Abstract

This manuscript describes the use of nitrophenyl-functionalized single-walled carbon nanotubes (NP-SWNT) in organic photovoltaic cells for the first time. We mainly focus on these innovative materials to scout for the replacement or doping of the universal buckminsterfullerene PCBM acceptor in the active layer. An optimization of the functional degree was first conducted for the position of energy bands and then experimentally confirmed. The morphology of the active layer was optimized with the NP-SWNT concentrations up to 20 wt% using additives and processing methods. The key step to avoid short circuits resulting from both high conductivity and high aspect ratio is controlling the NT functional degree and the film morphology. Using a specific functional degree (49 wt%), Organic photovoltaic (OPV) devices exhibit a maximum unprecedented efficiency of 0.13%, at an optimal nanotube loading of around 2 wt%, in BHJ with P3HT as the p-type semiconductor. In a leading precedent, our results constitute important progress for the application of NP-SWNTs in large area solution processed photovoltaic cells and provide insight into the role of structural organization in the device performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Photo-assisted devices such as batteries or solar cells are made from nano-structured semiconducting organic and/or inorganic materials that convert light into electricity. In the context of initial efforts to exploit nanoscience in the development of nanostructure based on nanomaterials for alternative energy generation, many environmental-friendly concepts have emerged (Zhang et al. 2018,2020; Nourdine et al. 2017; El-Moussawi et al. 2019; Lecarme et al. 2019). Carbon-based solar cells comprising conjugated polymers and fullerene derivatives are among the leaders in the future photovoltaic technologies with low-cost production (Su et al. 2012). In recent years, considerable effort has been devoted to exploring non-fullerene acceptors for use to substitute fullerene derivatives in bulk heterojunction (BHJ) organic solar cells (Ball et al. 2014; Jiang et al. 2014; Lin et al. 2012; Sun et al. 2015). Several non-fullerene acceptors have been developed and applied in BHJ solar cells, among them carbon nanotubes, conjugated polymers, perylenes and inorganic semiconducting nanoparticles (Dennler et al. 2009; Hoppe and Sariciftci 2007; Li et al. 2015; Lin et al. 2015). Recently, NFs have unexpectedly boosted the efficiency of OPVs to the highest values (Cui et al. 2019; Liu et al. 2020). For carbonaceous acceptors so far, only derivatives of C60 and C70 have been reported to give high efficiency, despite their non-ideal HOMO and LUMO levels and optical absorption for most donor polymers (Scharber et al. 2006). The valuable efforts to alter the energy levels by attaching electron-donating groups to the carbon cage, could only slightly shift (100–200 meV) the LUMO of C60 (Lenes et al. 2008). On the contrary, non-fullerene acceptors combine the advantages of low cost, synthetic versatility, strong absorption ability, improved processability, tunable energy levels and high environmental/thermal stability. They have recently emerged as a hot area of focus in the field of organic photovoltaics (Li and Wonneberger 2012; Meng et al. 2015; Würthner 2004). By virtue of strong quantum confinement and bandgap tunability, single-walled carbon nanotubes (SWNTs) could, however, play a crucial role in PV devices and have been the subject of large and ongoing research (Ajayan and Tour 2007; Baughman et al. 2002). Because organic semiconductors present carrier mobility that is hundredth that of inorganic materials, incorporating CNTs in organic solar cells (OSCs) could plausibly provide direct continuous electron pathways that do not rely on electron hopping, and thereby improve the device performances greatly. In 1998, Curran et al. (1998) showed that composites including arc-grown multiwalled carbon nanotubes (MWNTs) and meta-linked poly(p-phenylene vinylene) (PPV) derivatives could increase the LED stability in air (Curran et al. 1998). However, the addition of nanotubes in a composite structure precipitously induces short-circuits due to their high conductivity and critical aspect ratio. The proper use of SWNT aspect ratio and one-dimensionality requires a very good dispersion and distribution of the filler. Up to now, SWNTs have been incorporated in two ways to BHJ device configuration: either as an independent layer at desired locations, or as a blend with organic species (Chaudhary et al. 2007). Arnold et al. (2009), reported a solar cell device consisting of an all-carbon active layer with semiconducting nanotubes as both the light-absorbing and donor material and C60 as the acceptor. This work demonstrated the potential application of carbon-based materials as the primary photoactive electron-acceptors elements in an OPV cell. More recently Ramuz et al. (2012) laid the first all-carbon solar cell at a modest 0.1% efficiency, where a bilayer of polymer sorted semiconducting single-walled carbon nanotubes sc-SWNT was employed as the light absorber and C60 as the acceptor.

Depending on the application, SWNTs are often applied merely after separating and sorting. So far, a key point to avoid short circuits has been to use pure sc-SWNT in single or various chiralities, as sensitizers, dopants (Abeygunasekara et al. 2015), acceptors and charge transporters (Ren et al. 2011; Derbal-Habak et al. 2011; Stylianakis et al. 2010; Abdulrazzaq et al. 2013; Bernardi et al. 2012). These NTs are, however, rare and expensive. The metallic counterparts are more suited for conductive electrodes (Bernardi et al. 2012; Bindl et al. 2010; Jain et al. 2012). Recently, SWNTs have been prepared in non-polar dispersions with polyfluorene (Arnold et al. 2006) and polythiophene (Wang and Bao 2015; Wang et al. 2014) to obtain high-purity semiconducting SWNTs. However, the considerable interest in using CNTs for sustainable energy applications implies imperatively lower the processing cost.

We have already stated in a previous work that (El-Moussawi et al. 2019), unlike many covalent routes, nitrophenylation of CNTs using 4-nitrobenzene diazoether interestingly tunes the intrinsic conductivity of CNTs while avoiding even marginal damage to their initial structure. Accordingly, to avoid high prices, while combining good solution processability to modulated energy levels and retained structural integrity, we choose to employ exclusively nitrophenyl-functionalized SWNTs at 49 wt%, NP-SWNT-49, as acceptors, because they possess energy levels that are a priori compatible with those of P3HT, the paired light harvester.

Two device configurations are fabricated: bilayer and bulk. Evidently, BHJ yields the best performance (0.13%). We describe the combination of processing and active layer engineering strategies to overcome the short circuits and realize NP-SWNT-based photovoltaic devices. Although the highest PCE is low, we successfully introduce, without sorting or separation, the electron acceptor behavior of the NP-SWNTs with an open-circuit voltage (VOC) of 1.05 V and fill factor (FF) of 0.47. Such efficiency has been never reported for likewise SWNTs.

