Abstract

This study validated high hydrostatic pressure processing (HPP) for achieving greater than 5-log reductions of Escherichia coli O157:H7 in carambola juice and determined shelf life of processed juice stored at 4 °C. Carambola juice processed at 600 MPa for 150 s was identified capable of achieving greater than 5.15-log reductions of E. coli O157:H7, and the quality was compared with that of high temperature short time (HTST)-pasteurized juice at 110 °C for 8.6 s. Aerobic, psychrotrophic, E. coli/coliform, and yeasts and moulds in the juice were reduced by HPP or HTST to levels below the minimum detection limit (< 1.0 log CFU/mL), and showed no outgrowth after refrigerated storage of 40 days. There were no significant differences in pH and titratable acidity between the untreated, HPP, and HTST juices. However, HTST treatment significantly changed the color of juice, while no significant difference was observed between the control and HPP samples. HPP and HTST treatments reduced the total soluble solids in the juice, but maintained higher sucrose, glucose, fructose, and total sugar contents than untreated juice. The total phenolic and ascorbic acid contents were higher in juice treated with HPP than untreated and HTST juice, but there was no significant difference in the flavonoid content. Aroma score analysis showed that HPP had no effect on aroma, maintaining the highest score during cold storage. The results of this study suggest that appropriate HPP conditions can achieve the same microbial safety as HTST, while maintaining the quality and extending the shelf life of carambola juice.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High-pressure processing (HPP) is a food processing technology that inactivates microorganisms and enzymes in foods sealed in soft packaging material under 100–600 MPa of pressure at room temperature. HPP technology is a purely physical, non-thermal process and is significantly superior to conventional high temperature short time (HTST) thermal processing, as it enables the instant compression of the liquid medium, meaning that the food is uniformly subjected to pressure treatment, with short pasteurization time and low energy consumption (Rendueles et al. 2011). HPP can improve food safety by inactivating microorganisms causing food spoilage, increasing the shelf life of food products without affecting their sensory properties (Demazeau and Rivalain 2011). Advances in the development of HPP equipment have enabled their use in many countries, including the United States, Spain, the United Kingdom, Japan, and China. Currently, there are over 300 commercial HPP equipment units in use worldwide. In developed countries, HPP has been used to produce a variety of food products, such as meat, seafood, and fruit and vegetable products (Huang et al. 2017). In the pasteurization of fruit juice, HPP achieves comparable microbial safety to HTST, and many studies have demonstrated that HPP does not affect the nutritional composition and flavour of fruit juice, nor does it destroy its functional components. Heat-sensitive fruit juices such as mango, pineapple, watermelon, grape, berry, and coconut retain the same taste as fresh fruit juice after processing by HPP pasteurization, with extended shelf lives (Wang et al. 2016).

Carambola is a popular tropical fruit belonging to the Oxalidaceae family. The fruit is star-shaped, and is therefore popularly known as starfruit. The immature fruit is green and has a solid and hard texture. After maturation, it softens and has a golden yellow appearance. Carambola is widely cultivated in Southeast Asia, China, and the Indian subcontinent. Various components, including the fruit, roots, leaves, and flowers, are regarded as medicinal, and have beneficial effects for headache, nausea, diarrhoea, vomiting, cough, high blood sugar, type 2 diabetes, and inflammatory symptoms (Saghir et al. 2013). Mature carambola fruit can be eaten fresh or used in the preparation of fruit salads or jellies, candied fruits, and canned foods because of its distinct acidity and sweet flavour. Leelarungrayub et al. (2016) reported that after 4 weeks of continuous carambola juice consumption, pro-inflammatory indicators such as tumour necrosis factor-α (TNF-α), nitric oxide (NO), and interleukin (IL)-23 were inhibited. However, in contrast to many other fruit juices, which can be squeezed from the fruit and drank immediately, carambola juice is fermented, and requires the use of a salt-marinated mariculture for natural fermentation. Usually, fermentation and maturation take 1–3 months. However, because of the variable quality of natural fermentation, many studies have been conducted using mixed yeast inoculation to control the aroma, taste, and fermentation time (Chen 2008). Therefore, after the completion of fermentation, carambola juice must be stored at low temperatures to prevent continued microbial fermentation.

