Abstract

The effect of antioxidants, temperature, packaging materials and storage periods was investigated in medium shelled walnut kernels (Hamdan) variety. The kernels were mechanically dried (40 °C), standardized and treated with butylated hydroxylanisole and butylated hydroxytoluene in combination at concentrations (0.015%) each. Then packed in laminates under vacuum and high density polyethylene non vacuum packaging materials and stored under ambient and refrigerated temperature conditions (4 °C) for a period of 9 months. All tested extracts possessed appreciable antioxidant potential. The bioactive compounds were identified by using chromatographic techniques (GC–MS and LC–MS). Before storage dried kernels exhibited high values of total phenols (31.23 mgGAE/gm), DPPH (215.13 µmol TAEg−1) and low value of non enzymatic browning (0.63 OD). Walnuts packed in laminates under vacuum and refrigerated conditions exhibited higher values of total phenols, total flavonoids, DPPH and subsequently lower change in non-enzymatic browning reactions throughout the experiment. After 90 days of storage maximum loss in total phenols and DPPH value and highest value of non enzymatic browning was observed in high density polyethylene non vacuum packaging materials under ambient temperature. The major phenolic components identified by GC/MS and LC/MS analysis were linoleic acid, oleic acid, hexadecanoic acid, epicatechin, quercetin, epicatechin and ellagic acid respectively. This study validates the antioxidant potential of the walnut kernels and the positive relationship between total phenolic content, total flavonoids and antioxidant activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Walnut (Juglans regia L.) is one of the oldest cultivated fruit and is widely distributed throughout the world. Its edible part (kernel) represents about 40–60% weight and is consumed either fresh or in roasted form. Kernel skin is rich source of phenolic compounds and these are known to play significant role in preventing oxidation of fatty acids, thus results in longer shelf life of the walnut kernel (Salcedo et al. 2010). Earlier researchers determined several individual phenolics in walnut kernel, but their quantification is still lacking (Reguerio et al. 2014).Walnut kernels are known to be potential source of antioxidants (Halvorsen et al. 2006; Kornsteiner et al. 2006). As reported by researchers (Kader and Thompson 2002) walnuts could be stored for longer period of time, if they are stored at temperature below 10 °C. Major external factors that affect postharvest nut quality during storage are temperature and oxygen. During storage increasing temperature and oxygen availability leads to oxidation of phenolics thus results in nutritional and sensory attribute deterioration (Manzocco et al. 2000).

Walnuts are receiving increasing interest as a healthy foodstuff due to the fact that their regular consumption has been reported to decrease the risk of coronary heart disease (Blomhoff et al. 2006). The health benefits of walnuts kernel are usually attributed to their chemical composition. The walnut are regarded as highly valuable by an increasingly health conscious world due to various health benefits, being a great source of vitamin E, minerals, proteins, flavonoids, sterols, pectic substances, phenolic acids, omega-3 fatty acids and because of their ability to lower the level of cholesterol in human bodies (Savage 2001). They also contain high levels of arginine which helps in keeping the inner walls of blood vessels smooth and relaxed (Blomhoff et al. 2006).

The nutritional contents differs from one cultivar to another which can be influenced by genotype, cultivar, different ecology and different soil (Martinez et al. 2010).Walnuts contain other nutritional attributes in the form of Polyphenols (especially ellagic acid and gallic acid), ellagitannins (tannins) and compounds with potent anti-oxidant activity, such as melatonin, a hormone responsible for inducing and regulating the sleep (Fukuda et al. 2003; Blomhoff et al. 2006; Tapsell 2010). Consumption of walnuts reportedly helps in preventing erratic heat rhythms, cardiovascular risk factors, formation of free radicals and gall stones (Fukuda et al. 2003; Reiter et al. 2005). The physical, chemical and biological activity of the nuts is highly influenced by their processing conditions. The processing may increase or decrease the antioxidant activity of nuts. The objective of this study is to determine antioxidant activity and NEB of antioxidant treated medium shelled walnuts kernels packed in different packaging materials and to identify the compounds responsible for the nutraceutical potential of walnut kernels both volatile and non-volatile constituents of the walnuts were determined. The results will provide useful information to promote antioxidant treated walnut kernels as potential ingredients for human health.

