Abstract

Bioactive compounds from plant sources are generally categorized as natural antioxidants with well-known health benefits. The health-promoting characteristics of natural antioxidants include anti-inflammatory, anti-diabetic, and hepatic effects as well as free radical scavenging. Herein, a comprehensive and comparative review are presented about the effects of conventional (thermal and mechanical) and relatively new (non-thermal) processing methods on phytochemicals and discussed the importance of implementing the use of those methods that could be of very helpful retaining the quality of the bioactive compounds in plant-based foods. Plant-based foods rich in phenolics, vitamin C, carotenoids, and other compounds undergo a range of processing operations before they are consumed. Most of these methods involve thermal treatments of fruits, stems, leaves, and roots. These techniques have varying effects on bioactive compounds and their activities, and the magnitude of these effects depends on process parameters such as temperature, time, and the food matrix. Thermal processing can be detrimental to bioactive compounds while nonthermal procedures may not cause significant deterioration of important health-promoting phytochemicals and in some cases can improve their bio-activity and bio-availability. The detrimental effects of conventional processing on the quality of natural antioxidants have been compared to the effects of innovative nonthermal food treatments such as gamma and ultraviolet irradiation, ultraviolet light, pulsed electric fields, and high hydrostatic pressure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural antioxidants exist in many foods, particularly fruits and vegetables are their rich sources. Vitamins C, E, and A, polyphenols, lycopene, coenzyme Q10, and certain proteins are common natural antioxidants (Shahidi and Ho 2005). Natural antioxidants play important roles in both plant physiological systems and human health improvement (Shahidi and Ho 2005). The use of antioxidants in food preperations is aimed at maintaining the freshness and prevent browning and rancidity, particularly in case of foods containing large quantities of fats or oils, which are most vulnerable to oxidative rancidity. Antioxidants are also used as preservatives in vegetables and vegetable products; fruits and fruit products; cereals and bakery products; milk and milk products such as cheese; meat, fish, and their products; and spices and other dry foods such as sugars, honey, beverages, and chewing gum (Williamson et al. 2000). The addition of antioxidants to such food items as preservatives occurs in many stages of food production (Morton et al. 2000). Aside from their direct addition to food items, antioxidants can be used to prevent degradation during food processing, transportation, and storage (Williamson et al. 2000; Morton et al. 2000).

A variety of procedures are used during the handling of food from raw ingredients to finished or ready-to-eat products. These procedures influence the shelf life, safety, sensory, physical, and chemical properties of foods. Some of the changes induced by processing in foods are desired; such as increased shelf life through microbial inactivation, increased digestibility, and improved texture, flavor, and edibility. However, processing may also trigger side reactions that cause unwanted changes in the physicochemical, sensory, and nutritional characteristics of foods (Boekel et al. 2010). For example, thermal and nonthermal processes are usually carried out to ensure the safety of processed juice, and heat-assisted processing is generally given to ensure microbial food safety (Noranizan and Benchamaporn 2007). Conventional heat treatment is routinely used to extend shelf life and preserve fruits and vegetables and their products (Chipurura and Muchuweti 2010). The contents of antioxidant compounds such as phenolics and their biological activities in foods may be affected by certain thermal techniques (Oms-Oliu et al. 2012; Parmar et al. 2016). Conventional cooking of vegetables generally reduces total phenolic content and antioxidant activity.

Nonthermal techniques provide promising alternative to thermal processing, which is commonly used for microbial and enzyme inactivation in foods despite of its largely negative effects on bioactive compounds and undesirable changes to the sensory and nutritional characteristics of foods. The temperatures applied with nonthermal techniques do not exceed 50 °C, effectively reducing the destructive effects of high temperatures on nutrients and other quality attributes (Gallego-Juárez 2001). Nonthermal food processing methods are being applied with increasing frequency, and therefore, it is imperative to determine their effects on bioactive compounds in fruits and vegetables and compare their efficacy with that of conventional methods. Hence, this review is aimed at explaining the possible effects of various new non-thermal, conventional thermal and mechanical techniques of food processing on phytochemicals in order to ensure they have high quality and functionality. The review also aims to explore and suggest some strategies for fruits and vegetables handling and processing to ensure maximum consumer health benefits.