Safer, healthier food containing fewer additives has consumer appeal. However, non-pasteurized fresh fruit juice has short storage time, and there are microbial contamination risks. Although heat pasteurization technology can ensure the microbial safety of the fruit, the original natural flavor and nutrients can be lost in the process. In contrast, high-pressure pasteurized juice can retain its original flavor, color, aroma, and nutrient content, and can also inhibit enzyme activity, which can degrade product quality, while achieving the same level of food safety as pasteurization. Indicator microorganisms have different pressure resistances in different food environments, and inappropriate pressure treatment conditions not only fail to inhibit the growth of microorganisms, but may lead to unexpected food safety issues. Therefore, selection of the appropriate indicator bacteria based on the characteristics of the food product, and understanding its pressure resistance in different foods is a core factor in HPP (Sevenich et al. 2016). Boynton et al. (2002) used high-pressure treatment to maintain the quality of sliced carambola; however, there are no reports of the use of HPP for carambola juice pasteurization. In this study, carambola juice was subjected to HPP treatment, and the processing parameters were optimized to achieve a 5 log value reduction of the indicator bacteria Escherichia coli O157:H7. Pasteurization was evaluated and compared with traditional HTST pasteurization. The effects of the two pasteurization methods on the composition, physicochemical properties, carbohydrate contents, antioxidant content, and aroma of the juice were observed. In addition to maintaining the flavor of the carambola juice, non-heated pasteurization achieved the microbiological safety requirements of fruit juice, as defined by hazard analysis and critical control point (HACCP).

Materials and methods

Bacterial culture inoculum

Carambola juice was purchased from a traditional market in Taipei, Taiwan. A bacterial strain of E. coli O157:H7 was obtained from the Bioresource Collection and Research Center, Taiwan (BCRC No. 14824). The strain was cultured in nutrient broth (with 0.5% NaCl) at 37 °C until the stationary phase. The bacterial cells were harvested by centrifugation (10 min at 3000×g) and washed once in phosphate-buffered saline (PBS; 0.01 M phosphate, 0.137 M NaCl, pH 7.3). The cells were resuspended in 50 mL of carambola juice at a concentration of approximately 1 × 108 CFU/mL, and sealed in a sterile vacuum bag with a vacuum packaging machine. Samples used in all tests contained freshly prepared bacterial cultures obtained using identical procedures.

HPP treatment of carambola juice

The experimental high-pressure apparatus used in this study had an internal capacity of 6.2 L with a maximal operational pressure of 600 MPa (Bao Tou KeFa High Pressure Technology Co. Ltd, Baotou, China). Sealed packages of juice samples containing approximately 1 × 108 CFU/mL E. coli O157:H7 were placed in the high-pressure chamber and treated with 600 MPa of pressure for 30, 60, 90, 120, 150, 180, 210, and 240 s at 10 °C. The apparatus used water as the pressure-transmitting medium with a pressure increase rate of approximately 150 MPa/min and a pressure release time of ≤ 10 s after the completion of HPP treatment. During pressure treatment, the operating temperature increased by 3 °C/100 MPa. HPP samples were stored in an ice bath until further analyses were conducted.

Validation of HPP and HTST treatment of carambola juice

The minimum HPP required to produce a > 5 log value reduction of E. coli O157:H7 in carambola juice (600 MPa at 10 °C for 150 s) was selected to verify the efficacy of the process according to the HPP verification responsibilities of the United States Department of Agriculture (USDA). Fresh carambola juice was vacuum-packed in sterile polyethylene bags and treated by HPP at 600 MPa for 30–210 s and HTST at 110 °C for 8.6 s. After HPP or HTST treatment, samples were refrigerated and stored at 4 °C for the shelf life study, and sampled once every 10 days for 40 days to determine changes in overall qualities.

Microbiological analysis

The levels of total aerobic, psychrotrophic, and E. coli/coliform bacteria, as well as yeast and mould (Y&M) in carambola juice were measured using Petrifilm Rapid Count Plates (3 M Corp., St. Paul, MN, USA). After serial dilution in 0.1% buffered peptone water (BD, Franklin Lake, USA), samples were immediately plated on the Petrifilm™ Aerobic Count Plate and incubated at 30 °C for 24 h and 10 °C for 5 days for aerobic and psychrotrophic bacterial counts, respectively; the Petrifilm™ E. coli/Coliform Count Plates was incubated at 37 °C for 48 h; and the Petrifilm™ Yeast and Mold Count Plates was incubated at 25 °C for 5 days. At the end of incubation, plates containing 25–250 colonies were selected and the number of colonies was recorded. The minimum detection level was 1 colony forming unit (CFU)/mL.

Physicochemical analysis

The pH of the juice was measured using a JENCO 6173 pH meter (JENCO Quality Instruments, San Diego, CA) at 25 °C. Titratable acidity was determined according to the Association of Official Analytical Chemists (AOAC 1990). All color measurements were performed using a Hunter Lab Labscan spectrophotometer (CR-200; Minolta, Tokyo, Japan). Color was expressed as L*, a*, and b* values. Sample measurements were repeated three times to calculate the mean values. The total color difference (ΔE) was calculated using the following formula: ΔE = [(a* − a0)2 + (b* − b0)2 + (L* − L0)2]0.5, where L0, a0, and b0 represent the values of unprocessed juice.

