Abstract

Thermostable α-amylases are widely used in industry. The α-amylase from Bacillus licheniformis (BLA) with six potential glycosylation sites possessed excellent thermal and pH stability and high activity. Here, it was expressed in Pichia pastoris. The Pic-BLA-producing yeast without any antibiotics-resistant gene was cultivated in flasks and the amylase activity in fermentation supernatant reached 900 U/mL. The recombinant α-amylase Pic-BLA produced in P. pastoris was deeply glycosylated with 30% increase in molecular mass (MM). The deglycosylation treatment by Endoglycosidase H (Endo H) reduced the MM of Pic-BLA. Thermostability analysis showed that Pic-BLA and deglycosylated Pic-BLA were similar in heat tolerance. In order to eliminate the extra impact of Endo H, the BLA was also expressed in Escherichia coli to get non-glycosylated Eco-BLA. A comparative study between non-glycosylated Eco-BLA and glycosylated Pic-BLA showed no obvious difference in thermostability. It is speculated that the glycosylation has little effect on the thermostability of α-amylase BLA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

α-Amylase (EC.3.2.1.1) is widely distributed in animals, plants and microorganisms (Pandey et al. 2000), which can randomly hydrolyze the α-1, 4-glycosidic bond of starch to produce dextrin and oligosaccharides. Thus, α-amylase is widely used in industry (Souza and Magalhães 2010). Most α-amylases belong to the glycoside hydrolase family 13 (GH13), and probably present in the GH57 and GH119 families (Janecek et al. 2014). A typical feature of the GH13 family is (β/α)8-barrel containing two aspartic acid and one glutamic acid residues that play an essential role in catalysis (Sarian et al. 2017). Moreover, structurally, α-amylases possess three different domains. The highly conserved Domain A possesses the function of catalysis and substrate binding (van der Maarel et al. 2002), Domain B has been reported to have an impact on the enzymes’ function and stability (Svensson 1994) and Domain C is thought to stabilize the catalytic domain (MacGregor et al. 2001). Furthermore, most of α-amylases are metalloenzymes, which require calcium ions (Ca2+) for their activity, structural integrity and stability (Sindhu et al. 2017). In order to meet the demands of starch industry, many amylases resistant to high temperature, acid or alkali, Ca2+-independency and high activity have been discovered or engineered (Hiteshi and Gupta 2014; Rana et al. 2013; Souza and Magalhães 2010). For example, thermostable α-amylase from B. licheniformis (BLA) exhibits high specific activity at 70–90 °C and pH 6–9 (Priyadharshini and Gunasekaran 2007; Wu et al. 2018), which makes it widely used in detergent, baking, beer, alcohol manufacturing and starch sugar industries.

Thermostability of an enzyme refers to its ability to keep active for a long time in the enzyme reaction. The thermostability of α-amylase is also the prime importance for their successful applications in industry. Previous studies showed that some high-temperature α-amylases exhibited excellent thermostability and half-life (T1/2) can reach 4–12 h at their optimum temperature. For example, optimum temperature of α-amylase from Pyrococcus furiosus was 100 °C (Laderman et al. 1993), and optimum temperature of α-amylase from B. amyloliquifaciens TSWK1-1 was 70 °C (Kikani and Singh 2011). Despite different optimum temperatures, T1/2 of both α-amylases reached 12 h at their optimum temperature, respectively. Taking another contrary example, T1/2 of α-amylase from B. subtilis variants is only 5 min at 60 °C while that of mesophilic α-amylase from B. amyloliquifaciens F at 80 °C is also 5 min (Vihinen and Mäntsälä 2008). From an evolutionary perspective, the α-amylases from thermophilic microorganisms exhibited excellent thermostability to adapt the extreme environment while the α-amylases from animals, plants and mesophilic bacteria exhibited the limited thermostability. However, the excellent thermostability of α-amylases from thermophilic microorganisms was at the expense of structural inflexibility (Fields 2001), generally resulting in poor enzymatic activity. And some amylases from mesophilic microorganism showed excellent enzymatic activity. So, it’s highly necessary to improve the thermostability of α-amylases from the mesophilic microorganism to reduce the cost of application.

Many methods were developed to improve the thermostability of α-amylases (Dey et al. 2016). The recombinant engineering is a promising technology to improve the stability of enzymes. Glycosylation is widespread in eukaryotic expression systems and N-glycosylation is mainly related to the thermostability of protein (Table 1). In eukaryotes, most of secreted proteins undergo post-translational modification, and N-glycosylation is one of them, which is essential for protein to perform specific physiological functions (Blom et al. 2004). Benoit et al. isolated a glycosylated esterase FAEA from Aspergillus niger (Benoit et al. 2006), which is more thermostable than non-glycosylated one expressed in E. coli. P. pastoris is widely used as a eukaryotic expression system for the secretion of various recombinant proteins. Li et al. expressed a β-glucuronidase from Penicillium purpurogenum Li-3 in P. pastoris whose structural and functional stability was improved after glycosylation comparing to its natural sources (Li et al. 2013). The stability of most proteins can be improved by N-glycosylation (Sola and Griebenow 2009), however, sometimes, it is not the case. As two counter-examples, a recombinant alkalophilic Bacillus α-amylase produced in P. pastoris has lower thermostability than its natural source (Tull et al. 2001). Clark et al. added glycosylation sites into α-glucosidase from Beta vulgaris by site-directed mutagenesis, then expressed these variants in P. pastoris, getting several significantly improved thermostability mutants; However, the different mutants presented increased or decreased thermostability during the subsequent reduction of glycosylation sites (Clark et al. 2004).