Materials and methods

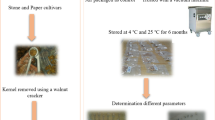

Walnut (Juglans regia L.) variety (Hamdan) was harvested in the month of September from trees cultivated in SKUAST Kashmir. Walnuts were harvested at the same maturity stage, when the husk was just beginning to split. Immediately nuts were hulled and dried in cabinet drier with an air velocity of 1500 m at 36 °C for 24 h. Dried walnuts were cracked manually and only healthy kernels free of diseases, were selected for analysis. Approximately 100 g kernels were given antioxidant treatment in combination (BHA + BHT 0.15% each) and packed in two different packaging materials viz. laminates vacuum packaging and high density polyethylene (HDPE) non vacuum packaging for a period of 9 months under ambient (19 ± 2 °C RH: 80 ± 2%) designated as (C1) and refrigerated condition (4 ± 1 °C and 65–70% RH) designated as (C2). The samples were then analysed for antioxidant properties and NEB after every three months for a period 9 months.

Chemicals used

2,2-Diphenyl-2-picrylhydrazyl (DPPH), Folin–Ciocalteu reagent, gallic acid, Na2CO3, ethanol were purchased from (Sigma-Aldrich and HiMedia). All other chemicals used were of analytical grade.

Determination of total phenolic content

Total phenolic content was determined with Folin–Ciocalteu reagent according to Vasco et al. (2008) using gallic acid as standard. Walnut powder of around 100 mg was thoroughly mixed with 15 mL of methanol and centrifuged for 10 min. Then 0.5 mL of supernatant was added to 2.5 mL Folin–Ciocalteu reagent (0.2 N) and allowed to stand for 5 min for reaction. After this, 2 mL of 7.5% sodium carbonate was added to the reaction mixture and diluted to 25 mL using distilled water. The mixture was allowed to stand for 2 h with intermittent shaking. The absorbance was measured at 760 nm using spectrophotometer (UV2100, Unico, Shanghai, China). The final results were expressed as milligram gallic acid equivalents per gram of defatted kernels (mg GAE/g).

Total flavonoid content

The total flavonoid content (TFC) was determined using the colorimetric method as described by Chandrasekara and Shahidi (2012). A standard curve was prepared with catechin hydrate. The TFC was expressed as mg of catechin equivalents (CE) per gram of dry sample (mg CE/g DS).

Total antioxidant activity (DPPH) radical scavenging activity

Total antioxidant activity was evaluated according to radical scavenging capacity of DPPH free radical based on method adopted by (Moon and Shibamoto 2009) with some modifications. About 100 mg of the defatted walnut powder sample was mixed with 15 mL of methanol and centrifuged for 10 min. Aliquot (1 mL) of the supernatant was added to 3 mL of DPPH-methanolic solution (0.0635 mM). The mixture was gently homogenized and left to stand at room temperature for 30 min. Absorbance was measured using spectrophotometer at 517 nm. Scavenging activity (%) = (A − As)/A where, As is the absorbance of the sample and A is the absorbance values of control. For antioxidant capacity assays, the selected incubation time of 30 min was required for the reaction to reach a plateau and the results were expressed as trolox acid (6-hydroxy-2, 5, 7, 8-tetramethylchroman 2-carboxylic acid) equivalents on a dry weight basis (µmol TAEg−1 DS).

Identification of bioactive compounds using GC–MS

The native walnut samples were extracted using stirring water bath. Two gram of fresh walnut sample were extracted with 50 mL methanol at constant temperature of 40 °C, for a period of 30 min and the extracts obtained were concentrated.

Instrument and chromatographic conditions

The powdered residue obtained after vacuum dried conditions (40 °C) was dissolved in 20 mL methanol and collected in corked glass test tubes. The extract was further subjected to analysis on a Shimadzu QP2010 Plus GC–MS system with nitrogen as carrier gas. Each compound was identified using WILEY library (8 L). The Liquid chromatography-mass spectroscopy (LC/MS) was analysed by Agilent 6520 Quadrupole time-of-flight (Q-TOF) mass spectrometer.

