Abstract

In this study, thermosonication was used as a combined treatment of raw goat milk (RGM) using pasteurization (72 °C for 15 s) and ultrasound treatments (20 kHz at the power variance of 150 W, 200 W, 300 W and 400 W for 10 min). Investigation on the impact of the microbial load, protein content, protein aggregation, the particle size of fat and casein micelles, pH, viscosity, turbidity, color, and soluble calcium and phosphorus contents were carried out, whiles RGM and PGM served as the control. Our results revealed that at 400 W, that thermosonication resulted in a significant reduction (α = 0.05) in the microbial load of the samples to less than 2.3 log cfu/mL in comparison to those of RGM and pasteurized goat milk (PGM) at 5.94 log cfu/mL and 4.76 log cfu/mL respectively. In RGM, the fat size (3.5 µm) decreased to 0.4 µm at 300 W; while those of casein micelles also decreased from 406 to 256.4 nm at 400 W. However, no significant effect was observed in the color and soluble calcium and phosphorus contents of all samples. The effect on the microbial load and fat homogenization would promote thermosonication process in the dairy industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Goat milk (Caprine milk) is one of the most important milk produced and consumed which has received widespread technological attention. Caprine milk is considered an alternative to cow milk because of its average basic nutrient composition (12.2% total solids, consisting of 3.8% fat, 3.5% protein, 4.1% lactose and 0.8% ash) similar to those in cow milk (Kapila et al. 2012).

Caprine milk is a natural food product with fast spoilage and not widely available in most countries. Nowadays, there is a challenge for the dairy industry to increase the preservation time to allow transport and handling with stability in its natural and chemical properties as well as for the milk to be safe for human consumption at a reasonable price.

Thermal treatment is one of the primary and traditional processing methods to extend the shelf life of the product, however, during the thermal process there were many insufficiencies like denaturation and modifications of the proteins (Lan et al. 2010), mineral balance (Seiquer et al. 2010) and color change (BermÚdez-Aguirre et al. 2009a). Recently, the trend towards the use of modern and safe technology on health which causes least damage on the nutritional ingredients with increase in preservation time of the products is being encouraged to replace the conventional thermal process.

Ultrasound (US) refers to waves are longitudinal sound waves frequency above 20 kHz, which is greater than the upper limit of human hearing (Leighton 2007). US is non-thermal, safe processing techniques, non-toxic and eco-friendly (Kentish and Ashokkumar 2011). Furthermore, it is used in a wide range of application in food processing like homogenization, enzyme inactivation, extraction, crystallization, drying, freezing, dehydration, thawing, crystallization of lactose, in cleaning operations and as an analytical tool (Bhaskaracharya et al. 2009). The main physical effects of US include cavitation (bubble in a liquid rapidly collapses) which can produce shockwave formation, shear forces high, localized temperatures, and pressures (Ashokkumar et al. 2007).

Thermosonication involves synergistic effect of both initial thermal treatment and radiation treatment by US power combined which is more effective than thermal process (Silva 2015). Hence, many studies on fluid milk such as influence of pressure and thermal treatments along with US on fat globule homogenization and microbial inactivation had been done (Bermúdez-Aguirre et al. 2009a, b; Erkaya et al. 2015). Meanwhile, investigated the change on casein micelles (Chandrapala et al. 2012; Liu et al. 2014b; Zhang et al. 2018), whey protein concentrates (Arzeni et al. 2012), whey protein aggregates (Ashokkumar et al. 2009; Zhang et al. 2018) and on milk coagulation (Madadlou et al. 2010; Zhao et al. 2014) were carried out. The US treatment induced a profound effect on the physical and functional properties of milk proteins and the fat distribution, promoting gel network (Liu et al. 2014a; Zhao et al. 2014; Nguyen and Anema 2017). Riener et al. (2009) noted that thermosonication treatment before inoculated the milk with the starter culture enhanced the microstructure, rheological properties, and prevented the whey separation of yogurt. Specific study on turkey’s fermented product (ayran) reported that thermosonication enhanced the rheology and sensory properties with a long shelf life during the storage (Erkaya et al. 2015). Although these advantages of thermosonication processing on the dairy industry, no information about its effects on goat milk. Therefore, in this present study, the effect of thermosonication on the physicochemical properties, and microbial load of goat milk were elucidated.