At present, multiple antibiotic resistance genes are introduced in the genetically modified strains to facilitate the screening of high-yield strain. However, antibiotic resistance genes increase a potential threat that may spread in the environment, affecting agriculture and animal husbandry (Popowska et al. 2017), even the bacteria in human colon carry numerous acquired antibiotic resistance genes (Salyers et al. 2004). Prokaryotes are more likely to exchange genes with other microorganisms in the environment (Martinez 2009). Antibiotic resistance genes in artificially modified strains may be transferred into some harmful pathogens, which is an important reason for forming the “Superbug”.

In order to investigate the effects of glycosylation on α-amylase, α-amylase gene bla was obtained from B. licheniformis WX-02, and heterologously expressed in P. pastoris without antibiotics-resistant gene and expressed in E. coli at the same time. This study also highlights the comparison of optimum temperature and pH, thermostability and pH stability between glycosylated and non-glycosylated α-amylase BLA.

Materials and methods

Plasmids, strains, reagents and media

Pichia pastoris expression vector pHBM905M was modified based on the pPIC9K (Zhang et al. 2006). E. coli XL10-Gold, E. coli BL21 (DE3) and plasmid pET-26b were purchased from Stratagene (Santa Clara, USA). B. licheniformis WX-02 was a gift from Prof. Chen Shouwen; P. pastoris GS115 was purchased from Invitrogen. Restriction enzymes: CpoI (No.1035A), NotI (No.1166A), SalI (No.1080A), BamHI (No.1010A); and Ex-Taq DNA polymerase (No.RR001A), PrimeSTAR® Max DNA polymerase (No.R045Q), PCR buffer, dNTP, DNA marker (No.3427A, 3401) and protein marker were purchased from TaKaRa (Dalian, China). T4 DNA ligase (No.M0202), T4 DNA polymerase (No.M0203S) and dTTP were purchased from NEB (Beverly, USA). Soluble starch (No.V900508) was purchased from Sigma (USA); the common reagents were of AR level.

LB medium (1.0% Tryptone, 0.5% Yeast Extract, 0.5% NaCl, solid medium, pH 7.0) was used for the cultivation of E. coli. LK medium (LB medium containing 50 μg/mL kanamycin) and LA medium (LB medium containing 100 μg/mL ampicillin) were used to screen recombinant E. coli containing different plasmids. Yeast Peptone Glucose Agar medium (YPD: 1.0% Yeast Extract, 2.0% Tryptone, 2.0% Glucose, pH 7.0) was used for the cultivation of P. pastoris. Histidine auxotrophic medium (MD: 2.0% Glucose, 0.34% Amino-free Nitrogen source, 1.0% (NH4)2SO4, pH 7.0) and starch substrate medium (1.0% Yeast Extract, 2.0% Tryptone, 0.34% Amino-free Nitrogen source, 1.0% (NH4)2SO4, 0.03% K2HPO4∙3H2O, 1.18% KH2PO4, 1.0% Glycerol, 0.05% Trypan blue, 1.0% Soluble Starch, pH 7.0) were used to screen P. pastoris expressing α-amylase. BMGY medium (1.0% Yeast Extract, 2.0% Tryptone, 0.34% Amino-free Nitrogen source, 1.0% (NH4)2SO4, 0.03% K2HPO4·3H2O, 1.18% KH2PO4, 1.0% Glycerol) and BMMY medium (1.0% yeast Extract, 2.0% Tryptone, 0.34% Amino-free Nitrogen source, 1.0% (NH4)2SO4, 0.03% K2HPO4·3H2O, 1.18% KH2PO4) were used to express α-amylase in P. pastoris. All medium can be supplemented with 1.5% agar for solid cultivation and were sterilized before use.

Cloning of α-amylase gene Eco-bla

The genomic DNA of B. licheniformis WX-02 (Genbank CP012110.1; Eco-bla: 695578–697116) was extracted and purified as described (Tai and Tanksley 1990). A pair of primers (Eco-BLA_F: 5′-TTCGGATCCGATGAAACAACAAAAACGGCTTTACG-3′ and Eco-BLA_R: 5′-AGTGCGGCCGCTCTTTGAACATAAATTGAAACCGACC-3′) were designed for Eco-bla amplification (SnapGene: https://www.snapgene.com/) based on the annotated α-amylase gene of B. licheniformis WX-02. α-Amylase gene Eco-bla was amplified by PCR using genomic DNA as a template. The PCR conditions were 28 cycles composed of 98 °C/15 s; 55 °C/15 s; 72 °C/20 s followed by a final extension of 72 °C/5 min using PrimeSTAR® Max DNA polymerase (Takara, China).