Sugar analysis

Total soluble solids (TSS; in °Brix (°Bx)) were measured using a handheld refractometer (Master Refractometer, ATAGO Co., Ltd., Tokyo, Japan). Sucrose, fructose, and glucose contents were analysed by HPLC according to Andrés et al. (2016). An evaporative light scattering detector (HPLC/ELSD) was used. Sugar samples and standards were dissolved in 50% ethanol. The mobile phase solution was 82:18 acetonitrile:ultrapure water (v/v), which was filtered through a membrane with a 0.45 μm pore size, and ultrasonically degassed before use. Sugar standard solutions were 1.0% glucose, fructose, and sucrose, and the internal standard was 10% xylose. To prepare the sugar standard mixture, 0.5 g of glucose, fructose, and sucrose were carefully weighed and completely dissolved in 50% ethanol in a 50 mL volumetric flask, and then the final volume was adjusted to 50 mL. The chromatographic column used was a Waters Xbridge Amide 3.5 µm (internal diameter: 4.6 mm × 150 mm), and the flow rate was 1.0 mL/min. The retention time and peak area of each sugar in carambola juice were compared with the sugar standards.

Aroma analysis

Aroma was evaluated by 20 trained panellists by opening the containers and sniffing the headspace, according to the method described by Fan et al. (2008). In bief, approximately 5 mL of treated or untreated juice samples were placed in two paper soufflé cups, which were placed in the refrigerator at 4 °C for 30 min. Duplicate samples were tested in each of three replicates. The aroma scale was set as:

-

9 = strong, characteristic cantaloupe-like aroma.

-

7 = pleasant, mild cantaloupe aroma, slightly “flat”;

-

5 = bland, faint cantaloupe odour, detectable off-odour;

-

3 = mild sour or other off-odours;

-

1 = distinct, strong off-odour, fermented-like.

Antioxidant content analysis

Gallic acid standards and samples (0.2 mL) were mixed with 1 mL of Folin–Ciocalteu reagent and 0.8 mL of Na2CO3 (7. 5%), mixed well, and let stand for 30 min, followed by spectrophotometric measurement of absorbance at 760 nm. The total phenolic content was calculated based on a standard curve of gallic acid. Results are presented as gallic acid equivalents (GAE) per 100 mL of juice sample (Taga et al. 1984). To measure flavonoid content, samples (0.5 mL), 1.5 mL of ethanol, 0.1 mL of 10% Al(NO3)3, 0.1 mL of 1 M CH3COOK, and 2.8 mL of H2O were mixed well and allowed to stand at 25 °C for 40 min. The absorbance at 415 nm was measured using a spectrophotometer. The flavonoid content was calculated based on the standard curve of quercetin (QE) per 100 mL of juice sample (Jia et al. 1999). Ascorbic acid (vitamin C) content was determined based on the 2,6-dichloroindophenol titrimetric method (AOAC 1995). Results were expressed as mg ascorbic acid per 100 mL sample and the results were calculated using the following equation: Ascorbic acid (mg/100 mL) = (titre × dye factor × concentration × 100) / (aliquot used for estimation × volume of sample used for estimation).

Statistical analysis

Data in this study represent the results of three independent replicates. Data processing and statistical analysis were performed using the Statistical Analysis System (SAS) statistical software suite (STATISTICA 1999 edition, StatSoft Co., Tulsa, OK, USA). One-way analysis of variance was performed and differences between groups were compared using Duncan’s multiple range method. Results were considered statistically significant at P < 0.05.

Result and discussion

Effects of HPP on the inactivation of E. coli O157:H7 in carambola juice

E. coli O157:H7 was inoculated in carambola juice, and various high-pressure treatments were performed. HPP for 30, 60, 90, and 120 s reduced the bacterial count by 1.22, 2.15, 3.2, and 4.39 log CFU/mL, respectively (Table 1). The amount of surviving bacteria decreased with increased treatment time. The bacterial count was reduced by more than 5 log CFU/mL with 150 s of processing time or more, suggesting that a treatment with 600 MPa at 10 °C for at least 150 s is needed to adequately reduce the bacterial count in carambola juice. According to the fruit juice hazard analysis and safety control point specifications from the US Food and Drug Administration (FDA), the pasteurization technology used requires a key control point where the pasteurization process is able to reduce the indicator pathogenic bacteria by five log values, to avoid health and safety concerns (FDA 2001). The Food Safety and Inspection Service of USDA also recommends that appropriate food indicator bacteria be selected for high-pressure pasteurized products. An HPP process that achieves a 5-log E. coli O157:H7 reduction should be sufficient for product produced under good manufacturing practices (USDA 2012). Pathanibul et al. (2009) studied the kinetics of E. coli and Listeria innocua to achieve a 5D-reduction in apple and carrot juices. Their results demonstrated that a 5-log reduction in E. coli could only be accomplished at pressures greater than 250 MPa and inactivation of L. innocua required greater than 300 MPa. Avocado products are pasteurized using HPP and a 5-log reduction of bacteria in guacamole can be achieved when pasteurized at a pressure of at least 500–600 MPa for more than 2 min (Tonello 2011).