Non-enzymatic browning (NEB)

Non-enzymatic browning of dried walnuts was recorded by measuring the optical density of alcoholic extracts of centrifuged samples (2000 rpm) at 440 nm in UV–Vis spectrophotometer (Shimadzu, Japan) using 60 per cent ethanol as blank (Rangana 1997).

Statistical analysis

Each result was replicated thrice and the data obtained were examined using SPSS Software (SPSS PASW 18.0) and means were separated using Duncan’s multiple range tests (p ≤ 0.05).

Result and discussion

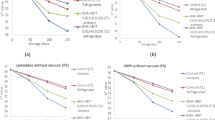

Data regarding the influence of antioxidant, packaging materials and storage periods on total phenol content and DPPH value are presented in (Figs. 1 and 2) respectively. Analysis of the data indicate that antioxidant, packaging materials, storage periods and storage temperatures significantly affected the total phenol content and DPPH value of the kernels during 270 days of storage.

Total phenol content and total antioxidant activity (DPPH)

Highest mean phenol content and DPPH value of 28.55 mg GAE/gm and 212.09 µmol TAEg−1 DW respectively was recorded in antioxidant treated kernels compared to value of 27.31 mgGAE/gm and 208.76 µmol TAEg−1 DW found in untreated samples. Mean phenol content and DPPH value of 29.44 mg/gm and 213.36 mol TAEg−1 DW respectively recorded in samples stored under refrigerated temperature was significantly higher than the samples stored under ambient temperature which showed 26.42 mg GAE/gm and 207.50 µmol TAEg−1 DW.

Significantly higher mean total phenol content and DPPH value of 28.93mgGAE/gm and 211.17 mol TAEg−1 DW was recorded in laminates with vacuum packed samples in comparison to value of 26.89 mg GAE/gm and 209.69 µmol TAEg−1 DW found in kernel samples packed in HDPE without vacuum packaging. Mean total phenol content of 29.28, 26.95 and 24.55 mg GAE/gm recorded at 90, 180 and 270 days of storage was significantly lower than the initial value of 31.23 mg GAE/gm at 0 days corresponding to a drop of more than 1.8 per cent over 270 days of storage. Similarly the highest mean DPPH value of 212.45 µmol TAEg−1 DW recorded at 90 days decreased to 208.62 µmol TAEg−1 DW at 180 days which further decreased to 205.53 µmol TAEg−1 DW at 270 days of storage. The mean DPPH value found in the samples was 215.13 mol TAEg−1 DW at 0 days of storage.

Maximum decline in total phenol content was observed in untreated samples packed in HDPE without vacuum under ambient temperature as the initial value of 31.23 mg GAE/gm observed at 0 days decreased to 27.42, 22.69 and 18.81 mg GAE/gm during 90, 180 and 270 days of storage respectively. However minimum decrease was observed in laminates with vacuum packed antioxidant treated samples stored under refrigerated temperature. The recorded values were 30.89, 30.54 and 30.22 mg GAE/gm at the same days of storage. However the highest DPPH value 214.50 µmol TAEg−1 DW was observed in antioxidant treated samples packed in laminates with vacuum at 90 days under refrigerated temperature, while as lowest value of 190.26 mg/100gm was recorded in untreated kernel samples packed in HDPE packaging without vacuum at 270 under ambient temperature from an initial value of 215.13 µmol TAEg−1 DW at 0 day of storage.

Storage of packaged kernel under low temperature restricted the total phenol content loss additively. The higher TP loss at higher temperature could be ascribed not only to the direct effect of temperature on phenolic oxidation, but also to its indirect effect via the increase in O2 concentration in the pouches stored at higher temperature. During storage the phenol content gets decreased due to the increased activity of enzymes like phenyl alanine, amino lyase and polyphenol oxidase responsible for the synthesis of phenolic compounds. The results are in conformity with the findings of Tsantilli et al. (2011) who reported decrease in phenol content of pistachio nuts during 90 days of storage. The findings are in close proximity with the results of (Christopolous et al. 2010; Arranz et al. 2008; Kornsteiner et al. 2006) who also reported decreased trend in different walnut cultivars stored in different packaging materials during long term storage.

