Abstract

The aim of this work is to develop an optimized enzymatic assisted extraction methodology to extract carotenoids and phenolic compounds from sunflower wastes (petals and florets) using natural hydrophobic green solvents. Several natural green hydrophobic solvents were used as well as natural hydrophobic eutectic solvents composed of d,l-menthol and different acids, with different hydrophobicity. The multi-enzyme complex Viscozyme® was used to disrupt the cell wall of petals and disc florets. The extracted carotenoids content into the hydrophobic phase was quantified using UV–Vis spectrophotometry and the carotenoids profile was studied using high-performance liquid and thin layer chromatography. The amount of total sugars in the aqueous phase was also analyzed using the dinitrosalicylic acid (DNS) method to infer about the enzymatic action in cell wall. Phenolic compounds also in the aqueous phase were analyzed by Folin Denis method. The eutectic solvent d,l-menthol:d,l-lactic acid (M:HLac) (1:2) was the best solvent for extraction of carotenoids from sunflower wastes, with 147 ppm of carotenoids extracted, in comparison to 115 ppm obtained with the standard solvent, n-hexane. In what concerns phenolic compounds, M:HLac was again better than the standard solvent. The use of the multi-enzyme complex Viscozyme® had different responses, depending on the solvent tested. For the green solvent M:HLac, the enzyme improved the carotenoids extraction, achieving 335 ppm of carotenoids in the extract. The role of enzyme, solvent, water and sunflower quantity in the carotenoid extraction was evaluated and optimized through a central composite rotatable design (CCRD), using the M:HLac as solvent. According to the analysis of CCRD, the most efficient extractions were carried out using more solvent and less raw material, whose best result reached 1449 mg carotenoids/100 g biomass ppm of carotenoids. This work emphasizes the possibility of developing more sustainable enzyme-assisted separation processes, through the substitution of toxic solvents with natural, environmentally friendly, solvents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sunflower (Helianthus annuus L., Compositae family) is an oilseed crop that shows high adaptability, resistance to dry periods and high grain/oil yield. Sunflower seeds are widely used in human nutrition due to their high content of lipids, proteins and bioactive compounds, including tannins, saponins, alkaloids, phenolic compounds and phytosterols. While seeds are harvested for oil production, florets and petals are usually discarded. Nevertheless, florets and petals have several uses, such as decorative elements, color and flavor agents in food industry and also in the preparation of herbal teas (Liang et al. 2013; Boriollo et al. 2017; Kumar and Gowda 2010; Mirzabe et al. 2018). Flower florets and petals contain carotenoids, unsaturated hydrocarbons with 40 carbon atoms, normally acting as organic hydrophobic pigments, antioxidants and photoprotectors in plants (Kishimoto et al. 2007; Farré et al. 2010, Rodriguez-Amaya 2001). Phenolic compounds, mainly hydroxycinnamic acid derivatives, are other antioxidant substances also present in petals and disc florets, playing a role in plant defense (Liang et al. 2013).

The antioxidant action of carotenoids protects human cells and tissues against damage caused by free radicals and singlet oxygen (Uenojo et al. 2007). Furthermore, carotenoids prevent atherosclerosis, cancer, cardiovascular, and degenerative diseases (Rojas-Garbanzo et al. 2017). According to a recent study, a diet rich in carotenoids showed a positive association with cognitive performance (Kesse-Guyot et al. 2013). Since these compounds are not synthesized by humans (Eggersdorfer and Wyss 2018), their consumption by ingestion of foods or supplements is of utmost importance not only for human wellbeing but also to prevent major public health diseases. For example, the regular consumption of lutein has been proven to prevent macular eye diseases, cataracts and also to increase the macular pigment (Bahrami et al. 2006). Other antioxidant compounds present are phenolic compounds, which besides their antioxidant activity also present other bioactivities such as antitumoral, antiviral, antimicrobial, anti-inflammatory, antimutagenic and antidiabetic (Ye et al. 2015).

