Abstract

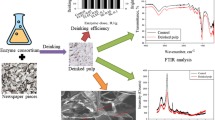

In this study, a chemical reduction strategy was explored for deinking of newspaper waste using xylano-pectinolytic catalysts. A remarkable reduction of 40% in toxic chemicals consumption was obtained by introducing this enzymatic approach of deinking along with improved level of various physical and optical properties. Similarly, a reduction of 18.89% and 17.68% in BOD, COD values of effluent has also been noticed. This combined deinking methodology also resulted in a gain of 5.82% in breaking length, 6.45% in tear factor, 8.57% in burst factor and 9.64% in viscosity, which greatly improved the quality of the handsheets. The study revealed that enzymatic deinking followed by chemical deinking with 40% less chemicals consumption, could be an effective method for reducing the negative impact over the environment caused by 100% deinking chemicals. This is the first report of newspaper waste deinking using xylano-pectinolytic catalysts produced concurrently in the same production media by a bacterial isolate using agricultural wastes as carbon sources.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

These days, the population explosion has resulted in a very high demand of paper for writing, printing, packaging or other purposes. To fulfil this anticipated demand, the paper industries are continuously harvesting green plants, which is eco lethal, as the process generates huge amount of solid waste, which is released into the environment. To overcome this constrain, recycling is the proven method, which involves deinking of the used paper. For this purpose, the paper industries are using toxic chemicals (sodium hydroxide, sodium carbonate, sodium silicate, magnesium sulphate, chelating agents, hydrogen peroxide and various types of surfactants), which affects the quality of paper as well as the environment (Desai and Iyer 2016; Hong et al. 2017; Ibara et al. 2012; Lee et al. 2007; Zang et al., 2008). The deinking using these toxic chemicals results into the release of toxic effluent containing large quantities of environmental pollutants, which interfere with the aquatic life. These alkaline chemical methods also increase the biological and chemical oxygen demand of the effluent, which further increase the treatment cost of the effluent. So, deinking using specific enzymes is an alternative and effective solution to these chemical deinking processes, which generate less pollution, save energy and also decrease the cost of effluent treatment (Desai and Iyer 2016; Hong et al. 2017; Kumar and Satyanarayana 2014; Pala et al. 2006; Xu et al. 2011). Several hydrolytic enzymes which are being used for this purpose are xylanases, pectinases, cellulases, lipases, cutinases and lignolytic enzymes. In this study, the synergistic effect of concurrently produced xylanase and pectinase enzymes has been explored for deinking of newspaper waste. The incorporation of these biological catalysts from a bacterial isolate, in deinking of newspaper waste will definitely make recycling safe, cost-effective, eco-friendly, with less consumption of various toxic alkaline deinking chemicals.

Materials and methods

Materials

A microbial strain, Bacillus pumilus AJK (MTCC Accession No. 10,414), was used for this deinking study. The bacterial culture was routinely subcultured and maintained on nutrient agar medium containing nutrients (g/l) (pH 7: Peptone, 5.0; Beef extract, 3.0; NaCl, 5.0; and Agar, 15.0). The substrates, such as xylan and polygalacturonic acid, used for the estimation of xylanase and pectinase activity were purchased from Sigma-Aldrich, while all other chemicals of industrial grade were used. Newspaper waste was collected from the Biotechnology Department of Kurukshetra University.

Methods

Enzymes production and assay conditions

The production was carried out under submerged fermentation in 250 ml Erlenmeyer flasks containing 50 ml basal medium containing 0.5% peptone and 10 mM MgSO4 (pH 7.0), supplemented with 2% wheat bran and 2% citrus peel (Kaur et al. 2017). The medium was inoculated with 2% inoculum of 21 h old bacterial culture and incubated at 37 °C for 60 h in an incubator shaker at 200 rpm. The cells were harvested by centrifugation and the clear supernatant obtained was used for enzymes assay. Birchwood xylan 1% and polygalacturonic acid 0.5% were used for estimation of xylanase and pectinase activity respectively (Miller 1959). The appropriately diluted enzyme was added into 490 µl of respective substrate prepared in Glycine–NaOH buffer (0.1M, pH 8.5 for xylanase and pH 9.0 for pectinase) and incubated at 55 °C for 10 min and the release of sugars was measured using 3,5- Dinitrosalicylic acid. One unit of xylanase and pectinase is the amount of enzyme that catalyses the release of 1 µmole of reducing sugar equivalent to xylose and galacturonic acid respectively per minute.

