Abstract

The conservation of the quality of special coffees depends on the storage conditions. Therefore, new technologies for the packaging of grains need to be studied. This work was carried out with the objective of evaluating the effect of different packages on the quality of the stored coffee. The free fatty acid profile, fat acidity and sensory characteristics of the grains were analyzed during storage. The coffees were stored for 12 months in 8 packaging types. Coffee stored in jute bags differed mainly due to the higher values of fat acidity and lower scores in sensory analysis. The high-barrier packages were more efficient in the storage of the coffee beans since they presented the lowest deterioration indicators, represented by the low values of fat acidity, free fatty acids and higher scores in the sensorial evaluation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

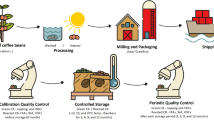

The storage of agricultural products is an excellent way to meet the logistical needs of production and marketing of agricultural products (Chaves et al. 2012). Most crops do not produce throughout the year, requiring a method that guarantees product supply in the off-season. According to Borém et al. (2008), storage is required in the production chain, and all coffee prepared for consumption requires this step postharvest, particularly specialty coffees, whose consumption has increased in recent years.

The maintenance of coffee quality depends on storage conditions (Coradi et al. 2008; Abreu et al. 2017), and the main factors that can lead to quality loss during this stage are fluctuations in temperature and relative humidity and exposure to light. Therefore, the type of packaging must be adequate to prevent such changes. According to Oliveira and Oliveira (2004), in addition to packing the product, one function of packaging is maintaining the maximum quality of the product by creating conditions that minimize chemical, biochemical and microbiological changes.

Since coffee is an agricultural product whose price is directly linked to its quality (Ribeiro et al. 2011), it becomes necessary to use a type of packaging that preserves its chemical and organoleptic properties, which are limiting factors for coffee enhancement (Saath et al. 2012). Jute bags are the leading package used in coffee bean storage; however, they do not provide barriers against gas exchanges, which makes their use virtually impossible in the storage of specialty coffees for long periods.

Recent studies, such as that of Ribeiro et al. (2011), show that new types of packaging, alternatives to jute bags, show promise in maintaining the color and quality of coffee; these include hermetic plastic bags (GrainPro®) and “big bags”, which are impermeable to gases, with and without the addition of CO2.

The deterioration of coffee beans and seeds may be indicated by chemical changes in the lipid fraction (Coradi et al. 2007; Marques et al. 2008), and the release of fatty acids derived from triglyceride hydrolysis is one of the first reactions that occurs under adverse conditions of postharvest handling (Marques et al. 2008). This reaction is a result of damage that compromises the stability of the cell membrane and the integrity of cell walls, events that are common in coffees with the worst quality (Coradi et al. 2008), because these unsaturated fatty acid chains can be readily oxidized to hydroperoxides and subsequently develop into several low-molecular-weight compounds that give the product an unpleasant flavor (Gutkoski and El-Dash 1999).

Given the importance of storage in the production chain, as well as the reflection of that postharvest stage in the quality of agricultural products and the need for new technologies that meet the requirements of the specialty coffee market, this study was conducted with the aim of evaluating the effect of different packaging types on coffee quality through changes in free fatty acid profile, fat acidity and sensory characteristics.

Materials and methods

Characterization of the raw material

The experiment was performed in the commercial warehouse of Bourbon Specialty Coffees S/A in the city of Poços de Caldas, MG, and in the Agricultural Products Processing Laboratory at the Engineering Department of the Federal University of Lavras.

The raw material needed for the experiment was provided by Bourbon Specialty Coffees S/A. Coffee beans (Coffea arabica L.) from a single commercial batch, harvest 2011, were previously selected and characterized; these materials scored higher than 85 points on the scale of the Specialty Coffee Association (SCA).

Packaging

Coffee beans were placed in five types of packaging: jute bags (J), GrainPro® bags (GP), plastic bags similar to GrainPro® bags (S-GP), foil pouch 1 (FP1) and foil pouch 2 (FP2). The specifications of the material constitution of each packaging type are presented in Table 1. These packages were chosen because of their use by coffee producers and exporters. However, scientific studies have not been conducted to validate the effects of each type of packaging on coffee quality maintenance during storage.