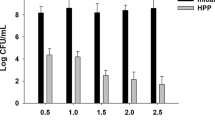

Changes of microbial counts in HPP and HTST juice during storage

Table 2 shows the variation in the total bacterial counts in carambola juice after cold storage for 40 days after treatment of 600 MPa at 10 °C for 150 s and after HTST treatment at 110 °C. The initial bacterial count in the fresh carambola juice was 6.2–6.5 log CFU/mL. After 40 days of cold storage, the bacterial count increased to 7.1 log CFU/mL. After 600 MPa pressure treatment, the total bacterial count was reduced to below 1.0 log CFU/mL. In comparison, HTST processing completely inhibited bacterial growth after 40 days. The psychrotrophic count was below the detection limit after both HPP and HTST processing, and did not increase significantly in the control group during the 40 days of cold storage, indicating that psychrotrophic growth was completely inhibited by both HPP and HTST. The E. coli/coliform and Y&M results showed similar trends to the psychrotrophic bacteria. In untreated carambola juice, there were 2.1 and 5.3 log CFU/mL of coliforms and Y&M, respectively. HPP was effective in reducing coliform and Y&M counts, and maintained similar microbial results during the 40-days cold storage period compared to HTST. Houška et al. (2006) pointed out that although the compositions of various fruits require different high-pressure pasteurization conditions, for fruit juice in general, achieving a reduction in coliforms, yeast, moulds, Salmonella, and other microorganisms of more than five log values requires processing for at least 500 MPa for 10 min to maintain optimal quality for 30 days at 4 °C. Varela-Santos et al. (2012) reported that after 350 MPa processing for 150 s, the total bacterial count in pomegranate juice was reduced by 4 log values, and the shelf life at 4 °C was extended to 35 days. In contrast, the bacterial count in the untreated fruit juice reached more than 105 after 10 days. Bull et al. (2005) used pressure-resistant Salmonella as an indicator to determine the pasteurization conditions for navel orange juice. The results indicated that to achieve a five log value reduction in the Salmonella count, the juice required processing at 20 °C under 300, 450, and 600 MPa for 198, 19, and 5 s, respectively. When the treatment pressure exceeded 400 MPa, Salmonella became sensitive to the acidic environment and died easily. Pathanibul et al. (2009) studied the 5-dimensional kinetic parameters of E. coli and Listeria innocua in apple and carrot juices. For E. coli, a pressure of at least 250 MPa was needed to achieve a 5 log value reduction, while for L. innocua, at least 300 MPa was needed. Avocado is the most common product pasteurized by HPP, and to achieve a 5 log value reduction in avocado juice bacterial count, at least 500–600 MPa treatment for more than 2 min was required (Tonello 2011).

Physicochemical characterizations

Table 3 shows the effects of HPP and HTST treatments on the pH, titratable acidity, and color of the carambola juice. The pH of the fresh carambola juice was 3.5, and neither treatment caused significant changes. During cold storage, the control samples displayed microorganism growth due to lack of pasteurization. With increased bacterial count and metabolic acid production, the pH value was significantly (P < 0.05) reduced over time. In contrast, after 40 days of cold storage, carambola juice processed with HPP and HTST treatments maintained the initial pH value of fresh carambola juice. There was no significant difference between the titratable acidities of untreated, HPP-, and HTST-treated carambola juices. HPP treatment caused an immediate slight colour change, which was not visually perceivable. The ΔE value reached 3.22 after 14 days, and increased to 3.9 after 28 days. In contrast, the ΔE value of the HTST-treated sample reached 3.2 immediately, changing the color of the carambola juice. After 40 days, the ΔE value reached 13.4. Therefore, HPP showed no significant effects on juice color, while HTST significantly darkened the carambola juice.