Pulp preparation

Pulp was prepared by soaking the torn newspaper overnight followed by washing and disintegration with a domestic grinder. The obtained slurry of pulp was then squeezed and dried in oven for further use.

Enzymatic deinking

To obtain best treatment conditions for deinking of newspaper waste, optimization was carried out using different parameters by one variable approach. During optimization, 2 g pulp was used for each treatment to get the most effective deinking condition. Pulp consistency in a range of 2.5–15.0% was used for optimization. While, different combination of xylanase (2.5–20.0 IU) and pectinase (2.0–17.5 IU) enzymes doses were used for effective deinking. Similarly, pH (7.0–9.0), temperature (40–60 °C) and treatment time (60–240 min) were also optimized to get the maximum deinking. Further different concentrations of tween-80 (0.1–2.0%) were used to increase the efficiency of enzymes on deinking. To maintain the uniform distribution of enzymes in the liquid media, the enzymes were added first following addition of pulp. This facilitate the maximum detachment of the ink particle from the newspaper waste pulp. Heat inactivated enzymes were used for control experiments.

Chemical deinking

The chemical deinking of newspaper waste pulp was performed as per the established protocol of Xu et al. (2011).

Chemical reduction strategy

In chemical reduction strategy, enzyme deinked pulp was used further for chemical deinking treatment with different concentration of chemicals (20–100% chemicals). The aim of this strategy was to obtain a reduction in the concentration of conventional toxic deinking chemicals along with nearly same physical and optical properties of handsheets as obtained after conventional chemical deinking method using 100% chemicals. The pulp obtained after each deinking treatment was squeezed and washed several times with tap water to remove the detached ink particles. A 200-mesh wire was used to recover the washed pulp. The effluent obtained after each deinking treatment was also collected for further analysis.

Sheet formation

The washed pulp obtained after deinking was mixed with water in a conical flask and filtered through a Buchner funnel using Whatman filter paper under suction. The sheets were taken from the funnel and pressed to remove the extra water followed by drying in oven at 45 °C.

Analysis of various properties of effluent and handsheets

Effluent analysis

Reducing sugars released after each deinking treatment were measured against control samples by DNSA method (Miller 1959), while the BOD (biological oxygen demand) and COD (chemical oxygen demand) of the effluent were calculated by IS: 3025 (part 44) and ALPHA method No. 5220 D3 (open reflux method). The effluent was further analysed for the removal of lignin by measuring the absorbance in the range between 220 and 400 nm.

ERIC analysis

Elrepho Lorentzen and Wetter device was used for the measurement of ERIC (effective residual ink content) values of the handsheets (T 567 om-04).

Handsheets’ properties

Handsheets were made after each deinking treatment according to standard TAPPI method (T 205 sp-02). The various optical properties of handsheets such as brightness (T 452 om-87), whiteness and yellowness (T 1216) were measured at 457 nm by ISO colourtech, USA. Moreover, different physical properties such as breaking length (T 494 om-01), burst factor (T 403 om-50), tear factor (T 414 om-04), viscosity (T 230 om-94) and bulk (T 500 cm-07) were also measured according to TAPPI standard methods (TAPPI test methods 1996). All the experiments were performed independently in triplicates and results were expressed as mean ± standard error of three replicates.

