Abstract

A grain based carbonated beverage premix with adequate nutritional composition and fizzing effect in the form of dry powder has been developed in the current study. Maize and Bengal gram were roasted at temperature 160–180 °C while finger millet at 80–120 °C for 10–30 min. The optimized conditions for the roasting of maize, Bengal gram and finger millet were 180 °C for 10 min, 180 °C for 27 min and 110 °C for 30 min, respectively using face centred composite design and response surface methodology (RSM). The formulation of the beverage premix obtained using linear programming was in the proportion of 30 g, 30 g, 10 g, 20 g and 10 g of roasted maize, Bengal gram, finger millet flours, sugar (powdered) and pea protein isolate, respectively. The effect of carbonation was found to be best with 8% carbonation powder concentration and 1:4 beverage premix to water ratio which showed an overall acceptability of 7.7. The developed carbonated beverage premix was light in color with a positive L* value of 79.01 ± 0.12 and slightly acidic with a pH of 5.56 ± 0.10. The nutritional composition of the final product comprised of 16% protein and several minerals viz. Fe (11.67 mg/100 g), Ca (36.67 mg/100 g) and Mg (86.26 mg/100 g).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the last few decades, the instant beverage premix market has increased globally due to the changes in lifestyle and eating habits of people. These premixes are nutritious and can be easily prepared with water or milk in less preparation time. Moreover, interest in non-alcoholic drinks as more health-conscious nutrition is increasing rapidly, creating a huge demand for such drinks. There is a huge demand for carbonated drinks amongst consumers. Most of the available carbonated drinks typically contain artificial sweeteners, colors and harmful additives leading to a set of diseases like diabetes, obesity, teeth & bone damage, a decrease in metabolism etc. However, carbonation can not only enhance the consumer acceptance because of the fizzing and sparkling effect but also reduces the growth of spoilage microorganisms and increases the shelf life of the products to double fold (Suresha and Jayaprakasha 2003). A range of dairy-based carbonated beverages is already available in the market but due to cholesterol content and lactose intolerance, there is a need for a much healthier alternative. In recent years, cereal grains have been investigated regarding their potential use in developing functional foods and beverages. Cereal based carbonated drinks are not very common currently, but they are healthy as compared to the soft drinks available in the market. Apart from the nutritional value, a higher shelf life, easy handling, convenient packaging, etc., makes these premixes popular among different age groups. The development of a dry carbonated cereal-based beverage mix has been in demand as it can combat the ecological drawback associated with canned and bottled carbonated beverages. There has been a changeover from a taste-based food approach to a nutrient-based food approach, which can be realized by the evidence found in recent research (Chavan et al. 2018; Sharma et al. 2014). The demand for carbonated beverages among people of all ages is rising owing to various reasons such as taste, thirst-quenching, refreshment, relaxation, pleasure, and sociability (Tiwari et al. 2011). Cereal based carbonated beverage is rarest among all sorts of beverages available in the market and the use of carbonation powder in a cereal-based beverage premix is a new concept to enhance the acceptability and organoleptic properties.

Carbonated beverages use the impregnation of carbon dioxide gas to boost flavor characteristics and to provide palate stimulation. The use of edible carbonation powder does not impart any off-taste but enhances the acceptability and organoleptic properties of the grain-based beverage. Grain-based beverages, due to their health and nutritional benefits are forecasted to explode as a potential alternative to harmful carbonated drinks with zero nutrition which is realized by consumers of all age groups (Bagchi et al. 2018).

Limited research has been reported on the physicochemical and functional properties of carbonated beverage premix made from locally available grains using roasting, colloidal milling, and freeze-drying (Khan and Saini 2016). Processes like roasting and extrusion increase soluble dietary fiber, improve digestibility, enhance nutrient density, and facilitate uniform formulation to obtain a nutritionally balanced product (Singh et al. 2007).

The formulation of instant functional non-alcoholic cereal-based carbonated beverage offers energy and nutritional values. Some non-alcoholic beverages like Borde, Kunun-Zaki, Mahewu, Pozol, Sattu are produced in different countries (Singh et al. 2013), but none have carbonation effects. So, by providing a dry carbonation source, carbonated beverage premix can be made, which will give a sparking effect when mixed with water with no undesirable flavors.

