Our developed scaffold exhibited smaller fiber diameters which might favors the enhanced cell attachment and cell proliferation and suitable for the vascular graft applications.

Infrared Spectrum of Electrospun PU and Composite Nanofibers

Figure 6 shows the FTIR spectra of electrospun pure PU and PU/chitosan nanofibers (8:2 (v/v) and 7:3 (v/v)). The pure PU exhibited peaks at 3322.47, 2939.11, 2854.16, 1728.98, 1702.19, 1530.29, 1413.24, 1368.17, 1104. 21 cm−1 respectively. A broad peak observed at 3322.47 cm−1 represents the N–H symmetrical vibration and the peak at 1530.29 cm−1 indicates the vibrations of NH group. The peaks seen at 2939.11 and 2854.16 cm−1 was attributed to the CH2 stretch and CH stretch vibrations and the vibrations of CH was observed 1412. 79 and 1368.17 cm−1 respectively. The sharp peaks observed at 1728. 98 and 1702.19 cm−1 indicates the CO group and the vibrations of CO group were seen at 1104.21 cm−1.14,16

The electrospun PU/chitosan membrane (8:2 v/v) showed peaks at 3330.13, 2941.56, 2872.60, 1729.05, 1702.15, 1530.40, 1413.30, 1368.82, and 1104.45 cm−1 respectively. Similarly in electrospun PU/chitosan membrane (7:3 v/v), the sharp peaks were observed at 3339.35, 2945.86, 2872.89, 1729.23, 1702.11, 1530.49, 1413.31, 1368.99, and 1104.30 cm−1 respectively. It was observed that the there was no formation of new peaks but the intensity of the PU peak was increased due to the formation of the hydrogen bond.32 Further, it was observed that the peak at 3322.47 cm−1 corresponding to NH group in pure PU was shifted to 3330.13 and 3339.35 cm−1 in 8:2 (v/v) and 7:3 (v/v) PU/chitosan nanofibers. Moreover, the peak at 2939.11 cm−1 in pure PU corresponds to CH group was shifted to 2941.56 and 2945.86 cm−1 in 8:2 (v/v) and 7:3 (v/v) PU/chitosan nanofibers respectively.30 The shift in peak clearly represents the interaction between the PU with the chitosan nanoparticles and the presence of Ch nanoparticles in the PU matrix.

Porosity of Electrospun PU and Composite Nanofibers

Figures 7a–7c depicts the pore size measurement of electrospun pure PU and PU/chitosan nanofibers [8:2 (v/v) and 7:3 (v/v)]. It was observed that the pore size diameter of the electrospun PU/chitosan nanofibers was found to be reduced compared to pure PU. It was observed that the pore size diameter of pure PU was found to be 1345 ± 149 nm, while for PU/chitosan nanofibers [8:2 (v/v) and 7:3 (v/v)], the pore size was observed to be 1299 ± 162 and 1191 ± 129 nm respectively. The obtained results clearly indicated that the electrospun PU/chitosan nanofibers exhibited reduced pore size diameter compared to control. Narayan et al. studied the effect of pore size on endothelial cell growth in poly lactic acid (PLLA) polymer. It was reported that the small pore size diameter showed endothelial cell growth compared to larger pore size diameter.24 Hence, in our developed nanocomposites, the pore size diameter was found to be decreased and it might favors the better endothelial cell growth.

Contact Angles of Electrospun PU and Composite Nanofibers

The contact angle measurement indicates the wettability of the electrospun nanofiber as indicated in Table 2. It was observed that the PU/chitosan nanofibers exhibited hydrophilic nature compared to pristine PU. The mean contact of pure PU was found to be 92.73 ± 1.42° and for PU/chitosan nanofibers electrospun at ratio 8:2 (v/v) and 7:3 (v/v) was found to be 72.00 ± 3.46° and 47.80 ± 2.74° respectively. Wang et al. prepared scaffold for vascular tissue engineering based on PU cross linked with PEGMA. It was observed that the incorporation of PEGMA into PU matrix resulted in the hydrophilic behavior. It was observed that the fabricated PU/PEGMA membranes with contact in the range of 55°–75° showed enhanced adhesion and growth of HUVECs. Further, the scaffolds with contact angle lower than this range showed decreased proliferation rate of HUVECs which might due to very hydrophilic nature. The increased hydrophilicity caused reduction in the absorption of protein and accordingly delayed the adhesion and proliferation of the HUVECs.33 Hence, the contact angle of electrospun PU/chitosan nanofibers at ratio 8:2 (v/v) was observed to within the limits and might be suitable for the vascular graft applications.