Experimental

Materials

Commercial single walled carbon nanotubes were purchased from Raymor NanoIntegris (RN-220 SWNTs, L < 1 µm, diameter 0.9–1.5 nm, purity of 85–90%, with 10–15 wt% of nickel, iron and cobalt catalyst content. SWNTs were purified and functionalized with 4-nitobenzenediazoether as described before (El-Moussawi et al. 2019). 6,6-Phenyl-C61 Butyric Acid Methyl Ester (PC60BM) was purchased from SES Research (99%), Poly(3-HexylThiophene) (P3HT) from Rieke Metals (RMI-001EE, rr = 96%, 36–90 kg/mol, electronic grade) and (Poly[[5,7-bis(2-ethylhexyl)-4,8-dioxo-4H,8H-benzo[1,2-c:4,5-c']dithiophene-1,3-diyl][3,3′''-bis(2-ethylhexyl)-3′',4′-difluoro[2,2′:5′,2′':5′',2′''-quaterthiophene]-5,5′''-diyl]]) (PBDD4T‐2F) from Ossila (138 kg/mol, PDI = 2.6).

Conductivity measurements of NP-SWNT

As detailed in (El-Moussawi et al. 2019), J-V characteristics were collected using Biologic Science instrument-SP 300 and data treated with EC-Lab software. Samples were assembled according to a developed procedure (Nourdine et al. 2017).

Electrochemical measurements

The cyclic voltammetry (CV) was carried in a standard three-electrode cell under nitrogen atmosphere (El-Moussawi et al. 2017).

UV–Vis–NIR spectroscopy

Polymer and SWNT absorption spectra were carried out on a UV-1800 Schimadzu spectrophotometer from 350 to 900 nm. The blend films were spin coated from fresh P3HT/SWNT solutions on glass and spectra collected relative to reference cell containing glass substrate.

Photoluminescence (PL) spectroscopy

Photoluminescence spectra were acquired on a Hitachi (Tokyo, Japan) F-4500 fluorescence spectrophotometer. A 470 nm excitation wavelength was used for acquisition of spectra.

SEM observations

Scanning electron microscopy was performed on blend films deposited on conductive ITO substrates at 30 kV. Silver paste was coated on top of the sample. The images were acquired using a SEM, model Zeiss Gemini 500. At least five images were acquired per sample for a credible measure and a reliable comparison.

Image treatments

All image treatments in this work were performed with the ImageJ freeware. During their treatment, all images were saved in a lossless 16-bits depth TIFF format.

Mechanical profilometry

Both thicknesses and surface roughness were probed by an Alpha step IQ mechanical profiler from KLA-Tencor-D500. Three consecutive scans on 0.8 mm were performed with a 0.1 mg stylus force at a 0.1 mm/s scanning speed leading to a 0.2 µm lateral resolution.

Assembly of organic solar cells

Bulk heterojunction

Organic solar cells were fabricated starting by commercially available Indium Tin Oxide (ITO) glass substrates from Ossila (reference: S101, dimensions: 20 mm × 15 mm × 1.1 mm) supporting a 100 nm layer of pixelated anodes (6 anodes per substrate with unitary surface of 4 mm × 1.5 mm ≈ 6 mm2, resistance ≈ 20 Ω/sq and roughness ≈ 1.8 nm RMS). Transparent substrates were sonicated in two consecutive hot distilled water baths (80 °C), and once in isopropanol. Substrates were blown with heat flow, and then exposed to UV-ozone treatment (Ossila UV ozone cleaner E511) for 30 min. 90 µL of PEDOT:PSS in water (Al 4083, Ossila, 13–17 g/L, 500–5000 Ω cm) were spin-coated (KLM SCC 200, Schaefer techniques) at 83 rotations per second (rps) for 30 s. An additional spinning step at 1 rps during 30 s was then performed to pre-dry the layer. A film is produced with a typical thickness of 30–40 nm and, if imperfections are visually inspected near the active pixels, the substrate is discarded. If not, it is baked on a hot plate at 120 °C for 15 min. P3HT:PCBM ratio was optimized at 1:0.8 after several experiments. Powder of each material was weighed using METTLER TOLEDO balance (10–2 mg precision) to prepare active layer solutions in chlorobenzene. The so-prepared solution was stirred at 60 °C for 4 h. If the acceptors are CNTs, however, only P3HT (20–30 g/L) is dissolved in chlorobenzene for 4 h at 60 °C. Few microliters of NP-SWNTs (0.5–2.5 g/L) are ultrasonicated also in chlorobenzene at 150 W for 15 min using high intensity “Fischer Scientific” sonicator. P3HT solution is mixed with the CNT dispersion and sonicated together in an ultrasonic bath for 1 min 50–70 µL of the photoactive solution were pipetted at the center of the substrate and spin cast at 25 rps during 40 s, then pre-dried 33 rps for 40 s. Devices were completed via thermal deposition of LiF/Al (2/100 nm) top electrode under secondary vacuum (10–6 mbar) using EDWARDS FTM6 thermal evaporator. Current density versus voltage (J–V) curves were measured with a Biologic Science Instrument SP-300 under AM1.5 illumination (ORIEL solar simulator LCS 100) at intensity of 100 mW cm–2. J = f(V) curves acquisition consists of applying a voltage sweep on the cells terminals and measuring the corresponding output current in the dark or under illumination. Data and PV parameters were collected using EC-lab software. Voltage sweeps were performed from − 1.5 to 1.5 V for P3HT:PCBM blend, and − 2.5 to 2.5 V when SWNTs are included, with a 0.05 V step between each measurement. The cell active area was defined 4.5 mm2 using an aperture mask.

Deposition of thin NP-SWNT layer for bilayer OPV cells

A number of optimization tests has been realized to find the best conditions to obtain, in the first place, a visually homogeneous layer of NP-SWNT at macroscopic scale and, in the second place, a continuous layer (control by profilmeter and scanning electron microscopy) at the microscopic scale. To do so, we made use of a vacuum chamber placed on a hot plate, connected to a temperature sensor, vacuum regulator and a pump, as indicated in Fig. 1. An optimal film was obtained at 40 °C (± 1 °C) and 10 mbar as indicated on the vacuum regulator (VAP 3000 vacuubrand, CVC 3000 vacuubrand). We have drop-coated 80 µL of dilute NP-SWNT-49 suspension in DMF (0.1 g/L) on clean ITO substrates. The four substrate edges were covered with a low-adhesive tape to help the solution spread homogeneously in a square pan (Fig. 2). Thickness measured by mechanical profilometry is 80–100 nm. However, the surface roughness is so rough (Fig. 2) that a very thick P3HT layer (800 nm) was needed for a conformal coating to avoid a short-circuit. Therefore, after drying, drops of a 20 g/L P3HT solution in chlorobenzene were deposited and left overnight under nitrogen pressure (2 mbar). This treatment could stimulate the penetration of P3HT into the inter-particle cavities of SWNT layer to form a good composite with enhanced polymer/SWNT interface. Next day, the polymer solution was completely dried under vacuum for 4 h and annealed at 50 °C for 5 min. To finish a 100 nm Al bands were thermally evaporated under vacuum using an aperture mask.