Materials and methods

Sample preparation

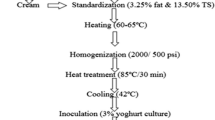

Raw goat milk (RGM) obtained from a goat farm in Hebei province (China) and was pasteurized at 72 °C for 15 s (PGM) used as control. The composition of raw goat milk was 3.25% protein, 4.47% fat, 4.76% lactose and 6.26 × 105/mL somatic cells, as determined by Beijing Dairy Cattle Center using Milko-Scan FT1 analyzer (Foss Electric, Denmark). Samples were stored overnight in a refrigerator.

Thermosonication treatment of goat milk (TSGM)

Two hundred milliliters of pasteurized goat milk (at 72 °C for 15 s) for each trial was placed in beaker jacketed with ice was sonicated by a 13 mm ultrasonic probe which immersed into the samples and about 3 cm depth. US was performed at a frequency of 20 kHz and a power of 150, 200, 300, 400 W for treatment time of 10 min using a cell disruptor (JY92-IIN, Ningbo Scientz, Zhejiang, China). The samples were equilibrated at room temperature for 30 min before measuring the parameters. All measurements were carried out on the same day of the sonication.

Microbiological analysis

For microbial analysis, samples were transferred in sterile screw cap tubes and microbiological load was evaluated. Enumeration microbial loads as total colony forming units of bacteria per one milliliter (CFU/mL) using Plate Count Agar (Beijing luqiao technology limited, liability). The samples were serially diluted in sterilized saline solutions (0.85% NaCl, w/v). Appropriate dilutions plated on plate count agar using the spread plate method. The plates were incubated at 35 °C for 48 h. All samples were evaluated as triplicate.

pH-measurements

All the samples were determined at room temperature using direct immersion with a glass electrode (Hanna HI1230) of pH meter type (pH 211, Hanna Instruments). Before the measurement the pH electrode was calibrated using standard buffers at pH 4.0, 7.0 and 10.0. All samples were measured as triplicate.

Soluble calcium and phosphorus analyses

Ten milliliters of milk samples were ultracentrifuged at 100,000×g for 1 h at 4 °C using a (Beckman Coulter Inc., Brea, CA T4-TI-70 rotor, Ultracentrifuge Hitachi). Supernatant was carefully obtained for determination of soluble calcium and phosphorus contents in the serum phase using inductively coupled plasma mass spectrometry (ICP-MS, Agilent, California, USA) whiles all samples were measured in triplicate.

Viscosity

Twenty milliliters of goat milk samples were analyzed at 25 °C with a physica MCR 301 rheometer, (Anton Paar, Austria) with a cup and probe type CC27SN13078 at 100 rpm every 300 s. Measurements were performed in triplicate.

Turbidity

The turbidity was measured with ElISA (spark 20 m multimode micro plate reader from TECAN, Mannedorf, Switzerland) using a wavelength of (λ = 860 nm). After centrifugation of the samples at 15,000×g for 1 h at 4 °C, the supernatants were obtained carefully separated from the fat and pellet and measurements were recorded three times.

Particle size measurements

Malvern Zetasizer Nano ZS (Malvern Instruments Ltd., Worcestershire, UK) were used to estimate of the changes in casein micelle size. Refractive index 1.46 for casein micelle proteins after appropriate dilutions of the untreated and thermosonication treated samples by distilled water (1:10, v/v). The size of the fat globules was observed as derived from the slope of the double-log plot of dispersion turbidity as a function of wavelength using Microtrac, BLUEWAVE with refractive index 1.45 for fat and the refractive index of the aqueous water as 1.33. Diluting the samples by (1:10, v/v) of EDTA solution (10 g/L adjusted to pH 7.6 with 1 M of sodium hydroxide) dissociated the casein micelles to observe clearly the size distribution of the fat globules. All the measurements were performed at 25 °C and were performed in triplicate.