Industrially, plant metabolites, as carotenoids and phenolic compounds, are extracted through well-established procedures using organic solvents, such as hexane, methanol and diethyl ether. However, these solvents are toxic and non-environmentally friendly (Saini and Keum 2018). The implementation of stricter legislation regarding the allowed solvents for pharmaceutical, cosmetic and food industries has been changing this scenario. Consequently, the use of less or non-toxic solvents, with low environmental impact, has recently been a subject of interest in the academia and industry. Additionally, the well-established health benefits afforded by carotenoids and phenolic compounds encourage the optimization of the extraction methodologies of these metabolites from plants. Yara-Varón et al. (2016) evaluated the use of green solvents [2-methyltetrahydrofuran (2-MeTHF)], dimethyl carbonate (DMC), cyclopentyl methyl ether (CPME), isopropyl alcohol (IPA) and ethyl acetate to extract carotenoids from carrots (Daucus carota). CPME, 2-MeTHF and ethyl acetate showed a great capacity to substitute the standard solvent, n-hexane, since CPME and 2-MeTHF extracted 27.3 and 12%, respectively, more carotenoids than n-hexane, while ethyl acetate showed the same extraction efficiency as n-hexane. Goula et al. (2017) used vegetable oils in ultrasound-assisted extraction to extract carotenoids from pomegranate (Punica granatum) waste, with an extraction efficiency between 85.7 and 93.8%. Lee and Row (2016) used ionic liquids and deep eutectic solvents (DES) as additives for the ultrasonic extraction of astaxanthin from marine sources. In particular, DES prepared from methyl triphenyl phosphonium bromide and 1,2-butanediol in the proportions of 1–4, extracted 73.49 mg/g astaxanthin, while the 1-ethyl-3-methyl imidazolium bromide ionic liquid extracted 47.30 mg/g astaxanthin from Portunus trituberculatus waste.

In the case of phenolic compounds, the use of green solvents with more hydrophilic characteristics has been reported. Lores et al. (2015) showed that similar extraction efficiencies could be obtained using aqueous solutions of ethyl lactate or methanol, with same concentration, in a pressurized liquid extraction (120 ºC, 1500 psi), recovering polyphenols from Cytisus scoparius. Hamiche et al. (2018) used eucalyptol (1,8-cineole) to extract phloroglucinols from brown alga Zonaria tournefortii, and although eucalyptol was not more efficient than the dichloromethane/methanol mixture, it showed a higher selectivity. Ionic liquids and DES have also been investigated in the extraction of phenolic compounds. Ribeiro et al. (2013) observed similar results in the extraction of polyphenols from green tea and mate using aqueous solutions of ethanol [30%(v/v)] and of ionic liquids, such as choline chloride and 1-ethyl-3-methyl imidazolium chloride [50% (m/m)]. Rajha et al. (2019) reported the combined use of natural DES and green processing (ultrasound and/or infrared techniques) for the extraction of phenolic compounds from pomegranate peels. In general, the metabolites extraction efficiency was 2.5 times higher when choline chloride:d,l-lactic acid (1:3) and malic acid: glucose: glycerol (1:1:1) DES were used, than when water or ethanol/water [50% (v/v)] were used.

Deep Eutectic Solvents are mixtures of at least two solid compounds at room temperature that have much lower melting temperatures than their parent compounds (Dai et al. 2013). NADES readily classified as green solvents due to their easy preparation, just mixing and heating, with 100% atom efficiency, low cost, low toxicity, biodegradability and compatibility with enzymes. Most DES initially proposed were a mixture of choline chloride and different hydrogen bond donors such as organic acids, amino acids, polyols, sugars, etc. In particular, DES that are exclusively composed of natural compounds are called NADES. Due to their hydrophilic nature, non-negligible amounts of water can be present in NADES (Florindo et al. 2019a). All natural hydrophobic eutectic solvents were originally developed in 2015, using d,l-menthol and organic acids (Ribeiro et al. 2015). Commonly, NADESs with hydrophobic nature and low viscosity enhance the activity and stability of enzymes (Florindo et al. 2019b).

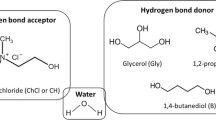

The aim of this work is to valorize a waste of the sunflower oil industry, the sunflower’s petals and florets, through the extraction of carotenoids and phenolic compounds using natural, nontoxic hydrophobic solvents combined with the use of the multi-enzyme complex Viscozyme® to disrupt the cell wall of petals and disc florets. The green hydrophobic solvents selected to be tested in this work are d-limonene, turpentine, d,l-menthol, sunflower oil and eutectic solvents based on the combination of d,l-menthol and natural organic acids (d,l-menthol: acetic acid, d,l-menthol: d,l-lactic acid and d,l-menthol: lauric acid) in (2:1) proportion (Fig. 1). All these solvents will form two phases with water (Ribeiro et al. 2015) and allowing the separation of the carotenoids (solvent phase) from the phenolic compounds (aqueous phase). It has been shown that the eutectic solvents are not stable when in contact with water, since the hydrophilic component, the acids in this case, will leach to water proportionally to their water solubility (Florindo et al. 2017). However, as it will be seen in the results section, some polarity (hydrophilicity) is beneficial in the extraction of carotenoids.

The performance of the multi-enzyme complex Viscozyme® L in the disruption of the cell wall of sunflower waste (petals and disc florets) will also be assessed by comparing the extraction results with and without enzyme. The measurement of the content of sugars will also allow evaluating the enzyme hydrolysis of the petal’s cell wall.