Results and discussion

Choice of optimal materials

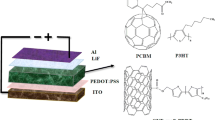

The Power Conversion Efficiency (PCE) primarily results from individual mechanisms in photovoltaic conversion: absorption, exciton diffusion, charge transfer and collection. PCE is, therefore, largely altered by the intrinsic properties of the electron donor (D) and electron acceptor (A) materials (Fig. 3), especially, their energy levels. Thus, for each material, it is important to optimize the D/A couple starting with their energy levels diagram, Fig. 4. We have synthesized a number of NP-SWNT derivatives (Table 1) to improve the processability and vary the HOMO/LUMO levels (El-Moussawi et al. 2019). Figure 4a depicts the orbital energy-level diagram of the different components, and the solvent processability of each one is conceptualized in Fig. 4b. As-received SWNTs exhibit polydispersed diameters (0.9–1.5 nm). This results in a distribution in energy levels, and a heterogeneity of the electronic properties of the NP-SWNTs (El-Moussawi et al. 2019). The estimated LUMO and HOMO of our NP-SWNTs were determined electrochemically as detailed in a previous publication and reported in Table 1 (El-Moussawi et al. 2019). The reference standards P3HT and PCBM were characterized with the same protocol.

a Energy-level diagram of the components in the OPV devices used in this study. The energy levels of P3HT, PCBM and NP-SWNT are estimated based on the onsets of oxidation and reduction potentials (adapted from El-Moussawi et al. 2019). The band gap of pristine SWNT is taken from a Ref. (Jeon et al. 2015). b Qualitative solvent processability of P3HT, PCBM, SWNT and NP-SWNT

aNP/SWNT (wt%) deduced from Raman (El-Moussawi et al. 2019)

bConductivity measured according to the conditions described in experimental section

cElectrical conductivity of PCBM is taken from Ref. (Nourdine et al. 2011)

dElectrical conductivity of P3HT is taken from Ref. (Obrzut and Page 2009)

eElectrochemical properties (HOMO, LUMO and band gap) of pristine SWNT are taken from Ref. (Jeon et al. 2015)

fElectrochemical properties (HOMO, LUMO and band gap) of PCBM and P3HTmesaured in previous work (El-Moussawi et al. 2017)

Depending on the light-harvesting donor, the incorporation of NP-functionalized SWNTs into the active layer as electron acceptor results in heterojunction P3HT/NP-SWNT. The band alignment at the D/A interface should exhibit positive valence energy offsets (ΔEV = ΔEHOMOD–HOMOA) to optimize the crucial step of photogenerated excitons dissociation (Opitz 2017; Wang et al. 2015). The conduction band offset (ΔEC = ΔELUMOD–LUMOA) should also be greater than 0.3 eV for an efficient exciton dissociation at the donor–acceptor interface. The photovoltaic gap ΔEPV, or in other words, the difference between the ionization energy, or HOMO of the donor and the electron affinity, or LUMO of the acceptor (ΔEPV = ΔELUMOA–HOMOD) (Opitz 2017). Higher ΔEPV should directly result in large open-circuit voltage (VOC), but this rule also suffers from exceptions (Elumalai and Uddin 2016). Here a modest ΔEPV (1.29 eV) inferred from the flat band diagram for P3HT:NP-SWNT-49 compared to PCBM-based counterpart (1.42 eV), corresponds to a large VOC of 1.9 V at 0.5 wt% load, using additives. The physics differs substantially between the fullerene and NT species. As shown in Table 2, ΔEV is positive between P3HT and all the functionalization degrees; they all should behave as acceptors. The LUMO levels of both NP-SWNT-21 and NP‐SWNT-49 are higher than the HOMO and lower than the LUMO of P3HT resulting in positive conduction band offset of 0.61 eV and 0.47 eV, respectively and respective photovoltaic band offset (ΔEPV) of 1.15 eV and 1.29 eV at P3HT/NP-SWNT interface. The band offsets are necessary to impel electron transfer from the donor polymer, whether P3HT to NP-SWNT after exciton dissociation at the heterointerface (Salim et al. 2016a).

Another important parameter is the solvent-processabilty. The polymeric donor (P3HT) is readily soluble in halogenated solvents. PCBM is also considered soluble (Boucher and Howell 2016). Pristine SWNTs are virtually tangled and quite awkward to process. However, functionalization prompts nanotube processability (Fig. 4b). We have demonstrated, for example, that the suspension of NP-SWNT-61 could be filtered over 0.45 µm membrane due to the outstanding nanotube dispersion (El-Moussawi et al. 2019). With a LUMO value of 3000 meV above the SWNT, the latter functional degree suffers, however, from energy misalignment with P3HT (ΔELUMO-LUMO < 0). Besides, an upper shift of the acceptor LUMO level is preferred as it usually promotes the highest efficiency uplift (Dennler et al. 2009), yet it should not exceed the donor LUMO. Note that NP-SWNT-61 could be used as the light harvesting material with PCBM due to the good match between their energy levels (Koleilat et al. 2016), or in applications where homogeneous NT suspensions are needed to be solution-processed into thin transparent films (10–50 nm). Here, we wish to provide a comprehensive discussion on the incorporation of NP-SWNT-49, the best trade-off between processability, energy levels and conductivity, in OPV devices.

Bilayer heterojunction devices based on P3HT/NP-SWNT-49

The P3HT/PCBM bilayer has been reported with significant photovoltaic properties (Cao and Xue 2014; Lin et al. 2014; Casalegno et al. 2015). The low PCE as compared to bulk heterojunction, was attributed to the difference in mesoscopic morphology (Lin et al. 2014). In such systems, most of the absorbed photon energy is not efficiently converted to free carriers, but dissipated by recombination. Because the donor and acceptor layers are around 40–60 nm thin, the photogenerated excitons are dissociated close to the interface between donor and acceptor.

Even if less efficient, the bilayer junction could be used to probe the viability of NP-SWNT in the photoactive layer. The layered configuration (transparent anode, NP-SWNT-absorbing polymer) is straight forward, it avoids the time-consuming optimization of the D/A ratio and morphology. In addition, the thickness of CNT films will not hinder the charge transport, because of the unique “ballistic” transport along their axes (Blackburn 2017). Finally SWNTs, unlike C60, are expected to both act as acceptors in bilayer and form interpenetrating network with the polymer chains, as shown by Ago et al. (1999).

