Abstract

The aims of the study were to develop and apply alginate and pectin-based edible coatings on minimally processed mango (Mangifera indica L.) variety ‘Espada’. A full experimental design was performed using alginate, pectin and glycerol concentrations as independent variables and total soluble solids as response variable. Minimally processed mango was immersed in each film forming solution, calcium chloride and glycerol solutions pretreated with 1% (w/v) solution of ascorbic acid, dried at 25 ± 2 °C for 24 h and then refrigerated at 8 ± 1 °C for 14 d. Based on the results of the experimental design, the following formulations were evaluated: 2% (w/v) alginate/3% (w/v) pectin (with and without glycerol) and 3% (w/v) alginate/0.5% (w/v) pectin (with and without glycerol). Fruits coated with biopolymers had lower total soluble solids content and titratable acidity compared to the control group. The formulation containing 2% (w/v) alginate, 3% (w/v) pectin and 5.5% (w/v) glycerol showed the best performance for long-term refrigerated storage of minimally processed mango for a period of 16 d.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Constant changes in the modern world have increased consumer demand for convenience food, such as minimally processed agricultural products. For this reason, today’s companies are working harder to develop innovative products in order to remain competitive in the long term. As well as vegetables, minimally processed fruits have been developed to meet consumer needs for ‘quick’ products (Goyeneche et al. 2014) and this is the major growing segment in the food market (Robles-Sánchez et al. 2013).

The term ‘minimally processed’ or ‘minimal processing’ refers to raw fruits and vegetables that have only been lightly processed, and involves a combination of procedures that eliminate non-edible parts. As a consequence of processing operations such as cutting, slicing, peeling, trimming, coring, and the like, cells and membranes are damaged, leading to metabolic alterations such as an increase in the respiration rate and ethylene production, changes in flavor and texture, and increased exposure to microbial agents, which all leads to a reduced shelf life of these products (Chen et al. 2016). According to González-Aguilar et al. (2008), the increase in the metabolic activity of fruit caused by minimal processing reduces the useful life of the fruit from 1 to 2 weeks to only 1–3 d, even at ideal temperatures.

Mangoes (Mangifera indica L.) are among the most widely cultivated and consumed fruits in tropical and subtropical regions, being widely appreciated for their flavor along with their high nutritional value (Oliveira et al. 2016) and are preferably consumed in a natural state (Medeiros et al. 2012). According to the USDA-ERS (2011), per capita mango consumption in the U.S. has increased from 0.25 to 0.92 kg over the last two decades.

There have been very few studies conducted on minimally processed mangoes (Sothornvit and Rodsamran 2008; Dea et al. 2010) and the market is still relatively scarce. Mango is a climacteric fruit and the shelf life of freshly cut mango cubes is limited by softening and browning of the flesh, resulting in the loss of product quality.

In order to extend the shelf life and retain the nutritional value of minimally processed fruits, several alternatives have been proposed, such as use of radiation (Huang et al. 2017), storage in a modified atmosphere (Belay et al. 2017), antibrowning agents (Goyeneche et al. 2014), chemical dipping (Lucera et al. 2012), and edible films and coatings (Robles-Sánchez et al. 2009; Rojas-Graü et al. 2007; Vargas-Torres et al. 2017).

According to McHugh (2000), an edible film (EF) is a pre-formed thin layer of edible material which is applied on or between food components, while an edible coating (EC) is a thin layer made of edible material formed as a coating on a food product. EFs and ECs have been used to protect fresh and/or minimally processed vegetables and fruits from degradation during storage, by being used to control permeability to water, oxygen and carbon dioxide (Espinel Villacres et al. 2014). ECs may also act as carriers for food additives such as antibrowning and antimicrobial agents, colorings, flavorings, nutrients and spices (Rojas-Graü et al. 2009). Moreover, the combined application of different treatments can extend the shelf-life of freshly cut fruit while maintaining the fruits sensory and organoleptic properties during shipping and storage.

Alginate and pectin are two of the most commonly used compounds to form edible coatings (Robles-Sánchez et al. 2013; Tavassoli-Kafrani et al. 2016). These polymers are reliably able to form gels in the presence of calcium, making them insoluble in water and able to form a barrier against water vapor (Falguera et al. 2011). Glycerol or sorbitol can be also be used as plasticizer agents to improve the flexibility and firmness of the coatings (Silva et al. 2009).

