Abstract

Banana peel, a by-product rich in phenolics and other bioactive compounds, has great potentials as a natural preservative or healthy food ingredient. However, the instability of bioactive compounds derived from banana peel limits their applications, and as such encapsulation is necessary to improve their stability and widen their applications. This study investigated the impact of spray drying conditions and coating materials on the physical, phytochemical, and antioxidant properties of the peel extract to identify the most suitable encapsulation process. The results showed that inlet temperature (ranging from 140 to 180 °C) and feeding rate (3–15 mL/min) did not significantly affect the total phenolic content (TPC) and antioxidant capacity but influenced the moisture content and recovery yield of the powder. The ratio of dry matter in fresh extract-to-coating material (DM-to-CM) (1:1–1:7 (w/w)) did not affect the moisture content. However, it affected the TPC, antioxidant properties, and recovery yield of the powder. Finally, the type of coating materials did not significantly affect TPC and antioxidant properties, but other physical properties, dopamine levels and recovery yield. The most suitable encapsulation conditions were identified as an inlet drying temperature of 150 °C, a feeding rate of 9 mL/min, a ratio of DM-to-CM of 1:1 (w/w), and coating with a combination of maltodextrin M100 and gum acacia. Powder prepared under the most suitable conditions had a spherical shape with a rough surface and had stable TPC under storage conditions of 40 °C for 4 weeks. It also has ideal physical, phytochemical and antioxidant properties and is suitable for further applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Banana is rich in health-beneficial components such as phenolics, carotenoids and dietary fibre (Baskar et al. 2011; Davey et al. 2006; Fatemeh et al. 2012; Nguyen et al. 2003). The fruit peel contains a higher level of bioactive compounds compared to the flesh (Vu et al. 2018). Further, the antioxidant activity of the peel is also higher than the fruit itself (Someya et al. 2002; Sulaiman et al. 2011). Banana peel is also an excellent source of the strong antioxidant dopamine. The catecholamine is believed to be significantly attributed to the antioxidant of the banana (Vu et al. 2018). In many countries, the banana peel has been used as a traditional medicine for centuries (Imam and Akter 2011; Kumar et al. 2012; Pereira and Maraschin 2015) indicating that the banana peel extract could be utilised as a functional ingredient in the food industry.

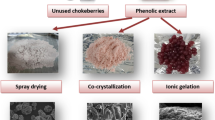

To enhance the function of bioactive compounds as such phenolic from the banana peel, it is necessary to extract these from the peel and then encapsulate to protect them from degradation and enhance storage efficiency. Optimal extraction and effective encapsulation are therefore extremely important for the preparation of the functional powder from banana peel. The optimal conditions for the extraction of phenolic compounds and antioxidants from banana peel were studied and reported in our previous study (Vu et al. 2019). However, optimal encapsulation conditions have not been previously reported for banana peel extract.

Amongst the available encapsulation techniques, spray drying is a popular method applied for food ingredients as the powder has high solubility, has low water activity and is suitable for transport and storage (Kha et al. 2010). During the spray drying process, the evaporation of the solvent is rapid, and the entrapment of the compound of interest occurs quasi-instantaneously. This process requires the optimization of the operating conditions as well as for the type of coating material (Gharsallaoui et al. 2007). Operating conditions such as inlet temperature, feeding rate, the ratio of dry matter in fresh extract-to-coating material (DM-to-CM) have been reported to affect recovery yield and quality of the powder. Additionally, the type of coating materials can affect the efficiency of the encapsulation process. Various coating materials, such as natural gums, proteins, and maltodextrins with different dextrose equivalence, waxes, and their blends have been applied (Gharsallaoui et al. 2007). Of those, maltodextrin and gum acacia are the most common materials used to encapsulate the intermediate polar compounds such as phenolic compounds (Robert and Fredes 2015; Çam et al. 2014; Robert et al. 2010; Zhang et al. 2007; Saikia et al. 2015).