We thus started with this simple double layer of P3HT and functionalized SWNTs to create new photovoltaic devices according the procedure described in experimental section. The final devices exhibited encouraging J(V) curves typical of PV systems (Fig. 5). The photocurrent appeared rather low, probably because of the thick P3HT active layer, as demonstrated by Romero et al. (1996). The generated photocurrent is very similar to a P3HT single junction with no acceptor, as presented in Table 3. The cell is likely dominated either by recombination or short-circuits. Any fractures or aggregates, even at the sub-micrometer level on the CNT film, can leave the anode in ohmic contact with the cathode. In other words thin NP-SWNT film with a smooth surface and similar electronic character should exhibit better photovoltaic properties in such junction. The very good VOC with these materials leads us to believe that they could be investigated further.

Bulk heterojunction BHJ devices based on P3HT/NP-SWNT-49

Defining the equivalent mass percentage (wt%) of SWNT and PCBM in a BHJ device

Several challenges need to be properly handled when integrating SWNT into the active layer in bulk heterojunction with the key objective of producing functional photovoltaic devices. The first one is the amount of nanotubes that could offer feasible access to processability and result in charge separation and long-lived radical pairs. SWNTs possess extreme aspect ratios (≈ 1000 for our NTs), and a large specific surface area SSA (1300 m2/g) (Peigney et al. 2001). In contrast, the SSA of PCBM is only the half (725 m2/g) (Papirer 2000). To benchmark our BHJ results, experiments involving P3HT:PCBM were carried, and the ratio 1:0.8 was found optimal with 2.7% efficiency. Accordingly, a close inspection reveals that this ratio corresponds to about 22 wt% of SWNT indeed (Fig. 6). The ultimate goal is now to obtain a homogeneous processable blend film at such high CNT load.

Defining the optimal nanotube load wt% for functional P3HT/NP-SWNT-49 BHJ device

The photovoltaic and optical properties of P3HT/NP-SWNT49 devices were studied in a wide range of nanotube concentrations. NP-SWNT-49 was dispersed in chlorobenzene in concentration of 2.5 g/L by ultrasonication for 30 min at 375 W. A separate solution of P3HT (20–30 mg/mL, in chlorobenzene) was also prepared. The desired compositions for the active layer were prepared by mixing the two solutions in appropriate proportions under stirring (nanotube concentration of 0.5, 1, 1.5, 2, 3, 4, 5, 10 and 20 wt%). For devices preparation, a PEDOT/PSS hole transporting layer was first deposited onto the ITO contact. Next, active layers consisting of both P3HT/NP-SWNT-49 were spin-cast from solution. Unless noted otherwise, active layers were not thermally annealed. When thermal annealing was performed, samples were heated at 80 °C for 10 min. Higher annealing temperature leads to immediate short circuits.

Figure 7 shows operating characteristics of non-annealed P3HT/NP-SWNT-49 devices at different nanotube concentrations (the results were obtained by averaging measurements from six devices for each nanotube concentration with a standard deviation presented on the graph); we report the complete set of results in Table 4. Due to the promoted D/A interfaces for charge transfer, both the open-circuit voltage and the short-circuit current density are first improved by the nanotube loading, at low SWNT weight concentrations (x < 2%). An optimal value of VOC = 0.73 V and JSC = 0.076 mA/cm2 was then reached. This is an order of magnitude less than the theoretically expected with C60, because of the morphology. The best device with x ≈ 2% furnished an AM1.5 power conversion efficiency of 0.02%. Beyond this NT load, the performances drop most likely due to the formation of aggregations a trained eye can easily distinguish. At 20 wt%, the film is so heterogeneous that devices are no longer functional (short-circuit). This induces a drop in shunt resistance (Rsh), due in part to the morphology, and in part to the percolation threshold that is likely attained at 11 wt%.(Kymakis and Amaratunga 2002; Sun and Sariciftci 2005). So the OSC behaves here as a resistive wire. The high aspect ratio of SWNTs could even more aggravate the damaged structure (0.3–1 μm in length) in comparison to the thin active layers (≈ 100 nm).

Experimental values of a the open-circuit voltage (closed black circles) and short-circuit current density (open orange circles), b fill factor (closed black squares) and power conversion efficiency (open orange squares) as a function of the NP-SWNT-49 weight fraction in the active layer for P3HT/NP-SWNT-49 based solar cells (color figure online)

Another major issue that limits the device performance of CNT-based solar cells is bundling and μm-scale aggregation, allowing only for low concentrations of SWNTs to be realized. Thus, an improvement of the active layer morphology appears necessary for the prevention of nanotube bundling. The amount of interface available for charge separation is reduced with SWNT aggregates, inducing exciton sinking and recombination. This substantially alters the properties of the individual tubes.

Optical properties and blend morphology

Most of the reported efforts have shown that CNTs could act as self-assembly “template” for conjugated polymers. Positive consequences of the polymer nano-structuring on optical properties have been discerned (Derbal-Habak et al. 2011; Bernardi et al. 2012). To assess the impact of the structural ordering in the P3HT/NP-SWNT-49 active layers, we recorded UV–Vis absorption spectra and photoluminescence PL measurements. Figure 8a shows the UV–Vis absorption spectra of as cast polymer/NP-SWNT-49 blends with various NP-SWNT-49 concentrations, revealing three shoulders. The first at 520 nm corresponds to the P3HT absorption peak and the vibronic shoulders at 560 nm and 610 nm (corresponding to 0–1 and 0–0 transitions, respectively) are representative absorption features of rr-P3HT. The corresponding absorption spectra of P3HT show a strong peak at 601 nm that is redshifted and broadened with an increase in NP-SWNT-49 concentration, which is a manifestation of enhanced π–π interactions among the polymer layers (Ren et al. 2011; Tsoi et al. 2011). High NT content (10 wt%) could give rise to an onset shift from 643 to 666 nm and intensify the vibronic shoulders. These changes provide evidence of the photoinduced charge transfer between P3HT and NP-SWNT-49, and suggest a more rigid structure of rr-P3HT molecules in the presence of CNTs (Salim et al. 2016b). It could also indicate hybridization between their LUMO levels. Nevertheless, the changes in absorption were impossible to confirm at higher NP-SWNT-49 loading (20 wt%), restricted by the heterogeneous nature of the films.

It has been shown that the addition of sc-SWNT result in PL quenching of rr‐P3HT (Kymakis et al. 2008; Tsukamoto and Mata 2004). Figure 8b compares PL spectra of three different NP-SWNT concentrations in P3HT, to P3HT:PCBM and P3HT in thin films, all deposited on ITO substrates. The PL quenching of the P3HT/NP-SWNT-49 exhibits an improvement with increasing NP-SWNT loads, and in P3HT:PCBM, the quenching is almost complete suggesting that NP-SWNTs form an intimate contact with the P3HT layers and they can improve the dissociation of excitons generated in the polymer.