Protein contents

All samples were determined as two repeated for total nitrogen (TN), non-casein nitrogen (NCN) and non- protein nitrogen (NPN) by using the Kjeldahl’s method (IDF 2014; AOAC 2010; method 991.20), according to Barbano et al. (1991). NPN was measured using AOAC 2010; method 991.21. Whiles, Casein nitrogen (CN) = TN–NCN; Whey protein nitrogen (WPN) = NCN–NPN; Whey protein denaturation \( \left( {\text{WPD}} \right) \, \% \, = \frac{{{100^* \text{(WPN control }}{-} {\text{WPN treated) }}}}{\text{(WPN control) }} \) (Manji and Kakuda 1987).

Gel electrophoresis

Sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS-PAGE) was performed using BIO-RAD-Mini-PROTEAN tetra system. The fat layer were removed after centrifugation of samples at 3000 rpm for10 min at 4 °C and the obtained defatted milk samples were diluted with deionized water to 2.5 mg/mL of protein. The samples were mixed with sample buffer (950 uL of 2 × laemmli sample buffer with 50 uL of β- mercaptoethanol). The protein solution was heated at 90 °C for 5 min and cooled at 4 °C immediately, then rotate at 1500×g for 10 min. Ten Microliters of protein marker and samples were injected carefully onto the gel’s wells composed by 15% separating gel and the gel was run by running buffer for 45 min at 140 V. Gel was stained with Coomassie Brilliant Blue R-250 with orbital shaker at 50 rpm for 4 h or overnight then destained with water for three times and destained solution (430 mL alcohol, 50 mL acetic acid and 520 mL distilled water) over the orbital shaker for 1.5 h until a clear background was achieved. Ultimately SDS–PAGE gel preservative into preservation solution (7% acetic acid) until scanning by Alpha Ease FC gel imaging system (Alpha Inc., city, USA).

Color measurement

Hunter Lab Color Quest XE Spectrophotometer (Birstall, Leicestershire, UK) using for evaluated the difference in color of untreated and thermosonication treated samples, transferred 15 mL of the samples to glass petri dishes for measuring at room temperature. After calibrated its original value with standard plates, based on the CIE L* a* b* color space, whereas L* = (0–100) refers to black to white, a* = (−) green to (+) red and b* = (−) blue to (+) yellow. All samples were measured in triplicate.

Statistical analysis

All determinations were carried out in triplicate. Analysis of variance (ANOVA) was conducted using the software Statistical Analysis systems (SAS) version 9.3 for windows (SAS Institute Inc., city, USA), the probability level of 5% (α = 0.05) was used to indicate the significance. The mean comparison was done using LSD procedure (α = 0.05).

Results and discussion

Microbiological analysis

In our study, the effect of ultrasonic treatment was evident in reduction of the logarithms numbers of the total count of mesophilic aerobic bacteria which decreased with increasing the sonication power level compared with RGM and PGM. The behavior of the microbiological count in goat milk after thermosonication as shown in (Fig. 1) portrays an interesting decrease of colonies count of the plates of TSGM 300 W and TSGM 400 W to less than 2.08 log cfu/mL and 2.37 log cfu/mL, respectively, whereas, some of plates at this power did not show any colonies. However, the cell counts of the RGM and PGM samples were evaluated higher than 5.96 log cfu/mL and 4.76 log cfu/mL, respectively. Based on the above results, it is evident that thermosonication process succeeded in reducing the microbiological load of goat milk compared to the RGM due to the cavitation force and the heat treatment. Similar results were reported that the ultrasonic treatment at 430 and 338 W on buffalo milk decreased the microbial load (Al-hilphy et al. 2012).

pH-measurements

As shown in Table 1 the pH measurement shown no significant change (α = 0.05) between all of TSGM at 150, 200, 300, 400 W compared with the control PGM. This result agreed with Zhang et al. (2018), which found similar results between the pH of the control and sonicated samples. While, the pH of TSGM (400 W) showed small decreased to 6.59 with significant respect with RGM, because of enzymatic hydrolysis of phosphoric esters in sonicated milk according to Walstra et al. (2006). Also, the average value of the pH (6.6) is acceptable for commercial goat milk as reported by Mayer and Fiechter (2012).