Experimental section

Materials

Sunflowers and sunflower oil (brand Liza) were purchased in a local market in Rio de Janeiro, Brazil; d,l-Menthol (purity 95%), d-limonene (purity 93%), lauric acid (purity 98%) and d,l-lactic acid (purity 98%)were purchased from Sigma-Aldrich, d-glucose (> 95%) were purchased from Vetec, n-hexane (> 95%) and glacial acetic acid (> 99.7%) were purchased from Isofar, turpentine was purchased from B.Herzog, tannic acid was purchased from Allied Chemical Corporation and Viscozyme L was provided by Novozymes. All reagents were used without any further purification.

Methods

Preparation of eutectic solvents

A series of eutectic solvents were prepared by mixing d,l-menthol and organic acids (lauric, acetic and d,l-lactic) in the 2:1 proportion, by weighing the appropriate amounts of each component into a glass vial, using an analytical balance (Ohaus Explorer AR2140, ± 0.0001 g precision). This proportion was chosen, since it yields liquid eutectic solvents at room temperature (Ribeiro et al. 2015). Since our aim is to develop solvents for the industry, the reagents were not dried before ES preparation. All the mixtures were heated up to 80 °C and kept under magnetic stirring until a clear, transparent and homogeneous liquid was obtained, at which point they were slowly cooled back to ambient temperature.

Carotenoids extraction procedure

The carotenoids of sunflower were extracted using a solid–liquid–liquid extraction. First, the disc florets and petals of sunflower was lyophilized and ground into a fine powder. Afterwards, samples containing sunflower powder, extraction solvent and water were preparedusing an analytical balance (Ohaus Explorer AR2140, ± 0.0001 g precision), into 15 mL centrifuge tubes, with and without enzyme, in the following proportions: sunflower powder/liquid (water and solvent), 1:10 (w/v) ratio; solvent/water, 1:1 (v/v) ratio; enzyme concentration of 0.25% of the liquid volume. Since all the solvent used were hydrophobic, they form a two-phase liquid–liquid system when in contact with water. The tubes were placed in a Nova Instruments NI 1713 incubator shaker, maintained at 200 rpm for 2 h at 40 °C and after the extraction, they were centrifuged in an Eppendorf® Centrifuge 5804R at 2655 g for 5 min, separating the aqueous and the hydrophobic solvent phase. The hydrophobic phase, which is expected to contain the carotenoids, was carefully sampled using an Eppendorf® Research® automatic pipette (volume 100–1000 μL). The total carotenoids content of the hydrophobic phase was analysed using a UV-based method described below, while the total sugars and phenolic compounds content of the water phase was analysed using the DNS and the Folin Denis method, respectively. All the samples were stored in the refrigerator, wrapped in aluminium foil to avoid the contact with light.

Optimization of the extraction methodology

The solvent that afforded the best extraction efficiency of carotenoids was chosen for optimization of the extraction conditions using a central composite rotatable design (CCRD). The statistical analysis was performed using the software Statsoft Statistica® version 7.0.The three experimental variables, the ratio of solvent to water, the ratio of raw material (sunflower’s petals + disc florets lyophilized) to liquid, and (%) of the enzyme (Viscozyme® L) to liquid, were investigated. The experiments were conducted at 40 °C and 200 rpm stirring speed in orbital shaker for 2 h. Temperature was chosen to be a fixed variable to avoid carotenoids degradation, since it is known that these compounds are heat sensitive (Borsarelli and Mercadante 2009), and also because the optimum temperature range of Viscozyme® is 25–55 °C.

Analytical methods

Total carotenoids content

The carotenoid content of hydrophobic phase samples was analyzed using a UV–Vis spectrophotometer (BEL Photonics 2000 UV), at 450 nm, according to Rodriguez-Amaya 2001 and Kishimoto et al. (2007). The concentration of carotenoids was calculated as shown below (Eq. 1), using the molar extinction coefficient (\(\varepsilon_{{\text{1 cm}}}^{1\% }\)) of lutein previously published in the literature, 2589 mol/cm (Kishimoto et al 2007). This approximation was used, since it is known that lutein is the major carotenoid of sunflower petals (Kumar and Gowda 2010).

where Abs, Vol and m are the absorbance of the peak at 450 nm, volume and mass of the sample, respectively.

Total sugars and phenolic compounds content

The amount of total sugars in the aqueous phase was analyzed using DNS method (Miller 1959), using d-glucose as standard. The amount of phenolic compounds in the aqueous phase was analyzed, using the Folin Denis method, according to Swain and Hillis (1959), using tannic acid as standard.

Thin-layer chromatography (TLC) analysis

TLC analysis was performed to compare the carotenoids profile in petals and in disc florets. Samples were obtained by extracting carotenoids from petals and disc florets (equal proportion in mass of petals and disc florets) with pure n-hexane [raw material/n-hexane ratio = 1/10 (w/v)]. The procedures of TLC analysis were carried out according to Rodriguez-Amaya (2001). The mobile phase used contained 5% of methanol in toluene and a silica gel plate was used as stationary phase. The retardation factor (Rf) of each sample was calculated (Eq. 2) and the results were compared with those in open literature, to verify the profile of carotenoids present in the samples.