The aim of this work was to develop an edible coating based on alginate and pectin for application on minimally processed ‘Espada’ mangoes (Mangifera indica L.) and to evaluate the coating effect on the shelf life after long-term refrigeration.

Materials and methods

Materials

Sodium alginate of medium viscosity (Grindsted®), pectin (Genu® pectin type B- rapid LM), calcium chloride (QuímicaModerna®) and food grade glycerol (Nuclear®) were used to obtain the film-forming dispersions. Ascorbic acid was obtained from Impex®. Polystyrene food trays (150 mm × 150 mm) and polyvinyl chloride films (Wyda®) were used to pack the product.

Mangoes (Mangifera indica L.) cv. Espada were purchased from a local market, in Bezerros, Pernambuco, Brazil. Individual fruits were selected based on quality, uniformity in size, shape, and without any apparent ripeness.

Preparation of film-forming solutions and minimally processed mangoes

The film-forming solutions were prepared by dissolving alginate and pectin in sterile water under constant stirring at 70 °C until a visible gel was observed, according to the concentrations defined in the experimental design.

Mangoes were sanitized with chlorinated water at 25 °C (200 mg l−1) for 15 min and rinsed under tap water, drained, hand-peeled and the pulp was then cut into slices (2 cm thick). The slices were randomly distributed and treated for 4 min by immersing them in an aqueous solution of 1% (w/v) ascorbic acid. The fruit was then drained for 2 min before immersing in the film-forming solution.

Experimental design and coating application

In order to optimize the final composition of edible coatings to be added to the minimally processed mangoes, three independent variables (concentrations of alginate, pectin and glycerol) and the response variable (total soluble solids—TSS) were evaluated using a full 23 factorial design, with three central points (level 0) and six axial points (levels ± α, where α = 1.68), totaling seventeen experiments (Rotational Central Composite Design – RCCD). The tests were performed randomly, and the data were subjected to analysis of variance (ANOVA) for analysis of regression coefficient, prediction equations and case statistics. Design-Expert® Software (version 10.0, Stat-Ease, Inc) was used for regression and graphical analysis of the data obtained using a 95% confidence level. Experimental error was obtained from the mean and standard deviation of the central points. Table 1 shows the experimental conditions investigated. Alginate, pectin and glycerol concentrations were selected based on information from a previous study (data not shown). In previous experiments, filmogenic solutions were prepared containing alginate and pectin in concentrations higher than 3%, where the formation of thick and nonhomogeneous films was observed. Thus, the 3% concentration was selected as the point + α of the experimental planning.

The mango slices were immersed in the film-forming solutions for 3 min, followed by immersion in a solution of 0.12 M CaCl2 and glycerol for 3 min.

Thereafter, samples were drained, placed in trays for drying at 25 ± 2 °C for 24 h, wrapped in PVC film and refrigerated at 8 ± 1 °C. Samples were analyzed after 14 d of storage.

Additional formulation tests

From the results obtained in the experimental design, additional formulations of film-forming solutions were created. The identification codes and composition of the samples are shown in Table 2. The sample control was used with no coating application (only immersed in ascorbic acid). Samples were analyzed after 1, 8 and 16 d of storage at 8 ± 1 °C for pH, total soluble solids and titratable acidity analyses in triplicate.

pH, titratable acidity (TA) and total soluble solids (TSS)

Mango juice using 5 g of fruit in 50 ml of distilled water was prepared and the pH of the juice was recorded. The titratable acidity (TA) was determined by titration with 0.1 M NaOH (Instituto Adolfo Lutz 1985).

Total soluble solids (TSS) was determined from mango juice using 10 g of fruit in 10 ml of distilled water using a digital refractometer (Hanna®) at 25 °C previously calibrated with distilled water. The results were expressed as the mean ± standard deviation of oBrix. For all experiments three replicates were used for each treatment.

Differences among samples were tested by analysis of variance (ANOVA) with storage time and treatment as factors. Tukey’s significant difference test with a 0.05 level of significance was applied to find significant differences. Analysis was conducted using the statistical software Assistat® (Assistat 7.7 Beta Version 16.0, Brazil).

Results

A rotational central composite design (23) was employed to optimize the composition of edible coatings on minimally processed mangoes in relation to concentrations of alginate, pectin and glycerol. The adequacy of the model was checked using ANOVA, which was tested through Fisher’s statistical analysis and the results are shown in Online Resource 1.