Nevertheless, to understand the influence of NP-SWNT-49 addition on electrical performance in cells, morphological properties of rr‐P3HT:NP-SWNT-49 bulk heterojunctions (BHJs) should be investigated.

In terms of photovoltaic properties, the transport properties and electrical device characteristics are further affected by the active layer morphology. As discussed above, the NP-SWNT-49 could play a key role in improving transport in the device in a range of nanotube loadings to 20 wt%. However, the SEM images shown in Fig. 9 show that the PV results can be qualitatively interpreted with morphological and structural changes of the blend.

The series of SEM images clearly reveals the evolution of the annealed film morphology change with increasing NP-SWNT-49 concentration in the blend. The 0.5 wt% NP-SWNT-49 forms nano-sized structures pointing outward, with estimated diameter of ≈ 20–35 nm and estimated length of ≈ 0.3–0.8 µm. Addition of NP-SWNT-49 (10 wt%) prompts the needle-like domain sizes to ≈ 30–60 nm and the length to 1 µm (Kim et al. 2012). The increasing trend with the increasing NP‐SWNT-49 amount reveals a fully percolated structure of anisotropic, elongated and interfering nanostructures, at NP-SWNT-49 loading of 20 wt%. On the other hand, the heat-treated P3HT:PCBM (superior control device) exhibits a posteriori embedded phase separation in the polymer matrix with domain sizes of 50–150 nm. It is obvious that the addition of NP-SWNT significantly coarsens the blend film, as shown by the textured surface morphology. This could be attributed to the growth of existing nanoscale crystalline regions at the expense of smaller ones (Verploegen et al. 2010).

We measured high series resistances Rs (kΩ cm2) for devices with P3HT:NP-SWNT-49 morphology compared to few 10 Ω cm2 for devices based on a mixture of P3HT and PCBM (not presented here). Subsequent heat treatment promotes the aggregation among the nanotubes and, therefore, favors self-trapping and recombination centers, severely limiting the exciton diffusion/separation process between P3HT and NP-SWNT-49. This suggests that carrier transport is strongly dependent on the active layer morphology and is not controlled by ballistic conduction in the SWNT phase but rather occurs in the diffusive regime in both SWNT and P3HT phases (Salim et al. 2016b).

This comparative study verifies that an approach to improve the morphology could be effective in avoiding aggregates at a certain loading limit, as aggregates contribute to device short-circuiting and poor shunting that results from percolating paths connecting both electrodes (Kymakis et al. 2008). Hence, we will discuss next the effects of improved morphology on the electrical properties.

Optimization of the morphology of the active layer (2 wt%) to seek better performance

To improve the morphology of the active layer, the experimental optimum 2 wt% receives additional treatment using a polar solvent N-methyl-2-pyrrolidone (NMP) and a processing additive at ambient temperature. NMP not only favors P3HT aggregation on the NP-SWNTs, but also improves the NP-SWNT miscibility. 1,8-diiodooctane (DIO) or 1- chloronaphthalene (CN) could favor the aggregation of P3HT on the NT acceptor (Su et al. 2011), leading to favorable phase separation. The mixtures were prepared by progressively increasing the solvent polarity by the addition of NMP between 1 and 20 vol%. The resulting solution showed visible aggregations that disappear after 2-min sonication bath followed by 1-min of mild heating at 40 °C. This step should be performed with great care, overheating rapidly precipitates the solutions. DIO or 1-chloronaphthalene was quickly injected at 3 vol%. to the P3HT-NP-SWNT-49/NMP solution, followed by quick agitation and directly spin coating. After a significant number of tests, the combination (NMP/DIO, 10/3, vol/vol) was identified the most suitable. Morphology was controlled by Scanning Electron Microscopy (Fig. 10).

Figure 11 shows the surface and cross-sectional SEM images of P3HT/NP-SWNT-49 (x = 2 wt%) before and after treatment by additives. Addition of NMP and DIO enhances the embedment of NP-SWNT in the polymer matrix. The tube-like structure on the blend surface have disappeared indicating a good nanotube dispersion, and large areas for charge transfer (Liu et al. 2014). Therefore, our NP‐SWNTs boost VOC to 1.05 V, JSC to 0.22 mA cm–2 and FF to 47%. The important comparison here is the relative performance. The improved JSC value is the consequence of additives that inhibited the SWNT bundling, while keeping a better carrier transport. The efficiency thereby improved three folds over the prior art with both semiconducting and metallic SWNTs combined with a polymer (Kymakis and Amaratunga 2002; Adikaari et al. 2010). In particular, the VOC value is really high. A similar effect has been observed by Ren et al. (Ren et al. 2011) who found that VOC in SWNT-based solar cells is regulated by carrier recombination mechanisms other than thermal generation of electron–hole pairs across the donor–acceptor interface. Nevertheless, the surface remains too rough after the additive processing. Figure 11 reveals that protrusions from the active layer, similarly to non-treated sample, could reach 500 nm, even after treatment. This could be a factor that hinders better improvement of the short-circuit current, perhaps due to low resistance to shunts that still connect the anode and the cathode.

In contrast with P3HT/PCBM system (Mayer et al. 2007), the thermal annealing degrades the PV performances of P3HT/NP-SWNT devices. In the first systems, the thermal annealing favors the formation of extended PCBM domains and enhances the carrier mobility in the P3HT/PCBM phases (Chiu et al. 2008) but in P3HT/NP-SWNT based active layer it induces the aggregation and percolation paths causing short-circuits and detrimental effects on performances as observed here (Ren et al. 2011).

Improving the morphology of P3HT/NP-SWNT-49 at 20 wt% in BHJ devices

Despite its failure in the initial testing, 22 wt% load of NP-SWNT-49 represents the theoretical optimal composition. It seemed a reasonable candidate to try and optimize the process for effective morphology with large SSA (10 times that of PCBM). Unlike the common procedure, an ultrasonication step was required to combine intimately the P3HT and NP-SWNT-49 solutions. The sonication time was found most favorable at 15 min. Liquid additives were also added in the same proportions as illustrated for x = 2 wt% in the previous section. After solvent casting, the solid morphology was observed. Optical microscopy (OM) disclosed surprisingly well the applicability of the final films.