Bean packaging

During packaging in plastic containers, three conditions were set with respect to gas concentration:

-

1.

passive modified atmosphere (PMA): packaging (bag GrainPro®, bag similar to GrainPro®, FP1 and FP2) was hermetically sealed, thus forming a modified atmosphere within these packages in the absence of gas addition;

-

2.

active modified atmosphere (AMA): applied to packaging FP1. This technique was chosen since it is currently used in the storage and transportation of various agricultural products. In recent studies, a modified atmosphere with 60% (Ribeiro et al. 2011) or 40% (Borém et al. 2008) carbon dioxide was used during the storage of coffee beans. However, the limiting conditions appropriate for raw coffee beans are unknown; and

-

3.

vacuum (V): applied to packaging FP1, and the partial pressure of oxygen (O2) was reduced using a partial vacuum in the packages.

Carbon dioxide (CO2) was injected to progressively expel intergranular air until the gas concentration reached the desired level of 10 ± 2% as measured by the device Anagas CD 98, coupled at one end of the package. The concentration of the gas inside the package was measured every 3 months.

The vacuum was maintained in a TecMaq-300 machine. To achieve the desired conditions, the vacuum time potentiometer in the equipment was adjusted to level 3, obtaining a vacuum of − 540 mmHg in the package, equivalent to approximately 95% of the total volume.

Implementation of the experiment

Packages of up to 8 kg with dimensions of 50 cm high and 45 cm wide were stored at ambient conditions (conventional warehouse). However, coffee in the jute bag packaging was stored in a conventional warehouse in a chamber under controlled conditions.

Sampling for quality evaluation was performed at intervals of 3 months starting from the beginning of storage and continuing for 12 months. The sampling amount used to perform all analyses was approximately 500 g for each package.

Treatments and design

Table 2 summarizes the identification and characterization of treatments.

This study investigated the effect of the packaging method on coffee beans during storage. The experimental design was completely randomized (CRD), with three replications in a 5 × 8 factorial scheme corresponding to five storage periods (0, 3, 6, 9 and 12 months) and eight packaging methods (FP1-PMA, FP1-AMA, FP1-V, GP, J-CW, J-CC, FP2-PMA, S-GP).

Quality characterization

The quality of coffee beans was evaluated by chemical and sensory analyses. Analyses were performed in the Agricultural Products Processing Laboratory at the Engineering Department of UFLA, the Chromatography Laboratory in the Chemistry Department of UFMG and the Coffee Quality Laboratory of Epamig in Lavras.

Chemical and sensory variables were assessed at 0, 3, 6, 9 and 12 months of storage, except for the evaluation of the fatty acid profile, which was analyzed at baseline (time zero) and at the end of the storage period (12 months).

Water content

The water content of raw coffee beans was determined by the oven drying method at 105 ± 1 °C for 16 h, according to the standard method ISO 6673 (International Organization for Standardization 1999).

Fat acidity

Fat acidity was determined by titration, according to the method described by the American Association of Cereal Chemists (1995). The fat acidity content was expressed in mL KOH−1 100 g DM, calculated using the following equations:

where DM—sample dry matter (g); U—water content on a wet basis (%); AG—fat acidity (mL KOH/100 g DM); and V—KOH volume used in titration (extract + indicator), in mL.

Free fatty acid profile

Extraction of free fatty acids

To microcentrifuge tubes containing 250 mg of ground coffee, 1.0 mL of hexane was added to remove oils and other nonpolar substances. The tubes were then placed in an ultrasonic bath for 10 min and centrifuged at 5500 rpm for 5 min. The supernatant was discarded. The degreased coffee samples were suspended in 1.0 mL of aqueous 0.1 N sodium hydroxide solution and subjected to an ultrasonic bath for 10 min. After centrifuging at 5500 rpm for 5 min, a 500 μL aliquot of the supernatant was transferred to another microcentrifuge tube. Subsequently, 50 μL of concentrated hydrochloric acid, a spatula tip of NaCl and 800 μL of ethyl acetate were added. After vortexing for 10 s, resting for 5 min and centrifuging for 3 min, a 400 μL aliquot of the organic layer was removed, placed in microcentrifuge tubes and dried by evaporation, thus obtaining free fatty acids.

Methylation of fatty acids

The free fatty acids were methylated with 100 μL of BF3/methanol (14%). Subsequently, the tube was heated for 10 min in a water bath at 80 °C. After cooling, 100 μL of methyl pentadecanoate (C15:0) at 1.05 mg/mL, used as an internal standard (Christie 1989), was added and then analyzed by gas chromatography.