The response surface three dimensional curves were employed in order to study the interactive effects of factors on the response variable (total soluble solids—TSS). Figure 1a shows the response surface curve of the relationship between alginate and pectin while the glycerol concentration was kept at 5.5% (w/v). Figure 1b shows the response surface curve of the relationship between pectin and glycerol while the alginate concentration was kept at 1.55% (w/v) and Fig. 1c shows the response surface curve of the relationship between alginate and glycerol while the pectin concentration was kept at 1.55% (w/v).

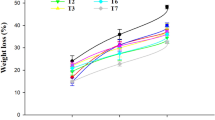

Figure 2 shows the effect of edible coatings on minimally processed mangoes during storage at 8 ± 1 °C with regards to pH, titratable acidity and total soluble solids. Despite the small variation in pH values between the treatments and during storage, it was observed that the fruits presented a significant decrease in pH (p < 0.05) (Fig. 2a) for all treatments and results were more sharp for the control group. After 16 d of storage, there were no significant differences among fruits coated with 3% alginate and 0.5% pectin (with and without glycerol—3A0.5P1 and 3A0.5P2, respectively) and 2% alginate, 3% pectin and 5.5% glycerol (2A3P1).

Results of pH (a), titratable acidity—TA (b) and total soluble solids—TSS (c) in coated minimally processed mangoes during storage at 8 ± 1 °C. Control = no coating application (only immersed in ascorbic acid); 3A0.5P1 = 3% (w/v) alginate, 0.5% (w/v) pectin, 5.5% (w/v) glycerol; 3A0.5P2 = 3% (w/v) alginate, 0.5% (w/v) pectin; 2A3P1 = 2% (w/v) alginate, 3% (w/v) pectin, 5.5% (w/v) glycerol; 2A3P2 = 2% (w/v) alginate, 3% (w/v) pectin. Bars are the mean ± SD (n = 3). Different lower-case letters (a–c) indicate significant differences (p < 0.05) in the same day; Different capital-case letters (A–C) indicate significant differences (p < 0.05) between the days

The control group, and mangoes coated with 2% (w/v) alginate, 3% (w/v) pectin and 5.5% (w/v) glycerol after 16 d storage are shown in Fig. 3. It is clearly visible that the coated mangoes displayed a better appearance after storage at 8 ± 1 °C.

Minimally processed mangoes at the beginning of the experiments (a—uncoated mangoes; b—mangoes coated with 2% (w/v) alginate, 3% (w/v) pectin and 5.5% (w/v) glycerol) and after 16 d of storage at 8 ± 1 °C (c—uncoated mangoes; d—mangoes coated with 2% (w/v) alginate, 3% (w/v) pectin and 5.5% (w/v) glycerol)

Discussion

The model F-value of 6.99 implies the model is significant and there is only a 0.89% chance that the F-value could occur due to noise. In this study, the independent variables were coded as alginate (A), pectin (B) and glycerol (C), and p-values less than 0.05 indicate model terms are significant. In this case A, A2, B2 and C2 are significant model terms.

The second-order polynomial model for the total soluble solids (TSS) was expressed by Eq. 1.

The lack-of-fit F-value of 9.58 implies that the lack-of-fit is not significant and there is only a 9.72% chance that this significant occurrence is due to noise. The predicted R2 value (0.7149) was close to the adjusted R2 (0.7712). Adequate precision measures the signal to noise ratio, and a ratio greater than four is desirable. A ratio of 7.941 was recorded and this indicates an adequate signal. Coefficient of variation (CV) (standard deviation/error) of 11.88% for each dependent variable showed that the statistical quality of the experimental results was acceptable prior to evaluation of the model.

The regression coefficient equation obtained showed that the value of coefficient determination (R2) was 0.8999, indicating that 89.99% of the variability in the response could be explained by the model.

Considering TSS content indicates the ripening of fruits, lower values are desirable to slow this process down. Thus, Fig. 1a demonstrated that TSS declined with the increase in polymers concentrations. A decrease in TSS was also observed with a decrease in the pectin concentration and an increase in the alginate concentration. Therefore, different concentrations of polymers change the TSS, and based on these results, additional formulations of film-forming solutions were prepared. In the first case, alginate concentration was set at 2% and pectin concentration was established at 3% (point + α of the experimental planning), and in the second case pectin concentration was set at 0.5% and the concentration of alginate was established at 3% (point + α of the experimental planning), with and without glycerol. In both cases, the glycerol concentration was 5.5% (w/v), concentration at the central point of the experimental planning.