Results and discussion

Enzymatic deinking optimization

The xylano-pectinolytic catalysts caused the breakdown of xylan and pectin and released the lignin from the pulp fibre. As a result of lignin removal, the bond between the ink particle and the fibre becomes loose, which causes the detachment and removal of the ink particles from the pulp fibre (Ibara et al. 2012). To make the deinking more efficient, the ink particle released after deinking treatment must be removed by washing, immediately after the treatment, which prevent the redeposition of these particles on to the pulp fibre (Viesturus et al. 1999). Several factors used for optimization of enzymatic deinking, significantly affected the different properties of the deinked pulp. The enzymes released most of the reducing sugars from the pulp at 10% pulp consistency (Table 1). Many researchers reported the use of pulp consistency ranging from 10 to 11% for enzymatic deinking, which promotes the fibre–fibre contact and favours the detachment of ink particles (Desai and Iyer 2016; Kumar et al. 2016; Pala et al. 2006; Soni et al. 2010; Vyas and Lachke., 2003; Xu et al. 2009, 2011). Xylanase and pectinase enzymes with a dose of 12.5 IU and 10 IU per gram pulp was found to be sufficient for removal of ink from newspaper waste pulp (Table 2). Different enzyme doses used by several workers showed that the enzymatic deinking is affected by several factors such as nature of enzyme used, type of waste paper and reaction conditions used for deinking (Chutani and Sharma 2015; Das et al. 2013; Desai and Iyer 2016; Hong et al. 2017; Ibara et al. 2012; Kumar and Satyanarayana 2014; Kumar et al. 2016; Lee et al. 2007, 2013; Soni et al. 2010; Virk et al. 2013; Vyas and Lachke 2003; Zhang et al. 2008).

Performance of enzymes was maximum at pH 8.5 (Table 3), which showed their alkaline nature and suitability for paper industries. Many researchers have used alkaline conditions for deinking of different types of waste paper (Hong et al. 2017; Kumar and Satyanarayana 2014; Virk et al. 2013; Vyas and Lachke 2003). Maximum removal of ink from the pulp was achieved after a treatment period of 150 min (Table 4). Various treatment times have been used by different workers for enzymatic deinking of different types of waste paper, such as 6 h for office waste paper (Das et al. 2013), 60 min for newspaper waste (Lee et al. 2013), 3 h for old newspaper pulp (Virk et al. 2013), 3 h for newspaper pulp (Chutani and Sharma 2015), and 60 min for mixed office waste (Kumar et al. 2016). The enzymes performed most effectively at 50 °C (Table 5). Several workers have reported different temperatures in the range of 50–60 °C for deinking of waste paper (Das et al. 2013; Desai and Iyer 2016; Hong et al. 2017; Kumar et al. 2016; Lee et al. 2007, 2013; Pala et al. 2006; Soni et al. 2010; Vyas and Lachke 2003; Zhang et al. 2008). Most of the deinking treatments have been carried out at lower temperature in comparison to high temperature involved in conventional chemical deinking processes, which showed that enzymatic deinking is an energy saving process. Further, the use of tween-80 with optimum concentration of 1.25% enhanced the various properties of the pulp (Table 6). The literature showed that the stability and performance of enzymes could be increased with the use of surfactants in the deinking media, which increase the removal of ink particles from the pulp (Chutani and Sharma 2015; Lee et al. 2007, 2013; Soni et al. 2010; Vyas and Lachke 2003). The surfactants get absorbed on the ink particles and convert them from hydrophobic to hydrophilic, which results into the attachment of ink particles with the air bubbles in the reaction medium and their removal in further washing steps.