Size distribution

Figure 2 defines the casein micelles size with significant change (α = 0.05). Particle size decreased with increasing power level of ultrasound. The casein micelles size was changed from 306.100 to 340.733 nm for RGM and PGM, to 256.467 nm in TSGM 400 W. While, observed significant change (α = 0.05) in the diameter of casein micelles of PGM, which increases to (340.733 nm). During pasteurization induced denaturation and aggregation of whey protein like (β-Lg) and linked with (κ-CN) on the new formed pellet surface (Donato et al. 2007). Previous study observed a decrease in the particle size of casein micelle for the ultrasonication milk (Liu et al. 2014b; Zhao et al. 2014). Therefore, it can be summarized that the disruption of the small fragments of κ-CN covered the surface of the micellar lead to reduction in the casein micelles size without inducing any change in native state of casein micelles by the shear forces of cavitation induced from ultrasound treatment.

a Size of the casein micelles present in the Raw goat milk (RGM), pasteurized goat milk (PGM) and thermosonicated goat milk samples at TSGM 150 W, TSGM 200 W, TSGM 300 W and TSGM 400 W. b Size of the fat globules present in the Raw goat milk (RGM), pasteurized goat milk (PGM) and thermosonicated goat milk samples at TSGM 150 W, TSGM 200 W, TSGM 300 W and TSGM 400 W. The standard deviation was used as the error-bar

A comparison of fat globules diameters obtained by TSGM affected by increasing the level power of ultrasound showed a reduction of higher magnitude. Whereas, numerous fat globules smaller than 1 µm in TSGM 200 W and TSGM 300 W thus smallest fat globule diameter (0.9970 µm and 0.4110 µm) respectively. Ertugay and Sengül (2004) observed a decrease in fat globules size on milk homogenization after ultrasound treatment. In our study, different behavior in TSGM 400 W showed no significant change (α = 0.05) in the fat globule diameter (3.3840 µm) since the fat globule diameters of RGM and PGM ranged between (3.5433 and 3.2640 µm), respectively. This similar results was reported by Shanmugam et al. (2012) who observed small increasing in the fat globules size of skim milk up to 5 nm in 60 min at 41 W and neglected it. The results might be the increase in diameter of the fat size due to the coalescence and conglutination of the fat globules after sonication treatment which agrees with results obtained by Kentish et al. (2008) who, observed an increase in droplets oil size during emulsification with ultrasonic of flaxseed oil in water at excess power. Thus, more studies need to be done on this observation.

Turbidity

Figure 3 demonstrates significant change (α = 0.05) of the turbidity as more translucent appearance of thermosonication sample respected with untreated sample of goat milk. Turbidity data of TSGM at 150, 200 and 300 W showed significant changes decrease in turbidity (0.1065, 0.1200 and 0.1213) comparison to RGM and PGM (0.3765 and 0.2840), respectively. While, in TSGM 400 W shown lower significant change as a decrease in turbidity to (0.27100) comparison to the control RGM. Whereas, no significant change between the same power comparison to the control PGM, meanwhile, at the same power observed no significant change on the fat globules size which could lead up to increase the turbidity. Previous studies observed decreasing in turbidity of skimmed milk after sonication treatment by Chandrapala et al. (2012), Shanmugam et al. (2012). US has significant effective of reduction of the diameter of particles size of fat and casein micelles in milk because of the shear forces of cavitation effected on the turbidity. Additionally, the reduction of turbidity due to the reduction in the whey protein aggregates or casein aggregates during the sonication (Shanmugam et al. 2012).

a Viscosity of the raw goat milk (RGM), pasteurized goat milk (PGM) and thermosonicated goat milk samples at TSGM 150 W, TSGM 200 W, TSGM 300 W and TSGM 400 W. b Turbidity of the Raw goat milk (RGM), pasteurized goat milk (PGM) and thermosonicated goat milk samples at TSGM 150 W, TSGM 200 W, TSGM 300 W and TSGM 400 W. The standard deviation was used as the error-bar