The mutation of restriction enzyme cleavage site on the α-amylase gene bla

The nucleotide sequence of Eco-bla gene was modified according to the codon preference (Sharp and Li 1987). The 1095th guanine in Eco-bla gene was replaced with adenine (glutamic acid GAG → GAA), and the new glutamate codon was more suitable for expression in P. pastoris. The new gene was renamed Pic-bla. Site-directed mutagenesis was performed by overlapping PCR technology (Steffan et al. 1989) to remove SalI cleavage site of Eco-bla. Overlapping PCR technology: genomic DNA of B. licheniformis WX-02 as a template, primers Pic-BLA_F (5′-GTCAAATGAAACAACAAAAACGGCTTTACG-3′) and Pic-BLA1095_R (5′-TGGACAGTCGATTCAAGCGATTGCCCCGGCTGTGTATCATGG-3′) were used for 1–1105 of the gene Eco-bla; primers Pic-BLA1095_F (5′-AATCGCTTGAATCGACTGTCCAAACATGGTTTAAGCCGCTTGCTT-3′) and Pic-BLA_R (5′-GGCCACTATCTTTGAACATAAATTGAAACCGACC-3′) were used for 1085–1509 of the gene Eco-bla. The next PCR was performed by primers PicBLA_F, PicBLA_R and mixed PCR products (1–1105 and 1085–1509 purified PCR products of the gene Eco-bla) as template. In PCR, the reactions were performed with 25 cycles which composed of 98 °C/15 s, 55 °C/15 s and 72 °C/20 s followed by a final extension of 72 °C/5 min using PrimeSTAR® Max DNA polymerase (Takara, China). The guanine of 1095th site in Eco-bla gene was mutated to adenine and meanwhile the SalI restriction site was removed.

Construction of α-amylase gene expression plasmid for P. pastoris and E. coli

Construction of P. pastoris expression plasmid: α-amylase gene Pic-bla was digested by T4 DNA polymerase with buffer containing dTTP in 22 °C for 20 min, and pHBM905M was digested by CpoI and NotI at 37 °C for 2 h. After recovered by Gel Extraction Mini Kit (Omega, USA), the digested Pic-bla and pHBM905 M were ligated by T4 DNA ligase and then transformed into E. coli XL10-Gold competent cells with 45 s heat-shock at 42 °C and another 90 min-incubation at 37 °C. After positive screening on ampicillin-resistant plates (LA) and negative screening on kanamycin-resistant plates (LK), the colonies which could not grow on LK plates but grow on LA plates were selected and cultivated in LA medium. The recombinant plasmid was extracted and sent for sequencing (Sangon, China). The correct recombinant plasmid was named pHBM905M-Pic-bla.

Construction of E. coli expression plasmid: α-amylase gene Eco-bla and vector pET-26b were digested with BamHI and NotI, respectively. The two digested products were ligated with T4 DNA ligase, then transformed into E. coli XL10-Gold competent cells, screened with LK plates, and the recombinant plasmid were testified by PCR and sequencing (Sangon, China). The correct recombinant plasmid was named pET26b-Eco-bla.

Expression and purification of α-amylase Pic-BLA and Eco-BLA

The recombinant plasmid pHBM905-Pic-bla linearized by SalI was transformed into P. pastoris GS115 competent cells through electroporation with the condition of 2.0 kv, 6.0 ms. The transformants were initially screened on MD plates, followed to be transferred on the starch substrate plates to obtain the strains with higher production of amylase. The plates were incubated invertedly at 28 °C, 400 μL methanol was uniformly added every 12 h on the cover of Petri dish until the significant haloes appeared around the colonies. The selected P. pastoris GS115 colonies with haloes were inoculated into BMGY medium and incubated in shaking incubator at 28 °C until OD600 = 15–30. The cells were harvested, centrifuged at 6000 rpm for 5 min. Then the cells were washed with sterile distilled water for 2–3 times and inoculated to BMMY medium. The culture was induced by adding of methanol (1% v/v) every 12 h at 28 °C for 9 days and fermentation supernatant was collected every 24 h and subjected to activity assay and SDS-PAGE analysis. In order to obtain purified Pic-BLA, fermentation supernatant containing α-amylase Pic-BLA was exchanged with 50 mM Tris–HCl buffer (pH 8.5) using Amicon (Millipore Corp.) 30-kDa filters.

Escherichia coli BL21 (DE3) containing pET-26b-Eco-bla was grown in LK medium at 37 °C until OD600 = 0.6–0.8, then protein expression was induced with 0.5 mM IPTG at 18 °C for 18 h. After incubation, cells were collected by centrifugation and disrupted by ultrasonication. Cells debris was removed by centrifugation at 12,000 rpm for 30 min at 4 °C. The supernatant was loaded on NTA column (Bio-Rad, USA) according to the manufacturer’s instruction. The purified protein was concentrated with Amicon 30-kDa filters and loaded on Hitrap™ Desalting column (GE Healthcare) in 50 mM Tris–HCl (pH 8.5). All purification steps were performed at 4 °C and MM of the purified protein was evaluated by SDS-PAGE.