According to the second-order polynomial model, the significant term for variable glycerol (C) has a negative value, which means that higher levels of glycerol induce lower TSS values. However, the coefficient assumes a value close to zero (− 0.06). For this reason, the variable glycerol was fixed at the central point of the experimental planning. It was also observed that for values of glycerol concentration at levels + 1 (8.17%) and + α (10%), the films formed are not homogeneous.

The addition of organic acids, such as ascorbic acid (AA), to food increases the proton concentration, thereby lowering the pH. Similar behavior was observed when malic acid was applied to mango slices using combined treatments of pulsed light and edible coating, resulting in a reduction of the natural pH of mango (Salinas-Roca et al. 2016). According to Ramos-Villarroel et al. (2011), the production of CO2 and its dissolution in the water of the cellular tissues can cause acidification of the cytoplasm and consequently decrease the pH.

A previous study demonstrated that when minimally processed mangoes were treated with calcium chloride, ascorbic acid and citric acid, and then immersed in film forming solutions of alginate and pectin, the best results were obtained with coatings using ascorbic acid, which showed improved color retention after 14 d of storage at 8 °C (data not shown). According to Robles-Sánchez et al. (2013), tissue browning is one of the main problems in freshly cut mango during storage, which limits the shelf-life of freshly cut cubes.

Ascorbic acid is a substance generally recognized as safe (GRAS) and is approved by the U.S. Food and Drug Administration (FDA) for use as a food additive in human diets because of its antioxidant potential. AA has long been used as an antibrowning agent in the processing of fruits and vegetables because of its ability to control polyphenol oxidase (PPO) enzyme activity by reduction of o-quinones, produced by PPO-catalysed oxidation of polyphenols, back to dihydroxy polyphenols (Jang and Moon 2011).

Tapia et al. (2008) studied a formulation of alginate and gellan-based edible coatings for freshly cut papaya pieces and observed that the addition of ascorbic acid as an antioxidant in the coatings improved the water vapor resistance of the polysaccharide coatings when combined with 1% w/v glycerol. The authors reported that AA can be used to control the penetration of oxygen into the edible coatings, which contributes to protection against oxidative reactions. However, AA alone is not effective in controlling browning since it is oxidized to dehydroascorbic acid producing o-quinones which lead to brown pigment formation (Rojas-Graü et al. 2006). Thus, the use of AA combined with other treatments such as ultrasound (Jang and Moon 2011), edible coatings (Robles-Sánchez et al. 2013), ethanol (Yan et al. 2017) and a low-oxygen atmosphere (Teixeira et al. 2008) are recommended.

Fruits from the control group presented an increase in the titratable acidity (TA) content, reaching higher values when compared to fruits coated with edible coatings during storage (Fig. 2b). For edible coatings of 3A0.5P1, 3A0.5P2 and 2A3P1, TA content increased until the eighth day of storage, and no significant differences (p < 0.05) were found in TA for all treatments on the same day. TA values remained stable after 16 d of storage for coated samples, except for the coating containing 2% alginate and 3% pectin (2A3P2), where the TA value increased significantly from 16.3 to 19.6%.

The observed increase in titratable acidity—TA content does not corroborate previous studies about the TA decline with mangoes ripening (Medeiros et al. 2012; Islam et al. 2013). According to Sadler and Murphy (1998), acids in fruit tend to decrease with fruit maturity as sugar content increases. The decline in acidity could be due to the susceptibility of citric acid (a major acid in mango) to oxidative destruction by the ripening process (Aina 1990), by starch hydrolysis leading to an increase in total sugars (Fuchs et al. 1980), or due to utilization of organic acids as respiratory substrates or converted to sugars (Appiah and Patrick 2011). However, according to the results presented here, the incorporation of AA contributed to the increase in TA during storage, being observed (as expected) an inverse relationship between titratable acidity and pH. The incorporation of AA into the coating matrix reduced browning compared to the use of the antioxidant alone.