After the complete optimization of biodeinking conditions, a gain of 3.12 and 2.78 units was obtained in brightness and whiteness of the enzymatic deinked pulp in comparison to control. Yellowness was also decreased by a value of 0.84 units. Handsheets prepared after enzymatic deinking showed less residual ink content as compared to control handsheets, which showed a deinking efficiency of 19.55% (Table 7). Lee et al. (2013) also reported a deinking efficiency of 12.9% for newspaper waste using commercial cellulase and hemicellulases. After enzymatic deinking, many researchers reported an increase in brightness as compared to control. Xu et al. (2011) obtained an increase of 3.1 units in brightness of old newspaper pulp deinked with hemicellulase. Moreover, Desai and Iyer (2016) reported an increase of 6.2 units in brightness of old newspaper pulp deinked with xylanase as compared to control. After enzymatic deinking of newspaper waste, UV spectra of the effluent showed a characteristic peak between 260 and 280 nm, which indicated the removal of lignin during the treatment. These peaks were also observed in the effluent of chemical deinking, which also indicated the removal of lignin and the detachment of the ink particles. Similarly, Xu et al. (2009) also observed two absorbance peaks at 205 nm and 280 nm in the effluent obtained after deinking of newspaper waste, which indicates the release of lignin, hence showed detachment of ink particle from the pulp.

Chemical deinking and reduction strategy

After chemical deinking, higher values of different properties such as whiteness and brightness of deinked pulp as compared to pulp deinked with xylano-pectinolytic enzymes were obtained. But the yellowness of the deinked pulp after chemical deinking is higher in comparison to enzymatically deinked pulp. Similar observations have been reported by other workers (Das et al. 2013; Desai and Iyer 2016; Hong et al. 2017). The presence of sodium hydroxide in the chemical deinking media is the cause of yellowness of the deinked pulp. Thus hydrogen peroxide is used to prevent the pulp yellowness during deinking (Hong et al. 2017; Park and Park 2001). The chemicals used in the deinking media deteriorate the structure of the pulp, which results in the fragmentation of the cellulose particles and detaches the ink particles from the fibre (Hong et al. 2017; Pala et al. 2006). The high alkaline nature of the chemical deinking media also causes the swelling of the pulp fibres, which increase the flexibility and detach the adhered ink particles (Ibara et al. 2012).

Despite of giving higher values of brightness and whiteness, the chemical deinking method affects the various physical and optical properties of the handsheets, such as lower strength and higher yellowness. Therefore, a chemical reduction strategy was designed, in which enzyme deinked pulp was used further for chemical deinking treatment with different concentrations of chemicals (20–100% chemicals), with an aim to reduce the amount of toxic chemicals from the deinking media. After performing these deinking experiments, we found that enzyme deinked pulp when treated with 60% chemicals gave nearly same extent of different physical and optical properties of handsheets as obtained after conventional deinking method using 100% chemicals (Table 7). By employing this chemical reduction strategy, a reduction of 40% in noxious chemicals with almost same level of various physical and optical properties was obtained. Therefore, deinking of newspaper waste with combination of xylano-pectinolytic enzymes plus 40% less alkaline chemicals resulted in a gain of 5.82% in breaking length, 6.45% in tear factor, 8.57% in burst factor and 9.64% in viscosity (Table 8), which greatly improved the quality of the handsheets. This combined strategy of enzymatic and chemical deinking method also reduced the BOD, COD of the effluent by a value of 18.89% and 17.68% in comparison to conventional chemical method (Table 8).

Conclusions

The study shows that xylano-pectinolytic catalysts by a microbial isolate can be an effective solution for reducing the pollution generated by conventional deinking processes. By employing this chemical reduction strategy with enzymatic deinked pulp, a reduction of 40% in the requirement of deinking chemicals has been observed along with enhanced level of handsheets quality. This strategy would also reduce the effluent treatment cost. Therefore, this chemical reduction strategy using two biological catalysts from a single microbe is cost-effective and eco-friendly method for deinking of newspaper waste, hence suitable and can be implemented at industrial level.