The grains like maize (Zea mays), Bengal gram (Cicer arietinum), and finger millet (Eleusine coracana) are considered for their abundant sources of dietary fiber, proteins, energy, minerals, and vitamins. Bengal gram is an excellent protein source with acceptable levels of the most essential amino acids (Jukanti et al. 2012). Finger millet is a rich source of calcium, iron, phosphorous, vitamins (B and E), and amino acids. The use of fermented and malted finger millet flours in the formulation of weaning foods, instant mixes, beverages, and pharmaceutical products have been gaining popularity nowadays (Verma and Patel 2012). Pea protein is a very healthy protein substitute for animal protein like whey protein, gluten-based protein (wheat), and soybean proteins. It has high nutritional value, low allergenicity, and low cost (Stone et al. 2015). Pea protein contains a high level of lysine which is generally deficient in cereals. So, it can be consumed along with cereals for essential amino acid balance. Therefore, the combination of maize, Bengal gram, finger millet flours, pea protein isolate, and sugar would serve a unique, nutrition-rich, and stable formulation with acceptable organoleptic properties for the present invention case. Balasubramanian et al. (2012) has developed a protein rich low cost millet-soy blend formulation which comprised of pearl millet (81.68%), finger millet (7.02%) and decorticated soybean (11.29%) with the lowest possible cost.

The present study was aimed to formulate a high energy cereal-based carbonated beverage premix using roasted maize, Bengal gram, and finger millet flour along with pea protein isolate, sugar, and carbonation powder. The study was divided into two parts, i.e. roasting and its effects on the physicochemical and functional properties of the roasted grain flours and formulation of the carbonated beverage premix, its characterization, and sensory evaluation.

Materials and methods

Raw materials and ingredients

Maize (Bio 22027 Cv.), Bengal gram (JG-62 Cv.), and finger millet (Eleusine coracana Cv. VL Mandua-149) were procured from the local market of Kharagpur, West Bengal, India. Unflavoured pea protein isolate (My Protein Brand) was procured from The Hut Group, Cheshire, UK. The grains were subjected to preliminary cleaning for the removal of dirt and debris; dried up to moisture content (10 ± 0.50% wb). The grains having uniform wholesomeness were used for the roasting process. Raw and roasted grains were ground in an attrition mill (M/s Annapurna Domestic Flour Mill, Kolkata) and kept in airtight containers at room temperature until use.

Roasting of grains for beverage preparation

The grains were roasted using a convective hot air roaster (M/s S.D. Instruments and Equipment, Kolkata). Maize kernels were subjected to roasting treatment for different time and temperature combinations similar to the ranges used by Raigar and Mishra (2018). Several preliminary trials were conducted to set the levels of roasting conditions for other two grains. The temperature (3 levels) and time (3 levels) combinations for maize and Bengal gram were 160–180 °C for 10–30 min while finger millet was roasted at 80–110 °C for 10–30 min. The roasted grains were ground into flours using an attrition mill and sieved through a 250 µm screen for the determination of different physicochemical and functional properties.

Experimental design for roasting process

A face-centered central composite design (FCCD) with two factors was assigned to the experimental data to produce thirteen experimental runs with five center points and eight non-center points (Table S1 and Table S2). The center points were used to check the reproducibility of the design (Anderson-Cook et al. 2009). Response surface methodology (RSM) was used to frame the mathematical model to establish the relationship between dependent and independent parameters. The responses and independent variables were related by using the quadratic Eq. (1).

where, a0 is constant, a1 and a2 are linear coefficients, a11 and a22 are quadratic coefficients and a12 are the interaction coefficient. The regression coefficients were used to evaluate the statistical calculations and the interactive effect of the factors on the dependent variables was visualized by generating 3D response surface plots (Anderson-Cook et al. 2009). Data were analyzed by regression analyses, and the statistical significance of each term was investigated by analysis of variance (ANOVA) for each response. All statistical analyses were done using a statistical software Design Expert 7.0 (Stat-Ease).

Physico-chemical properties of roasted grains

Browning index

The color parameters of maize, Bengal gram, and finger millet flours (raw and roasted) were determined using a hunter lab colorimeter (Model-CM-5, M/s Konica Minolta, Japan). The values L*, a*, and b* (lightness, redness, yellowness) were noted down for the raw and roasted samples. The average value of triplicate tests was taken for each sample analysis. The instrument was set in reflectance mode. Browning index (BI) was calculated by the method of (Kahyaoglu and Kaya 2006) using (Eq. 2).

