Abstract

The phenolics from grapefruit peel were obtained by ultrasound assisted extraction (UAE) and enzyme-assisted extraction (EAE). Extraction parameters were optimized using response surface methodology to maximize the yield of total phenolic content (TPC) and total flavonoid content (TFC). The optimized extracts from UAE and EAE were then compared with conventional solvent extraction for their TPC, TFC, antioxidant activity and phenolic composition. The best optimized conditions for UAE was obtained at 33.12 min extraction time, 71.11% amplitude and a solvent–solid (SS) ratio of 39.63 mL/g. The optimized parameters for EAE were 4.81 h extraction time, 0.9% enzyme concentration and 40 mL/g SS ratio. Similar values of experimental and predicted TPC and TFC at optimized conditions indicates the suitability of the quadratic model in optimizing the extraction parameters. Further characterization of extracts suggested EAE as most efficient process in extracting bioactive compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyphenols are natural antioxidants present widely in fruits and vegetables contributing to their sensory and nutritional qualities (Kim and Lee 2002). These secondary metabolites are particularly known for their antioxidant and anti-inflammatory activities (Imeh and Khokhar 2002). Phenolic antioxidants are classified into four major groups namely phenolic acids, flavonoids, stilbenes and lignans (Pandey and Rizvi 2009). In conjunction with pulp, other parts of fruits and vegetables like peel and seeds, has long been recognized for containing these phytochemicals in higher amounts (Hayat et al. 2009; Padilla-Camberos et al. 2014). However, due to improper processing facilities these functional byproducts goes waste and cause environmental havoc.

Citrus, a major processing crop of India generates these byproducts in a large quantity every year. This leftover of citrus processing has long been studied for their functional properties and reported to constitute of flavonoids (Hayat et al. 2009; Manach et al. 2004). Among citrus group, grapefruit is exclusively used for fresh juice preparations which accounts use of only half of the fruit weight. The remaining fraction of the fruit mainly peels have found limited utilization in processing industries for making marmalades, candied peels, pectin extraction and animal feed. The grapefruit peels contain large quantities of flavanones aglycones, naringenin; flavanones glycosides, naringin and narirutin and polymethoxylated flavones: tangeretin, nobiletin, and sinensetin which can find application as functional ingredients in food, nutraceutical, cosmetic, and pharmaceutical industries (Kelebek 2010).

Valorization of these potential waste byproducts using extraction technologies could help in exploitation of its potential and further achieving the goal of healthy and safe food. Recovery of these compounds is commonly performed through a conventional solvent extraction process (Xu et al. 2007). In recent years, non-conventional extraction technologies like microwave, enzyme and ultrasound assisted extraction are also being the interest of scientific studies for maximizing yield (Garcia-Castello et al. 2015; Li et al. 2006; Wang et al. 2011; Wilkins et al. 2007). However, no comprehensive study is available on comparison of EAE with UAE and CSE for phytochemical recovery from peel of grapefruit grown under semiarid- subtropical Indian conditions.

Hence, in this study, enzyme and ultrasound assisted extractions of phenolic compounds from grapefruit (cv. Redblush) peel have been optimized and compared with the conventional solvent extraction. The effect of operating variables such as extraction time, solvent–solid (SS) ratio, amplitude percentage (for UAE), and enzyme concentration (for EAE) on the yield of phenolics and flavonoids was evaluated using response surface methodology approach.

Materials and methods

Material

Plant material

Grapefruit (C. paradisi cv. Redblush) were procured from orchard of IARI, New Delhi. All selected fruits were mature and healthy. The same day, fruits were washed, peeled and cut into small pieces before drying in a tray dryer (Macro Scientific Works, India). Peels were dried at 60 °C for 48 h, cooled and ground to a fine powder in a kitchen grinder, and sieved (500 microns, ASTM no. 35) to obtain a uniform particle size. Dried samples were then stored in airtight bags until further processing.

Chemicals

The enzyme, Viscozyme L. (from Aspergillus aculeatus, V 2010), chemicals and solvents were purchased from Sigma Aldrich (St. Louis, MO, USA) and Merck (Darmstadt, Germany) respectively.