High-performance liquid chromatography (HPLC) analysis

Each sample (10 μL) was injected in a HPLC system, equipped with a Waters 1525 binary pump and a Waters 2487 UV–Vis detector. For data processing and analysis, the software Breeze v. 3.30 was used. The chromatographic separation was performed using a YMC-Pack ODS-A column (100 × 4.6 mm) with a pore size of 120 Ǻ. The mobile phase (flow rate of 1 mL/min) consisted of a mixture of acetonitrile/methanol/THF [50/45/5 (v/v/v)] plus 0.05% of trimethylamine, which was previously mixed using ultrasound. Samples of 10 μL were injected in HPLC, setting the detector wavelength at 450 nm (Rodriguez-Amaya 2001; Kishimoto et al. 2007).

Results and discussion

Enzymatic extraction of plant metabolites is based on the inherent ability of enzymes to catalyze reactions with specificity, regioselectivity and under mild processing conditions in aqueous and non-aqueous systems. Some enzymes, such as cellulases, hemicellulases, pectinases and amylases, can degrade or disrupt cell walls and membranes, thus enabling better release and more efficient extraction of bioactives. These enzymes have been applied to juice processing, promoting fast extraction and high juice recovery (Nadar et al. 2018; Puri et al. 2012). In this work, the synergistic effect of enzyme-assisted extraction of sunflower metabolites in triphasic system, biomass (ground petals and florets of sunflower), water, and green hydrophobic solvents is explored. The phenolic compounds and the released reducing sugars are mostly present in the aqueous phase, while most of the carotenoids are extracted to the green hydrophobic phase.

Total carotenoids

The results obtained from the extractions of carotenoids from sunflower petals using the green hydrophobic solvents phases are depicted in Fig. 2. The green solvents can be ranked according the following order of their capacity to extract carotenoids: M:HLac (147 ppm) > M:HAc (84.5 ppm) > M:HLaur (77 ppm) > turpentine (63 ppm) ~ limonene (63 ppm) > Menthol (40 ppm) > Sunflower oil (28 ppm). Consequently, it can be concluded that the three eutectic solvents present the best performance in the extraction of carotenoids from sunflower wastes, when compared to other green solvents.

Nevertheless, n-hexane, the standard solvent used in the industry in the extraction of carotenoids, also yielded a high content of extracted carotenoids (115 ppm), achieving the second-best position. On the other hand, it is interesting to see that the most hydrophobic eutectic solvent, M:HLau, composed of two hydrophobic compounds, does not provide the best extraction efficiency, clearly showing the hydrophobicity of the solvent is not the most important property in the extraction of carotenoids. Probably, the high polarity of the eutectic solvents containing acetic acid and d,l-lactic acid might explain the higher extraction efficiencies of these solvents, especially the last one. In what concerns the other green solvents, again it can be seen that hydrophobic solvents such as d,l-menthol and sunflower oil do not yield very high extraction efficiencies, and that d-limonene and turpentine have quite acceptable results.

Lutein is a carotenoid with two hydroxyl groups (Kumar and Gowda 2010; Kishimoto et al. 2007), belonging to the group of xanthophylls, carotenoids that contain two oxygen atoms, which confer them a somewhat polar character. The extraction of lutein from different sources using green solvents was already reported in the open literature. Castro-Puyana et al. (2013) used a mixture of limonene and ethanol and pressurized liquid extraction (1500 psi, 100–160 ºC) to extract carotenoids, mainly lutein, from microalga Neochloris oleoabundans. The highest extraction yield (100%) was observed for ethanol, confirming that high-polarity solvents are better for the extraction of xanthophylls. Song et al. (2018) used ultrasound-assisted extraction (45 kHz, 203 W) and ethanol/diethyl ether [2/1 (v/v)] to recover lutein from pumpkin (Cucurbita moschata) peels. They show that high extraction times at high temperatures leads to a high oxidative degradation and isomerization of carotenoids and the generation of free radicals by cavitation. This supports the choice of low temperature (40 ºC) and short extraction times (2 h) made of this work.

Total carotenoids extracts profile

According to Kishimoto et al. (2007), other carotenoids such as zeaxanthin (Z), antheraxanthin (Ax) and violaxanthin (V), can also be found in sunflower petals. All these carotenoids belong to the group of xanthophylls and their chemical structures are presented in Fig. 3.