Nonthermal food processing

Irradiation

Food irradiation includes the use of ionizing or non-ionizing energy to extend shelf life of foods (Gallego-Juárez 2001). It is a nonthermal food preservation method aimed at disinfecting foods by eliminating pathogenic microbes. Ionizing irradiation uses 2–7-kGy doses whereas non-ionizing irradiation involves only ultraviolet (UV) light. The effects of γ-irradiation on microbial decontamination, phenolic compounds, and in vitro antioxidant activity in pomegranate peels were reported by Mali et al. (2012). Various doses (5, 10, 15, and 25 kGy) were applied and a dose-dependent correlation was observed between total phenolics and antioxidant activity with increasing the dose from 5 to 10 kGy (p < 0.05; Table 1). These effects were observed after treatment and during post-irradiation storage for 60 days. Table 1 shows several recently reported effects of irradiation on bioactive compounds in fruit and vegetable-based foods. Such effects are variable and depend on the nature of the food matrix. The γ-Irradiation (10 kGy) increases phenolic acids in clove and cinnamon but not in nutmeg (Variyer et al. 1998). The studies indicate that the gamma-radiation induced breakdown of tannins that could be responsible for the changes in phenolic contents (Variyer et al. 1998). Mali et al. (2012) reported that the total phenolic content and in vitro antioxidant activity of irradiated (10 kGy) pomegranate peel powder increased by 4 and 12%, respectively. Phenolic content was 16.10 g gallic acid equivalents (GAE)/100 g dry mass in non-irradiated samples and gradually increased to 16.80 g GAE/100 g dry mass in irradiated samples. This increase was due to the degradation of higher-molecular-mass tannins and their conversion into simpler phenolic compounds such as tannic and gallic acids. Irradiation might have facilitated this breakdown of complex compounds into active components, including phenolics (Kumari et al. 2009).

Irradiation has also been shown to reduce the electron spin resonance, which increase in free radical scavengers (polyphenols) of some leguminous seeds (velvet bean seeds) (Bhat et al. 2007). The antioxidant activity increased in carrot juice while it decreased in kale juice after irradiation (Song et al. 2006). Alothman and Bhat (2009) discussed possible mechanisms of radiation-induced changes in antioxidants. The optimized use of irradiation combined with other methods, particularly the use of low heat, is recommended for the inactivation of pathogenic microbes and for the improvement of other food quality characteristics (Pan et al. 2004).

UV treatment

UV treatment is being used more frequently in food processing and similar to irradiation, its prime objective is microbial deactivation. UV light of different intensities or types (A, B, and C) is applied, although UVC is the most effective for food disinfection (Feng et al. 2013). The contents of some antioxidants can also be changed by UV treatment (Pan et al. 2004). Some reports have compared the effects of UV treatment and thermal processing on natural antioxidants (Artés-Hernández et al. 2010; Santhirasegaram et al. 2015). Antioxidant loss due to heat may degrade color in products such as carrot juice (121 °C, 30 min), as reported by Chen et al. (1995). Goh et al. (2012) reported that UV treatment of pineapple juice resulted in significantly higher ascorbic acid content than that treated by conventional heating. A further reduction in ascorbic acid in heat-treated juice was observed during storage, although UV treatment improved the retention of ascorbic acid. Heat treatment, on the contrary, improved the stability of flavonoids and carotenoids in stored pineapple juice. The antioxidant capacity of UV-treated juice was higher than that of heat-treated juice, but the difference was non-significant (p > 0.05). These findings are summarized in Table 1. Ascorbic acid, flavonoids, phenolic acids, carotenoids, and antioxidant activity were comparatively higher in UV-treated pineapple juice than in thermally processed juice, although both treatments reduced the quantities of these natural antioxidants.

Other examples of the effects of UV treatment on natural antioxidants from various sources are listed in Table 1. Feng et al. (2013) evaluated changes in lycopene and phenolic content in watermelon juice for 37 days after UVC (2.7–37.5 J/mL) treatment during storage at 5 ± 1 °C. Compared with no treatment, UVC treatment did not change the levels of bioactive compounds, which remained consistent until 25th day of storage which the levels deteriorated in both cases. UVC intensity had lower effect on the colors of watermelon juice. The exact mechanism and whether UV treatment increases or decreases lycopene content is unknown. Chen et al. (2009) reported that lycopene may degrade and isomerize once exposed to UV light. Another study reported that irradiation enhances the lycopene content of tomatoes (Liu et al. 2009). The lycopene contents of the tomatoes increased due to the red light treatment reported by the authors. Additional mechanistic studies are needed to elucidate the effects of various types and intensities of UV light on antioxidant compounds.

High hydrostatic pressure (HHP) treatment

HHP, normally in the range of 300–700 MPa, is applied in special reactors to inactivate microbes and enzymes in foods (Chawla et al. 2011). The high pressure is thought to affect all parts of a food sample equally, and the sensory and nutritional characteristics of HHP-treated foods are generally identical to those of fresh foods (Rastogi et al. 2007). HHP reportedly has physical effects in foods. For example, high-molecular-mass food components, including carbohydrates and proteins, may be altered, whereas low-molecular-mass pigments, volatiles, vitamins, and compounds related to the sensory, nutritional, and biological properties of foods are unchanged (Oey et al. 2008).

Some other reports have described the retention of phenolics and their activities after HHP treatment. Patras et al. (2008) observed non-significant decreases in antioxidant activity in HHP-treated carrot and tomato purees. HHP is a promising technique that is more appropriate than conventional thermal processing for preserving the nutraceutical and medicinal potential of fruits and vegetables (Gallego-Juárez 2001). The use of high pressure is superior to thermal pasteurization for retaining the stability of phenolic compounds in fruit smoothies (Keenan et al. 2011). The antioxidant properties and total carotenoid content in various vegetables remain unchanged after HHP treatment at ambient temperature (400 and 600 MPa, 2 min). Carotenoid availability changes slightly depending on vegetable type and the magnitude of applied pressure (McInerney et al. 2007).