Gas chromatography

Analyses were performed in an HP5890 gas chromatograph equipped with a flame ionization detector. An HP-INNoWax (HP) 15 m × 0.25 mm column was used, with a temperature gradient ranging from 150 to 220 °C at a heating rate of 7 °C/min, an injector (split 1/50) at 250 °C and a detector at 250 °C. Hydrogen was used as a carrier gas (2 mL/min), and the injection volume was 1 μL. Peak identification was made by comparison with methylated fatty acids standard SUPELCO37.

The fatty acid profile was characterized using gas chromatography and AOCS methods. The gas chromatograph provides high-resolution chromatography (HRGC) using an SP-2380 (30 m) capillary column, according to the methodology used by Christie (1989).

Sensory analysis

Sensory analysis was performed by panelists certified by the SCA, based on the sensory analysis protocol, according to the methodology proposed by Lingle (2011) for sensory evaluation of specialty coffees, with scores for fragrance/aroma, acidity, body, flavor, aftertaste, sweetness, smoothness, clean cup, balance and overall impression. Each of these attributes is described more fully by Lingle (2011). Acidity is often described as “brightness” when favorable or “sour” when unfavorable. Clean cup refers to a lack of interfering negative impressions from first ingestion to final aftertaste, a “transparency” of cup. The various aspects of flavor, aftertaste, acidity and body of the sample work together and complement or contrast to each other. The final result of the sensory evaluation was obtained according to the SCAA score scale.

Statistical analysis

The results were submitted to an analysis of variance and compared by the Scott–Knott test at 5% probability for packaging methods. In the study of the effect of storage time, a regression analysis was carried out. Statistical analyses were performed with the aid of the statistical software SISVAR (Ferreira 2011).

To study the correlations of packaging methods with storage time, multivariate principal component analysis (PCA) was performed with the statistical software Chemoface (Nunes et al. 2012).

Results and discussion

In general, an increase in fat acidity values can be observed during storage for all packaging methods. However, packaging in jute bags stored at ambient conditions (J-CW) should be highlighted since coffee beans stored under these conditions showed an increase in fat acidity of, on average, 17.14 to 28.66 mL KOH 100 g−1 (Fig. 1a and Table 3). Coffees stored under these conditions showed a significantly lower score in sensory analysis, indicating the potential of fat acidity to represent product quality.

According to Rendón et al. (2014), during storage, the hydrolysis of the fatty material begins before the hydrolysis of carbohydrates or proteins. Therefore, the content of free fatty acids can be used as an indicator of deterioration. Thus, the analysis of free fatty acids is of great importance in monitoring seed quality from maturity since the decrease in vigor occurs before the loss of viability. Saath et al. (2012) and Coradi et al. (2008) reported increases in the free fatty acid content of coffee by the fat acidity test due to the increase in the storage period. The fat acidity test expresses the content of free acids as a function of oil acidity. However, oil acidity can also be influenced by other acidic compounds. Thus, the content of free fatty acids determined by this method is only an approximate value (Speer and Kölling-Speer 2006).

More useful results can be observed in Table 4, which provides the free fatty acid profile, that is, fractionation of the major acids present in processed coffee bean samples at time zero and after 12 months of storage. Joët et al. (2010) identified ten fatty acids in coffee beans, Figueiredo et al. (2015) and Jham et al. (2008) identified seven, and Wagemaker et al. (2011) identified six, with palmitic and linoleic acids prevailing. In this study, four major fatty acids were identified, with palmitic acid in the highest proportion, followed by linoleic acid. In Table 4, it is possible to observe an increase in the concentration of total free fatty acids in relation to storage time in all packaging methods. It was also observed that all free fatty acids analyzed showed no significant differences with respect to the beginning and end of storage for coffee packaged in FP2 (FP2-PMA).

In Table 4, it is also possible to observe that coffee stored in J-CC had the lowest average levels of free fatty acids at the end of the storage period. This storage condition provided the beans with lower water content after 12 months (Table 3), as reported in a study conducted by Nobre et al. (2007); a low water content decreases the activity of lipases and peroxidases. Along with phospholipases, these enzymes are the main enzymes involved in reactions that increase the levels of free fatty acids (Zadernowski et al. 1999). The levels of palmitic and oleic acids had larger increases in coffee beans stored in jute bags at room conditions (J-CW). According to Dhingra et al. (1998), the content of free fatty acids indicates the amount of fatty acids released from the glycerol backbone and is associated with hydrolytic rancidity.