Water absorption index and water solubility index

WAI and WSI were calculated as stated by Dalbhagat and Mishra (2019) using Eqs. (3) and (4).

Microstructural characterization

Morphologies of both raw and roasted flours were investigated using SEM (ZEISS EVO 60) with Oxford EDS detector. A minute amount of dried grain flour (raw and roasted) was spread on aluminum stubs and coated with Gold–Palladium using a sputter coater (Model: POLARON-SC7620). A microscope having tungsten filament was set at the maximum acceleration voltage of 30 kV and SEM images were captured at 500 X, 2000 X, and 5000 X magnification.

Thermal characterization

The thermal properties of the raw and roasted grain flours were studied using a Differential Scanning Calorimeter (Pyris diamond DSC, USA). The calibration of the DSC analyzer was done using indium, and an aluminum pan without any sample was considered as the reference. The heating rate was 10 °C/min starting from − 10 to 250 °C. The thermal properties viz. onset temperatures (T0), peak temperature (Tp), end set temperature (Te), and enthalpy of gelatinization (ΔHgel) were determined. The degree of gelatinization (%) was determined as reported by Sharma et al. (2011), and the results were represented in the percent degree of gelatinization shown in Eq. (5).

Formulation of beverage premix using linear programming

Several trials have been done to formulate a final composition of the grain powder mix. The formulation was done using linear programming (LP) in MS Excel giving the required amount of protein, carbohydrates, and moisture as constraints. Keeping the minimum cost as an objective function (Z) and assigning the values of protein, carbohydrates, and moisture content, the following formulation was done (Table S5). The formulation of the beverage mix before carbonation obtained using linear programming was 30 g, 30 g, 10 g, 20 g, and 10 g of maize, Bengal gram, finger millet flours, sugar, and pea protein isolate, respectively.

Preparation of carbonated beverage premix

Raw grains (maize, Bengal gram, and ragi) were roasted at optimized conditions; ground and sieved to obtain the grain flours. All the ingredients were mixed well to obtain the beverage mix as per the formulation obtained in LP. The beverage mix was milled in a homogenizer (colloidal mill), with a clearance of 150 µm to avoid settling and make the beverage instant. The smooth and homogeneous beverage paste was kept in the deep freeze overnight and freeze-dried in Lyodel freeze dryer at (− 40 °C, 10–3 mbar). The freeze-dried beverage mix was ground and sieved through 150 µm sieve. The process flow chart for the preparation of grain-based carbonated beverage has been depicted in Fig. 1. The carbonation powder was formulated by using food grade sodium bicarbonate and citric acid as the major ingredients. The prepared carbonation powder of 0.8 g per 10 g of the beverage mix was added and mixed well to obtain the effective synergistic blend of the carbonated cereal beverage mix. The beverage mix to the water ratio was kept 1:2, 1:3, 1:4, 1:5, and 1:6.

Properties of carbonated beverage premix

Proximate analysis

The proximate analysis viz. (moisture, protein, fat, minerals, and ash content) was carried out using standard AOAC (2005) methods.

pH

Twenty milliliters (20 ml) of distilled water was added to a sample of 5 g of carbonated beverage mix and stirred for 30 min to homogenize the mixture. The reconstituted carbonated beverage was examined for its pH by using a calibrated digital pH meter (Systronics μ pH system, 361) using the method suggested by Rangnna (2007).

Acidity (% citric acid)

Total titratable acidity of the reconstituted carbonated beverage was determined by titration with 0.1 m NaOH solution as described by Wakil and Kazeem (2012) and expressed as percentage citric acid equivalent.

Mineral estimation

Atomic absorption spectrophotometer (Perkin Elmer, Analyst 700) was used to determine the Fe, Ca, Mg, Zn, Mn, and Cu in carbonated beverage mix. The samples were acid digested using a mixture of nitric acid, perchloric acid, and sulphuric acid (3:2:1). The amounts of minerals in the digested samples were determined by atomic absorption spectrophotometer following the method described by Hemalatha et al. (2007). The calibration curve was generated using standards obtained from Merck Company (Germany). All the measurements were carried out using standard flame operating conditions. The reproducibility values were within 2.0% for all the minerals.