Screening of variables and experimental design

Single factor experiment

Variables with major effects on total phenolic content (TPC) during UAE and EAE were investigated in preliminary experiments (Supplementary 1 and 2). The variable under study was varied while keeping others as constant. For UAE the values for ethanol concentration, amplitude, SS ratio and extraction time were kept constant as 70%, 60%, 30 mL/g and 25 min, respectively. In the EAE trials, the constant values of ethanol concentration, incubation time, enzyme concentration and SS ratio were 70%, 1 h, 0.8% and 40 mL/g, respectively. SS ratio was set at 30 mL/g in the trials for evaluating the influence of incubation time.

Experimental design

Box–Behnken Design (BBD) in Response surface methodology (RSM) was employed to investigate the effect of ultrasound and maceration enzyme on the extraction of TPC and TFC using Design-Expert software (Design-Expert 11) (Table 2). The experimental design comprises of 17 randomized runs. The coded factor levels were − 1 (low), 0 (central point) and 1 (high) (Table 1). The results were fitted to the following second-order polynomial model:

where, Y is the response variable (TPC and TFC); B0 is a constant coefficient; Bi, Bii and Bij are the regression coefficients of variables for intercept quadratic, linear, and interaction terms, respectively; Xi and Xj represents the actual independent variables (i = j). ANOVA was performed to determine the regression coefficients and significance of the selected model. Further 3-D surface plots were generated to show the correlation between the process variables and responses.

Validation study

To validate the adequacy of the models, three trials were performed at the optimized values of the parameters and the results thus obtained were compared with the predicted values of the quadratic model.

Comparison of UAE, EAE and CSE

After optimization of UAE and EAE, the resulted polyphenolic extract was compared with that obtained with CSE for their TPC, TFC, AOX and phenolic composition.

Ultrasound-assisted extraction (UAE)

For UAE an ultrasonicator with working frequency fixed at 20 kHz (Misonix Touch-Screen Sonicator S-4000, New York, USA) was used. The sample powder was mixed with the solvent and extracted under different processing conditions of solvent, solvent concentration, sonication time, amplitude and SS ratio (Supplementary 1 and Table 2). During sonication the temperature was controlled by circulating cold water (Dahmoune et al. 2013). The mixture thus obtained was centrifuged at 10,000×g for 10 min at 4 °C. Further, the supernatant was filtered through Whatman 1 paper in a Büchner funnel under vacuum, concentrated in rotary vacuum evaporator at 50 °C and 150 rpm (Heidolph VV2011, Schwabach, Germany), and stored below 4 °C until further use.

Enzyme-assisted extraction (EAE)

Enzymatic maceration was performed according to modified Xu et al. (2014) method. The citrus peel powder (0.5 g) was mixed with 20 mL 0.2 M sodium acetate buffer (pH 4.8) containing Viscozyme L. and incubated for varying period of time at 60 °C (Supplementary 2 and Table 2). The incubation conditions of pH 4.8 and 60 °C were selected according to enzyme data sheets. After the enzymatic hydrolysis, enzyme was inactivated by keeping the samples in water bath at 90 °C for 5 min. Then the extract was centrifuged at 10,000×g for 15 min at 4 °C. The supernatant thus obtained was collected. In the remaining pellet of sample, 70% ethanol was mixed in varying ratio (Supplementary 2 and Table 2), incubated in water bath at 50 °C for 5 min for maximum extraction of phenolics. This mixture was then centrifuged and supernatant was collected. To obtain maximum phenolics yield two extractions were performed per sample. For second extraction, the residue remaining after first enzyme hydrolysis was collected and subjected to same conditions of hydrolysis as before for 1 h followed by centrifugation. All the supernatant collected were mixed and stored at 4 °C for further analysis as mentioned for UAE.

Conventional solvent extraction (CSE)

Modified Spigno et al. (2007) method was used for conventional solvent extraction. For this, 0.5 g of peel powder was incubated with 20 mL of 70% ethanol in a shaking water bath for 2 h at 60 °C making 110 strokes per minute. The resulted extract was then analyzed for its polyphenol content and antioxidant activity.

Purification of crude extract

Purification of the crude extracts was performed using the method of Oszmianski and Lee (1990), where organic acids and sugars were removed from the extracts using C18 Sep-Pak cartridge (Waters, Milford).

Total phenolic content (TPC)

Folin–Ciocalteu reagent (FCR) method of Singleton et al. (1999) was used for estimating TPC. Total phenolic content was expressed in terms of Gallic acid equivalents [mg GAE/100 g (db)].