Total antioxidant activity is reduced with increasing storage time after HHP treatment of orange juice. However, ascorbic acid degradation is slower and antioxidant activity higher in HHP-treated orange juice than in heat-pasteurized juice (Polydera et al. 2004). A series of reactions or changes can occur during the processing or storage of orange juice that significantly influence its antioxidants content and structures (Arena et al. 2001). In some cases, processing and storage increase the antioxidant potential of natural compounds (Nicoli et al. 1999). Fernandez-Garcia et al. (2000) observed that HHP treatment and storage at 4°C for 21 days caused non-significant changes in antioxidant power and vitamin C and carotene content in pure orange juice and mixed (carrot and orange) juice.

Process modifications, such as incorporating other innovative techniques with HHP, can also enhance the beneficial effects for natural antioxidants. For instance, sonication before HHP treatment increases phenolic, ascorbic acid, and total antioxidant content and antiradical activity in apple juice (Abid et al. 2014). HHP combined with a complex enzyme treatment of fermented rice bran yields higher Ferulic acid and free amino acid content, which increases bioactivity (Kim and Han 2012). HHP treatments of 300–500 MPa at 25 °C for 5–20 min increase the bioactive content of apricot nectar (Huang et al. 2013) and gooseberry pulp (Vega-Gálvez et al. 2014); this increase is higher at elevated pressures and with increasing application time. We suggest that the proper selection of process parameters for HHP treatment of various fruit and vegetable products can maximize their nutraceutical benefits. HHP can also be used to modify existing food processing techniques to reduce the need for long, high-temperature treatments. Such prudent strategies can help maximize the health benefits of natural antioxidants in foods.

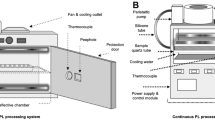

Pulsed electric field (PEF) treatment

PEF application is a nonthermal food processing method in which a PEF (20–80 kV/cm) is applied for a short time to a food product positioned between two electrodes. This treatment does not result in substantial heating of the treated food. A study by Odriozola-Serrano et al. (2008) showed that the temperature of strawberry juice measured at 0.1-s intervals did not exceed 40 °C during PEF treatment. PEF is an innovative technology that increases the shelf life and preserves the nutrients, phytochemical content, and antioxidant potential of foods (Elez-Martínez and Martín-Belloso 2007). Oms-Oliu et al. (1993) reported that watermelon juice treated with high-intensity PEF showed better retention of lycopene and antioxidant capacity with increasing PEF frequency and intensity. Higher-intensity treatment, however, reduced vitamin C content. Strength, pulse frequency, pulse polarity, and the width of the electric field significantly affected vitamin C and lycopene content and antioxidant power in watermelon juice. Compared with monopolar and bipolar pulses enhanced the lycopene content and antioxidant power of watermelon juice but reduced vitamin C retention. In another study, quercetin and kaempferol levels remained unchanged in strawberry juice after PEF treatment (Odriozola-Serrano et al. 2008). Once applied to apples before juice expression, PEF significantly increased the native polyphenols in the juice by 8.8% (Turk et al. 2012). In another study, the antioxidant compounds (ascorbic acid, total phenolics, and total anthocyanins) in PEF-treated (36 kV/cm, 100 µs) blueberry juice were compared with those in HHP-treated (600 MPa, 42 °C, 5 min) and untreated juice. Antioxidant capacity just after treatment and during 56 days of refrigerated storage was also compared. The ascorbic acid contents in each treated blueberry juice decreased by approximately 5%. At the end of refrigerated storage, unprocessed and PEF juices showed similar ascorbic acid losses (50%) compared with those in untreated juice. Total phenolics and total anthocyanins fluctuated in all processed juices after treatment and during storage. HHP-treated juices preserved antioxidant activity (21% loss) more than unprocessed (30%) and PEF-treated juices (48%) after 56 days at 4 °C (Barba et al. 2012).

In a recent study, Agcam et al. (2014) measured total phenolics, hydroxybenzoic acid, hydroxycinnamic acids, flavonols, flavones, and flavonones in orange juice before and after PEF treatment and thermal pasteurization followed by 180 days of storage at 4 °C. Total phenolics enhanced with the intensity of the PEF and thermal pasteurization. With the exception of syringic acid and neoeriocitrin, phenolic compound concentrations increased in orange juice after PEF treatment and thermal pasteurization. Compared with thermally pasteurized samples, the PEF-treated samples contained more stable flavonoids and phenolic acids. Moreover, the PEF-treated samples had sensory scores higher than those of the heat-treated samples. This brief review of studies examining the relationship between PEF treatment and bioactive compounds shows that more research is required to verify whether PEF increases, decreases, or stabilizes phenolics in various foods. There is also a need to study the underlying mechanisms to explain how PEF influences the bioactive compounds derived from fruits and vegetables.