Sensory analysis of beverage mix

The sensory evaluation of the reconstituted carbonated beverage mix was done in the Agricultural and Food Engineering Department, IIT Kharagpur, India. The analysis was done by a trained panel consisting of fifteen judges who carried out a subjective evaluation of the quality of the reconstituted beverage samples. Ethical assessment and consent prior to be enlisted in the consumer and descriptive panel, members were briefed about the study to enable them to make an informed decision. Those who agreed to participate had to sign consent forms. Members were free to withdraw from the study at any time. Five reconstituted carbonated beverage samples were prepared by mixing 0, 0.4, 0.6, 0.8, and 1.0 g of carbonation powder per 10 g of formulated beverage mix with 25% (w/v) reconstitution in fresh drinking water. The beverage was stirred well to dissolve every particle of the beverage mix in water. The judges were familiarized with the definitions of quality attributes such as color, aroma, taste, and mouthfeel of carbonated beverage before sensory evaluation. The judges were requested to give their preference for quality attributes of reconstituted carbonated beverage in general to the respective scale factors, viz. not at all Important, somewhat important, important, and extremely important. Sensory factors and their numerical values were based on a 9-point hedonic scale (BIS 1971) and the results are depicted in Table S3.

Results and discussion

Effect of roasting on properties of maize, Bengal gram, and finger millet flours

Browning index

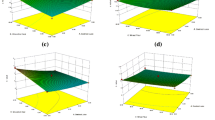

Browning index of the food products represents the extension of brown color. It is also used for controlling the processes and optimization of parameters apart from its importance in consumer acceptability. The degree of color formation especially helps in controlling the roasting process because of the increase in the brown-colored pigments with the advancement of reactions like non-enzymatic browning (Maillard reaction) and caramelization. The response surface graphs (Fig. 2a) present the effect of roasting time and temperature for BI of maize, Bengal gram, and finger millet flours. The results revealed that the BI value was increased as roasting temperature and time increased, but the temperature was the most influential factor. BI value was significantly (p < 0.001) affected by the quadratic term of roasting temperature and linear terms of both time and temperature (p < 0.001) for each flour, however insignificant (p > 0.05) quadratic effect of time and interaction effect of both roasting time and the temperature was observed (Table 1). An increase in BI of the flour is attributed to discoloration of yellow pigment and a decrease in the value of lightness of the kernels due to heating could be as a result of Maillard reaction, and it can be controlled by roasting process variables (Zzaman and Yang, 2014). Similar effects were also reported by Shittu et al. (2007) for a baked loaf of composite cassava-wheat flour-based bread.

Water absorption index

The values of WAI varied from 1.025 to 1.456, 1.025 to 1.515, and 1.059 to 1.235 for maize, Bengal gram, and finger millet flours, respectively. For all the grain flours, WAI increased slightly with time, but it followed an increasing trend up to a certain temperature and thereafter decreased gradually (Fig. 2b). A similar result was described by Dalbhagat and Mishra (2019). The increase in WAI of the roasted maize flour can be ascribed by the disorganization of starch granules causing increased interaction of hydrogen in water due to the release of the hydroxyl groups from amylose and amylopectin. The released hydroxyl groups can react with other groups that could cause polymerization and hence cause a reduction in hydrophobicity.

Water solubility index

The WSI varied from 2.801 to 4.654, 12.168 to 21.409, and 2.708 to 3.733 for maize, Bengal gram, and finger millet flours, respectively. The result revealed that WSI values for maize and Bengal gram flours increased with both the independent variables i.e. time and temperature, while increased gradually with time and decreased abruptly with temperature for finger millet flour (Fig. 2c). Roasting resulted in a decrease in WSI of the finger millet flour supported by earlier study on buckwheat (Christa et al. 2009). The decrease in WSI might be accountable for the structural changes within the endosperm and starch granules (Olayinka et al. 2008) of the finger millet grain because of more fiber content as well as the formation of amylase-lipid complexes within the grain during roasting (Gujral et al. 2011). The model was found to be significant (p < 0.001) for all the grain flours. The increase in the WSI in maize and Bengal gram could be attributed to the disruption in the grain structure which might have led to the increase in the solubility and attains maximum solubility index after a certain period. Roasting at high temperatures decreases the moisture content of grains that led to dry heat gelatinization. Moreover, roasting damages some of the starch granules leading to their enhanced water absorption capacity (Kumar and Saini 2016).