The total soluble solids (TSS) content of minimally processed mangoes during storage is shown in Fig. 2c. Control samples demonstrated a significant (p < 0.05) increase in TSS throughout the experiment and for samples 3A0.5P1 and 3A0.5P2 a gradual increase in TSS values was detected during storage. In sample 2A3P2, there was a slight increase in the TSS content at the beginning of the storage period and a steady state was reached by the sixteenth day of storage. On the other hand, the content of TSS remained stable throughout the entire storage period.

In general, the total soluble solid content represents the ripening process and tends to increase due to the degradation of polysaccharides and/or water loss, concentrating the solutes in the fruit tissue (Medeiros et al. 2012). The TSS content during the storage period under refrigeration (8 ± 1 °C) increased significantly in the uncoated mangoes, while the TSS of coated mangoes remained relatively stable during the total experimental period. These results suggest that the edible coatings promote a reduction in fruit metabolism, consequently extending the ripening period.

Similar results have been reported by Medeiros et al. (2012) in development of a nanomultilayer coating of pectin and chitosan in ‘Tommy Atkins’ mango. Authors observed that the TSS of coated mangoes remained relatively stable over forty-five days of storage. Salinas Roca et al. (2016) evaluated the combination of pulsed light (PL), alginate coating and malic acid on the reduction of Listeria innocua population and physicochemical parameters of mango slices over refrigerated storage, and reported significantly lower values of TSS for treated mango slices compared to untreated samples.

Considering the results in terms of the evaluated parameters, the coating formulation 2A3P1 (2% (w/v) alginate, 3% (w/v) pectin, 5.5% (w/v) glycerol) was selected as most capable of slowing the senescence of minimally processed mangoes stored at 8 °C for sixteen days. Moreover, this formulation was easy-to-handle and showed perfect adhesion to the mangoes slices, while higher alginate concentrations caused a very thick coating. The presence of glycerol as a plasticizer agent modified the structure of polymer chains, decreasing the intermolecular bonding forces and thus increasing the flexibility and extensibility of the polymer matrix (Espitia et al. 2014).

Conclusion

When minimally processed ‘Espada’ mangoes were treated with ascorbic acid as an antioxidant and coated with alginate and pectin-based edible coatings with the addition of glycerol as a plasticizer, the formulation of 2% (w/v) alginate, 3% (w/v) pectin and 5.5% (w/v) glycerol) was selected as the most suitable for extending shelf-life and maintaining the quality of freshly cut fruit when stored at 8 ± 1 °C for sixteen days.

References

Aina JO (1990) Physico-chemical changes in African Mango (Irvingia gabogensis) during normal storage ripening. J Food Chem 36:205–212. https://doi.org/10.1016/0308-8146(90)90055-9

Appiah F, Patrick K (2011) Effect of ripening stage on composition, sensory qualities and acceptability of keitt mango (Mangifera indica L.) chips. Afr J Food Agric Nut Dev 11:5096–5109. https://doi.org/10.4314/ajfand.v11i5.70439

Belay ZA, Caleb OJ, Opara UL (2017) Impacts of low and super-atmospheric oxygen concentrations on quality attributes, phytonutrient content and volatile compounds of minimally processed pomegranate arils (cv. Wonderful). Postharvest Biol Technol 124:119–127. https://doi.org/10.1016/j.postharvbio.2016.10.007

Chen C, Hu W, He Y, Jiang A, Zhang R (2016) Effect of citric acid combined with UV-C on the quality of fresh-cut apples. Postharvest Biol Technol 111:126–131. https://doi.org/10.1016/j.postharvbio.2015.08.005

Dea S, Brecht JK, Nunes MCN, Baldwin EA (2010) Occurrence of chilling injury in fresh-cut ‘Kent’ mangoes. Postharvest Biol Technol 57:61–71. https://doi.org/10.1016/j.postharvbio.2010.02.005

Espinel Villacres RA, Flores SK, Gerschenson LN (2014) Biopolymeric antimicrobial films: study of the influence of hydroxypropyl methylcellulose, tapioca starch and glycerol contents on physical properties. Mater Sci Eng C36:108–117. https://doi.org/10.1016/j.msec.2013.11.043

Espitia PJP, DuWen-Xian Avena-Bustillos RJ, Soares NFF, McHugh TH (2014) Edible films from pectin: physical–mechanical and antimicrobial properties—a review. Food Hydrocoll 35:287–296. https://doi.org/10.1016/j.foodhyd.2013.06.005