As carambola juice is fermented, its processing involves the participation of a variety of microorganisms, including lactic acid bacteria, yeast, acetic acid bacteria, etc. After fermentation, the juice has a distinct aroma and taste, and contains higher live bacterial counts than fresh fruit juices. Therefore, carambola juice must be stored in refrigerated conditions to inhibit further microbial growth, as the continuation of fermentation will affect its flavor. Also, to maintain the flavor of fermented carambola juice, traditional heat pasteurization cannot be used. Bhat et al. (2011) performed UV radiation pasteurization, and found that after irradiation with ultraviolet radiation for 30 or 60 s, the total number of bacteria, yeast, and mold was reduced to ≤ 1 log, and the pH, degrees Brix (°Bx), and titratable acidity were not significantly changed. However, with < 60 s of irradiation, ΔE increased to 1.98, and the total phenolic and flavonol contents and antioxidant capacity increased significantly. Consequently, in this study, high-pressure pasteurization treatment was performed at 10 °C. This terminated microbial fermentation, avoiding effects on the flavor of the juice. Hence, optimal pasteurization quality in terms of both microbial safety and flavor was achieved. Peñas et al. (2010) documented the treatment of sauerkraut using 300 MP HPP, and found that the total bacteria and lactic acid bacteria in untreated sauerkraut continued to grow during cold storage, and the quality of the sauerkraut deteriorated. In contrast, sauerkraut processed by HPP after cold storage displayed inhibited bacterial growth and extended shelf life. Yi et al. (2017) found that heat pasteurization changed the color of apple juice, with a ΔE 2 − 8 times higher after HTST compared to HPP, but there were no significant differences in physicochemical properties such as titration acidity, pH, and TSS. Xu et al. (2015) compared the effects of HPP at 550 MPa for 5 min and HTST at 110 °C for 8.6 s on the quality of a pepper and orange juice blend. The results showed that both treatments could ensure biological safety, but changes in the color, rheological characteristics, cloudiness, stability, and total phenolic content of the HPP fruit juice were significantly smaller than those of HTST juice, and more closely resembled those of fresh juice. Similar results were observed during clear cucumber juice pasteurization. When cucumber juice was treated by HTST at 110 °C for 8.6 s, variations in ΔE with increased treatment time. After 20 days of cold storage, it reached 3 times that of high-pressure processed cucumber juice. There were no significant differences in clarity or in physicochemical properties including titratable acidity, pH, and TSS (Liu et al. 2016). Moussa-Ayoub et al. (2017) studied the effects of pulsed electric fields, high pressure, and heat pasteurization on the quality of cactus juice, and showed that pulsed electric field and HPP methods retained higher levels of ascorbic acid, while heat pasteurization resulted in a 26% reduction. HPP and heat treatment also increased the juice viscosity. Koutchma et al. (2016) documented the use of high-pressure pasteurization conditions to reduce the pathogen count of fruit juice by 5 log values, which did not significantly affect the color of the fruit juice. Only watermelon and orange juices had ΔE values higher than 8 after HPP.

Sugar contents

Table 4 shows the TSS results and the concentrations of various carbohydrates in carambola juice. In the TSS analysis, it was found that both HPP and HTST slightly reduced the TSS content of carambola juice. Fresh carambola juice had a TSS content of 10.1oBx, while HPP reduced it to 9.7 °Bx, and during cold storage it gradually reduced to 9.1 °Bx. Heat treatment showed the same trend, reducing TSS content to 9.4 °Bx with further reduction to 9.3 °Bx after 40 days. Different proportions of sugar contents will affect the flavor and taste of carambola juice. In the unpasteurized juice, the growth of microorganisms, which require sugar as a nutrient source, continued, and not surprisingly, the glucose, fructose and total sugar contents decreased. Immediately after treatment, there were no significant differences in the concentrations of various carbohydrates in the three samples. After 40 days, the sucrose, glucose, fructose, and total sugar contents in the control group were reduced by 16.6, 25, 13.5, and 17%, respectively, while in the HPP group, these values were decreased by only 12.5, 8.3, 6.25, and 5.6%, respectively. The results showed that HPP indirectly maintained the original carbohydrate content by inhibiting the growth of microorganisms. There were no significant differences in the sugar contents of the HTST- and HPP-treated carambola juices. This result consistent with a report by Andrés et al. (2016), who found that the glucose, fructose, and lactose concentrations in milk- and soy-smoothies after 45 days of refrigeration did not significantly change after pasteurization at 450 MPa or more for 3 min. The glucose and fructose of unpasteurized milk- and soy-smoothies were significantly reduced, while the HTST-treated milk- and soy-smoothies were similar to the HPP-treated samples. Yi et al. (2017) found that after HPP at 600 MPa for 3 min and HTST at 85 °C for five min, there was no significant differences in total sugar, sucrose, glucose, and fructose content between pasteurized and unpasteurized apple juice samples.