Moisture content

The effect of roasting time and the temperature was also evaluated on moisture content (Fig. 2d) for maize, Bengal gram, and finger millet flours. The changes in the moisture content of the grain flours during the process of roasting are explained by a quadratic model (R2 > 0.95) as shown in Table 1. The values of MC (% wb) varied from 2.01 to 8.18 and 0.75 to 1.96 over the temperature range of 160–180 °C for maize and Bengal gram respectively, and 3.89 to 9.51 over the temperature range of 80–120 °C for finger millet. The results obtained by the experimental analysis confirmed that both roasting temperature and time were the main parameters influencing the moisture content. As time and temperature increased, MC of the all the grains decreased. The model was found significant at p < 0.001 for all the flours. The squared term for temperature and time was significant (p < 0.001), whereas the interaction was not significant. This finding is supported by the work of Shakerardekani et al. (2011). Kahyaoglu and Kaya (2006) discovered that moisture content is not the main parameter during roasting of sesame seeds.

Optimization of the roasting process

The roasting parameters (temperature and time) were optimized using the graphical method of RSM to obtain flours with acceptable properties. The main criteria for optimization were to minimize MC, maximize WAI and WSI, and BI to be in the range. Table 1 shows the regression coefficients for each response surface equation and model fit parameters for maize, Bengal gram, and finger millet flours. The predicted optimized conditions were validated by conducting the experiments in triplicates (Table 2). The closeness between predicted and experimental values and percentage error of less than 10% represented the model well fit for the experiments. The desirability of the predicted data for maize, Bengal gram, and finger millet flour given by the Design-Expert software were 0.89, 0.77, and 0.76, respectively.

Characterization of raw and roasted flours

Microstructure

Microstructural properties of the raw and roasted grain flours were investigated by SEM analysis. In the raw maize, Bengal gram, and finger millet flours, uniform and homogeneous microstructures were observed. Figure 3a (1–3) and 3(a) (4–6) depict the SEM images of raw and roasted maize flour, respectively at 500 X, 2000 X, and 5000 X magnifications. In raw maize flour samples, starch granules could be observed differing in shape from oval to polyhedral, along with smooth and porous surface (Liu et al. 2011). The roasted maize flour had closer micrographs to the raw flour, although the starch granules were slightly smaller than that of the raw flour. That might be due to the disorganization of starch granules after grinding and heat treatment in the process of roasting (Raigar et al. 2017). SEM images of raw and roasted Bengal gram flour are depicted in Fig. 3b (1–3) and 3(b) (4–6), respectively for 500 X, 2000 X, and 5000 X magnifications. For raw Bengal gram flour, the presence of large oval to small spherical shaped granules distributed randomly over the matrix was observed in 2000 X magnification. Roasted Bengal gram flour microstructure in Fig. 3b (4–6) illustrates that the granules had been fragmented, and the size of the starches had been reduced during the temperature and time treatment of roasting. The size reduction might be due to the interrelated processing conditions rather than relating it to a single parameter. Similarly, the SEM images of raw and roasted finger millet flours are shown in Fig. 3c (1–3) and 3 (c) (4–6), respectively. A study of microstructure for raw finger millet flour revealed that starch granules are visible with no pores at the surface; these are polygonal in shape with edges (Gull et al. 2016). However, the roasted finger millet flour was appeared to be fragmented, probably due to the denaturation of the protein. Moreover, the physical and compositional variations of the grains can be considerable (Oikonomou and Krokida 2011).

Thermal analysis

The thermal properties of the raw and roasted grain flours were investigated using differential scanning calorimetry method and the thermal curves for raw and roasted maize, Bengal gram, and finger millet flours are represented in Fig.S1 (a), (b), and (c), respectively. During the processing of cereal foods in the presence of heat, starch gelatinization, and protein denaturation takes place. When thermal-treated cereals are examined on DSC, the value of ΔHgel tends to decrease and the values of To, Tp, and Te tend to increase depending upon the extremity and type of heat treatment (dry heat or moist heat) and raw material composition (Table S4). Heat treatment during roasting had decreased the ΔHgel values for all the flours. The decrease in ΔHgel values were 27.76, 38.44, and 3.95 J/g for roasted maize, Bengal gram, and finger millet flours, respectively. The reduction in ΔHgel values were attributed to gelatization of starch during the process of roasting. Similar trends were observed for different barley cultivars after roasting by Sharma et al. (2011) and Gujral et al. (2011). Granfeldt et al. (2000) also reported a decrease in To and ΔHgel values for roasted oats and steamed barley flakes. The degree of gelatinization was 39%, 31.27%, and 4.01% for roasted maize, Bengal gram, and finger millet flours, respectively. Factors affecting starch gelatinization might be the heating rate, moisture content, amount of amylopectin and amylose, a method of heat-processing, and source of starch (Altay and Gunasekaran 2006).