α-Amylase BLA activity assay

α-Amylase activity was evaluated by DNS method (Miller et al. 1960) to measure the amount of reducing sugar which was released during the action of enzyme on soluble starch. In brief, assay mixtures contained 500 μL of 1% (w/v) soluble starch in 50 mM Tris–HCl buffer (pH 8.5) and appropriately diluted enzyme. After incubation at 70 °C for 10 min, 700 μL 3,5-dinitrosalicylic acid reagent (DNS) was added to stop the reaction by inactivating the enzyme. Then samples were heated at 100 °C for 10 min and cooled on ice for 5 min. The absorbance of samples were measured at 540 nm. One unit of α-amylase BLA activity was defined as the amount of enzyme releasing 1 µmol of reducing sugar per minute under the assay conditions, glucose as a standard. Protein concentration was quantified by Bradford assay using bovine serum albumin as the standard. Each value of the assay was the arithmetic means of triplicate measurements.

Deglycosylation and determination of thermostability of the α-amylase Pic-BLA

Assay mixtures containing 85 μL purified Pic-BLA, 5μL Endo H (NEB, USA) and 10 μL Endo H buffer were incubated at 37 °C for 20 min to obtain the deglycosylated Pic-BLA. Pic-BLA was incubated at 37 °C for 20 min simultaneously as a control. The thermostability of Pic-BLA and deglycosylated Pic-BLA were determined by pre-incubating the enzymes in 50 mM Tris–HCl buffer (pH 8.5) at 60 °C, 65 °C, 70 °C, respectively. Samples were taken every 10 min (total 50 min) and cooled rapidly on ice. The residual activity was measured by DNS assay at 70 °C and pH 8.5. Each value of the assay was the arithmetic means of triplicate measurements.

Effects of temperature on the enzyme activity and stability of Pic-BLA and Eco-BLA

The influence of temperature on the activity of α-amylase was investigated by conducting the enzyme reaction at different temperatures range from 60 to 90 °C for 10 min in Tris–HCl buffer (50 mM, pH 8.5). The thermostability was determined by pre-incubating the enzyme for different time (0–50 min) under different temperature (60, 65 and 70 °C), followed by residual activity determination using DNS assay at 70 °C and pH 8.5. The activity of 0-min samples were set as 100%. Each value of the assay was the arithmetic means of triplicate measurements.

Effects of pH on the enzyme activity and stability of Pic-BLA and Eco-BLA

Effects of pH on the activity of α-amylase was investigated in the range of pH 4.0–9.5 using citrate buffer (pH 4.0–6.0), phosphate buffer (pH 6.0–8.0), Tris–HCl buffer (pH 8.0–9.0) and Glycine–NaOH buffer (pH 9.0–9.5). The pH stability of α-amylase BLA was assayed by holding the enzyme at different buffers (pH 4.0–9.5) at 4 °C for 12 h. The residual activity was measured by DNS assay at 70 °C and pH 8.5. Each value of the assay was the arithmetic means of triplicate measurements.

Statistical analysis

The data were mean ± SD (three biological replicates). The error bars were gained according to STDEV. Student’s t-test (de Winter 2013) was used to calculate P value and the significant difference (*P < 0.05 or **P < 0.01) were labeled.

Results

Sequence analysis of α-amylase gene Eco-bla

A 1539-bp α-amylase encoding gene Eco-bla (NCBI Reference Sequence: CP012110.1) was cloned from B. licheniformis WX-02 by PCR with primers Eco-bla_F and Eco-bla_R, which encodes a protein of 512 amino acids. The ExPAsy website (https://web.expasy.org/) predicted that the theoretical MM and pI of Eco-BLA were 58.52 kDa and 6.33, respectively. The NetNGlyc 1.0 Sever (http://www.cbs.dtu.dk/services/NetNGlyc/) predicted that Eco-BLA had six potential N-glycosylation sites, which were located at the 4th, 27th, 275th, 280th, 309th, and 455th sites, respectively. By YaSaRa software, the structure of Eco-BLA whose sequence is 99% homologous to the α-amylase BLA (PDB ID: 1vjs) (Hwang et al. 1994) was modeled and all potential glycosylation sites were located on the surface of Eco-BLA (Fig. 1). In some studies, thermostability was also improved by the glycosylation of protein surface (Benoit et al. 2006; Sola and Griebenow 2009). Thus, effects of Eco-BLA glycosylation on thermostability were investigated.