Total flavonoids content (TFC)

TFC was measured by the method of Zhishen et al. (1999) and results were expressed as Quercetin equivalents (mg QE/100 g db).

Antioxidant activity (AOX)

Four in-vitro antioxidant assays were used for evaluating antioxidant activity of the extracts, namely Ferric reducing antioxidant power (FRAP) assay (Benzie and Strain 1996), DPPH (2,2-diphenyl-1-picrylhydrazyl) scavenging assay (Brand-Williams et al. 1995), cupric reducing antioxidant capacity (CUPRAC) assay (Apak et al. 2004) and Trolox equivalent antioxidant capacity (TEAC) (Re et al. 1999). The results obtained were expressed as μmol Trolox Equivalent/g (db).

Phenolic profiling using HPLC

The phenolic profile for extracts was obtained using a reverse phase HPLC system (Alliance, Waters 2998 Corp., U.S.A.) with a C-18 column (SUPELCO® U.S.A). A photodiode array detector (PDA) with an auto-injector (20 μL loop) was used in the system. For the analyses, 2 mL of extract was passed through a 0.4-μm nylon filter and then injected into the HPLC. The gradient used for analysis was composed of two-solvent mobile phase system, (A): water/formic acid (99.9:0.1, v/v) and (B): acetone nitrile/formic acid (99.9:0.1, v/v) with a flow rate of 0.5 mL/min. The gradient was as follows: 0 min, 0% B; 1 min, 0% B; 20 min, 20% B; 30 min, 30% B; 35 min, 50% B; 45 min, 100% B; 55 min, 0% B. The chromatographs were thus obtained at 280 nm. Further, the identification and quantification of compounds were carried out by comparing retention time and spectral characteristics of peaks of the standards.

Statistical analysis

All the analyses were carried out in 3 replicates and the data are presented as mean values. Analysis of Variance (ANOVA) at a significance level of P < 0.05 was performed to identify the influence of each factor on the TPC, TFC and antioxidant activity using SAS (9.4) software. Further, Tukey’s multiple comparison test was performed for pair-wise comparison of each process conditions and overall comparison of extraction treatments for the analyzed responses.

Results and discussion

UAE

Single-factor experiments

The phenolic compounds are bound with several bio-molecules in the plant matrix hence selection of a suitable extraction solvent becomes very crucial for their efficient extraction. In the preliminary experiments water, acetone, ethanol, and methanol were used as solvents and extract with 50% aqueous ethanol showed highest TPC (1369.04 mg GAE/100 g) recovery (Supplementary 1). This difference in the yield could be explained by the varying affinity of the phenolic compounds towards different solvents based upon their polarity as described by “polarity versus polarity” principle. Therefore high recovery of phenolics using ethanol could be attributed to similar polarity range of these two (Zhang et al. 2007). Further, better absorption of sonication energy by the ethanol could also be possibly resulted in high TPC yield as this phenomena releases the bound phenolics due to volumetric heating and breaking of cell walls. Thus, aqueous ethanol was selected for the further trials.

Next, the percentages of ethanol in water (40–100%) was optimized to recover maximum phenolics. Results revealed an increase in TPC yield with increasing ethanol concentration up to 70% (Supplementary 1). This could be due to the decrease in dielectric constant of the solvent by the ethanol, thus increase in the solubility and diffusion of polyphenols (Zhang et al. 2007). However, very high concentration of solvent leads to denaturation of cell wall proteins, and dehydration and collapse of the plant cells, hampering the extraction of polyphenols to the solvent (Libran et al. 2013). Hence with high TPC yield, 70% ethanol was selected for the optimization of extraction time, amplitude and SS ratio.

Investigation for appropriate extraction time revealed, the extraction yield was directly proportional to the ultrasonication time, up to 25 min. and thereafter it started decreasing. The increase in TPC recovery is supported by the increase in energy supply caused by longer sonication time, thus enhancing the extraction of the target compounds. However, after certain time, degradation of phenolic compounds begins due to longer exposure to the process conditions and sometimes re-adsorption into the ruptured tissue particles (Carrera et al. 2012). Similar observations were also reported in Citrus limon and marjoram (Dahmoune et al. 2013; Hossain et al. 2012). Thus, efficient sonication time range of 15–35 min was chosen for the RSM trials, while 25 min was used for the next single-factor trials.

