Abstract

In this study, the effects of conventional and microwave roasting on phenolic compounds, free acidity, peroxide value, fatty acid composition and tocopherol content of pecan walnut kernel and oil was investigated. The oil content of pecan kernels was 73.78% for microwave oven roasted at 720 W and 73.56% for conventional oven roasted at 110 °C. The highest free fatty acid content (0.50%) and the lowest peroxide value (2.48 meq O2/kg) were observed during microwave roasting at 720 W. The fatty acid profiles and tocopherol contents of pecan kernel oils did not show significant differences compared to raw samples. Roasting process in microwave oven at 720 W caused the reduction of some phenolic compounds, while the content of gallic acid exhibited a significant increase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pecan walnut draws attention because of nutritional and functional contents such as phenolic compounds, tocopherols and unsaturated fatty acids. There are reports that pecan phenolic compounds, which have antioxidant activity, reduced the risk of cancer, Alzheimer, Parkinson and the other degenerative diseases (Mertens-Talcott and Percival 2005; Tam et al. 2006; Magnuson et al. 2016). Particular attention has been focused on the antioxidant capacity of nuts due to their content of vitamin E, selenium, and phenols (Anderson et al. 2001). Benefits of nuts in reducing the risk of heart disease has been reasonably attributed to their composition of vitamins, minerals, unsaturated fatty acids, fiber and phytochemicals such as polyphenols, tocopherols, squalene and phytosterols (Azadmard-Damirchi et al. 2011). Monounsaturated fatty acid content as oleic acid, which are determined highly in pecan, are less susceptible to lipid peroxidation (Vaidya and Eun 2013). Phenolic compounds of pecans, except for gallic acid, were the lower in whole roasted kernel. Roasting process caused the negative effects on individual phenolics but not on the total phenolic content and antioxidant activity of kernels (Yang et al. 2015). As the nuts can be consumed as raw or roasted form andthe aim of the roasting process is to provide the desirable color, appearance, flavor and textural properties (Saklar et al. 1999). In addition, the reduction of moisture content and antinutritional components, prevention of microbial growth and enzyme activity and increase in the extraction yield are also observed during roasting process. However, heat processing has some disadvantages such as lipid modifications and detrimental effects on the nutritional compounds and natural antioxidants in foods (Arinola and Adesina 2014; Cang et al. 2016; Qu et al. 2016). Thermoanalytical techniques are commonly used to evaluate the stability of vegetable oils (Kowalski 1991; Wesolowski and Erecinska 1998) and have the advantage of providing information that conventional methods are incapable (Santos et al. 2004). Microwave energy has been tested in several drying studies (Silva and Marsaioli 2003; Berteli and Marsaioli 2005; Silva et al. 2006). The aim of this study was to investigate the effect of microwave (180, 360, 540 and 720 W) and conventional (70, 90, 110 and 130 °C) oven roasting on phenolic compounds and oil content, free acidity, peroxide value, fatty acid composition and tocopherol contents of pecan kernel and oils.

Materials and methods

Materials

About 5 kg pecan walnut (Carya illinoinensis(Wangenh.) K. Koch.) samples were obtained from Tarsus (Mersin) district in Turkey. After the walnut kernels were separated from hulls, they were dried, and stored at 4 °C up to analysis.

Methods

Roasting process

Pecan kernels were roasted in a conventional oven at 70, 90, 110 and 130 °C for 1 h; and in a microwave oven at 180, 360, 540 and 720 W for 5 min, respectively. The roasted samples were separately ground with a grinder before analysis.

Moisture content

Moisture content of pecan kernel was measured at 100 ± 5 °C in an oven (Nüve FN055 Ankara, Turkey) until a constant weight was obtained.

Oil content

Oil content of kernel was determined according to AOAC (1990). Total oil content of pecan kernel was extracted by Soxhlet Apparatus for 5 h (with petroleum benzine), and the solvent was removed with a rotary vacuum evaporator at 50 °C. Oil was kept at the − 18 °C till analyses.

Free acidity and peroxide values

Free fatty acids, expressed as free oleic acid percentage, were determined using AOCS (1989). Peroxide values (meq O2/kg) were determined according to AOCS method (1992).

Fatty acid composition

Fatty acid methyl esters esterificated according to ISO-5509 (1978) method were analysed by Gas Chromatography (Shimadzu GC-2010) equipped with flame-ionization detector (FID) and capillary column (Tecnocroma TR-CN100, 60 m × 0.25 mm, film thickness: 0.20 µm). The temperature of injection block and dedector was 260 °C. Mobile phase was nitrogen with 1.51 ml/min flow rate. Total flow rate was 80 ml/min and split rate was also 1/40. Column temperature was programmed 120 °C for 5 min and increased 240 °C at 4 °C/min and held 25 min at 240 °C (AOAC 1990).

Tocopherol content

Tocopherol contents of pecan oil were analyzed according to Spika et al. (2015). About 0.1 g of oil was dissolved in 10 ml of n-hexane, and filtered through a 0.45 µm nylon fitler. HPLC analyses of tocopherols was accomplished using Shimadzu-HPLC equipped with PDA detector and LiChroCART Silica 60 (4.6 × 250 mm, 5 µ; Merck, Darmstadt, Germany) column. Tocopherols were separated by isocratic chromatography using a mobile phase of 0.7% propan-2-ol in n-hexane. The flow rate of the mobile phase was 0.9 ml/min, and the injection volume was 20 µl. The peaks were recorded at 295 and 330 nm with PDA detector. Standard solutions of tocopherols (α, β, γ and δ-tocopherol) were constructed in the concentrations of 0–100 mg/L. All analyses were made in triplicate.