Glycosylation sites in the structure of α-Amylase BLA. The SWISS-MODEL program was used to construct the 3D structure of α-Amylase BLA based on α-Amylase BLA (PDB ID: 1vjs) from B. licheniformis. The visualization of the tertiary structure was done by YaSaRa. The 4th, 27th, 275th, 280th, 309th, 455th glycosylation sites were marked on the surface of BLA using Asparagine globular model (blue)

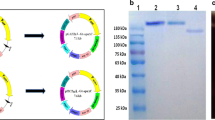

Expression of Pic-BLA

SDS-PAGE analysis showed that recombinant Pic-BLA migrated as two bands with MM of 84 kDa approximately, which was about 25 kDa larger than theoretical value of 58.5 kDa (Fig. 2a). The extent of glycosylation was calculated as 30%. Protein concentration and activity were both increased gradually with the time, the maximum activity was up to 900 U/mL at 168 h (Fig. 2b).

Fermentation analysis of Pic-BLA in Pichia pastoris. a SDS-PAGE analysis of Pic-BLA protein each 24 h. Lane M was the protein MM marker (250, 150, 100, 75, 50, 37, 25 kDa); lane 1–8 was the fermentation supernatant of Pic-BLA at different time (24th, 48th, 72th, 96th, 120th, 144th, 168th and 216th h). b The amylase activity of the fermentation supernatant at different time (24th, 48th, 72th, 96th, 120th, 144th, 168th and 216th h). Each value of the assay was the arithmetic means of triplicate measurements. Bars indicated mean ± SD (n = three biological replicates); Student’s t-tests were performed between different times (144th, 168th and 216th h) as **P < 0.01 or #P > 0.05

Deglycosylation and thermostability of α-amylase Pic-BLA

α-Amylase Pic-BLA was deglycosylated by Endo H. SDS-PAGE analysis showed that α-amylase Pic-BLA displayed single band after deglycosylation and its MM was consistent with the theoretical value (Fig. 3a), indicating that two distinct bands in fermentation supernatant were in different glycosylated degrees. In most cases, the thermostability of protein was increased by glycosylation (Table 1). However, both α-amylase Pic-BLA and deglycosylated Pic-BLA remain stable after pre-incubating at 60 °C for 50 min. When pre-incubating at 70 °C for 50 min, they can remain nearly 20% residual activity, and variation tendency were also similar (Fig. 3b). These results implied that the thermostability of α-amylase Pic-BLA was not improved by glycosylation. The degree of glycosylation of α-amylase Pic-BLA was about 30%, but its thermostability has not been changed. It was speculated that the addition of Endo H may affect the thermostability of α-amylase Pic-BLA and it was not clear whether deglycosylation affected the protein structure. Therefore, a non-glycosylated control possessing same amino acid sequence need to be obtained to study the effects of glycosylation on thermostability.

Deglycosylation of PicBLA with Endo H and SDS-PAGE analysis of Eco-BLA. a SDS-PAGE analysis of Pic-BLA. Line M was the protein MM marker (250, 150, 100, 75, 50, 37, 25, 20 kDa); line 1 was α-amylase Pic-BLA; line 2 was EndoH-treated Pic-BLA; line 3 was Endo H. b Effects of temperature on the stability of Pic-BLA and EndoH-treated Pic-BLA. Each value of the assay was the arithmetic means of triplicate measurements. Bars indicated mean ± SD (n = three biological replicates); Student’s t-tests were performed between Eco-BLA and Pic-BLA as *P < 0.05 or **P < 0.01. c Line M was the protein MM marker (250, 150, 100, 75, 50, 37, 25, 20 kDa); line 1 was α-amylase Eco-BLA purified by NTA

Construction of Eco-bla expression plasmid and purification of Eco-BLA

Endo H might make additional effects on α-amylase Pic-BLA during deglycosylation. Therefore, expressing the non-glycosylated α-amylase Eco-BLA in E. coli is a good strategy. The α-amylase gene Eco-bla was cloned into expression vector pET26b, and then transformed into E. coli BL21 (DE3) for inducible expression, then purified by Ni–NTA resin and GE HiTrap Desalting column. SDS-PAGE analysis (Fig. 3c) showed that the purified α-amylase Eco-BLA presented a single 58.5 kDa band, which was consistent with the theoretical MM of α-amylase BLA.

Effects of temperature on the activity and stability of Pic-BLA and Eco-BLA

The optimum temperature of α-amylase Pic-BLA and Eco-BLA both were 80 °C, but the activity of Eco-BLA above 80 °C was little higher (Fig. 4a). Both Pic-BLA and Eco-BLA can remain nearly 80% residual activity after pre-incubating for 50 min at 60 °C, but lost most activity after pre-incubating for 50 min at 70 °C (Fig. 4b). Although there was a little difference in relative activity under certain conditions, the overall trend keep similar. In short, glycosylation slightly affected the optimum temperature and thermostability of α-amylase BLA.