TLC analysis was carried out to establish the presence of these xanthophylls and HPLC analysis to verify carotenoid profile. According to Rodriguez-Amaya 2001, the presence of oxygen substituents in these carotenoids increases adsorption affinity, with the extent of this increase depending on the type, number, and location of the functional groups. As it can be seen from Fig. 4, using a mobile phase of 5% methanol in toluene, all carotenes elute with the solvent front, whereas monohydroxy carotenoids appear near the middle of the silica plate. In all three samples, only petals, only florets and a mixture of the two, xanthophylls with two oxygenated groups, lutein and zeaxanthin, have lower values of retardation factors(Rf), from 0.12 to 0.17, than violaxantin, with four oxygen atoms, which has Rf around 0.18–0.21. This spot is more intense for petals extract than for florets extract. Other spots can be visualized in TLC plates, indicating the presence of mono-oxygenated groups and carotenes, as β-cryptoxanthin, lutein 5,6-epoxide, rubixanthin and β-carotene (Goodwin 1980).

In what concerns the carotenoid profile of the extracts, the analysis of the HPLC chromatograms leads to the conclusion that very similar profiles were obtained for the extracts of all green solvents used. In Fig. 5, the HPLC chromatogram corresponding to the extraction of sunflower wastes carried out with d,l-menthol is presented as an example. This carotenoid profile is very similar to that reported by Kishimoto et al. (2007), with the major difference being that in this work the highest peak appears at 4–5 min, while in Kishimoto’s around 30 min. This is due to the different HPLC columns used in both experiments. A very large carotenoid peak, which was attributed by Kishimoto et al. (2007) to lutein (L), can be observed together with smaller peaks, which have been attributed zeaxanthin (Z), antheraxanthin (Ax), (9Z)-violaxanthin (9Z-V) and violaxanthin (V).

Enzymatic extraction

The results of the enzymatic assisted extraction of carotenoids using Viscozyme® and the hydrophobic green solvents are presented in Fig. 2. It can be observed that, generally, the use of an enzyme together with a green solvent does not always yield better results than the use of green solvents alone. For example, for M:HLaur (68 ppm with enzyme, 77 ppm without enzyme), the presence of Viscozyme® did not help the carotenoid extraction, while for d-limonene (61 ppm with enzyme, 63 ppm without enzyme) and turpentine (64 ppm with enzyme, 64 ppm without enzyme) similar results were obtained for the essays with and without enzyme. In Fig. 6, the total sugars released to the aqueous phase during enzymatic extraction of sunflower petals using green hydrophobic solvents, is presented. For all solvents, no enzymatic inhibition took place since the reducing sugars in the media increased, indicating plant cell wall degradation. Nevertheless, the presence of the enzyme favoured the carotenoid extraction in the case of n-hexane (189 ppm with enzyme, 115 ppm without enzyme), M:HLac (335 ppm with enzyme, 147 ppm without enzyme) and M:HAc (128 ppm with enzyme, 85 ppm without enzyme). To emphasize the excellent results achieved in the case of M:HLac with Viscozyme®, showing that this strategy can be of great value, if the enzyme remains active in the solvent. Thus, the knowledge of the physical chemical properties of the solvent is of utmost importance in the design of solvents for enzyme assisted extractions.

As mentioned before, the study of the total reducing sugars content might give valuable insights on the performance of the enzyme not only in the cell wall disruption, but also on the cleavage of glycosylated phenolic compounds, thus also favouring the extraction of phenolic compounds. It can be clearly seen that, in all the cases, the amount of total sugars is higher when Viscozyme® is used, evidencing the important role of the enzyme in the cleavage of sugars. Especially high differences were obtained for water (14.8 g/L with enzyme, 7.7 g/L without enzyme, a difference of 92%), n-hexane (18.4 g/L with enzyme, 8.1 g/L without enzyme, a difference of 127%), d-limonene (16.5 g/L with enzyme, 7.6 g/L without enzyme, a difference of 117%), sunflower oil (14.5 g/L with enzyme, 8.4 g/L without enzyme, a difference of 72%) and turpentine (21.5 g/L with enzyme, 8.2 g/L without enzyme, a difference of 162%). However, the use of the three eutectic mixtures allow for the smallest increase in the reducing sugars, M:HAc (8.8 g/L with enzyme, 6.3 g/L without enzyme, a difference of 39%), M:HLau (11.8 g/L with enzyme, 8.1 g/L without enzyme, a difference of 45%), and M:HLac (9.5 g/L with enzyme, 7.5 g/L without enzyme, a difference of 27%). This means that, although eutectics mixtures promoted some enzymatic inhibition, d,l-menthol enabled the permeabilization of plant matrices and the release of carotenoids. d,l-menthol and other terpenes are known to increase percutaneous absorption of drugs, interacting with lipid structure of stratum corneum (El-Kattan et al. 2001). Since cellulose, major component in plant cell wall, does not represent a significant barrier to d,l-menthol (Ma et al. 2013), it is possible that D,L-menthol can interact with plant metabolites, facilitating their extraction.