Physicochemical properties of beverage mix

The proximate composition, physicochemical properties like color, pH, titratable acidity, and mineral contents were investigated and the results are shown in Table 3. The produced carbonated beverage mix was sparkling in nature, light in color, slightly acidic and rich in protein and minerals. It was observed that the L* value (79.01 ± 0.12) of carbonated grain beverage mix found to be positive, indicating that the product was light in color. The value of a* indicates the level of redness (positive) and greenness (negative) and was measured to be 3.26 ± 0.43 and the b* value (positive-yellowness and negative-blueness) was found to be 22.52 ± 0.38, which indicates a slight tinge of yellowness to the product. The color of the beverage mix can hence be defined as sandalwood color. The high protein content (16%) of the product was due to the components like Bengal gram and pea protein isolate. The mineral values for Fe, Ca, Mg, Zn, and Mn were 11.67, 36.67, 86.26, 5.63, and 2.91 mg/100 g, respectively and were within the ranges of RDA.

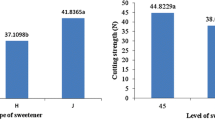

Sensory analysis

The reconstituted (1:4 w/v) cereal-based carbonated beverage was analyzed for its sensory acceptability using a 9-point hedonic scale (Table S6). The beverage was analysed for its color, aroma, appearance, taste, mouthfeel, carbonation and overall acceptability. Fig. S2 shows the mean scores for color, aroma, appearance, taste, mouthfeel, carbonation, and overall acceptability of the samples S1 (C0 or 0% carbonation powder), S2 (C4), S3 (C6), S4 (C8) and S5 (C10). All the concentrations were within the acceptable range. From the graph, it can be clearly seen that the sample S4 got the highest overall acceptability of 7.7. The effect of carbonation on the S4 (8% carbonation) showed the highest scores in appearance, mouthfeel and carbonation. Sample S5 did not show the highest score in carbonation though it contained the highest concentration that might be due to the early bubble formation and quick disappearance which left the fizzing carbonation effect for a lesser time. The other sensory parameters such as color and aroma were found quite similar to that of sample S4 which was the highest in the overall acceptability. Hence, the best sample was S4 having less carbonation than S5 but gave a quite stable result.

Conclusion

In this study, FCCD is proposed to obtain the optimum roasting conditions for maize, Bengal gram and finger millet. The optimally roasted grain flours were utilized for the beverage formulation using LP. Some conclusions can be summarized as follows.

-

a.

The optimized conditions for maize, Bengal gram and finger millet were 180 °C for 15 min, 180 °C for 27 min and 110 °C for 30 min, respectively. The increase in temperature and time positively affected the properties viz. WAI, WSI, MC and BI significantly at p < 0.001.

-

b.

The formulation obtained using LP comprised 30 g roasted maize, 30 g Bengal gram, 10 g finger millet flours, 20 g sugar powder, and 10 g pea protein isolate.

-

c.

The concentration of carbonation powder affected the consumers’ perception of the final product by altering the sensory attributes of the product. The carbonated beverage mix with 8% carbonation powder showed the highest overall acceptability. The carbonated beverage mix prepared was rich in protein, i.e. 16% and minerals viz. Fe, Ca, Mg 11.67, 36.67, 86.26 mg/100 g respectively.

-

d.

In addition, the proposed work can be easily applied for the value addition, instant food and beverage formulation using other grains also. Hence, the present invention of cereal/ grain based carbonated beverage mix serves the unique way to be used as a healthy and nutritious drink when mixed with water provides for fizzing and sparking effect of carbonation. Furthermore, carbonation can be an effective way to reduce the microbial stability, shelf life enhancement and improve overall acceptability.

Availability of data and material

The authors have full control of all the primary data and consent to the journal reviewing their data if requested.

Code availability

Not Applicable.