Thermal food processing

Various conventional thermal processing methods are used in the food industry, and the importance of bioactive compounds makes it worthwhile to evaluate these processes in terms of their effects on natural antioxidants and their activities. Conventional processes can be categorized as thermal (pasteurization, baking, refrigerating, freezing), nonthermal (pressure processing, microwaving, clarification), and mechanical (peeling, trimming, cutting, mixing). Some of these processes are applied at the domestic level for food preparation or further processing of packaged foods. A summary of the effects of conventional methods on phytochemicals is given in Table 2. Conventional thermal and mechanical methods may result in the loss of important bioactives.

Most vegetables are boiled in water or cooked in a microwave before consumption, which can cause various changes in their physicochemical properties (Zhang and Hamauzu 2004). Sahlin et al. (2004) observed that baking and boiling had minor effects on the vitamin C, phenolic, and lycopene content and antioxidant properties of tomatoes, whereas frying significantly decreased these parameters. Cooking reduced the bioactive compounds contents and antioxidant activity in broccoli. Zhang and Hamauzu (2004) observed that raw, fresh broccoli florets had 60.5% total antioxidant activity, which was reduced to 35 and 34.7% after 5 min of boiling and microwaving, respectively. The authors reported that the cooking caused significant losses of antioxidant activity due to antioxidants leached into the cooking water. Ismail et al. (2004) observed that heat treatments and cooking reduced the quantity of phenolics in vegetables such as spinach, shallots, kale, swamp cabbage, and cabbage. Their results indicated that phenolic compounds are sensitive to heat treatment even during a short period of cooking. Chu et al. (2000) observed that radical scavenging activities in the fresh green leaves of potatoes were identical to that in leaves blanched for 2 min at 100°C. Manzocco et al. (1998) reported that the pasteurization of tea extracts increased antioxidant activity, and they attributed the increase to the antioxidants formed during heating. Ismail et al. (2004) observed that antioxidant activities in vegetables boiled for 1 min were identical to those in fresh vegetables. A detailed discussion of the changes caused by common food processing methods is provided in the following subsections.

Roasting

The phenolic content of cashew nuts and peanuts is increased by roasting at 130°C for 33 min (Chandrasekara and Shahidi 2011). This could be attributed to the liberation of phenolics from cashew nuts and peanuts during roasting. In buckwheat flour, roasting at 120 °C for 40 min causes a 33% decrease in flavonoids (Zhang et al. 2010), whereas roasting at 160 °C for 30 min decreases total flavonoids by 15.9%. Rutin in buckwheat grouts is more heat stable than vitexin, isovitexin, homoorientin, and orientin after roasting at 160 °C for 30 min (Zielinski et al. 2009). Sharma and Gujral (2011) observed that roasting barley seeds at 280 °C for 20 s decreased the total phenolic content by 8.5–49.6%. Natural antioxidants in foods are generally depleted after thermal processing, and antioxidant power can be diminished by the chemical modifications induced by heat treatment (Horvathova et al. 2007). However, some heat-induced changes in naturally occurring compounds improve their functional properties, for example, the antioxidant properties of Maillard reaction products (Nicoli et al. 1999). A key primary effect of browning caused by the Maillard reaction is the formation of antioxidants; these reactions also take place at elevated temperatures (Nicoli et al. 1997).

Drying

Antioxidant content may also decrease due to oxidative damage caused by the drying of various plant materials (Goula et al. 2006). Drying causes flavonoid damage, the extent of which depends on the method. Hot-air drying can cause more damage than freeze-drying. Other safe options include vacuum and microwave drying (Zhang et al. 2009). Chen et al. (2011) observed that the total phenolic content in citrus fruit peels dried at 50 and 60 °C was significantly lower than that in fresh peels. The generation and accumulation of Maillard-derived melanoidins with various degrees of antioxidant activity also enhance antioxidant properties at high temperatures (80 and 90 °C) (Que et al. 2008). Madrau et al. (2009) showed that antioxidant capacity and chain-breaking activity increased significantly with increasing drying temperature in Cafona apricots. Increased antioxidant activity could be due to increased antioxidant power of polyphenols, increase in reducing sugar and formation of Maillard Reaction Products.

Blanching

Blanching is important for its desirable effects on certain food characteristics. It may be prudent to establish optimum conditions; for instance, blanching leafy vegetable dill at 90 °C for 30 s has been defined as optimal (Galoburda et al. 2012). Blanching time and temperature are the most important contributors to final product quality. Other contributing factors may include the physical and chemical properties of the vegetables being treated (Morales-Blancas et al. 2002). Reports have described the effects of routine and modified blanching methods on natural antioxidants. Zheng and Lee (2011) observed that microwave treatment is useful for stabilizing vitamin C and inactivating peroxidase catalysis before the blanching of green asparagus, thus influencing the quality of the blanched product. Olivera et al. (2008) observed that microwave treatment and blanching maintained and improved antiradical activity in Brussels sprouts.