This study investigated the impact of different spray drying conditions (inlet air temperature, and feeding rate) and coating materials on the physical, phytochemical, and antioxidant properties of the encapsulated banana peel extract to identify the most suitable encapsulation process. The stability of phenolic compounds in the encapsulated banana peel extract during storage was also investigated.

Materials and methods

Plant material

Ripened bananas (Musa cavendish) (fully yellow with green tip) were bought from a local market on Central Coast, NSW, Australia. Peels were separated from the flesh and dried using a freeze dryer (Thomas Australia Pvt., Ltd., Seven Hills, NSW, Australia), with the drying chamber pressure of 2 × 10−1 mbar and the cryo-temperature of − 45 °C. Dried peels were then ground and sieved through a 1.4 mm steel mesh, and kept under − 20 °C.

Three types of maltodextrin were received from the Grain Processing Corporation (1600 Oregon Street, Muscatine, Iowa 52761 USA) including M040 (Dextrose equivalent (DE) = 4.0–7.0), M100 (DE = 9.0–12.0), and M180 (DE = 16.5–19.9). Gum acacia (GA) was purchased from the Melbourne Food Depot (Melbourne, Australia). Soy protein isolate (SPI) was obtained from the Bulk Nutrient (7 Crabtree road, Grove, Tasmania, 7109).

Banana peel fresh extract preparations

Banana peel fresh extract was prepared following an optimized protocol developed in our previous study (Vu et al. 2019). Briefly, 10 g of banana peel powder was added into 500 mL acidified water (pH 1), the mixture was irradiated using a household microwave (1200 W, Frequency 2450 MHz, Sharp Carousel, Japan) set at 1200 W until boiling and continued for a further 6 min. The mixture was cooled quickly to room temperature using an ice bath, then filtered twice using a muslin cloth and filter paper (Whatman number 2). Acidified water (pH 1) was used to rinse through the peel residue solid to make up to 500 mL. The extract was neutralised to pH 7 using NaOH and stored at 4 °C within 2 days for further use. The fresh extract had a total phenolic content (TPC) of 52–66 mg GAE/100 mL and total solid content of 1.80 ± 0.04 g/100 mL.

Experimental design

Four parameters including spraying inlet air temperature, feeding rate, ratio of DM-to-CM and types of coating material were investigated to test their impact on yield, physical, phytochemical and antioxidant properties of the banana phenolic enriched powder.

To determine the impact of inlet air temperature, M40 was used as a coating material to mix with the fresh extract at the DM-to-CM ratio of 7:1 (w/w). The feeding rate was set at 9 mL/min. The mixture was spray-dried at a range of inlet air temperature from 130 to 180 °C.

To test the impact of feeding rate on spray drying, M40 was used as a coating material to mix with banana extract at a ratio of 7:1 (w/w). The mixture was spray-dried at a suitable inlet temperature of 150 °C, selected from the previous experiment, and a feeding rate ranging from 3 – 15 mL/min.

To examine the effect of ratio DM-to-CM, M40 was used as a coating material to mix with banana extract at a ratio ranging from 1:1 to 7:1 (w/w). The mixture was spray-dried at the inlet air temperature of 150 °C and a feeding rate of 9 mL/min.

To determine the most suitable coating materials, five materials including M40, M100, M180, GA, SPI, and a mixture of M100 and GA (8:2) were used as a coating material to mix with the banana extract at the ratio of 1:1 (w/w). The mixture was spray dried at an inlet temperature of 150 °C and feeding rate of 9 mL/min. A control run was conducted without the coating material, and similar spray conditions were applied.

A volume of 100 mL fresh extract was used for spray drying each time. The fresh extract was mixed with coating material as per experiment design, then homogenised (Silverson L4RT, Silverson machines Ltd. Waterside, Chesham, Bucks, England, HP5 1PQ) at 4000 rpm for 2 min and spray dried using Mini spray dryer Buchi 290 (Noble Park, VIC, Australia). After completion, only the dried powder in the collection vessel was collected. The particles remained in the drying chamber and cyclone were discarded. The powder was kept in sealed containers and stored at − 18 °C for further analysis.