Adverse postharvest conditions, such as the use of high drying temperatures and inadequate storage conditions, can cause significant changes in major grain reserves, changing the sensory characteristics of coffee. In general, one of the earliest changes associated with seed deterioration is the increase in free fatty acids produced from the hydrolysis of triacylglycerols by lipases (Soares et al. 2004). The hydrolysis of triacylglycerols during coffee storage releases fatty acids (AG), which, in turn, can be oxidized in the presence of oxygen, yielding other compounds, such as volatile aldehydes, which are associated with unpleasant flavor and aroma. However, the release of AG is not uniform, and degradation differs among acids (Coradi et al. 2008; Jham et al. 2008). Significant reductions in the contents of unsaturated fatty acids linoleic acid (C18:2) and linolenic acid (C18:3) are observed in stale beans, while the contents of the major saturated acid, stearic acid (C18:0), remain virtually unchanged (Jham et al. 2008). In this study, there was an increase in the release of fatty acids after 12 months of storage, with the exception of stearic and oleic acids, which maintained significant equal amounts for packaging FP2-PMA. The progressive increase in the release of fatty acids is in accordance with the loss of beverage quality based on the scores at the beginning and end of the storage period (Table 3).

In several studies, major existing fatty acids have been identified and quantified in raw coffee beans (Nikolova-Damyanova et al. 1998; Alves et al. 2003; Jham et al. 2008; Joët et al. 2010). However, studies aimed at correlating the profile of these fatty acids with the quality of the beverage packaged in different containers during storage have not yet been conducted.

The average final scores for the sensory analysis of processed coffee beans as a function of packaging methods during storage are shown in Table 3 and Fig. 1b. According to the evaluation proposed by the SCA, quality is quantified by a scale ranging from zero to one hundred points. Coffees with scores of 85–89 and 80–84 points are classified as specialty (excellent) and special (very good), respectively. Coffees scoring between 75 and 79 points are classified as regular coffees, although they are of good quality, and average coffees (weak) are those that score from 70 to 75 points (Lingle 2011). At the beginning of storage, the scores for all packaging methods did not significantly differ and were higher than 85 points, classifying them as excellent coffees according to the SCA. At 12 months of storage, only the coffee packaged in jute bags in a conventional warehouse (J-CW) scored below 80 points; that is, it was not classified as specialty coffee. However, two other groups formed, one with packaging FP1-PMA, FP1-AMA, FP1-V, GP and FP2-PMA, which differed significantly from other treatments and had the highest scores, above 82 points, and an intermediate group, which presented sensory scores below 82 points, formed by packagings J-CC and S-GP (Table 3).

Figure 1b shows that coffees packed in S-GP, J-CW and J-CC had more pronounced score reductions during storage. However, as shown in Table 3, coffee packaged in jute bags in a conventional warehouse (J-CW) can be highlighted because it presented a score of 74.08 at 12 months and was classified as an average coffee (weak). According to Salva and Lima (2007), changes in the concentration of free fatty acids during storage contribute to the formation of a woody taste, assigned to stale coffees. In this study, there was a change in the sensory aftertaste of coffee stored in jute bags at room conditions, presenting, after storage, the lowest score in sensory evaluation. Panelists reported changes in the taste of coffee beans stored in jute bags from the third month of storage, describing predominant flavors of paper, straw and sacking. These results are in agreement with those observed by Rendón et al. (2014), who stated that the increase in free fatty acids is associated with a long storage period and can be the result of enzymatic activity, which also causes some taste deterioration. It is important to emphasize that, from a commercial point of view, these differences in scores between coffees are extremely important. Coffees with overall scores between 80 and 84 points on the SCAA grading scale are classified as specialty and can achieve market values of up to 50% above commodity coffee.

As a function of the complexity of characterizing specialty coffees and their relationship with different packaging methods after storage, multivariate principal component analysis (PCA) was used to assist in the interpretation of the results.

Figure 2 shows the scores of the first principal components, PC1 and PC2, which explained 82.46% and 13.17%, respectively, of the data variation. Four distinct groups formed as a function of the similarity shown by the data. Principal component analysis allowed the differentiation of packaging methods after storage in different groups. Groups I, III and IV stood out. Group I is formed by coffees at time zero, regardless of packaging form, having the same fatty acid composition and sensory score. Group III is formed by the treatments that received the highest score in the sensory analysis (Table 3) after 12 months of storage, in addition to higher contents of fatty acids. In this group, low fat acidity values were also observed. Group III includes coffees stored in GrainPro® bags and all forms of packaging FP1. Group IV is composed solely of the coffee packed in jute bags. Group differentiation was mainly due to higher amounts of fat acidity and lower scores in sensory analysis.