Amin et al. (2006) reported that less intensive aquathermal processing of leafy vegetables, such as blanching, can cause a 50% decrease in antioxidant content, whereas boiling for 15 min causes an 82% antioxidant loss into the water. The ascorbic acid content of carrots, broccoli, and green beans declines after steam blanching and storage at 20 °C for up to a year. Most of this loss occurs during blanching, not storage.

Mechanical food processing

Common mechanical processes include chopping, trimming, peeling, crushing, slicing, sieving, and pressing. These processes have various effects on the content, availability, and activity of bioactives (Nicoli et al. 1999). Major flavonoid losses can occur during preparation when parts of fruits and vegetables are removed. Onion peeling and trimming cause a 39% loss in flavonoids (Ewald et al. 1999); the chopping and slicing of asparagus cause an 18.5% decrease in rutin content (Makris and Rossiter 2001). The peeling and dicing of tomato also causes losses of certain bioactives (Valverdú-Queralt et al. 2011). Polyphenolic compounds, which account for most of the antioxidant activity of apples, are distributed in the peel, flesh, and seed. During juice production, most of these apple polyphenols are removed. Clarification is the step at which most antioxidants are lost from the final product (Candrawinata et al. 2012). The clarification of apple juice significantly reduces polyphenolic content, as these compounds are mainly present in the pulp (Candrawinata et al. 2012).

Proper strategies must be formulated to improve the mechanical processing of fruits and vegetables to minimize antioxidant compound losses in final products. The peels and seeds of fruits such as grapes are rich sources of important bioactive compounds, including phenolics, triterpenoids (Boekel et al. 2010).

Conclusion

Various conventional processing methods have significant effects on natural antioxidants present in fruits and vegetables. Thermal processing procedures such as roasting, boiling, blanching, drying, and pasteurization can be detrimental to bioactive compounds. The deleterious effects of heat are more prominent in colored foods formulated using fruits or vegetables that contain antioxidant pigments such as anthocyanins. However, some studies have found that thermal damage to bioactive compounds does not reduce the overall antioxidant characteristics of food products. Nonthermal procedures (UV, PEF, HHP, irradiation and comibined non thermal methods) do not significantly deteriorate important health-promoting phytochemicals and in some cases may improve their activity and availability. Moreover, these techniques provide promising alternative to thermal processing, which is commonly used for microbial and enzyme inactivation in foods despite of its largely negative effects on bioactive compounds and undesirable changes to the sensory and nutritional characteristics of foods. Therefore, optimal processing methods should be selected to ensure the antioxidant quality of fresh fruits and vegetables and their products in order to achieve not only the desired objectives of a food processing method, but also preserve the activity and quality of natural health-promoting constituents or bioactive compounds. The careful selection of suitable food-handling methods from farm to consumer for each type of product can ensure that the health-related benefits of specific phytochemicals are maximized.

References

Abid M, Jabbar S, Hu B, Hashim MM, Wu T, Wu Z, Khan MA, Zeng X (2014) Synergistic impact of sonication and high hydrostatic pressure on microbial and enzymatic inactivation of apple juice. LWT Food Sci Technol 59:70–76

Agcam E, Akyildiz A, Evrendilek GA (2014) Comparison of phenolic compounds of orange juice processed by pulsed electric fields (PEF) and conventional thermal pasteurization. Food Chem 143:354–361

Alothman MR, Bhat KA (2009) Effects of radiation processing on phytochemicals and antioxidants in plant produce. Trends Food Sci Technol 20:201–212

Amin I, Norazaidah Y, Hainida KIE (2006) Antioxidant activity and phenolic content of raw and blanched Amaranthus species. Food Chem 94:47–52

Arena E, Fallico B, Maccarone E (2001) Evaluation of antioxidant capacity of blood orange juices as influenced by constituents, concentration process and storage. Food Chem 74:423–427

Artés-Hernández F, Robles AA, Gómez PA, Tomás-Callejas A, Artés F (2010) Low UV-C illumination for keeping overall quality of fresh-cut watermelon. Postharvest Biol Technol 55:114–120

Barba FJ, Jäger H, Meneses N, Esteve MJ, Frígola A, Knorr D (2012) Evaluation of quality changes of blueberry juice during refrigerated storage after high-pressure and pulsed electric fields processing. Innov Food Sci Emerg Technol 14:18–24

Bhat R, Sridhar KR, Bhushan B (2007) Free radicals in velvet bean seeds (Mucuna pruriens L. DC.) and their status after gamma-irradiation and conventional processing. LWT Food Sci Technol 40:1570–1577

Boekel MV, Fogliano V, Pellegrini N, Stanton C, Scholz G, Lalljie S, Somoza V, Knorr D, Jasti PR, Eisenbrand G (2010) A review on the beneficial aspects of food processing. Mol Nutr Food Res 54:1215–1247