The content of phenolic compounds in the aqueous phase is depicted in Fig. 7. The green solvents efficiency (without enzyme) in the extraction of phenolic compounds can be ranked according to the following order: M:Laur (1.41 g/L) ~ M:HLac (1.38 g/L) > d,l-menthol (1.19 g/L) > M:HAc (0.98 g/L) > turpentine (0.6 g/L) ~ water (0.6 g/L) > limonene (0.5 g/L) ~ sunflower oil (0.6 g/L). It can be concluded that again the M:HLac has an excellent performance in extracting the phenolic compounds to the water phase. In fact, the presence of two hydrophobic compounds, such as d,l-menthol and lauric acid, in the constitution of eutectic solvents seems to be important to push the phenolic compounds to the water phase.

In what concerns the use of the enzyme, no major differences were observed. These results suggest that the enzyme is not very efficient in the cleavage of glycosylated phenolic compounds. Nevertheless, it should be kept in mid that only 7% of the total polyphenols in sunflower petals are glycosylated phenolic acids (Liang et al. 2013; Ye et al. 2015), thus justifying the small decrease in polyphenols concentration after enzymatic action. Probably the use of a carbohydrase, such as cellulase, would promote a higher extraction of polyphenols by degradation of sunflower wastes and deglycosylation (Nadar et al. 2018).

Optimization of the extraction efficiencies

According to the results previously presented, the eutectic mixture d,l-menthol:d,l-lactic acid was the solvent that achieved the best results in carotenoids extraction, using the standard conditions [sunflower/liquid, 1:10 (w/v) ratio; solvent/water 1:1 (v/v) ratio; enzyme concentration of 0.25% in volume, 200 rpm of agitation, 40 °C for 2 h]. Therefore, this solvent was selected to carry out the optimization of the experimental design, varying the sunflower powder mass/volume of liquid (w/v) ratio, water/solvent (v/v) ratio and % of enzyme concentration, as shown in Table 1. With the conditions of experiment 11 [sunflower/liquid 0.65:10 (w/v) ratio; solvent/water 0.6:1 (v/v) ratio and enzyme concentration of 0.5% in volume], it was possible to extract 1449 mg carotenoids/100 g sunflower waste, a higher value than that achieved before the optimization (472 mg carotenoids/100 g biomass). Using the desirability function, plotted in Fig. 8, to obtain maximum yields of sunflower metabolites (carotenoids, phenolic compounds and reducing sugars released in enzymatic hydrolysis) in the extracts, the optimal experimental conditions were found: solvent/water ratio [0.93:1 (v/v)], sunflower/liquid ratio [0.15:10 (w/v)], and enzyme concentration (0.58% in volume).

According to the statistical analysis, terms related to the interaction between enzyme concentration and other parameters did not present statistical significance (p value < 0.05) for none of the response parameters (carotenoids, phenolic compounds and reducing sugars released concentrations). Linear terms related to enzyme concentration and solvent/water ratio presented a positive effect in extraction, while sunflower/liquid showed a negative effect. These results indicate that a high mass of eutectic solvents to a low mass of biomass is needed to achieve high extraction yields. Although the use of enzyme is also needed, above the concentration of [~ 0.5% (v/v)], this parameter does not significantly influence the extraction. The highest results of carotenoids extraction (1449 mg carotenoids/100 g biomass and 840 mg carotenoids/100 g biomass, experiments 11 and 6, respectively) also have the highest values of total sugars (20.92 g/L and 25.32 g/L, respectively), which implies the highest activity of enzyme in the breakage of the cell wall of the raw material (Table 1). The higher quantity of eutectic solvent and lower quantity of biomass improved the enzymatic action, due to a best diffusion of substrate. This probably facilitated the extraction of carotenoids for the solvent. The content of phenolic compounds was also higher in experiment 11, being the best condition for both carotenoids and phenolic compounds recovery.

Conclusions

In this work, the performance of hydrophobic green solvents in the extraction of valuable bioactive compounds, such as carotenoids and phenolics, from sunflower wastes is evaluated. From the different green solvents, belonging to different classes, used and it is possible to conclude that the eutectic solvent d,l-menthol/ d,l-lactic acid (2:1) was more efficient for carotenoids extraction than the standard solvent n-hexane, M:HLac extracted 335 ppm, while n-hexane extracted 189 ppm. This is probably due to the increased polarity of this solvent when compared to hexane, an hydrophobic but apolar solvent. Furthermore, the enzymatic assisted extraction using this solvent, in the presence of Viscozyme®, also achieved a recovery of carotenoids much higher (2.3 times) than the standard solvent n-hexane. The profile of carotenoids showed in HPLC was similar to that found in the literature, which allowed inferring the presence of lutein and other xanthophylls. The TLC analysis of the different sunflower parts showed the differences between the carotenoids profile in petals and disc florets, emphasizing a potential valorization of both parts. It is interesting to observe that the presence of xanthophylls is more evident in petals, while more hydrophobic carotenoids can be found in disc florets.