Scores of the first two principal components. TFFA = total free fatty acids. Beginning of storage (1-0: FP1-PMA = foil pouch packaging with passive modified atmosphere; 2-0 FP1-AMA = foil pouch packaging with active modified atmosphere; 3-0: FP1-V = foil pouch packaging with vacuum; 4-0: GP = GrainPro® bag; 5-0: J-CW = jute bag in conventional warehouse; 6-0: J-CC = jute bag in controlled chamber; 7-0: FP2-PMA = foil pouch packaging with passive modified atmosphere; 8-0: S-GP = bag similar to GrainPro®). After 12 months of storage (1-12: FP1-PMA; 2-12: FP1-AMA; 3-12: FP1-V; 4-12: GP; 5-12: J-CW; 6-12: J-CC; 7-12: FP2-PMA; 8-12: S-GP)

These results allow us to identify different behaviors in relation to the packaging forms used. All packaging forms in group III were more efficient in the storage of coffee beans, since they had the lowest deterioration indicators, as represented by low values of fatty acidity and free fatty acids and a higher final score in sensory evaluation. These packages have high potential for use in the maintenance of specialty coffee quality during storage.

This study is unique in that it links the beverage quality of coffees packaged in different packages with the fatty acid profile of the beans. In this study, it was verified that the progressive increase in the release of fatty acids is related to the quality loss of coffee. It was possible to identify differentiated quality outcomes in relation to the forms of packaging used due to the different barriers that the packages offer. Therefore, it is possible to select better packaging for the storage of specialty coffees, aiming at quality maintenance.

Conclusion

Coffee stored in jute bags in a controlled chamber had the lowest average levels of free fatty acids at the end of the storage period. The chemical feature of fat acidity enabled the differentiation of coffees packed in jute bags after 12 months of storage. Packaging in jute bags is not recommended for the storage of specialty coffees.

References

Abreu GF, Rosa SDVF, Cirillo MA et al (2017) Simultaneous optimization of coffee quality variables during storage. Bras Eng Agríc Ambient 21:56–60. https://doi.org/10.1590/1807-1929/agriambi.v21n1p56-60

Alves WM, Faroni LRDA, Corréa PC, Parizzi FC, Pimentel MAG (2003) Influência do pré-processamento e do período de armazenamento na perda de matéria seca em café (Coffea arabica L.) beneficiado. Rev Bras Armazenamento 7:122–127

American Association of Cereal Chemists (1995) Methods 02-02A: fat acidity: rapid method, for grain. Saint Paul, 1

Borém FM, Nobre GW, Fernandes SM et al (2008) Avaliação sensorial do café cereja descascado, armazenado sob atmosfera artificial e convencional. Ciênc. agrotec. 32:1724–1729. https://doi.org/10.1590/S1413-70542008000600007

Chaves TH, Resende O, Siqueira VC, Ullmann R (2012) Qualidade fisiológica das sementes de pinhão manso (Jatropha curcas L.) durante o armazenamento em três ambientes. Semin Agrar 33:1653–1662. https://doi.org/10.5433/1679-0359.2012v33n5p1653

Christie WW (1989) Gas chromatography and lipids. A pratical guide. The Oil Press, Ayr

Coradi PC, Borém FM, Saath R, Marques ER (2007) Effect of drying and storage conditions on the quality of natural and washed coffee. Coffee Sci 2:38–47. https://doi.org/10.13140/RG.2.1.4880.7523

Coradi PC, Borém FM, Oliveira JA (2008) Qualidade do café natural e despolpado após diferentes tipos de secagem e armazenamento. Rev Bras Eng Agrícola e Ambient 12:181–188. https://doi.org/10.1590/S1415-43662008000200011

Dhingra OD, Jham G, Napoleão IT (1998) Ergosterol accumulation and oil quality changes in stored soybean invaded by Aspergillus ruber (A. glaucus group). Mycopathologia 143:85–91. https://doi.org/10.1023/A:1006954506895

Ferreira DF (2011) Sisvar: a computer statistical analysis system. Ciênc. agrotec. 35:1039–1042. https://doi.org/10.1590/S1413-70542011000600001

Figueiredo LP, Borém FM, Ribeiro FC et al (2015) Fatty acid profiles and parameters of quality of specialty coffees produced in different Brazilian regions. Afr J Agric Res 10:3484–3493. https://doi.org/10.5897/AJAR2015.9697