Antioxidant properties

The total phenolic, flavonoid, and ascorbic acid contents of untreated carambola juice were 45.3 mg GAE/100 mL, 14.3 mg QE/100 mL, and 25.4 mg/100 mL, respectively, while for the HPP-treated carambola juice, the content was 46.2 mg GAE/100 mL, 14.8 mg QE/100 mL and 25.8 mg/100 mL, respectively (Fig. 1).

the contents of a total phenolics; b total flavonols; c ascrobic acid in the control, HPP and HTST carambola juice during storage at 4 °C for 40 days. Data are presented as mean ± SD (n = 3). Different lowercase letters above the bars of same concentration indicate significant differences among treatment means (P < 0.05)

We observed a slight decrease in the ascorbic acid content of carambola juice with increased storage time; however, this decrease was clearly observed in the HTST group on day 40. We also observed an increase in the flavonoid content of carambola juice treated by HPP with increase in storage time, which is similar to the trend shown by the total phenolic content. This indicates a higher antioxidant content in the HPP carambola juice than in untreated carambola juice; however, the differences were not significant. HTST treatment did not affect the total phenolic and flavonoid contents, but reduced the ascorbic acid content. During cold storage, the total phenol content of untreated carambola decreased by 2.6% after 40 days, but increased by 2.3 and 0.9%, respectively, in the HPP and HTST samples. The flavonoid content of untreated and HPP-treated carambola juice also increased slightly during cold storage, but was reduced by 3.5% in HTST-treated carambola juice. The ascorbic acid content was decreased in all samples. After 40 days, the HPP carambola juice had the highest ascorbic acid content, at 23.625 mg/100 mL, followed by untreated (22.9 mg/100 mL), and HTST (19.3 mg/100 mL) carambola juice. Pang et al. (2016) reported that carambola fruit is rich in vitamin C, oxalic acid, and phosphorous, and is a good source of antioxidants and nutrients. The total phenolic and flavonoid contents in the fruit are 174–293 mg gallic acid/100 g and 104–235 mg catechin/100 g. High-performance liquid chromatography (HPLC) analysis revealed that L-ascorbic acid, epicatechin, and gallic acid are the major antioxidants (Shui and Leong 2004). Similar results were observed in cactus juice, heat pasteurization reduced the vitamin C content, but there was no significant difference between the HPP and control groups, while total flavonoid content showed increases after both HPP and HTST treatment (Moussa-Ayoub et al. 2017). However, conflicting results were observed regarding the pasteurization of apple juice. Nayak et al. (2016) found that HPP increased the total phenolic content by 22.3%, but decreased the total flavonoid content by 35.7%, while having no significant influence on ascorbic acid content. In contrast, heat pasteurization under 80 °C for 60 s resulted in decreased total phenolic, flavonoid, and ascorbic acid content in apple juice during cold storage. Chen et al. (2015) found that higher treatment pressure could inhibit the growth of pathogenic bacteria, but at a pressure of 400 MPa or more reduced the total phenolic and ascorbic acid contents of asparagus juice; however, the levels were still higher than those in heat-pasteurized asparagus juice. High pressure and heat pasteurization both reduced the antioxidant capacity.

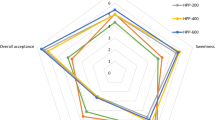

Aroma

The fruit of carambola were found to have C13- and C15-norisoprenoid volatile aroma substances, and variety volatile compounds were identified from fermented 60 days of carambola juice, including tetradecane, isoamyl alcohol, nonanol, nonanal, ethyl acetate, isoamyl acetate, ethyl hexanoate, ethyl heptanoate, ethyl octanoate, ethyl nonanoate, ethyl decanoate, ethyl dodecanoate, β-ionone (Tseng 2004). The fermented carambola juice has a distinct aroma, which is an important quality indicator. The aroma score of the fresh carambola sample was 8.5, but as the storage time increased, the aroma composition changed due to the actions of microorganisms. The aroma score gradually decreased to 6.8 after 40 days. HPP inhibits the growth of microorganisms; therefore, the aroma composition remained stable during the low temperature storage period. On day 0, the aroma scores before and after HPP were not different. Although a gradual decrease was observed during the cold storage period, after 40 days the aroma score was better than that of the untreated sample. In contrast, the aroma score reduced to 6.6 immediately after HTST treatment, indicating that heat treatment destroys the aromatic composition of carambola juice. However, during the cold storage period, the aroma score of heat-treated carambola juice decreased only slightly. Nayak et al. (2016) found that HPP apple juice odor during the cold storage was evaluated to be lower than that of heat-pasteurized apple juice. After 60 days of storage, it dropped from 8.82 to 6.42, while heat-pasteurized apple juice was still 7.84, suggesting that high-pressure treatment destroyed the aroma of apple juice. Yi et al. (2017) analysed the aromatic components of apple juice by gas chromatography-mass spectrometry (GC-MS), and found that heat pasteurization caused Maillard and oxidative reactions. Therefore, after HTST, not only had the colour changed, but aldehydes, alcohols, ketones, and organosulfur compounds were produced, which were absent with HPP treatment. Liu et al. (2016) compared variations in the key aromatics of cucumber juice treated by HPP and HTST. The results showed that both methods resulted in significant increases in the aroma contents, with higher increases observed with HPP compared to heat treatment. In aroma tests after 0 and 20 days of cold storage, the flavour score of HPP cucumber juice was highest after 0 d. After 20 days, the scores for the HPP and untreated cucumber juices were both higher than the initial (0 day) score of the heat-pasteurized cucumber juice, suggesting that heat pasteurization caused cucumber juice to produce a bad smell, while HPP maintained a high aroma rating. HPP treatment of asparagus juice enhanced the contents of aroma components such as aldehydes, alcohols, ketones, esters, and organic acids. In a sample treated at 600 MPa for 20 min, the content was 877.4 μg/L, while in the control and heat pasteurized groups, the contents were 595.9 and 431.3 μg/L, respectively (Table 5).