To validate the processing method, complete devices were prepared with the binary blends at x = 20 wt%. All were found inefficient with the as-cast films, Fig. 12. However, after a gentle thermal annealing at 50 °C the J–V plot deviated to reveal a PV effect that further improved after 24 h under inert atmosphere. Surprisingly, analogous effects could be observed when the P3HT:NP-SWNT-49 mixtures were left to settle, with up to 40% increase in PCE with the devices made from solutions that rested for 5 days. This was attributed to the formation of P3HT/NP-SWNT-49 ordered nanofilaments that favor the charge dissociation (Ren et al. 2011). The modest open-circuit voltage (≈ 0.3 and ≈ 0.4 V), was caused by remaining shunts (Rp = 1890 Ω cm2 then 8100 Ω cm2). The PCE improvement resulted from a better JSC (0.09 then 0.11 mA cm−2), FF (31 then 37%), and Rs (Rs = 2168 Ω cm2 then 4230 Ω cm2). These three parameters most likely progressed as a result of the gradual improvement of the various interfaces, in the D/A layer or between the layers. both of which are the manifestation of enhanced wettability and π–π interactions among P3HT molecules and NP-SWNTs, which leads probably to the formation of crystallite domains with comparable size to the exciton diffusion length. It is noted that the JSC value could be increased if the percolation networks were separated from the upper electrode using a thin layer of solution-processable electron extracting material, like Bathocuproine (BCP) which would afford better wettability and increase the shunt resistance of the underlying rough, nanoscale aggregated film.

The ternary OSC is another promising approach to improve device performance (Cheng and Zhan 2015). The introduction of PBDD4T‐2F (Poly[[5,7-bis(2-ethylhexyl)-4,8-dioxo-4H,8H-benzo[1,2-c:4,5-c']dithiophene-1,3-diyl][3,3′′′-bis(2-ethylhexyl)-3′′,4′-difluoro[2,2′:5′,2′′:5′',2′′′-quaterthiophene]-5,5′′′-diyl]]) in the front cell of tandem solar cells increases VOC lead to remarkable efficiency (Qin et al. 2017; Lin et al. 2018). A 0.6:0.4 ratio between PBDD4T‐2F and P3HT:NP-SWNT-49 with respect to P3HT, leads to 2.5-fold higher VOC (1 V) and a PCE of 0.06%.

Conclusions

In conclusion, a covalent functionalization approach made SWNT considerably easier to manipulate and tolerably soluble. Thin and smooth NP-SWNT-49 layers were successfully incorporated as acceptors in bilayer configuration to generate functional devices. However, the application of functionalized SWNTs in bulk heterojunction was found more desirable. Using a mixture of NMP and DIO, we developed an optimal dispersion/distribution technique that leads to PCE of 0.13% at 2 wt% of NP-SWNT-49 nanotube load. The NMP helps disperse the NP-SWNT, while DIO favors the aggregation of P3HT on the NT acceptor. A particularly high VOC (> 1 V) is a characteristic of SWNT insertion in BHJ PV devices and shows a distinct operational mechanism from the PCBM-based counterpart. Mild thermal annealing at 50–80 °C improved the PCE thanks to improved interfacial charge transfer.

The strategy illustrated herein is still not fully optimized for high loads of NP-SWNT. Deeper investigation of the kinetics of charge separation and charge recombination is needed. Orientation of the NTs to fit the ≈200 nm thick active layer could be also envisioned, together with the introduction of high mobility polymers to accumulate benefits and balance the charge transport of electrons and holes in the device setups. The tuned NP-SWNTs could be also used as thin transparent electrodes due to their high processability. Therefore, these materials have ample room for potential improvement and investment in optoelectronics.

References

Abdulrazzaq OA, Saini V, Bourdo S, Dervishi E, Biris AS (2013) Organic Solar Cells: A Review of Materials, Limitations, and Possibilities for Improvement. Part Sci Technol 31(5):427–442

Abeygunasekara WL, Hiralal P, Samaranayake L, Chien C-T, Kumar A, Flewitt AJ, Karunaratne V, Amaratunga GA (2015) Incorporating semiconducting single-walled carbon nanotubes as efficient charge extractors in organic solar cells. Appl Phys Lett 106(12):361

Adikaari ADT, Dissanayake DNM, Silva SRP (2010) Organic–inorganic solar cells: recent developments and outlook. IEEE J Sel Top Q Electron 16(6):1595–1606

Ago H, Petritsch K, Shaffer MS, Windle AH, Friend RH (1999) Composites of carbon nanotubes and conjugated polymers for photovoltaic devices. Adv Mater 11(15):1281–1285

Ajayan PM, Tour JM (2007) Materials science: nanotube composites. Nature 447(7148):1066

Arnold MS, Green AA, Hulvat JF, Stupp SI, Hersam MC (2006) Sorting carbon nanotubes by electronic structure using density differentiation. Nat Nanotechnol 1(1):60

Arnold MS, Zimmerman JD, Renshaw CK, Xu X, Lunt RR, Austin CM, Forrest SR (2009) Broad spectral response using carbon nanotube/organic semiconductor/C60 photodetectors. Nano Lett 9(9):3354–3358

Ball M, Zhong Y, Wu Y, Schenck C, Ng F, Steigerwald M, Xiao S, Nuckolls C (2014) Contorted polycyclic aromatics. Acc Chem Res 48(2):267–276

Baughman RH, Zakhidov AA, De Heer WA (2002) Carbon nanotubes–the route toward applications. Science 297(5582):787–792

Bernardi M, Lohrman J, Kumar PV, Kirkeminde A, Ferralis N, Grossman JC, Ren S (2012) Nanocarbon-based photovoltaics. ACS Nano 6(10):8896–8903

Bindl DJ, Wu M-Y, Prehn FC, Arnold MS (2010) Efficiently harvesting excitons from electronic type-controlled semiconducting carbon nanotube films. Nano Lett 11(2):455–460

Blackburn JL (2017) Semiconducting single-walled carbon nanotubes in solar energy harvesting. ACS Energy Letters 2(7):1598–1613

Boucher D, Howell J (2016) Solubility characteristics of PCBM and C60. J Phys Chem B 120(44):11556–11566

Cao W, Xue J (2014) Recent progress in organic photovoltaics: device architecture and optical design. Energy Environ Sci 7(7):2123–2144

Casalegno M, Kotowski D, Bernardi A, Luzzati S, Po R, Raos G (2015) The effect of donor content on the efficiency of P3HT:PCBM bilayers: optical and photocurrent spectral data analyses. Phy Chem Chem Phys 17(4):2447–2456

Chaudhary S, Lu H, Müller AM, Bardeen CJ, Ozkan M (2007) Hierarchical placement and associated optoelectronic impact of carbon nanotubes in polymer-fullerene solar cells. Nano Lett 7(7):1973–1979

Cheng P, Zhan X (2015) Versatile third components for efficient and stable organic solar cells. Mater Horizons 2(5):462–485

Chiu M-Y, Jeng U-S, Su C-H, Liang KS, Wei K-H (2008) Simultaneous use of small- and wide-angle X-ray techniques to analyze nanometerscale phase separation in polymer heterojunction solar cells. Adv Mater 20(13):2573–2578