Antioxidants are substances that can delay or inhibit the oxidation of lipids or other molecules by inhibiting the initiation or propagation of oxidizing chain reactions. The packaging may have caused the better extraction of compounds other than phenols like bioactive proteins and carbohydrate and saturated and mono-unsaturated fatty acids and the increase in antioxidant activity can be associated with these compounds. DPPH assay measures the ability of antioxidants present in oil, kernels and pellets to scavenge free radical. Studies reveal that major part of the antioxidant activity is due to compounds such as flavonoids, isoflavones, catechin and other phenolics (Sriwardhana et al. 2006). Samples with higher DPPH showed the strongest free radical scavenging effect. The results showed the antioxidant treated samples retained the antioxidant potential as compared to untreated samples. Manzocco et al. (2001) reported that the loss of antioxidant capacity of polyphenols is due to enzymatic or chemical oxidation. The results were found in conformity with findings of Esfahlan and Jamei (2012) who observed the same trend during an investigation on the storage of Almonds.

Total flavonoid content (mgCE/gm DS)

Flavonoids are poly phenolic compounds containing multiple aromatic rings. These compounds inhibit lipid oxidation by scavenging free radicals, chelating metals, activating antioxidant enzymes, reducing tocopherol radicals and inhibiting enzymes that cause oxidation reactions (Heim et al. 2002). Data regarding the influence of antioxidant treatment, packaging materials and storage temperatures on flavonoid content during different storage periods are presented in (Fig. 3). Non significant effect of treatments was observed in antioxidant treated walnut kernels. Significantly high flavonoid content 31.57 mgCE/g was recorded for samples packed in laminates under vacuum compared to samples packed in HDPE without vacuum which showed flavonoid content of 28.82 mgCE/g. Kernels stored under ambient temperature also showed high flavonoid content 31.44 mgCE/g than samples stored at refrigerated temperatures, which showed flavonoid content of 28.95 mg CE/g. Although kernels showed significant decrease in flavonoid content during entire storage period of 270 days, but antioxidant treated samples packed in laminates with vacuum stored under refrigerated temperatures showed comparatively less decrease than untreated samples.

Decrease in flavonoid content during storage could be due to decrease in enzyme activity, which lead to formation of these phenolic compounds. The results are in agreement to the study of Esfahlan and Jamei (2012) while studying the properties of biological activity of ten wild almond (Prunus amygdalus L.) species.

Non enzymatic browning (OD)

Statistical analysis of the data revealed significant influence of antioxidants, storage temperature and periods on the non enzymatic browning of the kernels during storage (Table 1). It was observed that packaging materials, antioxidant, storage temperature and periods showed significant effect on NEB of walnut kernels. Control sample showed initial NEB value 0.63 and this increased significantly and at the end of storage period in both ambient and refrigerated conditions (0.80 and 0.68) respectively. While as samples treated with BHT and BHA in combination also showed increase in NEB value (0.63–0.74) and (0.63–0.64) for samples packed in laminates with vacuum (P1). Although treated samples show increase in NEB value during storage but this increase was significantly lower than control (untreated sample).Similar trend was also noticed for samples packed in HDPE without vacuum (P2). The browning action was directly related to the packaging materials and it was found in higher amount in the untreated samples stored in HDPE without vacuum compared to samples stored in laminates under vacuum. Results obtained are in agreement with findings reported for pistachio nuts by (Maskan and Gogus 1997), while studying the filling of various models to water sorption isotherms of pistachio nut paste and (Faruk Gamli and Hayoglu 2007) who observed that NEB values increased at higher temperature in Pistachio Nut paste during storage period of 210 days.