Analysis of physicochemical and antioxidant properties of the encapsulated powder

Yield, moisture content, water activity, bulk density, and solubility

Recovery yield was calculated according to Eq. 1:

where Y is the recovery yield (%), m1 is the weight of the encapsulated powder (g), X is the moisture content of the encapsulated powder (%), m2 is the dry matter (DM) (g) in 1 mL feed (g) and V is the input volume feed (mL).

Moisture content (%) of the spray-dried powder was determined by drying the encapsulated powder at 105 °C for 24 h (LABEC, Laboratory Equipment Pty Ltd., Marrickville, NSW, Australia) and then calculated based on weight difference. Water activity was measured using a water activity meter (Pawkit, Decagon Devices, Washington, D.C., USA). Bulk density (g/cm3) was determined by the weight and its bulk volume (Krokida and Maroulis 1999). Solubility (%) was measured according to the previously described method (Krokida and Maroulis 1999). Briefly, 2.5 g of spray-dried powder was added to 30 mL of deionised water, vortexed for 30 s and incubated for 30 min at 37 °C, then centrifuged at 4000 rpm for 20 min. The supernatant was collected and dried at 105 °C until a constant weight was achieved. The solubility was calculated based on Eq. 2:

where m1 is the initial weight of the encapsulated powder (g), m2 is the dry weight of the supernatant after drying (g).

Phenolic content, encapsulation efficiency, phenolic recovery

Total phenolic content (TPC) of the encapsulated powder was determined by dissolving the powder (1 g) with deionised water (30 mL) and then analysed using the Folin-Ciocalteu method (Vu et al. 2019). The results of TPC were expressed as mg gallic acid equivalents (GAE) per gram of dry matter (DM). The phenolic compound remaining on the surface of the encapsulated particles (surface PC) was also determined using the method described by Akhavan Mahdavi et al. (2016) with some modifications. The surface phenolic solution was prepared by washing 1 g of powder with 10 mL of absolute ethanol followed by filtration using a 0.45 nylon Phenex syringe filter. Surface PC was then determined using the Folin-Ciocalteu method (Vu et al. 2019).

Encapsulation efficiency (%) was calculated according to Eq. 3 (Akhavan Mahdavi et al. 2016).

where E is encapsulation efficiency, TPC and Surface PC are the total phenolic content and surface phenolic content, respectively.

Phenolic recovery (%) was calculated using Eq. 4.

where P is the phenolic recovery (%), m is the mass of the encapsulated powder generated from V mL of the extract through spray drying; V is the fresh extract volume (mL). TPC in encapsulated powder and the fresh extract was expressed as mg GAE/g DM and mg GAE/mL, respectively.

Dopamine content of the encapsulated powder

The dopamine content was evaluated by HPLC analysis (Shimadzu, Kyoto, Japan), using the column Synergi 4 µm hydro RP 80A, 250 × 4.6 mm (Phenomenex, USA), at oven temperature 25 °C, with isocratic elution with 20 mM potassium phosphate buffer pH 2.5 and flow rate of 0.8 mL/min. For this process, the detector UV–Vis SPD-10AV VP was set at 254 and 280 nm and 10 µl of the sample was injected using an auto-injector (SIL-10A HT). Identification of dopamine was achieved by matching with the retention time in the dopamine standard (Sigma Aldrich), and quantification of dopamine was performed based on a calibration curve of the dopamine standard, and finally, results were expressed as mg/100 DM.

Antioxidant properties

Two antioxidant assays, including the 1,1-diphenyl-2-picrylhydrazyl radical scavenging ability (DPPH) and ferric reducing antioxidant power (FRAP) assay, were used to evaluate antioxidant properties of encapsulated extracts. The two assays were evaluated using colourimetric methods as described in a previous study (Vu et al. 2019). Trolox was used as the standard, and the results were expressed in mg Trolox equivalents (TE) per gram of dry matter (mg TE/g DM).

Morphology of the encapsulated powder

Morphology of the encapsulated powder was assessed using a Zeiss VP field emission SEM, with EHT = 1 kV and aperture size of 30 µm. A small amount of powder was fixed onto an aluminium specimen holder. The additional force was used to break particles to view the internal structure of the particle.