References

Bahrami H, Melia M, Dagnelie G (2006) Lutein supplementation in retinitis pigmentosa: PC-based vision assessment in a randomized double-masked placebo-controlled clinical trial [NCT00029289]. BMC Ophthalmol 6:1–12. https://doi.org/10.1186/1471-2415-6-23

Boriollo M, Silva T, Silva J, Netto M, Höfling J, Chavasco J (2017) Genotoxicidade de Helianthus annuus Linné, 1753 (Asteraceae): novas perspectivas e tendências. Rev Fitos 11:173–188. https://doi.org/10.5935/2446-4775.20170026

Borsarelli CD, Mercadante AZ (2009) Thermal and photochemical degradation of carotenoids. In: Landrum JT (ed) Carotenoids: physical, chemical, and biological functions and properties. Taylor and Francis, Boca Raton, pp 229–253

Castro-Puyana M, Herrero M, Urreta I, Mendiola JA, Cifuentes A, Ibáñez E, Suárez-Alvarez S (2013) Optimization of clean extraction methods to isolate carotenoids from the microalga Neochloris oleoabundans and subsequent chemical characterization using liquid chromatography tandem mass spectrometry. Anal Bioanal Chem 405:4607–4616. https://doi.org/10.1007/s00216-012-6687-y

Dai Y, Spronsen JV, Witkamp G-J, Verpoorte R, Choi YH (2013) Natural deep eutectic solvents as new potential media for green technology. Anal Chim Acta 766:61–68. https://doi.org/10.1016/j.aca.2012.12.019

Eggersdorfer M, Wyss A (2018) Carotenoids in human nutrition and health. Arch Biochem Biophys 652:18–26. https://doi.org/10.1016/j.abb.2018.06.001

El-Kattan AF, Asbill CS, Kim N, Michiniak BB (2001) The effects of terpene enhancers on the percutaneous permeation of drugs with different lipophilicities. Int J Pharm 215:229–240. https://doi.org/10.1016/S0378-5173(00)00699-2

Farré G, Sanahuja G, Naqvi S, Bai C, Capell TC, Zhu C, Christou P (2010) Travel advice on the road to carotenoids in plants. Plant Sci 179:28–48. https://doi.org/10.1016/j.plantsci.2010.03.009

Florindo C, Branco LC, Marrucho IM (2017) Development of hydrophobic deep eutectic solvents for extraction of pesticides from aqueous environments. Fluid Ph Equilibr 448:135–142. https://doi.org/10.1016/j.fluid.2017.04.002

Florindo C, Branco LC, Marrucho IM (2019a) In the quest for green solvents design: from hydrophilic to hydrophobic (deep) eutectic solvents. Chem Sus Chem 12:1549–1559. https://doi.org/10.1002/cssc.201900147

Florindo C, Lima F, Ribeiro BD, Marrucho IM (2019b) Deep eutectic solvents: overcoming 21st century challenges. Curr Opin Green Sustain Chem 18:31–36. https://doi.org/10.1016/j.cogsc.2018.12.003

Goodwin TW (1980) The Biochemistry of Carotenoids, vol 1 Plants, 2nd edn. Chapman and Hall, London

Goula AM, Ververi M, Adamopoulou A, Kaderides K (2017) Green ultrasound-assisted extraction of carotenoids from pomegranate wastes using vegetable oils. Ultrason Sonochem 34:821–830. https://doi.org/10.1016/j.ultsonch.2016.07.022

Hamiche S, Bouzidi N, Daghbouche Y, Badis A, Garrigues S, De la Guardia M, El Hattab M (2018) Eucalyptol-based green extraction of brown alga Zonaria tournefortii. Sustain Chem Pharm 10:97–102. https://doi.org/10.1016/j.scp.2018.10.005

Kesse-Guyot E, Andreeva VA, Ducros V, Jeandel C, Julia C, Hercberg S, Galan P (2013) Carotenoid-rich dietary patterns during midlife and subsequent cognitive function. Brit J Nutrit 111:915–923. https://doi.org/10.1017/S0007114513003188

Kishimoto S, Sumitomo K, Yagi M, Nakayama M, Ohmiya A (2007) Three routes to orange petal color via carotenoid components in 9 compositae species. J Jpn Soc Horticult Sci 76:250–257. https://doi.org/10.2503/jjshs.76.250

Kumar MC, Gowda TV (2010) Sunflower (Helianthus annuus L.) petals: a new biological source of Lutein. Res J Pharm Biol Chem Sci 1:438–448

Lee YR, Row KH (2016) Comparison of ionic liquids and deep eutectic solvents as additives for the ultrasonic extraction of astaxanthin from marine plants. J Ind Eng Chem 39:87–92. https://doi.org/10.1016/j.jiec.2016.05.014

Liang Q, Cui J, Li H, Liu J, Zhao G (2013) Florets of Sunflower (Helianthus annuus L.): potential new sources of dietary and phenolic acids. J Agric Food Chem 61:3435–3442. https://doi.org/10.1021/jf400569a