Gutkoski LC, El-Dash AA (1999) Efeito do cozimento por extrusão na estabilidade oxidativa de produtos de moagem de aveia. Pesqui Agropecu Bras 34:119–127. https://doi.org/10.1590/S0100-204X1999000100016

International Organization for Standardization (1999) Green coffee: determination of loss in mass at 105°C: ISO 6673. 17

Jham GN, Muller HV, Cecon P (2008) Triacylglycerol molecular species variation in stored coffee beans determined by reverse-high-performance liquid chromatography/refractive index detector. J Stored Prod Res 44:82–89. https://doi.org/10.1016/j.jspr.2007.05.003

Joët T, Laffargue A, Descroix F et al (2010) Influence of environmental factors, wet processing and their interactions on the biochemical composition of green Arabica coffee beans. Food Chem 118:693–701. https://doi.org/10.1016/j.foodchem.2009.05.048

Lingle TR (2011) The coffee cupper’s handbook: systematic guide to the sensory evaluation of coffee’s flavor, 4th edn. Long Beach, Californian

Marques ER, Borém FM, Pereira RGFA, Biaggioni MAM (2008) Eficácia do teste de acidez graxa na avaliação da qualidade do café Arábica (Coffea arabica L.) submetido a diferente períodos e temperaturas de secagem. Ciênc. agrotec. 32:1557–1562. https://doi.org/10.1590/S1413-70542008000500030

Nikolova-Damyanova B, Velikova R, Jham GN (1998) Lipid classes, fatty acid composition and triacylglycerol molecular species in crude coffee beans harvested in Brazil. Food Res Int 31:479–486. https://doi.org/10.1016/S0963-9969(99)00016-2

Nobre GW, Borém FM, Fernandes SM, Pereira RGFA (2007) Alterações químicas do café cereja descascado durante o armazenamento. Coffee Sci 2:1–9. https://doi.org/10.25186/cs.v2i1.33

Nunes CA, Freitas MP, Pinheiro ACM, Bastos SC (2012) Chemoface: a novel free user-friendly interface for chemometrics. J Braz Chem Soc 23:2003–2010. https://doi.org/10.1590/S0103-50532012005000073

Oliveira LM, Oliveira PAPLV (2004) Revisão: principais agentes antimicrobianos utilizados em embalagens plásticas. Braz J Food Technol 7:161–165

Rendón MY, Salva TJG, Bragagnolo N (2014) Impact of chemical changes on the sensory characteristics of coffee beans during storage. Food Chem 147:279–286. https://doi.org/10.1016/j.foodchem.2013.09.123

Ribeiro FC, Borém FM, Giomo GS et al (2011) Storage of green coffee in hermetic packaging injected with CO2. J Stored Prod Res 47:341–348. https://doi.org/10.1016/j.jspr.2011.05.007

Saath R, Biaggioni MAM, Borém FM et al (2012) Alterações na composição química e sensorial de café (Coffea arabica L.) nos processos pós-colheita. Rev Energ na Agric 27:96–112. https://doi.org/10.17224/EnergAgric.2012v27n2p96-112

Salva TJG, Lima VB (2007) A composição química do café e as características da bebida e do grão. O Agronômico 59:57–59

Soares TA, Biaggioni MAM, Boff CE, Ferreira WA (2004) Análise de acidez graxa como índice de qualidade em grãos de soja. Energ Agric 20:91–102

Speer K, Kölling-Speer I (2006) The lipid fraction of the coffee bean. Braz J Plant Physiol 18:201–216. https://doi.org/10.1590/S1677-04202006000100014

Wagemaker TAL, Carvalho CRL, Maia NB et al (2011) Sun protection factor, content and composition of lipid fraction of green coffee beans. Ind Crops Prod 33:469–473. https://doi.org/10.1016/j.indcrop.2010.10.026

Zadernowski R, Nowak-Polakowska H, Rashed AA (1999) The influence of heat treatment on the activity of lipo- and hydrophilic components of oat grain. J Food Process Preserv 23:177–191. https://doi.org/10.1111/j.1745-4549.1999.tb00378.x

Acknowledgements

Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Instituto Nacional de Ciência e Tecnologia do Café (INCT-CAFÉ) and Bourbon Specialty Coffees.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Borém, F.M., Ribeiro, F.C., Figueiredo, L.P. et al. Sensory analysis and fatty acid profile of specialty coffees stored in different packages. J Food Sci Technol 56, 4101–4109 (2019). https://doi.org/10.1007/s13197-019-03879-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03879-3