Soluble calcium and phosphorus analyses

Calcium and Phosphorus analysis were performed to investigate the stability of CCP relative the structure of casein micelles. Table 1 showed that there was no significant change of calcium and phosphorus concentration in the serum phase between the RGM, PGM and TSGM. The small decrease observed in the size of casein micelles for TSGM may be accounted for hydrolysis of the κ-CN present at the outer surface and possibly due aggregation of the micelles into small clusters without effects on the casein micelles structure by the ultrasound shear forces, whereas, the pH in milk and concentration of soluble calcium and phosphorus in the serum phase regarded indirectly indicators for solubility of CCP (Chandrapala et al. 2010). Therefore, in this study the pH in goat milk samples and concentration of calcium and phosphorus in the serum phase showed a non-significant modification of the behavior at the different power levels. So, it can be concluded that the CCP in casein micelles still stable in TSGM. Similar result were obtained by Shanmugam et al. (2012) who, found no change in pH and the soluble calcium concentration of skim milk after ultrasound treatment.

Color

The color parameter was confirmed by statistical analysis L*, a* and b* are shown in Table 1 for untreated and the thermosonication treated samples. The L* and b* values were very close to each other of treated goat milk samples that showed the same behavior of RGM with increasing of sonication power. Whereas a* values changed from (− 1.5589) in RGM to (− 1.9989) in PGM and to (− 2.3456) in TSGM. Predominately, ultrasound couldn’t be achieved observant change on the color of goat milk, whereas no significant change (α = 0.05) for RGM, PGM and TSGM. These results indicate that thermosonication processing didn’t induce Maillard reactions. BermÚdez-Aguirre et al. (2009a) evaluated the change of the color that improved in thermosonication of whole milk at 400 W during storage time for 16 days. On the other, the lightness value of milk related to the fat globules size distribution because of the cavitation effect, whereas other study noted that homogenized milk by thermosonication treatment whiter than the untreated (Bermúdez-Aguirre et al. 2008).

Protein content

In accordance with the statistical analysis in Table 2 the samples treated with thermosonication observed increase of whey protein denaturation not significantly difference (α = 0.05). Whereas, the thermosonication samples from TSGM 150 to TSGM 400 W showed increase of denaturation of whey protein from 16.725 to 17.065% respectively, with insignificantly difference (α = 0.05). The increase of (WPD %) is attributed primarily to the use of heat treatment as PGM plus ultrasound as TSGM. This result agrees with BermÚdez-Aguirre et al. (2009a).

Viscosity

The behavior of fluid milk changes is mainly dependent on milk components as casein, whey protein and milk fat content. The viscosity of goat milk samples is affected by sonication power at TSGM (200, 300 and 400 W). As showed in Fig. 3 the viscosity of TSGM, RGM and PGM showed significant changes (α = 0.05) it was decreased steadily at increasing the level power of ultrasound while there was decrease in viscosity. Whereas, at TSGM 150 W and PGM had shown significant change (α = 0.05) comparison to RGM as increasing of viscosity because of the denaturation and aggregates of whey protein formed during pasteurized treatment. Other studies suggested the changes of viscosity as decrease in sonicated skimmed milk due to the impact of cavitation induced ultrasonic power that could break up whey protein or the aggregates of CN-whey protein, which formed during pasteurization, without changes in the structure of casein micelles themselves by Chandrapala et al. (2012). Also Ultrasonication frequencies couldn’t achieve major change in viscosity of goat milk as shown in (Fig. 3) those results agree with Shanmugam et al. (2012) who, did not observe significant difference in viscosity of skim milk after sonication.