Candrawinata VI, Blades BL, Golding JB, Stathopoulos CE, Roach PD (2012) Effect of clarification on the polyphenolic compound content and antioxidant activity of commercial apple juices. Int Food Res J 19:1055–1061

Chandrasekara N, Shahidi F (2011) Effect of roasting on phenolic content and antioxidant activities of whole cashew nuts, kernels, and testa. J Agric Food Chem 59:5006–5014

Chawla R, Patil GR, Singh AK (2011) High hydrostatic pressure technology in dairy processing: a review. J Food Sci Technol 48(3):260–268

Chen BH, Peng HY, Chen HF (1995) Changes of carotenoids colour and vitamin A contents during processing of carrot juice. J Agric Food Chem 43:1912–1918

Chen J, Shi J, Xue SJ, Ma Y (2009) Comparison of lycopene stability in water and oil-based food model systems under thermal- and light-irradiation treatments. LWT Food Sci Technol 42:740–747

Chen ML, Yang DJ, Liu SC (2011) Effects of drying temperature on the flavonoid, phenolic acid and antioxidative capacities of the methanol extract of citrus fruit [Citrus sinensis (L.) Osbeck] peels. Int J Food Sci Technol 46:1179–1185

Chipurura BM, Muchuweti MF (2010) Effects of thermal treatment on the phenolics content and antioxidant activity of some vegetables. Asian J Clin Nutr 2:93–100

Chu Y, Chang C, Hsu H (2000) Flavonoid content of several vegetables and their antioxidant activity. J Sci Food Agric 80:561–566

Darfour B, Agbenyegah S, Ofosu DO, Okyere AA, Asare IK (2014) Gamma irradiation of Tetrapleura tetraptera fruit as a post-harvest technique and its subsequent effect on some phytochemicals, free scavenging activity and physicochemical properties. Radiat Phys Chem 102:153–158

Elez-Martínez P, Martín-Belloso O (2007) Effects of high intensity pulsed electric field processing conditions on vitamin C and antioxidant capacity of orange juice and gazpacho, acold vegetable soup. Food Chem 102:201–209

Ewald C, Fjelkner-Moding S, Johansson K, Sjoholm I, Akesson B (1999) Effect of processing on major flavonoids processed onions, green beans, and peas. Food Chem 64:231–235

Fanaro GB, Hassimotto NMA, Bastos DHM, Villavicencio ALCH (2014) Effects of γ-radiation on microbial load and antioxidant proprieties in black tea irradiated with different water activities. Radiat Phys Chem 97:217–222

Feng M, Ghafoor K, Seo B, Yang K, Park J (2013) Effects of ultraviolet-C treatment in Teflon®- oil on microbial populations and physico-chemical characteristics of watermelon juice. Innov Food Sci Emerg Technol 19:133–139

Fernandez-Garcia A, Butz P, Tauscher B (2000) Does the antioxidant potential of high pressure treated apple juice change during storage? High Press Res 19:543–550

Gallego-Juárez JA (2001) High power ultrasound. Wiley, London

Galoburda R, Kruma Z, Ruse K (2012) Effect of pretreatment method on the content of phenolic compounds, vitamin C and antioxidant activity of dried dill. World Acad Sci Eng Technol 64:1075–1081

Goh SG, Noranizan M, Leong CM, Sew CC, Sobhi B (2012) Effect of thermal and ultraviolet treatments on the stability of antioxidant compounds in single strength pineapple juice throughout refrigerated storage. Int Food Res J 19:1131–1136

Goula AM, Adamopoulos KG, Chatzitakis PC, Nikas VA (2006) Prediction of lycopene degradation durin a drying process of tomato pulp. J Food Eng 74:37–46

Horvathova J, Suhaj M, Simko P (2007) Effect of thermal treatment and storage on antioxidant activity of some spicies. J Food Nutr Res 46:20–27

Huang W, Bi X, Zhang X, Liao X, Hu X, Wu J (2013) Comparative study of enzymes, phenolics, carotenoids and color of apricot nectars treated by high hydrostatic pressure and high temperature short time. Innov Food Sci Emerg Technol 18:74–82

Hunter KJ, Fletcher JM (2002) The antioxidant activity and composition of fresh, frozen, jarred and canned vegetables. Innov Food Sci Emerg Technol 3: 399–406

Hussain PR, Chatterjee S, Variyar PS, Sharma A, Dar MA, Wani AM (2013) Bioactive compounds and antioxidant activity of gamma irradiated sun dried apricots (Prunus armeniaca L.). J Food Compos Anal 30:59–66

Ismail A, Marjan ZM, Foong CW (2004) Total antioxidant activity and phenolic content in selected vegetables. Food Chem 87:581–586

Keenan DF, Brunton N, Gormley R, Butler F (2011) Effects of thermal and high hydrostatic pressure processing and storage on the content of polyphenols and some quality attributes of fruit smoothies. J Agric Food Chem 59:601–607

Kim D, Han DG (2012) High hydrostatic pressure treatment combined with enzymes increases the extractability and bioactivity of fermented rice bran. Innov Food Sci Emerg Technol 16:191–197