Identification of various components using GC/MS and LC/MS

A number of phytochemical constituents were determined by GC–MS chromatograms which were identified on the basis of charge to mass ratio spectra. All detected components identified by GC/MS and LC/MS techniques are presented in (Tables 2 and 3). Phenolic compounds deter- mined in extracts of walnut kernels were hydrolysable tannins, these are characterized by their hexahydroxydiphenoyl (HHDP) group. As shown in (Table 3) only one hydrolysable tannins have been detected. Another flavanol group identified was (epicatechin). Presence of these compounds has also been confirmed by some authors (Grace et al. 2014; Reguerio et al. 2014). Gomez-Caravaca et al. (2008) in walnut kernels. Besides these hydroxybenzoic acids such as gallic, ellagic, quercetin have also been identified as shown in (Table 3). These identified compounds are popular for their health benefits like anti-inflammatory activities, anti-carcinogenic, fight depression and anxiety promotes brain development and reduce risk of heart diseases (Anderson et al. 2001; Carvalho et al. 2010).

Conclusion

The present work highlights of effect of temperatures, packaging materials and storage periods on antioxidant activity and non-enzymatic browning of antioxidant treated walnut kernels. Total phenol and DPPH value was higher in antioxidant treated walnut kernels compared to untreated. Main results of this work were also referred to the positive and additive effect of lower temperature (4 ± 1 °C) and reduced O2 in the packaging atmosphere. The higher oxidative stability of walnut kernel was partly due to the barrier effect of the protein film around the oil droplets and properties of the interfacial region as packaging of walnut kernels treated with (BHA + BHT) in laminates with vacuum and their subsequent storage refrigerated temperature for a period of 270 days proved superior in maintaining high antioxidant activity. Most important walnut antioxidants identified are gallic acid, ellagic acid, HHDP-glucose and epicatechin. Recommended temperature for storage of walnut kernels is below 10 °C in laminates under vacuum. Further investigations are needed to investigate the active compounds responsible for such a great antioxidant potential of kernels. Present investigation also concluded that new improved scientific processing practices are to be adopted in all unit operations of post-production sequence for maintaining quality of walnut kernels.

References

Anderson KJ, Teuber SS, Gobeille A, Cremin P, Waterhouse AL, Steinberg FM (2001) Walnut polyphenolics inhibit invitro human plasma and LDL oxidation. J Nutr 131(11):2837–2842

Arranz S, Perez-Jimenez J, Saura-Calixto F (2008) Antioxidant capacity of walnut (Juglans regia L.): contribution of oil and defatted matter. Eur Food Res Technol 227(2):425–431

Blomhoff R, Carlsen MH, Anderson LF, Jacobs DR (2006) Health benefits of nuts: potential role of anti-oxidants. Br J Nutr 2:552–560

Carvalho M, Ferreira PJ, Mendes VS, Silva R, Pereira JA, Jeronimo C (2010) Human cancer cell antiproliferative and antioxidant activities of Juglans regia L. Food Chem Toxicol 48(1):441–447

Chandrasekara A, Shahidi F (2012) Bioaccessibility and antioxidant potential of millet grain phenolics as affected by simulated in vitro digestion and microbial fermentation. J Fun Foods 4(1):226–230

Christopolous MV, Tsantili ME, Papageorgiou V, Komitis M, Rouskas D (2010) Effect of package atmosphere and temperature on phenolics. Total antioxidant capacity and colour in kernels of Franquette walnuts during 8 month storage. Acta Hortic 858:75–81

Esfahlan AJ, Jamei R (2012) Properties of biological activity of ten wild almonds (Prunus amygdalus L.) species. Turk J Biol 36:201–209

Faruk Gamli O, Hayoglu I (2007) The effect of the different packaging and storage conditions on the quality of pistachio nut paste. J Food Eng 78:443–448

Fukuda T, Ito H, Yoshida T (2003) Antioxidative polyphenols from walnuts (Juglans regia L.). Phytochem 63:795–801

Gomez-Caravaca AM, Verardo V, Segura-Carretero A, Caboni MF, Fernandez-Gutierrez A (2008) Development of a rapid method to determine phenolic and other polar compounds in walnut by capillary electrophoresis-electrospray ionization time-of-flight mass spectrometry. J Chromat A 1209(1–2):238–245