Stability of phenolic content in the encapsulated powder under an elevated storage temperature

To test the impact of higher temperature storage on the stability of TPC in the banana peel extracts with and without encapsulation with different coating materials, the banana peel powdered were stored at 40 °C for 4 weeks. The powders were packed in brown sealed plastic containers (1 g/tube) and stored in a 40 °C incubator. Samples were taken every 7 days, and TPC was analysed (Vu et al. 2019).

Data analysis

All experiments were conducted in triplicate. Differences between means were determined by performing one-way analysis of variance (ANOVA) and Tukey’s post hoc test (using SPSS statistical software version 25, IBM Corp., NY). The differences were taken at the significance level of p < 0.05.

Results and discussion

Effect of inlet air temperature on the recovery yield and the physicochemical properties of encapsulated powder

During the spray drying process, inlet air temperature plays a crucial role as it links with recovery yield, quality as well as stability of the heat-sensitive compounds. The very high temperature can destroy all the bioactive substances, while too low a temperature leads to high moisture content and an undesirable, sticky powder (Fang and Bhandari 2010). This part of the study examined the effect of inlet air temperature ranging from 130 to 180 °C on various physical, phytochemical and antioxidant properties to identify the most suitable temperature. Table 1 shows that the inlet air temperature within the tested range did not significantly affect the TPC (ranging from 5.8 to 6.4 mg GAE/g DM) and antioxidant capacity of the powder. This finding suggests that the phenolic compounds in the banana peel are quite heat stable. Alternatively, the short contact with high heat in spray drying was efficient in retaining the activity of phenolic compounds. Even though our records indicate that the use of high temperature does not affect on the total phenolic content of the spray-dried powder, literature reported greater losses of anthocyanin at high inlet temperature (> 160–180 °C) (Fang and Bhandari 2010).

Besides, the inlet air temperature did affect the recovery yield. The highest recovery yield (76.16%) was recorded at a temperature of 150 °C. The inlet air temperature at 130, 140, 160 and 170 °C gave a significantly lower recovery yield of powder when compared to that of 150 °C. Besides, powder spray-dried at 150 °C also had the lowest moisture content and higher recovery of TPC than those prepared at 130, 140, and 160 °C. The high inlet air temperature may carry two effects on recovery yield. The hot inlet air may generate efficient water removal resulting in very dry powder and subsequently, high recovery yield. In contrast, high temperature of inlet air may heat the particles above its glass transition temperature which will result in a sticky powder and lower the recovery yield (Tontul and Topuz 2017). This complex effect of hot inlet air likely explains the fluctuation of recovery yield in our experiment. Our findings were similar to the results found in previous studies (Tontul and Topuz 2017), which reported the fluctuation of recovery yield. Of note, recovery yield observed in this experiment is considerably higher when compared to the reports on spray-dried vegetable extracts, such as spray-dried tamarind pulp (59%) (Muzaffar and Kumar 2015) and gac oil and fruit aril (up to 65%) (Kha et al. 2010, 2014a).

Regarding the moisture content, powder generated from the 150 °C drying temperature has lower moisture content than powder from 170 °C and 180 °C and similar to that of the powder generated from the 190 °C. The observation suggests that high inlet air temperature does not always give low moisture content. The water activity of the powder was also evaluated. The results show that higher inlet air temperature gave powder with lower water activity. The appearance of the powders also showed a dried, well separated when sprayed with a temperature higher than 140 °C. While powder dried with 130 °C was sticky and coagulated into blocks. According to our observation, high moisture content did not always result in high water activity. Our observation was supported by literature where water activity and moisture content are not always positively correlated (Tontul and Topuz 2017). In general, inlet air temperature of 150 °C was the most suitable and was selected as the optimum temperature for the subsequent experiments.