Cytocompatibility of Electrospun PU and Composite Nanofibers

Figure 8 depicts the cell attachment and proliferation percent of electrospun pure PU and PU/chitosan nanofibers [8:2 (v/v) and 7:3 (v/v)]. The results indicated that the fabricated membranes were able to facilitate the HDF cell proliferation without any toxic effects. It was observed from the MTS assay that the fabricated membranes exhibited enhanced proliferation of HDF cells than the control plates. Further, the electrospun PU/chitosan membranes showed enhanced attachment and proliferation percent of HDF cells than the pristine PU membrane. The cell attachment and proliferation percent of pure PU was observed to be 141.9 ± 2.264 and for PU/chitosan nanofibers electrospun at ratio 8:2 (v/v) and 7:3 (v/v) were found to be 181.8 ± 2.611 and 180.8 ± 3.846 respectively. The results clearly indicates the presence of chitosan in the PU matrix induced enhanced proliferation of HDF cells significantly [*mean differences were significant compared with pure PU (p < 0.05)]. Unnithan et al. fabricated polyurethane wound dressing blended with the emu oil. It was reported that the blending of emu oil into the PU matrix resulted in the reduction of the fiber diameter and favored improved fibroblast cell adhesion and proliferation.31 Since, our fabricated membranes rendered smaller diameter than the pristine PU which might have favored the enhanced proliferation of HDF cells. Jang et al. fabricated electrospun small diameter vascular graft based on poly (l-lactide-co-ε-caprolactone) seeded with fibroblast cells. It was reported that the fibroblast cells located in adventitia of native blood vessel which play a vital role in healing process, remodeling of the tissue repair and producing interstitial collagens, fibronectins, and other matrix components. Moreover, fibroblast cells were reported to capable of producing and secreting angiogenic factors and growth factors such as VEGFs and FGFs which facilitate the cell viability and function without genetic manipulation.13 Hence in our study, the fabricated membranes showed enhanced cell attachment and proliferation of the HDF cells which might be suitable for the vascular graft applications.

Conclusion

The vascular graft based on PU blended Ch nanoparticles was fabricated successfully using electrospinning technique. The synthesized Ch nanoparticles obtained through ionic gelation method exhibited absorption peak in the range of 285–300 nm and particle size diameter in the range of 134 ± 58 nm. Further, the FTIR analysis confirmed the existence of the chitosan. The incorporation of Ch nanoparticles reduced the fiber and pore size diameter compared to pristine PU. The existence of chitosan in PU matrix was identified by peak shifting of CH and NH stretching as revealed in the FTIR. Further, the addition of Ch nanoparticles into the PU matrix decreased the contact angle indicating hydrophilic nature of the prepared vascular graft. Moreover, the cytocompatibility studies revealed the non-toxic behavior of the fabricated graft. Hence, the developed vascular graft with significant physico-chemical and non-toxic characteristics might be a potential candidate in overcoming cardiovascular diseases. However, its mechanical properties have to be investigated in detail to further promote its candidacy.

References

Alhosseini, S. N., F. Moztarzadeh, M. Mozafari, S. Asgari, M. Dodel, A. Samadikuchaksaraei, S. Kargozar, and N. Jalali. Synthesis and characterization of electrospun polyvinyl alcohol nanofibrous scaffolds modified by blending with chitosan for neural tissue engineering. Int. J. Nanomed. 7:25, 2012.

Anicuta, S. G., L. Dobre, M. Stroescu, and I. Jipa. Fourier transform infrared (FTIR) spectroscopy for characterization of antimicrobial films containing chitosan. Analele Universită Ńii din Oradea Fascicula: Ecotoxicologie, Zootehnie şi Tehnologii de Industrie Alimentară 1234–1240, 2010.

Badylak, S. F., G. C. Lantz, A. Coffey, and L. A. Geddes. Small intestinal submucosa as a large diameter vascular graft in the dog. J. Surg. Res. 47:74–80, 1989.