Cui Y, Yao H, Zhang J, Zhang T, Wang Y, Hong L, Xian K, Xu B, Zhang S, Peng J, Wei Z, Gao F, Hou J (2019) Over 16% efficiency organic photovoltaic cells enabled by a chlorinated acceptor with increased open-circuit voltages. Nat Commun 10(1):2515

Curran SA, Ajayan PM, Blau WJ, Carroll DL, Coleman JN, Dalton AB, Davey AP, Drury A, McCarthy B, Maier S (1998) A composite from poly (m-phenylenevinylene-co-2, 5-dioctoxy-p-phenylenevinylene) and carbon nanotubes: a novel material for molecular optoelectronics. Adv Mater 10(14):1091–1093

Dennler G, Scharber MC, Brabec CJ (2009) Polymer-fullerene bulk-heterojunction solar cells. Adv Mater 21(13):1323–1338

Derbal-Habak H, Bergeret C, Cousseau J, Nunzi J (2011) Improving the current density Jsc of organic solar cells P3HT: PCBM by structuring the photoactive layer with functionalized SWCNTs. Sol Energy Mater Sol Cells 95:S53–S56

El-Moussawi Z, Medlej H, Nourdine A, Berson S, Toufaily J, Hamieh T, Flandin L (2017) Development of dithienosilole-pyridalthiadiazole-based copolymer as an electron donor in organic photovoltaic cells. IEEE Trans Nanotechnol 16(4):574–581

El-Moussawi Z, Nourdine A, Medlej H, Hamieh T, Chenevier P, Flandin L (2019) Fine tuning of optoelectronic properties of single-walled carbon nanotubes from conductors to semiconductors. Carbon 153:337–346

Elumalai NK, Uddin A (2016) Open circuit voltage of organic solar cells: an in-depth review. Energy Environ Sci 9(2):391–410

Hoppe H, Sariciftci NS (2007) Polymer solar cells. In Photoresponsive Polymers II. Springer, Berlin, pp 1–86

Jain RM, Howden R, Tvrdy K, Shimizu S, Hilmer AJ, McNicholas TP, Gleason KK, Strano MS (2012) Polymer-free near-infrared photovoltaics with single chirality (6, 5) semiconducting carbon nanotube active layers. Adv Mater 24(32):4436–4439

Jeon I, Chiba T, Delacou C, Guo Y, Kaskela A, Reynaud O, Kauppinen EI, Maruyama S, Matsuo Y (2015) Single-walled carbon nanotube film as electrode in indium-free planar heterojunction perovskite solar cells: investigation of electron-blocking layers and dopants. Nano Lett 15(10):6665–6671

Jiang W, Li Y, Wang Z (2014) Tailor-made rylene arrays for high performance n-channel semiconductors. Acc Chem Res 47(10):3135–3147

Kim HJ, Han AR, Cho C-H, Kang H, Cho H-H, Lee MY, Fréchet JMJ, Oh JH, Kim BJ (2012) Solvent-resistant organic transistors and thermally stable organic photovoltaics based on cross-linkable conjugated polymers. Chem Mater 24(1):215–221

Koleilat GI, Vosgueritchian M, Lei T, Zhou Y, Lin DW, Lissel F, Lin P, To JW, Xie T, England K (2016) Surpassing the exciton diffusion limit in single-walled carbon nanotube sensitized solar cells. ACS Nano 10(12):11258–11265

Kymakis E, Amaratunga G (2002) Single-wall carbon nanotube/conjugated polymer photovoltaic devices. Appl Phys Lett 80(1):112–114

Kymakis E, Kornilios N, Koudoumas E (2008) Carbon nanotube doping of P3HT: PCBM photovoltaic devices. J Phys D Appl Phys 41(16):165110

Lecarme L, Consonni V, Lafolet F, Cossuet T, Mermoux M, Sauvage F, Nourdine A, Alloin F, Leprêtre J-C (2019) ZnO nanowires as a promotor of high photoinduced efficiency and voltage gain for cathode battery recharging. ACS Appl Energy Mater 2(9):6254–6262

Lenes M, Wetzelaer GJA, Kooistra FB, Veenstra SC, Hummelen JC, Blom PW (2008) Fullerene bisadducts for enhanced open-circuit voltages and efficiencies in polymer solar cells. Adv Mater 20(11):2116–2119

Li C, Wonneberger H (2012) Perylene imides for organic photovoltaics: yesterday, today, and tomorrow. Adv Mater 24(5):613–636

Li H, Hwang YJ, Courtright BA, Eberle FN, Subramaniyan S, Jenekhe SA (2015) Fine-tuning the 3D structure of nonfullerene electron acceptors toward high-performance polymer solar cells. Adv Mater 27(21):3266–3272

Lin Y, Li Y, Zhan X (2012) Small molecule semiconductors for high-efficiency organic photovoltaics. Chem Soc Rev 41(11):4245–4272

Lin X, Seok J, Yoon S, Kim T, Kim B, Kim K (2014) Morphological investigation of P3HT/PCBM heterojunction and its effects on the performance of bilayer organic solar cells. Synth Met 196:145–150

Lin Y, Wang J, Zhang ZG, Bai H, Li Y, Zhu D, Zhan X (2015) An electron acceptor challenging fullerenes for efficient polymer solar cells. Adv Mater 27(7):1170–1174

Lin Y-C, Cheng H-W, Su Y-W, Lin B-H, Lu Y-J, Chen C-H, Chen H-C, Yang Y, Wei K-H (2018) Molecular engineering of side chain architecture of conjugated polymers enhances performance of photovoltaics by tuning ternary blend structures. Nano Energy 43:138–148

Liu C-M, Su Y-W, Jiang J-M, Chen H-C, Lin S-W, Su C-J, Jeng US, Wei K-H (2014) Complementary solvent additives tune the orientation of polymer lamellae, reduce the sizes of aggregated fullerene domains, and enhance the performance of bulk heterojunction solar cells. J Mater Chem A 2(48):20760–20769

Liu Q, Jiang Y, Jin K, Qin J, Xu J, Li W, Xiong J, Liu J, Xiao Z, Sun K, Yang S, Zhang X, Ding L (2020) 18% Efficiency organic solar cells. Sci Bull 65(4):272–275

Mayer AC, Scully SR, Hardin BE, Rowell MW, McGehee MD (2007) Polymer-based solar cells. Mater Today 10(11):28–33

Meng D, Sun D, Zhong C, Liu T, Fan B, Huo L, Li Y, Jiang W, Choi H, Kim T (2015) High-performance solution-processed non-fullerene organic solar cells based on selenophene-containing perylene bisimide acceptor. J Am Chem Soc 138(1):375–380

Nourdine A, Perrin L, Bettignies RD, Guillerez S, Flandin L, Alberola N (2011) Synthesis and characterization of fullerene based systems for photovoltaic applications: Evidence for percolation threshold. Polymer 52(26):6066–6073