Falguera V, Quintero JP, Jiménez A, Muñoz JA, Ibarz A (2011) Edible films and coatings: structures, active functions and trends in their use. Trends Food Sci Technol 22:292–303. https://doi.org/10.1016/j.tifs.2011.02.004

Fuchs Y, Pesis E, Zauberman G (1980) Changes in amylase activity, starch and sugar contents in mango fruit pulp. Sci Hort 13:155–160. https://doi.org/10.1016/0304-4238(80)90080-1

González-Aguilar GA, Wang CY, Buta JG (2008) Maintaining quality of fresh-cut mangoes using antibrowning agents and modified atmosphere packaging. J Agric Food Chem 48:4204–4208. https://doi.org/10.1021/jf991384j

Goyeneche R, Aguëro MV, Roura S, Scala K (2014) Application of citric acid and mild heat shock to minimally processed sliced radish: color evaluation. Postharvest Biol Technol 93:106–113. https://doi.org/10.1016/j.postharvbio.2014.02.011

Huang H, Ge Z, Limwachiranon J, Li L, Li W, Luo Z (2017) UV-C treatment affects browning and starch metabolism of minimally processed lily bulb. Postharvest Biol Technol 128:105–111. https://doi.org/10.1016/j.postharvbio.2017.02.010

Instituto Adolfo Lutz (1985) Normas Analíticas do Instituto Adolfo Lutz. v.1: Métodos químicos e físicos para análise de alimentos. IMESP, São Paulo

Islam K, Khan MZH, Sarkar MAR, Absar N, Sarkar SK (2013) Changes in acidity, TSS, and sugar content at different storage periods of the postharvest mango (Mangifera indica L.) influenced by bavistin DF. Int J Food Sci 8:1–8. https://doi.org/10.1155/2013/939385

Jang J-H, Moon K-D (2011) Inhibition of polyphenol oxidase and peroxidase activities on fresh-cut apple by simultaneous treatment of ultrasound and ascorbic acid. Food Chem 124:444–449. https://doi.org/10.1016/j.foodchem.2010.06.052

Lucera A, Şimşek F, Conte A, Del Nobile MA (2012) Minimally processed butternut squash shelf life. J Food Eng 113:322–328. https://doi.org/10.1016/j.jfoodeng.2012.05.026

McHugh TH (2000) Protein–lipid interactions in edible films and coatings. Nahrung 44:148–151. https://doi.org/10.1002/1521-3803(20000501)44:3%3c148:AID-FOOD148%3e3.0.CO;2-P

Medeiros BGS, Pinheiro AC, Carneiro-da-Cunha MG, Vicente AA (2012) Development and characterization of a nanomultilayer coating of pectin and chitosan—evaluation of its gas barrier properties and application on ‘Tommy Atkins’ mangoes. J Food Eng 110:457–464. https://doi.org/10.1016/j.jfoodeng.2011.12.021

Oliveira BG, Costa HB, Ventura JA, Kondratyuk TP, Barroso MES, Correia RM, Pimentel EF, Pinto FE, Endringer DC, Romão W (2016) Chemical profile of mango (Mangifera indica L.) using electrospray ionisation mass spectrometry (ESI-MS). Food Chem 204:37–45. https://doi.org/10.1016/j.foodchem.2016.02.117

Ramos-Villarroel AY, Martín-Belloso O, Soliva-Fortuny R (2011) Bacterial inactivation and quality changes in fresh-cut avocado treated with intense light pulses of specific spectra. Eur Food Res Technol 233:395–402. https://doi.org/10.1111/ijfs.12284

Robles-Sánchez RM, Rojas-Graü MA, Odriozola-Serrano I, González-Aguilar GA, Martín-Belloso O (2009) Effect of minimal processing on bioactive compounds and antioxidante activity of fresh-cut ‘Kent’ mango (Mangifera indica L.). Postharvest Biol Technol 51:384–390. https://doi.org/10.1016/j.postharvbio.2008.09.003

Robles-Sánchez RM, Rojas-Graü MA, Odriozola-Serrano I, González-Aguilar G, Martin-Belloso O (2013) Influence of alginate-based edible coating as carrier of antibrowning agents on bioactive compounds and antioxidant activity in fresh-cut Kent mangoes. LWT Food Sci Technol 50:240–246. https://doi.org/10.1016/j.lwt.2012.05.021