Effect of feeding rate on the recovery yield and the physicochemical properties of encapsulated powder

The feeding rate represents how fast the mixture of banana extract and the coating material is pumped into the drying chamber. The feeding rate contributes to the recovery yield and affects particle size, and moisture content of the powder. A feeding rate that is too high will lead to a wet product, while too low will result in inefficient use of the equipment, wasting of energy and increase time consumption (Patel et al. 2015). Therefore, the impact of feeding rate ranging from 3 to 15 mL/min on the physical, phytochemical and antioxidant properties of the encapsulated powder was investigated, and the results are shown in Table 2. The results showed that the different feeding rates neither influenced the total phenolic content, encapsulation efficiency, solubility, bulk density, nor the antioxidant properties. However, it affected the moisture of the encapsulated powder, water activity, recovery yield, and TPC recovery. The moisture content and water activity of the encapsulated powder increased with the feeding rate, which is explained by the increased droplet size and subsequently increased moisture content and water activity (Patel et al. 2015). Moisture content and water activity of the encapsulated powder were less than 4.2% and 0.4, respectively, revealing that the powder can have minimal impact by oxidation and bacteria (Tontul and Topuz 2017). When the feeding rate exceeded 9 mL/min, the recovery yield of the powder significantly decreased. A similar observation was recorded for the recovery of TPC. These findings were supported by other studies (Muzaffar and Kumar 2015; Tontul and Topuz 2017) and can be explained by large droplet sizes that were produced when feeding with a high flow rate, which could negatively influence the yield of powder (Tontul and Topuz 2017). However, it would take long time if a very slow feeding rate is applied; hence the feeding rate of 9 mL/min was selected as the most suitable feeding rate for further experiments.

Effect of ratio of DM-to-CM on the recovery yield and the physicochemical properties of the encapsulated powder

The ratio of DM-to-CM is an important parameter in encapsulation. The amount of coating material added was calculated based on the total solid content of the extract. The results showed that DM-to-CM ratio did not significantly affect the moisture content, but affected other physical properties as well as phytochemicals and antioxidant properties (Table 3). Increasing the amount of coating material reduced the recovery yield from 80% (at the ratio of 1:1) to 67.42% (at the ratio of 1:7) (Table 3). This phenomenon can be explained by the high viscosity of the feed, when more coating material is used, which negatively affects drying performance (Tontul and Topuz 2017). Our findings were supported by Çam et al. (2014), who reported that increasing coating material leads to a decrease in production yield of pomegranate peel powder.

In addition, TPC and antioxidant capacity of the encapsulated powder decreased significantly when the DM-to-CM ratio changed from 1:1 to 1:7. Reduction of TPC and antioxidant can be explained by the decreasing proportion of solid from the fresh extract, which contains TPC and antioxidants. Encapsulation efficiency, TPC recovery, bulk density, water activity, and solubility were only slightly affected when the DM-to-CM ratio was changed. The observation showed a minor reduction of encapsulation efficiency (from 98.74% to 95.50%) when less coating material was used. However, 95.5% of phenolic compounds were encapsulated with the least amount of coating material (ratio 1/1). This encapsulation efficiency is considered as well encapsulated. In contrast to our observation, Akhavan Mahdavi et al. (2016) reported a poor encapsulation efficiency at the core/wall ratio of 1/1 when encapsulating natural anthocyanins by maltodextrin and GA. Overall, encapsulation efficiency at different DM-to-CM ratios was over 95%, which indicates a well-encapsulated process (Fang and Bhandari 2010). Our encapsulation efficiency was higher than that reported for other materials, such as Averrhoa carambola extract up to 79% (Saikia et al. 2015), natural anthocyanin and gac oil with 70–96% (Akhavan Mahdavi et al. 2016; Kha et al. 2014b). Overall, the DM-to-CM ratio of 1:1 was considered as the most suitable ratio and was used for further experiments. Of note, the fresh extract has a total solid content of 1.8 g DM/100 mL, which is not economical in terms of energy efficiency. The solvent removal process using heat was not suitable because of the suspension. Therefore adjustment to the extraction process for example increasing solid/solvent ratio and using pectinase maybe worthy to further investigate to increase the solid content of the extract.