The results for varying amplitude showed an improvement in TPC yield with increase in amplitude level up to 80% (Supplementary 1). This was in agreement with the reports of Hossain et al. (2012). High ultrasonication amplitude cause cavitation in plant cell wall and increase the contact area between solid and solvent phase, enhancing solvent penetration and thus releasing more solutes. However, very high amplitudes also causes a reduction in TPC yield due to scavenging action of these on newly formed free radicals (Ma et al. 2009). Based on results obtained, 80% amplitude was used for SS ratio optimization and a range of 60–100% was selected for the RSM trials.

Lastly, the SS ratio was optimized. The yield of TPC found to increase with increasing the ratio up to 30 mL/g and thereafter it showed a declining phase. These results were consistent with the mass transfer principle which explains the development of larger concentration gradient at high SS ratio and thus higher phenolics diffusion in the extract. However after a certain level saturation occurs and further increase in SS ratio causes non-uniform distribution of phenolics and more exposure to ultrasonication heat, leading a significant reduction in phenolic compounds (Dahmoune et al. 2013; Nayak et al. 2015). Based upon these results a range of 20–40 mL/g was selected for the RSM optimization.

Optimization by RSM

Modeling of the extraction process

17 runs were performed according to BBD for the optimization of UAE process (Table 2). The results of TPC and TFC in the CPE ranged from 1387.87 to 2103.2 mg GAE/100 g and 118.5 to 274.28 mg QE/100 g, respectively. Table 3 showing the model analysis with R2, F and P values used in evaluating the significance of independent variables and their effect on responses. A higher R2 values of 0.96 and 0.95 for TPC and TFC, respectively and a low coefficient of variance (CV< 10%), suggested the significance and goodness of fit of the quadratic model (P < 0.05) for better reproducibility of the data. The following second-order polynomial Eqs. (2) and (3) described the interaction between extraction time (X1), amplitude (X2) and SS ratio (X3) and their effect on TPC and TFC.

Regression analysis revealed the linear effect of the three independent variables on the yields of TPC and TFC. In the equations, positive coefficient depicted its effect on increasing the yield of both TPC and TFC and vice a versa. As shown in Table 3, the TPC was more significantly affected by amplitude and SS ratio (P < 0.01), than by sonication time (P < 0.05). The quadratic terms, X22 were highly significant at P < 0.01 however X12 and X32 were non-significant (P > 0.05). The interaction of extraction time and SS ratio (X1X3), and amplitude and SS ratio (X2X3) were also found significant for TPC (P < 0.1). The similar trend in effect of linear, quadratic and interactive terms were observed for TFC yield.

Figure 1a–c shows three dimensional response surface curves depicting the effect of the process variables on the extraction yield of TPC and TFC. Figure 1a shows the effects of amplitude and extraction time on the TPC and TFC of the extract. By increasing the amplitude from 60 to 71% with extraction time fixed at 15 min, the TPC increases from 1785.97 to 1823.74 mg GAE/100 g and then decreased to 1544.84 mg GAE/100 g at 100% amplitude. However, maximum TPC 1957.80 mg GAE/100 g was observed on the simultaneous increase in amplitude and extraction time to 76% and 34.98 min respectively. Similarly, maximum TFC (234.24 mg QE/100 g) was obtained at 34.99 min and 74.39% amplitude. The interaction between amplitude and SS ratio also showed significant effect on the recovery of TPC and TFC (Fig. 1b). The recovery reached its maximum of 2040.47 mg GAE/100 g at 72.03% amplitude and SS ratio of 39.99 mL/g. However, the maximum TFC (258.93 mg QE/100 g) was obtained at 64.5% amplitude and SS ratio of 39.99 mL/g and revealed similar trend as that of TPC.

Response surface analysis for the total phenolic content (TPC) and flavonoid yield from C. paradisi peels with ultrasound assisted extraction (UAE) with respect to amplitude percentage and extraction time (a); solvent-to-solid ratio and amplitude percentage (b); solvent-to-solid ratio and extraction time (c)

Figure 1c illustrates the interaction between extraction time and SS ratio (P < 0.05); the TPC increased from 1619.19 to 1909.31 mg GAE/100 g when the time was fixed at 15 min and ratio varies for 20–40 mL/g. The TPC yield reaches a maximum of 2138.78 mg GAE/100 g at 34.96 min and at extraction ratio 39.74 mL/g. In case of TFC, an increase from 197.72 to 213.69 mg QE/100 g was observed when the ratio varies from 20–40 mL/g at extraction time of 15 min. The maximum TFC (277.59 mg QE/100 g) obtained at 35 min and at extraction ratio of 40 mL/g.