SDS-PAGE analysis

The results supported by performing SDS-PAGE analysis which observed no significant change between the TSGM samples and the control of RGM in the bands intensity of α-CN, β-CN and κ-CN in the electrophoretic patterns (Fig. 4). While, we observed an increase of the band of β-CN after treating the PGM samples by US. The samples of PGM showed a decrease in the band of β-CN because of the heat effect on β-CN, which is the most hydrophobic among all the caseins, and induced interaction between β-CN molecules and the re-assembly of β-CN with the micelles. These results agree with Zhang et al. (2018). Thus, as discussed in viscosity that indicates US didn’t effect on the individual subunits of goat milk protein in and didn’t attribute significant difference in the denaturation of soluble whey proteins followed by the self-aggregation and aggregation with other free caseins. In addition to, the shear forces generated by acoustic cavitation could disassemble the aggregates of whey protein denatured or of CN-whey protein formed during pasteurization.

Conclusion

Thermosonication treatment is a novel and promising technology in the dairy industry. Thermosonication treatment reduced the total count of bacteria, whereas at TSGM 300 W and TSGM 400 W, achieved the lowest values of the log cfu/mL. The results of this study confirmed that thermosonication processing effect on goat milk decreased the viscosity, turbidity, and particle size of fat and casein micelles. However, no significant effect observed on the native state of casein micelles, minerals balance, and the color properties. So, thermosonication can be used in the food industry for inactivation the bacteria, and homogenization the fat globules, promoting the quality of milk production.

References

Al-hilphy ARS, Niamah AK, Al-temimi AB (2012) Effect of ultrasonic treatment on buffalo milk homogenization and numbers of bacteria. Int J Food Sci Nutr Eng 2(6):113–118

AOAC (2010) Official methods of analysis, 17th edn. AOAC International, Gaithersburg

Arzeni C, Martínez K, Zema P, Arias A, Pérez OE, Pilosof AMR (2012) Comparative study of high intensity ultrasound effects on food proteins functionality. J Food Eng 108(3):463–472

Ashokkumar M, Lee J, Kentish S, Grieser F (2007) Bubbles in an acoustic field. Ultrason Sonochem 14:470–475

Ashokkumar M, Lee J, Zisu B, Bhaskarcharya R, Palmer M, Kentish S (2009) Sonication increases the heat stability of whey proteins. J Dairy Sci 92(11):5353–5356

Barbano DM, Lynch JM, Fleming JR (1991) Direct and indirect determination of true protein content of milk by Kjeldahl analysis: collaborative study. J Assoc Anal Chem 74:281–288

Bermúdez-Aguirre D, Corradini MG, Mawson R, Barbosa-Cánovas GV (2008) Microstructure of fat globules in whole milk after thermosonication treatment. J Food Sci 73:325–332

Bermúdez-Aguirre D, Corradini MG, Mawson R, Barbosa-Cánovas GV (2009a) Composition properties, physicochemical characteristics and shelf life of whole milk after thermal and thermo-sonication treatments. J Food Qual 32(3):283–302

Bermúdez-Aguirre D, Corradini MG, Mawson R, Barbosa-Cánovas GV (2009b) Modeling the inactivation of Listeria innocua in raw whole milk treated under thermo-sonication. Innov Food Sci Emerg Technol 10(2):172–178

Bhaskaracharya RK, Kentish S, Ashokkumar M (2009) Selected applications of ultrasonics in food processing. Food Eng Rev 1(1):31–49

Chandrapala J, McKinnon I, Augustin MA, Udabage P (2010) The influence of milk composition on pH and calcium activity measured in situ during heat treatment of reconstituted skim milk. J Dairy Res 77(3):257–264

Chandrapala J, Martin GJO, Zisu B, Kentish SE, Ashokkumar M (2012) The effect of ultrasound on casein micelle integrity. J Dairy Sci 95(12):6882–6890

Donato L, Guyomarc’h F, Amiot S, Dalgleish DG (2007) Formation of whey protein/κ-casein complexes in heated milk: preferential reaction of whey protein with κ-casein in the casein micelles. Int Dairy J 17(10):1161–1167

Erkaya T, Başlar M, Şengül M, Ertugay MF (2015) Effect of thermosonication on physicochemical, microbiological and sensorial characteristics of ayran during storage. Ultrason Sonochem 23:406–412

Ertugay MF, Sengül M (2004) Effect of ultrasound treatment on milk homogenization and particle size distribution of fat. Turk J Vet Anim Sci 28:303–308