Berger, K., L. R. Sauvage, A. M. Rao, and S. J. Wood. Healing of arterial prostheses in man: its incompleteness. Ann. Surg. 175(1):118, 1972.

Cooper, A., N. Bhattarai, and M. Zhang. Fabrication and cellular compatibility of aligned chitosan–PCL fibers for nerve tissue regeneration. Carbohydr. Polym. 85(1):149–156, 2011.

Cooper, A., S. Jana, N. Bhattarai, and M. Zhang. Aligned chitosan-based nanofibers for enhanced myogenesis. J. Mater. Chem. 20:8904–8911, 2010.

Esquivel, R., J. Juárez, M. Almada, J. Ibarra, and M. A. Valdez. Synthesis and characterization of new thiolated chitosan nanoparticles obtained by ionic gelation method. Int. J. Polym. Sci. 2015. https://doi.org/10.1155/2015/502058.

Garg, K., S. A. Sell, P. Madurantakam, and G. L. Bowlin. Angiogenic potential of human macrophages on electrospun bioresorbable vascular grafts. Biomed. Mater. 4(3):031001, 2009.

Hong, S., and G. Kim. Fabrication of electrospun polycaprolactone biocomposites reinforced with chitosan for the proliferation of mesenchymal stem cells. Carbohydr. Polym. 83(2):940–946, 2011.

Huynh, T., G. Abraham, J. Murray, K. Brockbank, P. O. Hagen, and S. Sullivan. Remodeling of an acellular collagen graft into a physiologically responsive neovessel. Nat. Biotechnol. 17(11):1083, 1999.

Ishii, O., M. Shin, T. Sueda, and J. P. Vacanti. In vitro tissue engineering of a cardiac graft using a degradable scaffold with an extracellular matrix-like topography. J. Thorac. Cardiovasc. Surg. 130:1358–1363, 2005.

Jaganathan, S. K., M. P. Mani, M. Ayyar, N. P. Krishnasamy, and G. Nageswaran. Blood compatibility and physicochemical assessment of novel nanocomposite comprising polyurethane and dietary carotino oil for cardiac tissue engineering applications. J. Appl. Polym. Sci. 2017. https://doi.org/10.1002/app.45691.

Jang, B. S., J. Y. Cheon, S. H. Kim, and W. H. Park. Small diameter vascular graft with fibroblast cells and electrospun poly (l-lactide-co-ε-caprolactone) scaffolds: cell matrix engineering. J. Biomater. Sci. Polym. Ed. 29:942–959, 2017.

Jia, L., M. P. Prabhakaran, X. Qin, and S. Ramakrishna. Guiding the orientation of smooth muscle cells on random and aligned polyurethane/collagen nanofibers. J. Biomater. Appl. 29:364–377, 2014.

Kamat, V., D. Bodas, and K. Paknikar. Chitosan nanoparticles synthesis caught in action using microdroplet reactions. Sci. Rep. 6:22260, 2016.

Kim, S. E., D. N. Heo, J. B. Lee, J. R. Kim, S. H. Park, S. H. Jeon, and I. K. Kwon. Electrospun gelatin/polyurethane blended nanofibers for wound healing. Biomed. Mater. 4(4):044106, 2009.

Kim, S., and S. Liu. Smart and biostable polyurethanes for long-term implants. ACS Biomater. Sci. Eng. 2018. https://doi.org/10.1021/acsbiomaterials.8b00301.

Lee, S. J., J. J. Yoo, G. J. Lim, A. Atala, and J. Stitzel. In vitro evaluation of electrospun nanofiber scaffolds for vascular graft application. J. Biomed. Mater. Res. A. 83(4):999–1008, 2007.

Loh, Q. L., and C. Choong. Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng. B 19(6):485–502, 2013.

Malheiro, V. N., S. G. Caridade, N. M. Alves, and J. F. Mano. New poly (ε-caprolactone)/chitosan blend fibers for tissue engineering applications. Acta Biomater. 6(2):418–428, 2010.