Effect of the type of coating materials on the recovery yield and the physicochemical properties of the encapsulated powder

The type of coating material is an important factor contributing to the encapsulation efficiency as well as quality, stability, solubility and sensory of the final product. In this study, three types of maltodextrin, including M040, M100, M180 as well as GA, and SPI were studied. Furthermore, a combination of M100 and GA (8:2) was also investigated. Also, a sample was generated by spray drying without the coating material, and another sample was produced by freeze-drying, with both acting as control samples for comparison.

The results (Table 4) show that coating materials did not affect the level of phenolic content, and the free radical (2,2-diphenyl-1-picrylhydrazyl) scavenging capacity but affected other physical, phytochemical and antioxidant properties of the encapsulated powder. Among the coating materials, M100 and the combination of M100 and GA gave the highest recovery yield (83%). Powder prepared from these two materials (M100; a combination of M100 and GA), had high encapsulation efficiency, high TPC recovery and strong ferric antioxidant power (Table 4). Besides, powder prepared from M100, and the combination of M100 and GA had relatively higher dopamine content as compared to that of the other powders. Therefore, these two coating materials were found to be most suitable for coating banana peel extracts. Since both maltodextrin and GA have their advantages and limitations, application of individual materials may not possess all the desired properties when used in isolation. As such, a combination of maltodextrin and gum acacia may overcome limitations of each coating material (Gharsallaoui et al. 2007). Therefore a combination of M100 and GA is recommended for coating banana phenolic enriched extracts. The banana peel powder coated by mixture of M100 and GA has 21.47 mg GAE/g DM. This content was less than that in pomegranate peel powder (287.3 mg GAE/g), and higher than in lemon peel (mg GAE/g DM), sour cherry (< 1 mg/g), spent coffee ground (2.04 mg GAE/g), and similar to what in star fruit pomace powder (21–22 mg/g) (Çam et al. 2014; Papoutsis et al. 2018; Saikia et al. 2015; Tumbas Šaponjac et al. 2016; Ballesteros et al. 2017).

In comparison with uncoated powder and freeze-dried powder, powder spray-dried with a combination of M100 and GA (M100&GA powder) had lower recovery yield. However, the M100&GA powder had similar TPC and dopamine levels as compared to freeze-dried powder. Powder prepared by freeze-drying and powder prepared without coating material were both well dried. However they absorbed moisture very quickly and easily turned into sticky powder. M100&GA powder also had low moisture content, low water activity, high encapsulation efficiency, high solubility and possessed potent antioxidant properties, further suggesting that combination of M100 and GA is suitable for coating banana phenolic enriched extracts.

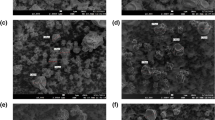

Morphology of the M100&GA powder was also tested and compared with morphology of powders prepared without coating material and freeze-drying (Fig. 1). The M100&GA powder (Fig. 1a) had a spherical shape with a rough surface. No pores were observed in the broken particles. Besides, the particle size is smaller than 10 µm. In contrast, the non-coating powder (Fig. 1b) had a round shape with a smooth surface. The broken particles were also observed with the solid wall, but inside was empty, indicating particles may be hollow. The freeze-dried powders were very fluffy with thin particles and rough surfaces (Fig. 1c). Spherical shape morphology is also reported in gac oil powder encapsulated by whey protein concentrate and gum acacia by spray drying (Kha et al. 2014b). However, the authors reported bigger particle size (up to 20 µm), and pores were observed within the particle walls. The morphology of spherical shape without hole or pore of the M100&GA powder suggests that the powder may be less influenced by ambient moisture and oxidation. Thus the encapsulated antioxidant compounds can remain stable during storage.

Changes of phenolic content in banana peel encapsulated powder stored under an elevated temperature

To test the stability of TPC in the encapsulated powders, the powders were stored at 40 °C for 4 weeks. The stability of TPC in the M100&GA powder was compared with powders prepared from other coating materials. The results (Table 5) show that there was no significant change in TPC of all tested powders coated with different coating materials. These findings suggest that all the coating materials were a good protector for phenolic compounds in the banana peel, and thus it is predicted that the encapsulated powder is suitable for long term storage.