Conclusion

Carambola juice has a distinct flavour due to its microbial fermentation; however, this high microbial count also makes it difficult to maintain initial quality. In this study, it was found that 600 MPa treatment for 150 s could reduce the indicator bacteria in the carambola juice by up to 5 log values, which meets the microbial safety requirements of HACCP fruit juice production. In addition, the original physicochemical characteristics of carambola juice, functional ingredients, sugar content, aroma, and other quality characteristics were maintained. Therefore, HPP can replace HTST in carambola juice pasteurization, eliminating the need for added preservatives, extending its shelf life during cold chain transport and sale, and preserving the taste of fresh carambola juice.

References

Andrés V, Villanueva M, Tenorio M (2016) Influence of high pressure processing on microbial shelf life, sensory profile, soluble sugars, organic acids, and mineral content of milk- and soy-smoothies. LWT Food Sci Technol 65:98–105

Bhat R, Ameran SB, Voon HC, Karim AA, Tze LM (2011) Quality attributes of starfruit (Averrhoa carambola L.) juice treated with ultraviolet radiation. Food Chem 127:641–644

Boynton BB, Sims CA, Sargent S, Balaban MO, Marshal MR (2002) Quality and stability of precut mangos and carambolas subjected to high-pressure processing. J Food Sci 67:409–415

Bull Mk, Szabo EA, Cole MB, Stewart CM (2005) Toward validation of process criteria for high-pressure processing of orange juice with predictive models. J Food protect 68:949–954

Chen PK (2008) Organic acid analyses of sweet carambola pickling brines by reverse phase high performance liquid chromatography. Master Thesis. National Taiwan University. Taiwan

Chen X, Qin W, Ma L, Xu F, Jin P, Zheng Y (2015) Effect of high pressure processing and thermal treatment on physicochemical parameters, antioxidant activity and volatile compounds of green asparagus juice. LWT Food Sci Technol 62:927–933

Demazeau G, Rivalain N (2011) The development of high hydrostatic pressure processes as an alternative to other pathogen reduction methods. J Appl Microbiol 110:1359–1369

Fan X, Annous BA, Beaulieu JC, Sites JE (2008) Effect of hot water surface pasteurization of whole fruit on shelf life and quality of fresh-cut cantaloupes. J Food Sci 73:91–98

FDA (2001) Hazard analysis and critical control point (HACCP), procedures for the safe and sanitary processing and importing of juice: final rule (21 CFR Part 120). Fed. Regist., vol 66. US Food and Drug Administration, Washington, pp 6137–6202

Houška M, Strohalm J, Kocurová K, Totušek J, Lefnerová D, Tříska J, Vrchotová N, Fiedlerová V, Holasova M, Gabrovská, Paulíčková I (2006) High pressure and foods—fruit/vegetable juices. J Food Eng 77:386–398

Huang HW, Wu SJ, Lu JK, Shyu YT, Wang CY (2017) Current status and future trends of high-pressure processing in food industry. Food Control 72:1–8

Jia Z, Tang M, Wu J (1999) The determination of flavonoid contents in Mulberry and their scavenging effects on superoxide radicals. Food Chem 64:555–559

Koutchma T, Popovic P, Ros-Polski V, Popielarz A (2016) Effects of Ultraviolet Light and high-pressure processing on quality and health-related constituents of fresh juice products. Compr Rev Food Sci F 15:844–867