Kumari N, Kumar P, Mitra D, Prasad B, Tiwary BN, Varshney L (2009) Effects of ionizing radiation on microbial decontamination, phenolic contents, and antioxidant properties of triphala. J Food Sci 74:M109–M113

Liu LH, Zabaras D, Bennett LE, Aguas P, Woonton BW (2009) Effects of UV-C, red light and sun light on the carotenoid content and physical qualities of tomatoes during post-harvest storage. Food Chem 115:495–500

Madrau MA, Piscopo A, Sanguinetti AM, Del Caro A, Poiana M, Romeo FV, Piga A (2009) Effect of drying temperature on polyphenolic content and antioxidant activity of apricots. Europ Food Res Technol 228:441–448

Makris DP, Rossiter JT (2001) Domestic processing of onion bulbs (Allium cepa) and asparagus spears (Asparagus officinalis): effect of flavonol content and antioxidant status. J Agric Food Chem 49:3216–3222

Mali A, Khedkar K, Lele S (2012) Effect of gamma irradiation on total phenolic content and in vitro antioxidant activity of pomegranate (Punica granatum L.) peels. Food Nutr Sci 2:428–433

Manzocco L, Anese M, Nicoli MC (1998) Antioxidant properties of tea extracts as affected by processing. LWT Food Sci Technol 31:694–698

McDonald H, Arpaia ML, Caporaso F, Obenland D, Were L, Rakovski C, Prakash A (2013) Effect of gamma irradiation treatment at phytosanitary dose levels on the quality of ‘Lane Late’ navel oranges. Postharvest Biol Technol 86:91–99

McInerney JK, Seccafien CA, Stewrt CM, Bird AR (2007) Effects of high pressure processing on antioxidant activity, and total carotenoid content and availability, in vegetables. Innov Food Sci Emerg Technol 8:543–548

Morales-Blancas EF, Chandia VE, Cisneros-Zevallos L (2002) Thermal inactivation kinetics of peroxidase and lipoxygenase from broccoli, gren asparagus and carrots. J Food Sci 67:146–154

Morton LW, Caccetta RA, Puddey IB, Croft KD (2000) Chemistry and biological effects of dietary phenolic compounds: relevance to cardiovascular disease. Clin Exp Pharmacol Physiol 27:152–159

Nicoli MC, Anese M, Parpinel MT, Franceschi S, Lerici CR (1997) Loss and/or formation of antioxidants during food processing and storage. Cancer Lett 114:71–74

Nicoli MC, Anese M, Parpinel M (1999) Influence of processing on the antioxidant properties of fruit and vegetables. Trends Food Sci Technol 10:94–100

Noranizan M, Benchamaporn P (2007) Potential of nonthermal processing for food preservation in Southeast Asian Countries. ASEAN Food J 14:141–152

Odriozola-Serrano I, Soliva-Fortuny R, Martın-Belloso O (2008) Phenolic acids, flavonoids, vitamin C and antioxidant capacity of strawberry juices processed by high-intensity pulsed electric fields or heat treatments. Europ Food Res Technol 228:239–248

Oey I, Plancken IV, Loey AV, Hendrickx M (2008) Does high pressure processing influence nutritional aspects of plant based food systems? Trends Food Sci Technol 19:300–308

Olivera DF, Vina SZ, Marani CM, Ferreyra RM, Mugridge A, Chaves AR, Mascheroni RH (2008) Effect of blanching on the quality of Brussels sprouts (Brassica oleracea L. gemmifera DC) after frozen storage. J Food Eng 84:148–155

Oms-Oliu G, Odriozola-Serrano I, Soliva-Fortuny R, Martin-Belloso O (1993) Effect of high- intensity pulsed electric field processing condition on lycopene, vitamin C and antioxidant capacity of watermelon juice. Food Chem 115:1312–1319

Oms-Oliu G, Odriozola-Serrano I, Soliva-Fortuny R, Elez-MartInez P, Martin-Belloso O (2012) Stability of health-related compounds in plant foods through the application of non thermal processes. Trends Food Sci Technol 23:111–123

Pan J, Vicente AR, Martinez GA, Chaves AR, Civello PM (2004) Combined use of UV-C irradiation and heat treatment to improve postharvest life of strawberry fruit. J Sci Food Agric 84:1831–1838

Parmar N, Singh N, Kaur A, Virdi AS, Thakur S (2016) Effect of canning on color, protein and phenolic profile of grains from kidney bean, field pea and chickpea. Food Res Int 89:526–532

Patras A, Brunton N, Da Pieve S, Butler F, Downey G (2008) Effect of high pressure processing on antioxidant activity and instrumental colour of tomato and carrot purees. Innov Food Sci Emerg Technol 10:16–22

Polydera AC, Nikolaos GS, Taoukis PS (2004) The effect of storage on the antioxidant activity of reconstituted orange juice which had been pasteurized by high pressure or heat. Int J Food Sci Technol 39:783–791