Conclusion

This study is the first report on the encapsulation of phenolic extract from banana peel. Finding from this study showed that spray drying is an efficient method to encapsulate banana peel extract. The inlet air temperature did not significantly affect TPC and antioxidant capacity but recovery yield of the powder. Similarly, the feeding rate did not influence TPC, encapsulation efficiency, solubility, bulk density, nor the antioxidant properties. However, it affected the moisture of the encapsulated powder, recovery yield, and TPC recovery. Also, DM-to-CM ratio significantly affected the phytochemical and antioxidant properties of the powder. Finally, the type of coating material did not affect TPC, antioxidant capacity, but affected recovery yield and physical properties of the encapsulated powder. Amongst the tested coating materials, a combination of M100 and GA gave the highest recovery yield (83%). The most suitable encapsulating conditions were recommended as inlet air temperature of 150 °C, a feeding rate of 9 mL/min, a ratio of DM-to-CM of 1:1 (w/w), and a combination of M100 and GA. Powder prepared under these conditions had a spherical shape with a rough surface and had TPC stable under storage conditions of 40 °C for 4 weeks. Overall, encapsulated powder prepared under the most suitable conditions has good physical, phytochemical and antioxidant properties and thus it is suitable for further applications. Further studies are recommended to test the utilisation of this encapsulated powder as a natural preservative or healthy food ingredient.

References

Akhavan Mahdavi S, Jafari SM, Assadpoor E, Dehnad D (2016) Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. Int J Biol Macromol 85:379–385

Ballesteros LF, Ramirez MJ, Orrego CE, Teixeira JA, Mussatto SI (2017) Encapsulation of antioxidant phenolic compounds extracted from spent coffee grounds by freeze-drying and spray-drying using different coating materials. Food Chem 237:623–631

Baskar R, Shrisakthi S, Sathyapriya B, Shyampriya R, Nithya R, Poongodi P (2011) Antioxidant potential of peel extracts of banana varieties (Musa sapientum). Food Nutr Sci 02(10):1128–1133

Çam M, İçyer NC, Erdoğan F (2014) Pomegranate peel phenolics: microencapsulation, storage stability and potential ingredient for functional food development. LWT Food Sci Technol 55(1):117–123

Davey MW, Keulemans J, Swennen R (2006) Methods for the efficient quantification of fruit provitamin A contents. J Chromatogr A 1136(2):176–184

Fang Z, Bhandari B (2010) Encapsulation of polyphenols—a review. Trends Food Sci Technol 21(10):510–523

Fatemeh SR, Saifullah R, Abbas FMA, Azhar ME (2012) Total phenolics, flavonoids and antioxidant activity of banana pulp and peel flours: influence of variety and stage of ripeness. Int Food Res J 19(3):1041–1046

Gharsallaoui A, Roudaut G, Chambin O, Voilley A, Saurel R (2007) Applications of spray-drying in microencapsulation of food ingredients: an overview. Food Res Int 40(9):1107–1121

Imam MZ, Akter S (2011) Musa paradisiaca L. and Musa sapientum L.: a phytochemical and pharmacological review. J Appl Pharm Sci 1(05):14–20

Kha TC, Nguyen MH, Roach PD (2010) Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 98(3):385–392

Kha TC, Nguyen MH, Roach PD, Stathopoulos CE (2014a) Microencapsulation of gac oil by spray drying: optimization of wall material concentration and oil load using response surface methodology. Drying Technol 32(4):385–397

Kha TC, Nguyen MH, Roach PD, Stathopoulos CE (2014b) Microencapsulation of Gac oil: optimisation of spray drying conditions using response surface methodology. Powder Technol 264:298–309

Krokida MK, Maroulis ZB (1999) Effect of microwave drying on some quality properties of dehydrated products. Drying Technol 17(3):449–466