International Dairy Federation (2014) Milk and milk products determination of nitrogen content—Part 1: Kjeldahl principle and crude protein calculation. Belgium, Brussels

Kapila R, Kavadi PK, Kapila S (2012) Comparative evaluation of allergic sensitization to milk proteins of cow, buffalo and goat. Small Rumin Res 112:191–198

Kentish S, Ashokkumar M (2011) The physical and chemical effects of ultrasound. In: Feng H, Barbosa-Canovas G, Weiss J (eds) Ultrasound technologies for food and bioprocessing. Food engineering series. Springer, New York, pp 1–12

Kentish S, Wooster TJ, Ashokkumar M, Balachandran S, Mawson R, Simons L (2008) The use of ultrasonics for nanoemulsion preparation. Innov Food Sci Emerg Technol 9:170–175

Lan XY, Wang JQ, Bu DP, Shen JS, Zheng N, Sun P (2010) Effects of heating temperatures and addition of reconstituted milk on the heat indicators in milk. J Food Sci 75(8):653–658

Leighton TG (2007) What is ultrasound? Prog Biophys Mol Biol 93:3–83

Liu Z, Juliano P, Williams RPW, Niere J, Augustin MA (2014a) Ultrasound improves the renneting properties of milk. Ultrason Sonochem 21:2131–2137

Liu Z, Juliano P, Williams RPW, Niere J, Augustin MA (2014b) Ultrasound effects on the assembly of casein micelles in reconstituted skim milk. J Dairy Res 81:146–155

Madadlou A, Emam-Djomeh Z, Mousavi ME, Mohamadifar M, Ehsani M (2010) Acid-induced gelation behavior of sonicated casein solutions. Ultrason Sonochem 17(1):153–158

Manji B, Kakuda Y (1987) Determination of whey protein denaturation in heat-processed milks: comparison of three methods. J Dairy Sci 70(7):1355–1361

Mayer HK, Fiechter G (2012) Physicochemical characteristics of goat’s milk in Austria-seasonal variations and differences between six breeds. Dairy Sci Technol 92(2):167–177

Nguyen NHA, Anema SG (2017) Ultrasonication of reconstituted whole milk and its effect on acid gelation. Food Chem 217:593–601

Riener J, Noci F, Cronin DA, Morgan DJ, Lyng JG (2009) The effect of thermosonication of milk on selected physicochemical and microstructural properties of yoghurt gels during fermentation. Food Chem 114:905–911

Seiquer I, Delgado-Andrade C, Haro A, Navarro MP (2010) Assessing the effects of severe heat treatment of milk on calcium bioavailability: in vitro and in vivo studies. J Dairy Sci 93(12):5635–5643

Shanmugam A, Chandrapala J, Ashokkumar M (2012) The effect of ultrasound on the physical and functional properties of skim milk. Innov Food Sci Emerg Technol 16:251–258

Silva FVM (2015) Thermosonication versus thermal processing of skim milk and beef slurry: modeling the inactivation kinetics of psychrotrophic Bacillus cereus spores. Food Res Int 67:67–74

Walstra P, Geurts TJ, Walstra P, Wouters JTM (2006) Dairy science and technology, 2nd edn. CRC Taylor and Francis, Boca Raton

Zhang R, Pang X, Lu J, Liu L, Zhang S, Lv J (2018) Effect of high intensity ultrasound pretreatment on functional and structural properties of micellar casein concentrates. Ultrason Sonochem 47:10–16

Zhao L, Zhang S, Uluko H, Liu L, Lu J, Xue H et al (2014) Effect of ultrasound pretreatment on rennet-induced coagulation properties of goat’s milk. Food Chem 165:167–174

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 31871834), National Key R&D Program of China (2018YFD0400900), Beijing innovation Teem of Technology System in Dairy Industry.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ragab, E.S., Lu, J., Pang, X.Y. et al. Effect of thermosonication process on physicochemical properties and microbial load of goat’s milk. J Food Sci Technol 56, 5309–5316 (2019). https://doi.org/10.1007/s13197-019-04001-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-04001-3