Mano, J. F., G. A. Silva, H. S. Azevedo, P. B. Malafaya, R. A. Sousa, S. S. Silva, L. F. Boesel, J. M. Oliveira, T. C. Santos, A. P. Marques, and N. M. Neves. Natural origin biodegradable systems in tissue engineering and regenerative medicine: present status and some moving trends. J. R. Soc. Interface 4(17):999–1030, 2007.

McCarthy, S. J., G. F. Meijs, N. Mitchell, P. A. Gunatillake, G. Heath, A. Brandwood, and K. Schindhelm. In-vivo degradation of polyurethanes: transmission-FTIR microscopic characterization of polyurethanes sectioned by cryomicrotomy. Biomaterials 18(21):1387–1409, 1997.

Mokhena, T. C., V. Jacobs, and A. S. Luyt. A review on electrospun bio-based polymers for water treatment. Polym. Lett. 9(10):839–880, 2015.

Narayan, D., and S. S. Venkatraman. Effect of pore size and interpore distance on endothelial cell growth on polymers. J. Biomed. Mater. Res. A 87(3):710–718, 2008.

Pektok, E., B. Nottelet, J. C. Tille, R. Gurny, A. Kalangos, M. Moeller, and B. H. Walpoth. Degradation and healing characteristics of small-diameter poly (e-caprolactone) vascular grafts in the rat systemic arterial circulation. Circulation 118(24):2563–2570, 2008.

Pillai, C. K., W. Paul, and C. P. Sharma. Chitin and chitosan polymers: chemistry, solubility and fiber formation. Prog. Polym. Sci. 34(7):641–678, 2009.

Sathiyabama, M., and R. Parthasarathy. Biological preparation of chitosan nanoparticles and its in vitro antifungal efficacy against some phytopathogenic fungi. Carbohydr. Polym. 151:321–325, 2016.

Subramaniam, A., and S. Sethuraman. Biomedical applications of nondegradable polymers. Nat. Synth. Biomed. Polym. 2014. https://doi.org/10.1016/B978-0-12-396983-5.00019-3.

Syazana, N., and I. Sukmana. Electrospun-based fibrous scaffold for cardiovascular engineering applications: a review. J. Eng. Appl. Sci. 11(7):4778–4781, 2006.

Tijing, L. D., M. T. Ruelo, A. Amarjargal, H. R. Pant, C. H. Park, D. W. Kim, and C. S. Kim. Antibacterial and superhydrophilic electrospun polyurethane nanocomposite fibers containing tourmaline nanoparticles. Chem. Eng. J. 197:41–48, 2012.

Unnithan, A. R., P. T. Pichiah, G. Gnanasekaran, K. Seenivasan, N. A. Barakat, Y. S. Cha, C. H. Jung, A. Shanmugam, and H. Y. Kim. Emu oil-based electrospun nanofibrous scaffolds for wound skin tissue engineering. Colloid Surf. A 415:454–460, 2012.

Unnithan, A. R., P. B. Tirupathi, G. Gnanasekaran, K. Seenivasan, A. M. B. Nasser, Y. S. Jung, and J. Che-Hun. Emu oil-based electrospun nanofibrous scaffolds for wound skin tissue engineering. Colloids Surf. A 415:454–460, 2012.

Wang, H., Y. Feng, B. An, W. Zhang, M. Sun, Z. Fang, W. Yuan, and M. Khan. Fabrication of PU/PEGMA crosslinked hybrid scaffolds by in situ UV photopolymerization favoring human endothelial cells growth for vascular tissue engineering. J. Mater. Sci. 23(6):1499–1510, 2012.

Wang, W., and C. Wang. Polyurethane for biomedical applications: a review of recent developments. Des. Manuf. Med. Device 2012. https://doi.org/10.1533/9781908818188.115.

Funding

This work was supported by the Ministry of Higher Education Malaysia with the Grant Number Q.J130000.2545.14H59.

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editors Craig Simmons and Ajit P. Yoganathan oversaw the review of this article.

Rights and permissions

About this article

Cite this article

Subramaniam, R., Mani, M.P. & Jaganathan, S.K. Fabrication and Testing of Electrospun Polyurethane Blended with Chitosan Nanoparticles for Vascular Graft Applications. Cardiovasc Eng Tech 9, 503–513 (2018). https://doi.org/10.1007/s13239-018-0357-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13239-018-0357-y