Validation of predicted model for UAE

For the optimized conditions of extraction time (33.12 min), amplitude (71.11%) and SS ratio (39.63 mL/g), the model predicted a maximum response of 2110.51 mg GAE/100 g for TPC and 280.94 mg QE/100 g for flavonoid with a desirability of 1. To validate the reliability of the model, UAE was performed at optimal condition and an experimental yield of TPC equal to 2116.71 ± 1.73 mg GAE/100 g and 276.53 ± 1.41 mg QE/100 g TFC close to the predicted value was obtained. Hence, the insignificant difference between these results verifies the adequacy of the model in optimizing the process conditions.

EAE

Single-factor experiments

Different EAE parameters viz. ethanol concentration, incubation time, enzyme concentration and SS ratio showed effect on TPC yield (Supplementary 2). Maximum TPC was recovered at 80% ethanol concentration and this was used further for all experiments. With respect to extraction time, the TPC increased significantly up to 4.5 h and thereafter decreased for longer incubation time. This could be attributed to the catalytic action of carbohydrase on release of bound phenolics in initial stage of maceration which further get inactivated by bioactive inhibitors (phenolic compounds), or degraded by adverse process conditions [temperature (60 °C), cell enzymes, etc.] and additional side reactions (Arnous and Meyer 2010). Thus, 4.5 h was used for the next single-factor experiments and a range of 4–6 h for the RSM trials.

Further, different enzyme concentrations revealed significant (P < 0.05) effect on TPC yield. The concoction of enzyme at 0.8% resulted in maximum phenolic yield of 2651.92 mg GAE/100 g. The correlation between phenolics yield and enzymes could be attributed to disruption of integrity of the cell walls by the multi-enzyme complex (cellulases, hemicellulases, and pectinases) used in this study; leading more efficient extraction. Our results corroborate with the findings of de’ Camargo et al. (2016). The next process variable, SS ratio was optimized with 0.8% enzyme concentration and a ratio of 30 mL/g yielded maximum TPC. These results suggested a range of 0.7–0.9% of enzyme and 20–40 mL/g SS ratio for the final RSM optimization.

Optimization by RSM

Response surface analysis

The effects of process variables i.e. extraction time, enzyme concentration and SS ratio on TPC and TFC yield were evaluated using BBD (Table 3). Various regression models were fitted to the experimental data to check the adequacy of the model. The significant terms of the developed model at P < 0.05 for both TPC and TFC with higher R2 values and insignificant lack of fit depicted a good correlation between the experimental and predicted values and accuracy of the model for selected responses. Moreover, an accepted value of CV indicating a better precision and reliability of the experimental values. Furthermore, analysis of variance of the experimental data showed the TPC yield was affected significantly only by extraction time (P = 0.0001) whereas TFC illustrated the effect of both extraction time and enzyme concentration (Table 3). The second-order polynomial equations predicted for the responses are given in (Eqs. 4 and 5):

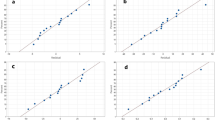

The response surfaces showing the effect of variables during EAE are shown in Fig. 2a–c. Figure 2a shows an interaction between the enzyme concentration and time; the TPC increased roughly from 2722.85 to 3065.63 mg GAE/100 g when the time was fixed at 4 h and enzyme concentration varies for 0.7–0.9%. The TPC yield reaches a maximum (3108.46 mg GAE/100 g) at 0.89% enzyme concentration and 4.39 h extraction time and maximum TFC (322.26 mg QE/100 g) was obtained at 4.83 h and 0.89% enzyme.

Response surface for TPC and TFC with varying ratio of SS and extraction time are shown in Fig. 2b. The change in SS ratio did not reveal any significant change in TPC. However, a noticeable increase was observed with increase in extraction time up to 5 h. The TPC reaches a maximum of 3046.6 mg GAE/100 g at approximately 4.44 h and 39.99 mL/g SS ratio. In case of TFC, an increase was observed up to 4.9 h for a fixed SS-ratio. The maximum TFC yield (318.68 mg QE/100 g) was obtained at 4.87 h and 39.97 mL/g SS ratio. Figure 2c revealed insignificant effects of interaction of SS ratio and enzyme concentration on the TPC and TFC.