Nourdine A, Flandin L, Albérola N, Perrin L, Planès E, Hiltner A, Baer E (2017) Extrusion of a nano-ordered active layer for organic photovoltaic cells. Sustain Energy Fuels 1(9):2016–2027

Obrzut J, Page KA (2009) Electrical conductivity and relaxation in poly(3-hexylthiophene). Phys Rev B 80(19):195211

Opitz A (2017) Energy level alignment at planar organic heterojunctions: influence of contact doping and molecular orientation. J Phys 29(13):133001

Papirer E (2000) Adsorption on silica surfaces, vol 90. CRC Press, Boca Raton

Peigney A, Laurent C, Flahaut E, Bacsa R, Rousset A (2001) Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 39(4):507–514

Qin Y, Chen Y, Cui Y, Zhang S, Yao H, Huang J, Li W, Zheng Z, Hou J (2017) Achieving 12.8% efficiency by simultaneously improving open-circuit voltage and short-circuit current density in tandem organic solar cells. Adv Mater 29(24):1606340

Ramuz MP, Vosgueritchian M, Wei P, Wang C, Gao Y, Wu Y, Chen Y, Bao Z (2012) Evaluation of solution-processable carbon-based electrodes for all-carbon solar cells. ACS Nano 6(11):10384–10395

Ren S, Bernardi M, Lunt RR, Bulovic V, Grossman JC, Gradecak S (2011) Toward efficient carbon nanotube/P3HT solar cells: active layer morphology, electrical, and optical properties. Nano Lett 11(12):5316–5321

Romero DB, Carrard M, De Heer W, Zuppiroli L (1996) A carbon nanotube/organic semiconducting polymer heterojunction. Adv Mater 8(11):899–902

Salim T, Lee H-W, Wong LH, Oh JH, Bao Z, Lam YM (2016a) Semiconducting carbon nanotubes for improved efficiency and thermal stability of polymer-fullerene solar cells. Adv Func Mater 26(1):51–65

Salim T, Lee HW, Wong LH, Oh JH, Bao Z, Lam YM (2016b) Semiconducting carbon nanotubes for improved efficiency and thermal stability of polymer–fullerene solar cells. Adv Func Mater 26(1):51–65

Scharber MC, Mühlbacher D, Koppe M, Denk P, Waldauf C, Heeger AJ, Brabec CJ (2006) Design rules for donors in bulk-heterojunction solar cells—towards 10% energy-conversion efficiency. Adv Mater 18(6):789–794

Stylianakis MM, Mikroyannidis JA, Kymakis E (2010) A facile, covalent modification of single-wall carbon nanotubes by thiophene for use in organic photovoltaic cells. Sol Energy Mater Sol Cells 94(2):267–274

Su M-S, Kuo C-Y, Yuan M-C, Jeng U-S, Su C-J, Wei K-H (2011) Improving device efficiency of polymer/fullerene bulk heterojunction solar cells through enhanced crystallinity and reduced grain boundaries induced by solvent additives. Adv Mater 23(29):3315–3319

Su Y-W, Lan S-C, Wei K-H (2012) Organic photovoltaics. Mater Today 15(12):554–562

Sun S-S, Sariciftci NS (2005) Organic photovoltaics: mechanisms, materials, and devices. CRC Press, Boca Raton

Sun D, Meng D, Cai Y, Fan B, Li Y, Jiang W, Huo L, Sun Y, Wang Z (2015) Non-fullerene-acceptor-based bulk-heterojunction organic solar cells with efficiency over 7%. J Am Chem Soc 137(34):11156–11162

Tsoi WC, Spencer SJ, Yang L, Ballantyne AM, Nicholson PG, Turnbull A, Shard AG, Murphy CE, Bradley DD, Nelson J (2011) Effect of crystallization on the electronic energy levels and thin film morphology of P3HT: PCBM blends. Macromolecules 44(8):2944–2952

Tsukamoto J, Mata J (2004) Influence of small amounts of dispersed single-walled carbon-nanotubes on the optical properties of Poly-3-hexylthiophene. Jpn J Appl Phys 43(2A):L214

Verploegen E, Mondal R, Bettinger CJ, Sok S, Toney MF, Bao Z (2010) Effects of thermal annealing upon the morphology of polymer–fullerene blends. Adv Func Mater 20(20):3519–3529

Wang H, Bao Z (2015) Conjugated polymer sorting of semiconducting carbon nanotubes and their electronic applications. Nano Today 10(6):737–758

Wang H, Koleilat GI, Liu P, Jiménez-Osés G, Lai Y-C, Vosgueritchian M, Fang Y, Park S, Houk KN, Bao Z (2014) High-yield sorting of small-diameter carbon nanotubes for solar cells and transistors. ACS Nano 8(3):2609–2617

Wang QK, Wang RB, Shen PF, Li C, Li YQ, Liu LJ, Duhm S, Tang JX (2015) Energy level offsets at lead halide perovskite/organic hybrid interfaces and their impacts on charge separation. Adv Mater Interfaces 2(3):1400528

Würthner F (2004) Perylene bisimide dyes as versatile building blocks for functional supramolecular architectures. Chem Commun 14:1564–1579

Zhang Z, Shi Z, Du Y, Yu Z, Guo L, Guo D (2018) A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl Surf Sci 427:409–415

Zhang Z, Liao L, Wang X, Xie W, Guo D (2020) Development of a novel chemical mechanical polishing slurry and its polishing mechanisms on a nickel alloy. Appl Surf Sci 506:144670

Acknowledgements

This work was performed within the framework of the Centre of Excellence of Multifunctional Architectured Materials “CEMAM”. The financial support from the MESRI (Ministère de l'Enseignement supérieur, de la Recherche et de l’Innovation) through the “allocation doctorale 2014-2017” grant is gratefully acknowledged. This work was also financed by the USMB (Université Savoie Mont Banc). This work received the support of the “Solar Academy” (Ecole universitaire de recherche, program ‘Investissements d’avenir’ PIA3).

Author information

Authors and Affiliations

Contributions

The authors thank MM and SJ for their help on photoluminescence spectroscopy experiments. The authors thank also HM and TH from Laboratory of Materials, Catalysis, Environment and Analytical Methods at Lebanese University, and PC from Institute for Nanoscience and Cryogenics at University of Grenoble Alpes for their previous collaboration (El-Moussawi et al. 2019) during 2014–2018.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-Moussawi, Z., Nourdine, A. & Flandin, L. A key progress in introducing single walled carbon nanotubes to photovoltaic devices. Appl Nanosci 12, 2277–2290 (2022). https://doi.org/10.1007/s13204-020-01561-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01561-1