References

Chutani P, Sharma KK (2015) Biochemical evaluation of xylanases from various filamentous fungi and their application for the deinking of ozone treated newspaper pulp. Carbohydr Polym 127:54–63

Das A, Paul T, Halder KS, Jana A, Maity C, Das PK, Pati MB, Mondal KC (2013) Production of cellulolytic enzymes by Aspergillus fumigatus ABK9 in wheat bran-rice straw mixed substrate and use of cocktail enzymes for deinking of waste office paperpulp. Biores Technol 128:290–296

Desai DI, Iyer BD (2016) Biodeinking of old newspaper pulp using a cellulase-free xylanase preparation of Aspergillus niger DX-23. Biocatal Agric Biotechnol 5:78–85

Hong R, Su L, Chen S, Long Z, Wu J (2017) Comparison of cutinases in enzymic deinking of old newsprint. Cellulose 24:5089–5099 https://doi.org/10.1007/s10570-017-1424-5

Ibara D, Monte MC, Blanco A, Martinez AT, Martinez MJ (2012) Enzymatic deinking of secondary fibres: cellulases/hemicellulases versus laccase-mediator system. J Ind Microbiol Biotechnol 39:1–9

Kaur A, Singh A, Dua A, Mahajan R (2017) Cost effective and concurrent production of industrially valuable xylano-pectinolytic enzymes by a bacterial isolate Bacillus pumilus AJK. Prep Biochem Biotech 47:8–18

Kumar V, Satyanarayana T (2014) Production of endoxylanase with enhanced thermostability by a novel polyextremophilicBacillus halodurans TSEV1 and its applicability in waste paper deinking. Proc Biochem 49:386–394

Kumar A, Dutt D, Gautam A (2016) Production of crude enzyme from Aspergillus nidulans AKB-25 using black gram residue as the substrate and its industrial applications. J Genet Eng Biotechnol 14:107–118

Lee CK, Darah I, Ibrahim CO (2007) Enzymatic deinking of laser printed office waste papers: some governing parameters on deinking efficiency. Bioresour Technol 98:1684–1689

Lee CK, Ibrahim D, Omar IC (2013) Enzymatic deinking of various types of waste paper: efficiency and characteristics. Proc Biochem 48:299–305

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:420–428

Pala H, Mota M, Gama FM (2006) Factors influencing MOW deinking: laboratory scale studies. Enzyme Microb Technol 38:81–87

Park J, Park K (2001) Improvement of the physical properties of reprocessed paper by using biological treatment with modified cellulase. Bioresour Technol 79:91–94

Soni R, Nazir A, Chadha BS (2010) Optimization of cellulase production by a versatile Aspergillus fumigatus fresenius strain (AMA) capable of efficient deinking and enzymatic hydrolysis of Solka floc and bagasse. Ind Crops Prod 31:277–283

TAPPI test methods (1996) Technical association of the pulp and paper industry. TAPPI Press, Atlanta

Viesturs U, Leite M, Eisimonte M, Eremeewa T, Treimanis A (1999) Biological deinking technology for the recycling of waste office papers. Bioresour Technol 67:255–265

Virk AP, Puri M, Gupta V, Capalash N, Sharma P (2013) Combined enzymatic and physical deinking methodology for efficient eco-friendly recycling of old newsprint. Plos One 128:290–296

Vyas S, Lachke A (2003) Biodeinking of mixed office waste paper by alkaline active cellulases from alkalotolerant Fusarium sp. Enzyme Microb Technol 32:236–245

Xu Q, Fu Y, Gao Y, Qin M (2009) Performance and efficiency of old newspaper deinking by combining cellulase/hemicellulase with laccase–violuric acid system. Waste Manag 29:1486–1490

Xu QH, Wang YP, Quin MH, Fu YJ, Li ZQ, Zhang FS, Li JH (2011) Fibre surface characterization of old newsprint pulp deinked by combining hemicellulase and laccase mediator system. Bioresour Technol 102:6536–6540

Zhang X, Renaud S, Paice M (2008) Cellulase deinking of fresh and aged recycled newsprint/magazines (ONP/OMG). Enzyme Microb Technol 43:103–108

Acknowledgements

The financial support (Grant number: HSCST/2258) provided by Department of Science and Technology, Government of Haryana, India is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest concerning the publication of this article.

Rights and permissions

About this article

Cite this article

Singh, A., Kaur, A., Yadav, R.D. et al. An efficient eco-friendly approach for recycling of newspaper waste. 3 Biotech 9, 51 (2019). https://doi.org/10.1007/s13205-019-1590-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1590-2