Validation of predicted model for EAE

The selected model was verified by performing EAE under the new optimal conditions of 4.81 h extraction time, 0.9% enzyme concentration and 40 mL/g SS ratio with a predicted yield of 3162.96 mg GAE/100 g for TPC and 334.21 mg QE/100 g for TFC with a desirability of 0.97. The experimental yields obtained for TPC and TFC were 3170.35 ± 8.72 mg GAE/100 g and 329.89 ± 1.37 mg QE/100 g, respectively. The predicted and experimental values were found to be statistically same, confirming the adequacy of model for optimization of EAE.

Comparison between UAE, EAE and CSE

TPC and TFC

Comparative evaluation of UAE and EAE with CSE revealed a significant increase in TPC and TFC yield (Table 4). The CSE resulted a TPC yield of 1528 mg GAE/100 g while UAE and EAE yielded 2116.71 and 3170.35 mg GAE/100 g respectively. This improved TPC yield in UAE and EAE is in agreement with previous studies on extraction of polyphenols (Garcia-Castello et al. 2015; Zhou et al. 2017). TFC also revealed higher yield from EAE (264.63 mg QE/100 g), as compare to UAE and CSE. This high extraction efficiency of EAE could be due to the selected cocktail enzyme formulation having a group of carbohydrases, comprising of arabanase, cellulase, β-glucanase, hemicellulase, and xylanase. This concoction of enzyme facilitated the hydrolysis of pectin and other structural carbohydrates of citrus peels liberating both free and bound phenolics and aiding solvent penetration into the substrate, hence improving the extraction of total polyphenols (Zhu et al. 2016).

Moreover high extraction yield of UAE as compare to CSE could be attributed to the interaction of ultrasounds with the powdered peel sample, promoting the penetration of solvent into the plant matrix and further release of phenolic compounds to the extracting medium (Ramic et al. 2015). Further, the difference in extraction efficiency of EAE and UAE was due to induction of free radicals formation during UAE triggering oxidation and degradation of the bioactives (Hayat et al. 2009).

HPLC characterization of phenolic compounds

The major phenolic compounds found in citrus peels are shown in Table 5 and supplementary 3. Naringin was the predominant phenolic compound found in all the extracts. This phenolic compound was presented in highest amount in CSE extract irrespective of high TPC of EAE, depicting no correlation between TPC and individual phenolic compounds in all the three extracts. The decrease in amount of individual phenolics in UAE and EAE as compare to CSE indicates the conversion of galloylated form of phenolics to agalloylated form which have high antioxidant potential, showing an interesting structure–activity relationship (Williamson et al. 1999). This finding was consistent with the report of Nayak et al. (2015) and Londoño-Londoño et al. (2010) on various citrus peels (sweet orange, lime, orange and tangerine). The compounds enumerated in EAE were more as compared to UAE and CSE which attributed to the effectiveness of enzyme in releasing these phenolic compounds.

Antioxidant activity (AOX)

The antioxidant activity of a sample matrix is an indicator of their polyphenolic profile. Change in the AOX activity during processing shows the effect of processing conditions on the release and stability of bioactive compounds. Results of AOX revealed the high antioxidant activity in extract obtained from EAE (Table 4). This is in agreement with the higher TPC of EAE and confirms the usual correlation between AOX and TPC (Cho et al. 2016). Moreover, the high antioxidant activity of EAE irrespective of its low individual phenolic compounds further confirms the modification of phenolics to more potent antioxidants i.e. to the agalloylated form. This demonstrated that antioxidant activity decreases with glycosylation and enhanced with hydroxylation, release of sugar moiety from galloylated phenolic compounds and the presence of C2–C3 double bond in conjugation with a 4-oxo function, which can be facilitated by ultrasonic and enzymatic processing ((Williamson et al. 1999). Several reports highlighted the structure–antioxidant activity relationship of flavonoid subclasses in citrus extracts. In an investigation on comparison between conventional and UAE for extracting flavonoids from grapefruit solid waste, Garcia-Castello et al. (2015) reported a 1.7 fold increase in antioxidant activity in extract from UAE. A similar amplifying effect of ultrasound on antioxidant activity of C. limon extract was observed, where the activity was high in extract obtained from UAE as compare to microwave extraction (Dahmoune et al. 2013). Conversely, the lower activity of UAE and CSE extract could be resulted from extended extraction time, hence exposure to unfavorable conditions such as light and oxygen. Also, it is commonly known that ultrasonication could induce free radicals formation within the liquid medium, thus causing oxidation and degradation of the active compounds (Hayat et al. 2009).