Abbreviations

- %:

-

Percent

- µm:

-

Micrometer

- °C:

-

Degree Celsius

- AAS:

-

Atomic absorption spectrophotometer

- ANOVA:

-

Analysis of variance

- AOAC:

-

Association of Official Analytical Chemists

- BI:

-

Browning Index

- BIS:

-

Bureau of Indian Standards

- cm:

-

Centimeter

- DSC:

-

Differential scanning calorimetry

- et al.:

-

And others

- FAO:

-

Food and Agriculture Organization

- FCCD:

-

Face centred composite design

- g:

-

Gram

- IIT:

-

Indian Institute of Technology

- LP:

-

Linear programming

- MC:

-

Moisture content

- mg:

-

Milligram

- min:

-

Minute

- ml:

-

Milliliter

- MS:

-

Microsoft

- ns:

-

Non significant

- p:

-

Probability

- R:

-

Gelatinization range

- R2 :

-

Coefficient of determination

- RDA:

-

Recommended dietary allowances

- RSM:

-

Response surface methodology

- SEM:

-

Scanning electron microscopy

- T:

-

Temperature

- T0 :

-

Onset temperature

- Te :

-

End temperature

- Tp :

-

Peak temperature

- w/v:

-

Weight/volume

- WAI:

-

Water absorption index

- wb:

-

Wet basis

- WSI:

-

Water solubility index

- ΔHgel :

-

Enthalpy of gelatinization

References

Altay F, Gunasekaran S (2006) Influence of drying temperature, water content, and heating rate on gelatinization of corn starches. J Agric Food Chem 54(12):4235–4245

AOAC (2005) Official methods of analysis, 18th edn. Association of Official Analytical Chemists, Gaithersburg

Anderson-Cook CM, Borror CM, Montgomery DC (2009) Response surface design evaluation and comparison. J Stat Plan Inference 139(2):629–641

Bagchi D, Nair S, Sen CK (2018) Nutrition and enhanced sports performance: muscle building, endurance, and strength. Academic Press, Cambridge

Balasubramanian S, Singh KK, Patil RT, Onkar KK (2012) Quality evaluation of millet-soy blended extrudates formulated through linear programming. J Food Sci Technol 49(4):450–458

BIS (1971) Guide for sensory evaluation of foods, Pt. II. IS: 6273. Methods and evaluation cards. Bureau of Indian Standards, Manak Bhawan

Chavan M, Gat Y, Harmalkar M, Waghmare R (2018) Development of non-dairy fermented probiotic drink based on germinated and ungerminated cereals and legume. LWT 91:339–344

Christa K, Soral-Śmietana M, Lewandowicz G (2009) Buckwheat starch: structure, functionality and enzyme in vitro susceptibility upon the roasting process. Int J Food Sci Nutr 60(sup4):140–154

Dalbhagat CG, Mishra HN (2019) Effects of extrusion process conditions on system parameters; physicochemical properties and cooking characteristics of extruded fortified rice kernels. J Cereal Sci 89:102782

Granfeldt Y, Eliasson AC, Björck I (2000) An examination of the possibility of lowering the glycemic index of oat and barley flakes by minimal processing. J Nutr 130(9):2207–2214

Gujral HS, Sharma P, Rachna S (2011) Effect of sand roasting on beta glucan extractability, physicochemical and antioxidant properties of oats. LWT Food Sci Technol 44(10):2223–2230

Gull A, Prasad K, Kumar P (2016) Evaluation of functional, antinutritional, pasting and microstructural properties of Millet flours. J Food Meas Charact 10(1):96–102

Hemalatha M, Manu B, Bhagwat S, Leelavathi K, Rao UJP (2007) Protein characteristics and peroxidase activities of different Indian wheat varieties and their relationship to chapati-making quality. Eur Food Res Technol 225(3–4):463–471

Jukanti AK, Gaur PM, Gowda C, Chibbar RN (2012) Nutritional quality and health benefits of chickpea (Cicer arietinum L.): a review. Br J Nutr 108(S1):S11–S26

Kahyaoglu T, Kaya S (2006) Modeling of moisture, color and texture changes in sesame seeds during the conventional roasting. J Food Eng 75(2):167–177

Khan A, Saini CS (2016) Effect of roasting on physicochemical and functional properties of flaxseed flour. Cogent Eng 3(1):1145566

Kumar S, Saini C (2016) Study of various characteristics of composite flour prepared from the blend of wheat flour and gorgon nut flour. Int J Agric Environ Biotechnol 9(4):679–689

Liu TY, Ma Y, Yu SF, Shi J, Xue S (2011) The effect of ball milling treatment on structure and porosity of maize starch granule. Innov Food Sci Emerg Technol 12(4):586–593