Leelarungrayub J, Laskin JJ, Bloomer RJ, Pinkaew D (2016) Consumption of star fruit juice on pro-inflammatory markers and walking distance in the community dwelling elderly. Arch Gerontol Geriatr 64:6–12

Liu F, Zhang X, Zhao L, Wang Y, Liao X (2016) Potential of high-pressure processing and high-temperature/short-time thermal processing on microbial, physicochemical and sensory assurance of clear cucumber juice. Innov Food Sci Emerg Technol 34:51–58

Moussa-Ayoub TE, Jager H, Knorr D, El-Samahy SK, Kroh LW, Rohn S (2017) Impact of pulsed electric fields, high hydrostatic pressure, and thermal pasteurization on selected characteristics of Opuntia dillenii cactus juice. LWT Food Sci Technol 79:354–542

Nayak PK, Rayaguru K, Krishnan KR (2016) Quality comparison of elephant apple juices after high-pressure processing and thermal treatment. J Sci Food Agric 97:1404–1411

Pang D, You L, Li T, Zhou L, Sun-Waterhousea D, Liu RH (2016) Phenolic profiles and chemical- or cell-based antioxidant activities of four star fruit (Averrhoa carambola) cultivars. RSC Adv 6:90646–90653

Pathanibul P, Taylor TM, Davidson PM, Harte F (2009) Inactivation of Escherichia coli and Listeria innocua in apple and carrot juices using high pressure homogenization and nisin. Int J Food Microbiol 129:316–320

Peñas E, Frias J, Gomez R, Vidal-Valverde C (2010) High hydrostatic pressure can improve the microbial quality of sauerkraut during storage. Food Control 21:524–528

Rendueles E, Omer MK, Alvseike O, Alonso-Calleja C, Capita R, Prieto M (2011) Microbiogical food safety assessment of high hydrostatic pressure processing: a review. LWT-Food Sci Technol 44:1251–1260

Saghir S, Sadikun A, Khaw KY, Murugaiyah V (2013) Star fruit (Averrhoa carambola L.): from traditional uses to pharmacological activities. Bol Latinoam Caribe Plant Med Aromat 12:209–219

Sevenich R, Rauh C, Knorr D (2016) A scientific and interdisciplinary approach for high pressure processing as a future toolbox for safe and high quality products: a review. Innov Food Sci Emerg Technol 38:65–75

Shui G, Leong SL (2004) Analysis of polyphenolic antioxidants in star fruit using liquid chromatography and mass spectrometry. J Chromatogr A 1022:67–75

Taga MS, Miller EE, Pratt DE (1984) Chia seeds as a source of natural lipid antioxidants. J Am Oil Chem Soc 61:928–931

Tonello C (2011) Case studies on high pressure processing of foods. In: Zhung HQ, Barbosa-Cánovas GV, Balasubramaniam VM, Dunne CP, Farkas DF, Yuan JTC (eds) Nonthermal processing technologies for food. Blackwell Publishing, Chicago, pp 36–50

Tseng MF (2004) Studies on changes in microflora and chemical constituents of sweet carambola pickling brine during fermentation. Master Thesis, Graduate Institute of Horticulture, National Taiwan University

United States Department of Agriculture (2012) High pressure processing (HPP) and inspection program personnel (IPP) verification responsibilities. Food Safety and Inspection Service 6120:2

Varela-Santos E, Ochoa-Martinez A, Tabilo Munizaga G, Reyes JE, Pérez-Won M, Briones-Labarca V, Morales-Castro J (2012) Effect of high hydrostatic pressure (HHP) processing on physicochemical properties, bioactive compounds and shelflife of pomegranate juice. Inno Food Sci Emerg Technol 13:13–22

Wang CY, Huang HW, Hsu CP, Yang BB (2016) Recent advances in food processing using high hydrostatic pressure technology. Crit Rev Food Sci Nutr 56:527–540

Xu Z, Lin T, Wang Y, Liao X (2015) Quality assurance in pepper and orange juice blend treated by high pressure processing and high temperature short time. Innov Food Sci Emerg Technol 31:28–36

Yi J, Kebede BT, Dang DNH, Buvé C, Grauwet T, Loey AV, Hu X, Hendrickx M (2017) Quality change during high pressure processing and thermal processing of cloudy apple juice. LWT Food Sci Technol 75:85–92

Acknowledgements

This research work was supported by the Ministry of Science and Technology, MOST 105-2311-B-002 -023-, Taiwan, Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, HW., Chen, BY. & Wang, CY. Comparison of high pressure and high temperature short time processing on quality of carambola juice during cold storage. J Food Sci Technol 55, 1716–1725 (2018). https://doi.org/10.1007/s13197-018-3084-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3084-3