Effects of temperature and pH on the activity and stability of Eco-BLA and Pic-BLA. a Effects of temperature on the activity of Eco-BLA and Pic-BLA. The maximum activity was set as 100%. b Effects of temperature on the stability of Eco-BLA and Pic-BLA. c Effects of pH on the activity of Eco-BLA and Pic-BLA. d Effects of the pH on the stability of Eco-BLA and Pic-BLA. Each value of the assay was the arithmetic means of triplicate measurements. Bars indicated mean ± SD (n = three biological replicates); Student’s t-tests were performed between Eco-BLA and Pic-BLA as *P < 0.05 or **P < 0.01

Effects of pH on the activity and stability of α-amylase Pic-BLA and Eco-BLA

Both Pic-BLA and Eco-BLA presented high activity over wide range pH, and the optimum pH were 6.0–7.5. They both present more than 80% relative activity between pH 5.5–7.5 (Fig. 4c). Student’s t-test showed that their relative activity had significant difference (P value < 0.05) at pH 5.0–5.5 and 8.0–9.5. pH stability assay indicated that Pic-BLA and Eco-BLA exhibited excellent pH stability in broad range, with more than 60% residual activity from pH 5.5 to 9.5 (Fig. 4d). Student’s t-test was used to analyze the difference between Pic-BLA and Eco-BLA in different pH. Results showed the stability of Pic-BLA was significantly higher than EcoBLA between pH 5.0 and 8.0 (P value < 0.05).

Discussion

Pichia pastoris has been widely used to produce many enzymes in industry, but most engineered strains contain antibiotics resistance genes, which are threat to our environment and health. The P. pastoris strain obtained in this study has been designed to remove kanamycin or ampicillin resistance gene, which can eliminate this threat and make the strain more suitable for industrial application, and environmental-friendly (Zhang et al. 2006).

α-Amylase Pic-BLA contains six potential N-glycosylation sites which are located at the 4th, 27th, 275th, 280th, 309th, and 455th residues, respectively. In previous reports, the proteins containing N-glycosylation sites exhibited different degrees of glycosylation in P. pastoris, and its MM increased to different extent (Lee et al. 2003; Powers et al. 2001; Zhang et al. 2006, 2013). Therefore, the two bands shown for Pic-BLA in SDS-PAGE analysis (Fig. 2a) could be glycosylated to different degrees. Subsequent deglycosylation experiments confirmed this predication and the MM of Pic-BLA was reduced by 25 kDa after treatment with the Endo H (Fig. 3a). The α-amylase ABA from alkaliphilic Bacillus was expressed in P. pastoris. After treatment with Endo H, its MM reduced by about 12 kDa and seven N-glycosylation sites were identified by MS and HPLC (Tull et al. 2001). The N-glycosylated sugar chains of P. pastoris are similar in size, generally between 8 and 14 monosaccharides (Bretthauer and Castellino 1999). Pic-BLA contained six N-glycosylation sites with 25 kDa increase in MM, which implied that it was deeply glycosylated in P. pastoris.

In our study, there was small difference in thermostability between the α-amylase Pic-BLA and Endo H-treated Pic-BLA (Fig. 3b). Endo H deglycosylation cannot remove completely the sugar chain of glycosylated protein, an N-acetylglucosamine residue was retained (Maley et al. 1989). Residual sugar residues might affect the structure of enzyme. To eliminate the factor, bla was expressed in E. coli to get non-glycosylated α-amylase Eco-BLA. The properties of Pic-BLA and Eco-BLA were determined under the same conditions, and results were similar. The optimum temperatures of Pic-BLA and Eco-BLA were 80 °C. Both remain stable at alkaline conditions and unstable at acidic conditions. The difference of thermostability was not significant at 60–70 °C. It was reported that the thermostability of most proteins are improved after glycosylation in P. pastoris, whereas, in this study, glycosylation did not affect the thermostability of amylase BLA significantly. The main reason may be that good thermostability of amylase BLA masked the effect of glycosylation on thermostability.

Based on our experience and previous reports, the glycosylation would mostly improve the thermostability of a protein that was expressed in P. Pastoris, no matter whether the genes were derived from prokaryote or eukaryote (Table 1). Most reports showed that glycosylation could increase the thermostability of proteins and few reports revealed glycosylation had no or little effects on proteins’ thermostability. Interestingly, few reports studied the thermostability of α-amylase after glycosylation, and only one report found that glycosylation reduced the thermostability of amylase, which was surprisingly consistent with our results.

In addition, glycosylation decreases the flexibility of protein structure and by which improves the structural and thermal stability of the enzyme. The 27th, 275th, and 309th glycosylation sites of the α-amylase Pic-BLA are located on α-helix. These structures are relatively stable, so glycosylation cannot affect the stability of these helices. Both the 4th and 280th glycosylation sites are located on the short loop of the stable (β/α)8-barrel region and the short loop is less flexible (Gurung et al. 2015), sugar chain could not enhance or weaken the structural stability of this area. Therefore, the structure associated with Pic-BLA stability was not affected significantly by glycosylation. B. licheniformis-derived thermostable α-amylase bla was expressed in P. pastoris, and there was no significant difference in thermostability compared to non-glycosylated Eco-BLA. This phenomenon may also be caused by the glycosylation sites located in the inflexible region of α-amylase BLA.