Oikonomou NA, Krokida MK (2011) Literature data compilation of WAI and WSI of extrudate food products. Int J Food Prop 14(1):199–240

Olayinka OO, Adebowale KO, Olu-Owolabi BIJFH (2008) Effect of heat-moisture treatment on physicochemical properties of white sorghum starch. Food Hydrocolloids 22(2):225–230

Raigar RK, Mishra HN (2018) Study on the effect of pilot scale roasting conditions on the physicochemical and functional properties of maize flour (Cv. Bio 22027). J Food Process Preserv 42(5):13602

Raigar RK, Upadhyay R, Mishra HN (2017) Optimization of microwave roasting of peanuts and evaluation of its physicochemical and sensory attributes. J Food Sci Technol 54(7):2145–2155

Rangnna S (2007) Handbook of analysis and quality control for fruits and vegetable products. Tata Mcgrawhill, New Delhi

Shakerardekani, A., Karim, R., Ghazali, H. M., & Chin, N. L. (2011). Effect of roasting conditions on hardness, moisture content and colour of pistachio kernels. In: Moisture Content and Colour of Pistachio Kernels.

Sharma, M., Mridula, D., Gupta, R. J. J. o. f. s., & technology. (2014). Development of sprouted wheat based probiotic beverage. 51(12), 3926–3933.

Sharma P, Gujral HS, Rosell CM (2011) Effects of roasting on barley β-glucan, thermal, textural and pasting properties. J Cereal Sci 53(1):25–30

Shittu T, Raji A, Sanni L (2007) Bread from composite cassava-wheat flour: I. Effect of baking time and temperature on some physical properties of bread loaf. Food Res Int 40(2):280–290

Singh R, Mishra B, Shukla K, Jain N, Sharma K, Kumar S, Ranjan J (2013) Fermentation process for alcoholic beverage production from mahua (Madhuca indica JF Mel.) flowers. Afr J Biotechnol 12(39)

Singh S, Gamlath S, Wakeling L (2007) Nutritional aspects of food extrusion: a review. Int J Food Sci Technol 42(8):916–929

Stone AK, Karalash A, Tyler RT, Warkentin TD, Nickerson MT (2015) Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res Int 76:31–38

Suresha KB, Jayaprakasha HM (2003) Utilization of ultrafiltration whey permeate for preparation of beverage. Indian J Dairy Sci 56(5):278–284

Tiwari R, Tiwari G, Rai A (2011) Probiotic novel beverages and their applications. Syst Rev Pharm 2(1):30

Verma V, Patel S (2012) Nutritional security and value added products from finger millets (ragi). Appl Chem 1:485–489

Wakil S, Kazeem M (2012) Quality assessment of weaning food produced from fermented cereal-legume blends using starters. Int Food Res J 19(4):1679–1685

Zzaman W, Yang TA (2014) Moisture, color and texture changes in cocoa beans during superheated steam roasting. J Food Process Preserv 38(3):1364–1370

Acknowledgements

The authors are thankful to MHRD (Ministry of Human Resource Development), the Government of India, and ICAR (Indian Council of Agricultural Research) for providing the financial support. We would like to extend our sincere gratitude to the anonymous reviewers and the JFST editorial team for their in-depth evaluation and valuable suggestions for improving the current manuscript.

Funding

Ministry of Human Resource Development (MHRD) Fellowship to the first author.

Author information

Authors and Affiliations

Contributions

A.T.: Conceptualization, Methodology, Investigation, Validation, Formal analysis, Data analysis, Visualization, Writing—original draft. P.P.: Methodology, Investigation, Writing—review & editing. C.G.D.: Writing—review & editing. H.N.M.: Conceptualization, Supervision, Writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest in this work.

Ethics approval

Written informed consent was obtained from all study participants for sensory evaluation.

Consent to participate

All authors have approved and reviewed the final manuscript.

Consent for publication

All the authors confirm that this manuscript has not been published elsewhere and is not under consideration by any other journal. All authors have approved the manuscript and agreed with its submission to the journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Thakur, A., Pandey, P., Dalbhagat, C.G. et al. Development of grain-based carbonated beverage premix using maize (Zea Mays), Bengal gram (Cicer Arietinum), and finger millet (Eleusine Coracana). J Food Sci Technol 59, 1637–1648 (2022). https://doi.org/10.1007/s13197-021-05175-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05175-5