Rojas-Graü MA, Sobrino-Lopez A, Tapia MS, Martin-Belloso O (2006) Browning inhibition in fresh-cut ‘Fuji’ apple slices by natural antibrowning agents. J Food Sci 71:59–65. https://doi.org/10.1111/j.1365-2621.2006.tb12407.x

Rojas-Graü MA, Tapia MS, Rodríguez FJ, Carmona AJ, Martín-Belloso O (2007) Alginate and gellan-based edible coatings as carriers of antibrowning agents applied on fresh-cut Fuji apples. Food Hydrocoll 21:118–127. https://doi.org/10.1016/j.foodhyd.2006.03.001

Rojas-Graü MA, Soliva-Fortuny R, Martín-Belloso O (2009) Edible coatings to incorporate active ingredients to fresh-cut fruits: a review. Trends Food Sci Technol 20:438–447. https://doi.org/10.1016/j.tifs.2009.05.002

Sadler GD, Murphy PA (1998) pH and titratable acidity. In: Nielsen S (ed) Food analysis. Aspen Publishers Inc, Maryland, pp 101–116

Salinas-Roca B, Soliva-Fortuny R, Welti-Chanes J, Martín-Belloso O (2016) Combined effect of pulsed light, edible coating and malic acid dipping to improve fresh-cut mango safety and quality. Food Control 66:190–197. https://doi.org/10.1016/j.foodcont.2016.02.005

Silva MA, Bierhalz ACK, Kieckbusch TG (2009) Alginate and pectin composite films crosslinked with Ca2+ ions: effect of the plasticizer concentration. Carbohydr Polym 77:736–742. https://doi.org/10.1016/j.carbpol.2009.02.014

Sothornvit R, Rodsamran P (2008) Effect of a mango film on quality of whole and minimally processed mangoes. Postharvest Biol Technol 47:407–415. https://doi.org/10.1016/j.postharvbio.2007.08.005

Tapia MS, Rojas-Graü MA, Carmona A, Rodríguez FJ, Soliva-Fortuny R, Martín-Belloso O (2008) Use of alginate- and gellan-based coatings for improving barrier, texture and nutritional properties of fresh-cut papaya. Food Hydrocoll 22:1493–1503. https://doi.org/10.1016/j.foodhyd.2007.10.004

Tavassoli-Kafrani E, Shekarchizadeh H, Masoudpour-Behabadi M (2016) Development of edible films and coatings from alginates and carrageenans. Carbohydr Polym 137:360–374. https://doi.org/10.1016/j.carbpol.2015.10.074

Teixeira GHA, Durigan JF, Alves RE, O’Hare TJ (2008) Response of minimally processed carambola to chemical treatments and low-oxygen atmospheres. Postharvest Biol Technol 48:415–421. https://doi.org/10.1016/j.postharvbio.2007.08.011

USDA-ERS [United States Department of Agriculture e Economic Research Service] (2011) US per capita consumption data. http://www.ers.usda.gov/. Accessed 23.01.18

Vargas-Torres A, Becerra-Loza AS, Sayago-Ayerdi SG, Palma-Rodríguez HM, García-Magaña ML, Montalvo-González E (2017) Combined effect of the application of 1-MCP and different edible coatings on the fruit quality of jackfruit bulbs (Artocarpus heterophyllus Lam) during cold storage. Sci Hortic 214:221–227. https://doi.org/10.1016/j.scienta.2016.11.045

Yan S, Luo Y, Zhou B, Ingrame DT (2017) Dual effectiveness of ascorbic acid and ethanol combined treatment to inhibit browning and inactivate pathogens on fresh-cut apples. LWT Food Sci Technol 80:311–320. https://doi.org/10.1016/j.lwt.2017.02.021

Acknowledgements

The authors acknowledge the Master’s degree scholarship provided by Project IBPG-0113-2.12/14 of the Fundação de Amparo a Ciência e Tecnologia de Pernambuco (FACEPE) (Pernambuco, Brazil). The authors also thank the Pró-Reitoria de Pesquisa e Pós-Graduação (Propesq) of the Universidade Federal de Pernambuco (UFPE, Brazil) for the financial support throughout this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Silva, F.A., Finkler, L. & Finkler, C.L.L. Effect of edible coatings based on alginate/pectin on quality preservation of minimally processed ‘Espada’ mangoes. J Food Sci Technol 55, 5055–5063 (2018). https://doi.org/10.1007/s13197-018-3444-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3444-z