In this study, P. pastoris expressing α-amylase BLA without antibiotic resistance gene was obtained, and expression activity reached 900 U/mL, which has potential application prospect in starch industry. More importantly, we explored the effect of P. pastoris glycosylation on the properties of α-amylase BLA.

Abbreviations

- BLA:

-

Amylase from B. licheniformis

- Pic-BLA:

-

BLA expressed in P. pastoris

- Eco-BLA:

-

BLA expressed in E. coli

- Endo H:

-

Endoglycosidase H

- MM:

-

Molecular mass

- GH:

-

Glycoside hydrolase

References

Benoit I et al (2006) Respective importance of protein folding and glycosylation in the thermal stability of recombinant feruloyl esterase A. FEBS Lett 580:5815–5821

Blom N, Sicheritz-Ponten T, Gupta R, Gammeltoft S, Brunak S (2004) Prediction of post-translational glycosylation and phosphorylation of proteins from the amino acid sequence. Proteomics 4:1633–1649

Borriss R, Buettner K, Maentsaelae P (1990) Structure of the beta-1,3-1,4-glucanase gene of Bacillus macerans: homologies to other beta-glucanases. Mol Gen Genet 222:278–283

Bretthauer RK, Castellino FJ (1999) Glycosylation of Pichia pastoris-derived proteins. Biotechnol Appl Biochem 30:193–200

Chang X, Xu B, Bai Y, Luo H, Ma R, Shi P, Yao B (2017) Role of N-linked glycosylation in the enzymatic properties of a thermophilic GH 10 xylanase from Aspergillus fumigatus expressed in Pichia pastoris. PLoS One 12:e0171111

Clark SE, Muslin EH, Henson CA (2004) Effect of adding and removing N-glycosylation recognition sites on the thermostability of barley α-glucosidase. Protein Eng Des Sel 17:245–249

de Winter J (2013) Using the Student’s t-test with extremely small sample sizes. Res Eval 18:1531–7714

Dey TB, Kumar A, Banerjee R, Chandna P, Kuhad RC (2016) Improvement of microbial α-amylase stability: strategic approaches. Process Biochem 51:1380–1390

Fields PA (2001) Protein function at thermal extremes: balancing stability and flexibility. Comp Biochem Phys A 2–3:417–431

Gurung SP, Schwarz C, Hall JP, Cardin CJ, Brazier JA (2015) The importance of loop length on the stability of i-motif structures. Chem Commun 15:5630–5632

Hiteshi K, Gupta R (2014) Thermal adaptation of α-amylases:a review. Extremophiles 18:937–944

Hofemeister J, Kurtz A, Rorriss R, Knowles J (1986) The β-glucanase gene from Bacillus amyloliquefaciens shows extensive homology Bacillus subtilis. Gene 49:177–187

Hwang KY et al (1994) Crystal structure of thermostable alpha-amylase from Bacillus licheniformis refined at 1.7 A resolution. Mol Cells 7:251–258

Janecek S, Svensson B, MacGregor EA (2014) alpha-Amylase: an enzyme specificity found in various families of glycoside hydrolases. Cell Mol Life Sci 71:1149–1170

Kikani BA, Singh SP (2011) Single step purification and characterization of a thermostable and calcium independent alpha-amylase from Bacillus amyloliquifaciens TSWK1-1 isolated from Tulsi Shyam hot spring reservoir, Gujarat (India). Int J Biol Macromol 48:676–681

Laderman KA, Davis BR, Krutzsch HC, Lewis MS, Griko YV, Privalov PL, Anfinsen CB (1993) The purification and characterization of an extremely thermostable α-amylase from the Hyperthermophilic Archaebacterium Pyrococcus furiosus. J Biol Chem 15:24394–24401

Lee CK, Hsu TA, Wu JM (2003) Expression of the gene coding for bacterial hemoglobin improves β-galactosidase production in a recombinant Pichia pastoris. Biotechnol Lett 25:1457–1462

Li C, Zou S, Huang S, Kaleem I (2013) N-Glycosylation enhances functional and structural stability of recombinant beta-glucuronidase expressed in Pichia pastoris. J Biotechnol 164:75–81

MacGregor EA, Janeček Š, Svensson B (2001) Relationship of sequence and structure to specificity in the α-amylase family of enzymes. BBA Protein Struct Mol Enzymol 1546:1–20

Maley F, Trimble RB, Tarentino AL, PlummerJr TH (1989) Characterization of glycoproteins and their associated oligosaccharides through the use of endoglycosidases. Anal Biochem 180:195–204

Martinez JL (2009) The role of natural environments in the evolution of resistance traits in pathogenic bacteria. Proc Biol Sci 276:2521–2530

Meldgaard M, Svendsen I (1994) Different effects of N-glycosylation on the thermostability of highly homologous bacterial (1,3-1,4)-β-glucanases secreted from yeast. Microbiology 140:159–166

Miller GL, Blum R, Glennon WE, Burton AL (1960) Measurement of carboxymethylcellulase activity. Anal Biochem 1:127–132