Lores M, Pájaro M, Álvarez-Casas M, Domínguez J, García-Jares C (2015) Use of ethyl lactate to extract bioactives compounds from Cytisus scoparius: comparison of pressurized liquid extraction and medium scale ambient temperature systems. Talanta 140:134–142. https://doi.org/10.1016/j.talanta.2015.03.034

Ma M, Tan L, Dai Y, Zhou J (2013) An investigation of flavor encapsulation comprising of regenerated cellulose as core and carboxymethyl cellulose as wall. Iran Polym J 22:689–695. https://doi.org/10.1007/s13726-013-0167-x

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Mirzabe AH, Chegini GR, Khazaei J (2018) Sunflower petals: Some physical properties and modeling distribution of their number, dimensions, and mass. Inform Process Agric 5:185–198. https://doi.org/10.1016/j.inpa.2018.03.002

Nadar SS, Rao P, Rathod VK (2018) Enzyme assisted extraction of biomolecules as an approach to novel extraction technology: a review. Food Res Int 108:309–330. https://doi.org/10.1016/j.foodres.2018.03.006

Puri M, Sharma D, Barrow CJ (2012) Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol 30:37–44. https://doi.org/10.1016/j.tibtech.2011.06.014

Rajha HN, Mhanna T, Kantar S, El Khoury A, El LN, Maroun RG (2019) Innovative process of polyphenol recovery from pomegranate peels by combining green deep eutectic solvents and a new infrared technology. LWT Food Sci Technol 111:138–146. https://doi.org/10.1016/j.lwt.2019.05.004

Ribeiro BD, Coelho MAZ, Rebelo LPN, Marrucho IM (2013) Ionic liquids as additives for extraction of saponins and polyphenols from mate (Ilex paraguariensis) and tea (Camellia sinensis). Ind Eng Chem Res 52:12146–12153. https://doi.org/10.1021/ie400529h

Ribeiro BD, Florindo C, Iff LC, Coelho MAZ, Marrucho IM (2015) Menthol-based eutectic mixtures: hydrophobic low viscosity solvents. ACS Sustain Chem Eng 3:2469–2477. https://doi.org/10.1021/acssuschemeng.5b00532

Rodriguez-Amaya DB (2001) A guide to carotenoid analysis in foods. ILSI Press, Washington

Rojas-Garbanzo C, Gleichenhagen M, Heller A, Esquivel P, Schulze-Kaysers N, Schieber A (2017) Carotenoid Profile, Antioxidant Capacity, And Chromoplasts Of Pink Guava (Psidium guajava L. Cv. ‘Criolla’) during fruit ripening. J Agric Food Chem 65:3737–3747. https://doi.org/10.1021/acs.jafc.6b04560

Saini RK, KeumY-S, (2018) Carotenoid extraction methods: a review of recent developments. Food Chem 240:90–103. https://doi.org/10.1016/j.foodchem.2017.07.099

Song J, Yang Q, Huang W, Xiao Y, Li D, Liu C (2018) Optimization of trans lutein from pumpkin (Cucurbita moschata) peel by ultrasound-assisted extraction. Food Bioprod Process 107:104–112. https://doi.org/10.1016/j.fbp.2017.10.008

Swain T, Hillis WE (1959) The phenolic constituents of Prunus domestica. I.—The quantitative analysis of phenolic constituents. J Sci Food Agric 10:63–68. https://doi.org/10.1002/jsfa.2740100110

Uenojo M, Maróstica Junior MR, Pastore GM (2007) Carotenóides: propriedades, aplicações e biotransformação para formação de compostos de aroma. Quím Nova 30:616–622. https://doi.org/10.1590/S0100-40422007000300022

Yara-Varón E, Fabiano-Tixier AS, Balcells M, Canela-Garayoa R, Bily A, Chemat F (2016) Is it possible to substitute hexane with green solvents for extraction of carotenoids? A theoretical versus experimental solubility study. RSC Adv 6:27750–27759. https://doi.org/10.1039/c6ra03016e

Ye F, Liang Q, Li H, Zhao G (2015) Solvent effects on phenolic content, composition, and antioxidant activity of extracts from florets of sunflower (Helianthus annuus L.). Ind Crops Prod 76:574–581. https://doi.org/10.1016/j.indcrop.2015.07.063

Acknowledgements

We are thankful for the support provided by the CQE project (UID/QUI/00100/2013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interests.

Rights and permissions

About this article

Cite this article

Ricarte, G.N., Coelho, M.A.Z., Marrucho, I.M. et al. Enzyme-assisted extraction of carotenoids and phenolic compounds from sunflower wastes using green solvents. 3 Biotech 10, 405 (2020). https://doi.org/10.1007/s13205-020-02393-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-020-02393-0