Kumar KPS, Bhowmik D, Duraivel S, Umadevi M (2012) Traditional and mecicinal uses of banana. Pharmacogn Phytochem 1(3):53–63

Muzaffar K, Kumar P (2015) Parameter optimization for spray drying of tamarind pulp using response surface methodology. Powder Technol 279:179–184

Nguyen TBT, Ketsa S, van Doorn WG (2003) Relationship between browning and the activities of polyphenoloxidase and phenylalanine ammonia lyase in banana peel during low temperature storage. Postharvest Biol Technol 30(2):187–193

Papoutsis K, Golding JB, Vuong Q, Pristijono P, Stathopoulos CE, Scarlett CJ, Bowyer M (2018) Encapsulation of citrus by-product extracts by spray-drying and freeze-drying using combinations of maltodextrin with soybean protein and iota-carrageenan. Foods 7(7):115

Patel BB, Patel JK, Chakraborty S, Shukla D (2015) Revealing facts behind spray dried solid dispersion technology used for solubility enhancement. Saudi Pharm J 23(4):352–365

Pereira A, Maraschin M (2015) Banana (Musa spp) from peel to pulp: ethnopharmacology, source of bioactive compounds and its relevance for human health. J Ethnopharmacol 160:149–163

Robert P, Fredes C (2015) The encapsulation of anthocyanins from berry-type fruits. Trends in foods. Molecules 20(4):5875–5888

Robert P, Gorena T, Romero N, Sepulveda E, Chavez J, Saenz C (2010) Encapsulation of polyphenols and anthocyanins from pomegranate (Punica granatum) by spray drying. Int J Food Sci Technol 45(7):1386–1394

Saikia S, Mahnot NK, Mahanta CL (2015) Optimisation of phenolic extraction from Averrhoa carambola pomace by response surface methodology and its microencapsulation by spray and freeze drying. Food Chem 171:144–152

Someya S, Yoshiki Y, Okubo K (2002) Antioxidant compounds from bananas (Musa Cavendish). Food Chem 79(3):351–354

Sulaiman SF, Yusoff NAM, Eldeen IM, Seow EM, Sajak AAB, Supriatno Ooi KL (2011) Correlation between total phenolic and mineral contents with antioxidant activity of eight Malaysian bananas (Musa sp). J Food Compos Anal 24(1):1–10

Tontul I, Topuz A (2017) Spray-drying of fruit and vegetable juices: effect of drying conditions on the product yield and physical properties. Trends Food Sci Technol 63:91–102

Tumbas Šaponjac V, Ćetković G, Čanadanović-Brunet J, Pajin B, Djilas S, Petrović J, Lončarević I, Stajčić S, Vulić J (2016) Sour cherry pomace extract encapsulated in whey and soy proteins: incorporation in cookies. Food Chem 207:27–33

Vu HT, Scarlett CJ, Vuong QV (2018) Phenolic compounds within banana peel and their potential uses: a review. J Funct Foods 40:238–248

Vu HT, Scarlett CJ, Vuong QV (2019) Maximising recovery of phenolic compounds and antioxidant properties from banana peel using microwave assisted extraction and water. J Food Sci Technol 56:1360–1370

Zhang L, Mou D, Du Y (2007) Procyanidins: extraction and micro- encapsulation. J Sci Food Agric 87(12):2192–2197

Acknowledgements

The first author would like to thank Dr Dipangkar Kundu (Australian Public Service) for the proofreading and insightful reviews, which has significantly contributed to the quality of this publication. The first author would like to thank Ms Yun Lin and staff of the University of Newcastle Electron Microscope and X-ray Unit (EMX) for their support in the SEM analysis. The first author would like to thank Grain Processing Corporation for providing samples of maltodextrin. The awarding of a VIED-TUIT scholarship to the first author from Vietnam International Education Development and the University of Newcastle is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vu, H.T., Scarlett, C.J. & Vuong, Q.V. Encapsulation of phenolic-rich extract from banana (Musa cavendish) peel. J Food Sci Technol 57, 2089–2098 (2020). https://doi.org/10.1007/s13197-020-04243-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04243-6