Netterstrøm B, Kristensen TS, Damsgaard MT, Olsen O, Sjøl A (1991) Job strain and cardiovascular risk factors: a cross sectional study of employed Danish men and women. Br J Ind Med 48:684–689

Pandey A, Nigam P, Soccol C, Soccol V, Singh D, Mohan R (2000) Advances in microbial amylases. Biotechnol Appl Biochem 31:135–152

Popowska M, Cytryn E, Markiewicz Z (2017) Antibiotics and antibiotics resistance genes dissemination in soils. Soil Biol Biochem 15:151–190

Powers DB et al (2001) Expression of single-chain Fv-Fc fusions in Pichia pastoris. J Immunol Methods 251:123–135

Priyadharshini R, Gunasekaran P (2007) Site-directed mutagenesis of the calcium-binding site of alpha-amylase of Bacillus licheniformis. Biotechnol Lett 29:1493–1499

Rana N, Walia A, Gaur A (2013) α-Amylases from microbial sources and its potential applications in various industries. Nat Acad Sci Lett 36:9–17

Salyers AA, Gupta A, Wang Y (2004) Human intestinal bacteria as reservoirs for antibiotic resistance genes. Trends Microbiol 12:412–416

Sarian FD et al (2017) A new group of glycoside hydrolase family 13 alpha-amylases with an aberrant catalytic triad. Sci Rep 7:44230

Sharp PM, Li WH (1987) The codon adaptation index-a measure of directional synonymous codon usage bias, and its potential applications. Nucl Acids Res 15:1281–1295

Sindhu R, Binod P, Pandey A (2017) 1-α-Amylases. In: Pandey A, Negi S, Soccol CR (eds) Current developments in biotechnology and bioengineering. Elsevier, pp 3–24

Sola RJ, Griebenow K (2009) Effects of glycosylation on the stability of protein pharmaceuticals. J Pharm Sci 98:1223–1245

Souza PM, Magalhães PO (2010) Application of microbial α-amylase in industry—a review. Braz J Microbiol 41:4

Steffan NH, Henry DH, Robert MH, Jeffrey KP, Larry RP (1989) Site-directed mutagenesis by overlap extension using the polymerase chain reaction. Gene 77:51–59

Svensson B (1994) Protein engineering in the α-amylase family: catalytic mechanism, substrate specificity, and stability. Plant Mol Biol 25:141–157

Tai TH, Tanksley SD (1990) A rapid and inexpensive method for isolation of total DNA from dehydrated plant tissue. Plant Mol Biol 8:297–303

Tull D et al (2001) Extensive N-glycosylation reduces the thermal stability of a recombinant alkalophilic Bacillus alpha-amylase produced in Pichia pastoris. Protein Expr Purif 21:13–23

van der Maarel MJEC, van der Veen B, Uitdehaag JCM, Leemhuis H, Dijkhuizen L (2002) Properties and applications of starch-converting enzymes of the α-amylase family. J Biotechnol 94:137–155

Vihinen M, Mäntsälä P (2008) Microbial Amylolytic Enzyme. Crit Rev Biochem Mol Biol 24:329–418

Wang Z, Guo C, Liu L, Huang H (2018) Effects of N-glycosylation on the biochemical properties of recombinant bEKL expressed in Pichia pastoris. Enzyme Microb Technol 114:40–47

Wu X, Wang Y, Tong B, Chen X, Chen J (2018) Purification and biochemical characterization of a thermostable and acid-stable alpha-amylase from Bacillus licheniformis B4-423. Int J Biol Macromol 109:329–337

Yang H, Zhu Q, Zhou N, Tian Y (2016) Optimized expression of prolyl aminopeptidase in Pichia pastoris and its characteristics after glycosylation. World J Microbiol Biotechnol 32:176

Zhang GM, Hu Y, Zhuang YH, Ma LX, Zhang XE (2006) Molecular cloning and heterologous expression of an alkaline xylanase from Bacillus pumilus HBP8 in Pichia pastoris. Biocatal Biotransform 24:371–379

Zhang C, Yao J, Zhou C, Mao L, Zhang G, Ma Y (2013) The alkaline pectate lyase PEL168 of Bacillus subtilis heterologously expressed in Pichia pastoris is more stable and efficient for degumming ramie fiber. BMC Biotechnol 13:1

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31670069), Technical Innovation Special Fund of Hubei Province (2017ACA171), and 2016 Wuhan Yellow Crane Talents (Science) Program. Thanks very much to Dr. K.V. Arivizhivendhan for helping us revise the English.

Author information

Authors and Affiliations

Contributions

The experiments were conceived and designed by XH, PW and GZ. The experiments and data analysis were performed by XH and XY. The manuscript was prepared by XH, NH, TZZ, PW and GZ.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Hu, X., Yuan, X., He, N. et al. Expression of Bacillus licheniformis α-amylase in Pichia pastoris without antibiotics-resistant gene and effects of glycosylation on the enzymic thermostability. 3 Biotech 9, 427 (2019). https://doi.org/10.1007/s13205-019-1943-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1943-x