Conclusion

Enzyme assisted extraction was most efficient method for extraction of polyphenolics from grapefruit peels than conventional solvent and ultrasound assisted extraction. Response surface methodology revealed a high correlation and accuracy of the quadratic model to predict the extraction of TPC and TFC. The results from BBD pointed out the SS ratio and amplitude as the most influential factor in the UAE process whereas for EAE, extraction time was found to be significantly affecting TPC and TFC yield. Further analysis of phenolic composition showed varying effect of different treatments on release of polyphenolics, depicting naringin being the most abundant flavonoid in all extracts. Overall characterization of extracts suggested the strong potential of EAE in enhancing the recovery of natural antioxidant compounds from food byproducts, aiming at replacing synthetic antioxidants and thus the valorization of biomass residues in a more efficient way.

References

Apak R, Güçlü K, Özyürek M, Karademir SE (2004) Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine: CUPRAC method. J Agric Food Chem 52(26):7970–7981

Arnous A, Meyer AS (2010) Discriminated release of phenolic substances from red wine grape skins (Vitis vinifera L.) by multicomponent enzymes treatment. Biochem Eng J 49(1):68–77

Benzie IF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239(1):70–76

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28(1):25–30

Carrera C, Ruiz-Rodríguez C, Palma M, Barroso CG (2012) Ultrasound assisted extraction of phenolic compounds from grapes. Anal Chim Acta 732:100–104

Cho M, Ko SB, Kim JM, Lee OH, Lee DW, Kim JY (2016) Influence of extraction conditions on antioxidant activities and catechin content from bark of Ulmus pumila L. Appl Biol Chem 59(3):329–336

Dahmoune F, Boulekbache L, Moussi K, Aoun O, Spigno G, Madani K (2013) Valorization of Citrus limon residues for the recovery of antioxidants: evaluation and optimization of microwave and ultrasound application to solvent extraction. Ind Crops Prod 50:77–87

de Camargo AC, Regitano-d’Arce MAB, Biasoto ACT, Shahidi F (2016) Enzyme-assisted extraction of phenolics from winemaking by-products: antioxidant potential and inhibition of alpha-glucosidase and lipase activities. Food Chem 212:395–402

Garcia-Castello EM, Rodriguez-Lopez AD, Mayor L, Ballesteros R, Conidi C, Cassano A (2015) Optimization of conventional and ultrasound assisted extraction of flavonoids from grapefruit (Citrus paradisi L.) solid wastes. LWT Food Sci Technol 64(2):1114–1122

Hayat K, Hussain S, Abbas S, Farooq U, Ding B, Xia S, Jia C, Zhang X, Xia W (2009) Optimized microwave-assisted extraction of phenolic acids from citrus mandarin peels and evaluation of antioxidant activity in vitro. Sep Purif Technol 70(1):63–70

Hossain MB, Brunton NP, Patras A, Tiwari B, O’Donnell CP, Martin-Diana AB, Barry-Ryan C (2012) Optimization of ultrasound assisted extraction of antioxidant compounds from marjoram (Origanum majorana L.) using response surface methodology. Ultrason Sonochem 19:582–590

Imeh U, Khokhar S (2002) Distribution of conjugated and free phenols in fruits: antioxidant activity and cultivar variations. J Agric Food Chem 50(22):6301–6306

Kelebek H (2010) Sugars, organic acids, phenolic compositions and antioxidant activity of Grapefruit (Citrus paradisi) cultivars grown in Turkey. Ind Crops Prod 32:269–274

Kim DO, Lee CY (2002) Extraction and isolation of polyphenolics. In: Wrolstad RE (ed) Current protocols in food analytical chemistry. Wiley, New York, pp I1.2.1–I1.2.12

Li BB, Smith B, Hossain MM (2006) Extraction of phenolics from citrus peels: II. Enzyme-assisted extraction method. Sep Purif Technol 48(2):189–196

Libran CM, Mayor L, Garcia-Castello EM, Vidal-Brotons D (2013) Polyphenol extraction from grape wastes: solvent and pH effect. Agric Sci 4(9B):56–62