Grace MH, Yousef GG, Gustafson SJ, Truong VD, Yencho GC, Lila MA (2014) Phytochemical changes in phenolics, anthocyanins, ascorbic acid, and carotenoids associatedwithsweetpotatostorageandimpactsonbioactiveproperties. Food Chem 145:717–724

Halvorsen BL, Carlsen MH, Phillips KM, Bøhn SK, Holte K, Jacobs DR Jr, Blomhoff R (2006) Content of redox-active compounds (i.e, antioxidants) in foods consumed in the United States. Am J Clin Nutr 84:95–135

Heim KE, Tagliaferro AR, Bobilya DJ (2002) Flavanoids antioxidants: chemistry, metabolism and structure activity relationships. J Biochem 13:572–584

Kader AA, Thompson JE (2002) Postharvest handling systems: tree nuts. In: Kader A (ed) Postharvest technology of horticultural crops. University of California, Division of Agriculture and Natural Resources, Oakland, pp 399–406

Kornsteiner M, Wagner KH, Elmadfa I (2006) Tocopherols and total phenolics in 10 different nut types. Food Chem 98:381–387

Manzocco L, Calligaris S, Mastrocola D, Nicoli MC, Lerici CR (2000) Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci Technol 11:340–346

Manzocco L, Calligaris S, Mastrocola D, Nicoli MC, Lerici CR (2001) Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci Technol 11:340–346

Martinez ML, Labuckas DO, Lamarque AL, Maestri DM (2010) Walnut (Juglans regia L.): genetic resources, chemistry, by-products. J Sci Food Agric 90:1959–1967

Maskan M, Gogus F (1997) The filling of various models to water sorption isotherms of pistachio nut paste. J Food Eng 33:227–237

Moon JK, Shibamoto T (2009) Antioxidant assays for plant and food components. J Agric Food Chem 57:1655–1666

Rangana S (1997) Handbook of analysis and quality control for fruit and vegetable products, 3rd edn. Tata McGraw Hill Publishing Co., New Delhi, pp 127–137

Reguerio J, Sanchez-Gonzalez C, Vallverdue-Queralt A, Simal-Gandara J, Lamuela-Raventos R, Izquierdo-Pulido M (2014) Comprehensive identification of walnut polyphenols by liquid chromatography coupled to linear ion trap- orbit trap mass spectrometry. Food Chem 152:340–348

Reiter RJ, Manchester LC, Tan DX (2005) Melatonin in walnuts: influence on levels of melatonin and total antioxidant capacity of blood. Nutrition 21:920–924

Salcedo CL, deMishima BAL, Nazareno MA (2010) Walnuts and almonds as model systems of foods constituted by oxidisable, pro-oxidant and antioxidant factors. Food Res Int 43(4):1187–1197

Savage GP (2001) Chemical composition of walnuts (Juglans regia L.) grown in New Zealand. Plant Food Hum Nutr 60:75–82

Sriwardhana SKW, Amarowicz R, Shahidi F (2006) Antioxidant activity of almonds and their by-products in food model system. J Am Oil Chem Soc 83:223–230

Tapsell LC (2010) Health benefits of walnut consumption. Acta Hortic 861:409–416

Tsantilli E, Konstantindis K, Christopolous MV (2011) Total phenolics and flavonoids and total antioxidant capacity in pistachio nuts in relation to cultivar and storage condition. Sci Hortic 129:694–700

Vasco C, Ruales J, Kamal-Eldin A (2008) Total phenolic compounds and antioxidant capacities of major fruits from Ecuador. Food Agric Org Chem 111:816–823

Acknowledgements

The first author is thankful to UGC New Delhi for providing financial assistance (MANF) to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahad, T., Gull, A., Nissar, J. et al. Effect of storage temperatures, packaging materials and storage periods on antioxidant activity and non-enzymatic browning of antioxidant treated walnut kernels. J Food Sci Technol 57, 3556–3563 (2020). https://doi.org/10.1007/s13197-020-04387-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04387-5