Que F, Mao L, Fang X, Wu T (2008) Comparison of hot air drying and freeze-drying on the physicochemical properties and antioxidant activities of pumpkin (Cucurbita moschata Duch) flours. Int J Food Sci Technol 43:1195–1201

Ranilla LG, Genovese MI, Lajolo FM (2009) Effect of different cooking conditions on phenolic compounds and antioxidant capacity of some selected Brazilian bean (Pheselous vulgaris L.) cultivars. J Agric Food Chem 57:5734–5742

Rastogi NK, Raghavarao KS, Balasubramaniam VM, Niranjan K, Knorr D (2007) Opportunities and challenges in high pressure processing of foods. Crit Rev Food Sci Nutr 47:69–112

Sahlin E, Savage GP, Lister CE (2004) Investigation of the antioxidant properties of tomatoes after processing. J Food Compos Anal 17:635–647

Salem IB, Fekih F, Sghaier H, Bousselmi M, Saidi M, Landoulsi A, Fattouch S (2013) Effect of ionising radiation on polyphenolic content and antioxidant potential of parathion-treated sage (Salvia officinalis) leaves. Food Chem 141:1398–1405

Santhirasegaram V, Razali Z, George DS, Somasundram C (2015) Effects of thermal and non- thermal processing on phenolic compounds, antioxidant activity and sensory attributes of chokanan mango (Mangifera indica L.) juice. Food Bioprocess Technol 8:2256–2267

Scattino C, Castagna A, Neugart S, Chan HM, Schreiner M, Crisosto CH, Tonutti T, Ranieri A (2014) Post-harvest UV-B irradiation induces changes of phenol contents and corresponding biosynthetic gene expression in peaches and nectarines. Food Chem 163:51–60

Shahidi F, Ho C (2005) Phenolics in food and natural health products: an overview. ACS Symp Ser 909:1–8

Sharma P, Gujral HS (2011) Effect of sand roasting and microwave cooking on antioxidant activity of barley. Food Res Int 44:235–240

Song HP, Kim DH, Jo C, Lee CH, Kim KS, Byun MW (2006) Effects of gamma irradiation on the microbiological quality and antioxidant activity of fresh vegetable juice. Food Microbiol 23:372–378

Turk MF, Vorobiev E, Baron A (2012) Improving apple juice expression and quality by pulsed electric fieldon an industrial scale. LWT Food Sci Technol 49:245–250

Valverdú-Queralt A, Medina-Remón A, Andres-Lacueva C, Lamuela-Raventos RM (2011) Changes in phenolic profile and antioxidant activity during production of diced tomatoes. Food Chem 126:1700–1707

Variyer P, Bandyopadhyay C, Thomas P (1998) Effect of gamma irradiation on the phenolic acids of some Indian spices. Int J Food Sci Technol 33:533–537

Vega-Gálvez A, López J, Torres-Ossandón MJ, Galotto MJ, Puente-Díaz L, Quispe-Fuentes I, Scala KD (2014) High hydrostatic pressure effect on chemical composition, color, phenolic acids and antioxidant capacity of Cape gooseberry pulp (Physalis peruviana L.). LWT Food Sci Technol 58:519–526

Wanyo P, Meeso N, Siriamornpun S (2014) Effects of different treatments on the antioxidant properties and phenolic compounds of rice bran and rice husk. Food Chem 157:457–463

Williamson G, Day AJ, Plumb GW, Couteau D (2000) Human metabolic pathways of dietary flavonoids and cinnamates. Biochem Soc Trans 28:16–22

Zhang D, Hamauzu Y (2004) Phenolics, ascorbic acid, carotenoids and antioxidant activity of broccoli and their changes during conventional and microwave cooking. Food Chem 88:503–509

Zhang M, Hettiarachchy NS, Horax R, Chen P, Over KF (2009) Effect of maturity stages and drying methods onthe retention of selected nutrients and phytochemicals in bittermelon (Momordica charantia) leaf. J Food Sci 74(6):C441–C446

Zhang M, Chen H, Li J, Pei Y, Liang Y (2010) Antioxidant properties of tartary buckwheat extracts as affected by different thermal processing methods. LWT Food Sci Technol 43:181–185

Zheng H, Lee H (2011) Effect of microwave pretreatment on the kinetics of ascorbic acid degradation and peroxidase inactivation in different parts of green asparagus (Asparagus officinalis L.) during water blanching. Food Chem 128:1087–1093

Zielinski H, Mishalska A, Amigo-Benavent M, Del Castillo MD, Piskula MK (2009) Changes in protein quality and antioxidant properties of buckwheat seeds and groats induced by roasting. J Agric Food Chem 57:4771–4777

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Al-juhaimi, F., Ghafoor, K., Özcan, M.M. et al. Effect of various food processing and handling methods on preservation of natural antioxidants in fruits and vegetables. J Food Sci Technol 55, 3872–3880 (2018). https://doi.org/10.1007/s13197-018-3370-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3370-0