Londoño-Londoño J, de Lima VR, Lara O, Gil A, Pasa TBC, Arango GJ, Pineda JRR (2010) Clean recovery of antioxidant flavonoids from citrus peel: optimizing an aqueous ultrasound-assisted extraction method. Food Chem 119(1):81–87

Ma YQ, Chen JC, Liu DH, Ye XQ (2009) Simultaneous extraction of phenolic compounds of citrus peel extracts: effect of ultrasound. Ultrason Sonochem 16(1):57–62

Manach C, Scalbert A, Morand C, Rémésy C, Jiménez L (2004) Polyphenols: food sources and bioavailability. Am J Clin Nutr 79(5):727–747

Nayak B, Dahmoune F, Moussi K, Remini H, Dairi S, Aoun O, Khodir M (2015) Comparison of microwave, ultrasound and accelerated-assisted solvent extraction for recovery of polyphenols from Citrus sinensis peels. Food Chem 187:507–516

Oszmianski J, Lee CY (1990) Inhibitory effect of phenolics on carotene bleaching in vegetables. J Agric Food Chem 38(3):688–690

Padilla-Camberos E, Lazcano-Díaz E, Flores-Fernandez JM, Owolabi MS, Allen K, Villanueva-Rodríguez S (2014) Evaluation of the inhibition of carbohydrate hydrolyzing enzymes, the antioxidant activity, and the polyphenolic content of Citrus limetta peel extract. Sci World J 2014:121760

Pandey KB, Rizvi SI (2009) Plant polyphenols as dietary antioxidants in human health and disease. Oxid Med Cell Longev 2(5):270–278

Ramic M, Vidovic S, Zekovic Z, Vladic J, Cvejin A, Pavlic B (2015) Modeling and optimization of ultrasound-assisted extraction of polyphenolic compounds from Aronia melanocarpa by-products from filter-tea factory. Ultrason Sonochem 23:360–368

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biol Med 26(9–10):1231–1237

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol 299:152–178

Spigno G, Tramelli L, De Faveri DM (2007) Effects of extraction time, temperature and solvent on concentration and antioxidant activity of grape marc phenolics. J Food Eng 81(1):200–208

Wang Z, Shang Q, Wang W, Feng X (2011) Microwave-assisted extraction and liquid chromatography/mass spectrometry analysis of flavonoids from grapefruit peel. J Food Process Eng 34(3):844–859

Wilkins MR, Widmer WW, Grohmann K, Cameron RG (2007) Hydrolysis of grapefruit peel waste with cellulase and pectinase enzymes. Bioresour Technol 98(8):1596–1601

Williamson G, Plumb GW, Garcia-Conesa MT (1999) Glycosylation, esterification and polymerization of flavonoids and hydroxycinnamates: effects on antioxidant properties. Basic Life Sci 66:483–494

Xu G, Ye X, Chen J, Liu D (2007) Effect of heat treatment on the phenolic compounds and antioxidant capacity of citrus peel extract. J Agril Food Chem 55(2):330–335

Xu C, Yagiz Y, Borejsza-Wysocki W, Lu J, Gu L, Ramírez-Rodrigues MM, Marshall MR (2014) Enzyme release of phenolics from muscadine grape (Vitis rotundifolia Michx.) skins and seeds. Food Chem 157:20–29

Zhang S, Bi H, Liu C (2007) Extraction of bioactive components from Rhodiola sachalinensis under ultrahigh hydrostatic pressure. Sep Purif Technol 57(2):277–282

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64(4):555–559

Zhou Z, Shao H, Han X, Wang K, Gong C, Yang X (2017) The extraction efficiency enhancement of polyphenols from Ulmus pumila L. barks by trienzyme-assisted extraction. Ind Crops Prod 97:401–408

Zhu Z, He J, Liu G, Barba FJ, Koubaa M, Ding L, Bals O, Grimi N, Vorobiev E (2016) Recent insights for the green recovery of inulin from plant food materials using non-conventional extraction technologies: a review. Innov Food Sci Emerg Technol 33:1–9

Acknowledgements

The authors acknowledge the Division of Horticulture and Agricultural Chemicals, IARI, New Delhi, India, for providing fruits and research facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nishad, J., Saha, S., Dubey, A.K. et al. Optimization and comparison of non-conventional extraction technologies for Citrus paradisi L. peels: a valorization approach. J Food Sci Technol 56, 1221–1233 (2019). https://doi.org/10.1007/s13197-019-03585-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03585-0