Extraction of phenolic compounds

Phenolic compounds of pecan kernels were extracted according to Slatnar et al. (2015). About 2.5 g of dried and ground samples were added to 22.5 ml of mixture of methanol: water (60:40, v/v). The mixture was kept in ultrasonic water-bath for 1 h, followed by centrifugation at 6000 rpm for 10 min. The supernatant was filtered through a 0.45 µm nylon filter. All analyses were carried out in triplicate.

Phenolic compounds

Phenolic compounds of pecan kernels were determined by Shimadzu-HPLC equipped with PDA detector and Inertsil ODS-3 (5 µm; 4.6 × 250 mm) column. The mobile phase consisted of 0.05% acetic acid in water (A) and acetonitrile (B) mixture. The flow rate of the mobile phase and the injection volume were 1 ml/min at 30 °C and 20 µl, respectively. The peak records were carried out at 280 and 330 nm.

Statistical analyses

Analysis of variance (ANOVA) was performed by using JMP version 9.0 (SAS Inst. Inc., Cary, N.C.U.S.A). The analytical results were mean ± standard deviation (MSTAT C) of independent kernel samples (Püskülcü and İkiz 1989).

Results and discussion

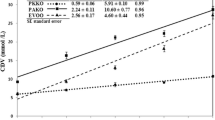

Moisture, oil content, acidity and peroxide values

The oil yield, moisture content, free acidity and peroxide values of pecan kernel and oils after microwave and conventional oven roasting are given in Table 1. oil yields of pecan roasted in conventional oven varied between 68.93 and 73.56%, oil yields of pecan roasted in microwave oven remained between 70.22 and 73.78%. The oil content of pecan kernels increased by microwave oven roasting at 720 W (73.78%) and conventional oven roasting at 110 °C (73.56%). Arinola and Adesina (2014) reported that the oil content of African walnut increased from 54.14% (raw nut) to 60.52% after roasting in hots for 1 h. Free acidity of pecan oils varied between 0.22 and 0.50%. The free acidity of pecan oil significantly increased by microwave roasting at 720 W, with the range of 0.50%. Conventional roasting at 70 °C did not effect the free fatty acid content when compared to raw pecan oil. But, the highest peroxide value was found for raw pecan oil (17.33 meq O2/kg), followed by pecan roasted in microwave oven at 180 W (10.05 meq O2/kg). It was observed that the roasting process, either in conventional oven or in microwave oven, resulted in peroxides degradation. The maximum degradation was determined when samples were roasted at 720 W, and the peroxide values decreased from 17.33 to 2.48 meq O2/kg. There were significant differences according to control group in moisture and oil contents, free acidity and peroxide values of pecan kernel and oils roasted in microwave and ordinary oven (p < 0.05). According to the study of Vaidya and Eun (2013), peroxide value increased from 0.01 (unroasted walnut) to 2.34 meq/kg oil (roasted at 160 °C for 15 min). Qu et al. (2016) applied different drying methods such as direct oven drying and intermittent oven drying, and reported that the highest acid value was determined in sun dried walnuts. The peroxide values were observed as 1.94 meq/kg in direct oven dried samples and 1.82 meq/kg in oil of kernel dried in intermittent oven. The peroxide values of macadamia kernels increased from 0.54 meq/kg (raw sample) to 0.77 meq/kg roasted in microwave oven, and from 0.54 meq/kg (raw sample) to 1.13 meq/kg roasted in hot air (Silva et al. 2006).

Fatty acid composition and tocopherol contents

The fatty acid compositions and tocopherol contents of pecan oils are shown in Table 2. The dominant fatty acids of pecan oil were oleic (59.14–61.87%), linoleic (26.31–28.67%), palmitic (6.39–7.19%) and stearic (2.51–3.52%) acids. Both conventional oven and microwave roasting processes affected the fatty acid profiles in pecan oils. There was significant differences between microwave and oven roasted pecan kernel oils in fatty acid compositions (p < 0.05). The pecan oil contained only γ-tocopherol, and its content ranged from 3.09 to 4.65 mg/g. α-, β- and δ- tocopherols were not detected in any of the pecan oils. However, microwave roasting at 720 W caused a major γ-tocopherol decrease (from 4.65 to 3.09 mg/g). More γ-tocopherol reduction was observed in conventionally roasted (30 °C) oil which showed a decrease from 28.83 to 26.31%. Both roasting processing did not caused any important changes in tocopherol contents at different microwave powers and temperatures, however tocopherol contents exhibited significant differences in relation to control group (p < 0.05). Vaidya and Eun (2013) informed that significant differences in fatty acid composition of raw and unroasted walnut oils did not observed. γ-Tocopherol was the main isomer of raw and unroasted walnut oils, and its content was decreased from 258.10 to 230.65 µg/g after roasting process (Vaidya and Eun 2013).

Phenolic compounds

The results about phenolic compounds are presented in Table 3 and it can be observed that the gallic acid, 3,4-dihydroxybenzoic acid, 1,2-Dihydroxybenzene, (+)-catechin, syringic acid, rutin and trans ferulic acid were the major phenolic compounds found in control and roasted samples. In addition to these phenolic compounds, minor amounts of caffeic acid, p-coumaric acid, apigenin 7 glucoside, resveratrol, quercetin, trans-cinnamic acid, kaempferol, isorhamnetin and naringenin were also detected. The amount of gallic acid content increased during roasting process, while 3,4-dihydroxybenzoic acid, 1,2-Dihydroxybenzene and syringic acid contents were decreased during heat treatment. The results demonsrated that the major decrease in (+)-catechin, 3,4-dihydroxybenzoic acid and 1,2-Dihydroxybenzene were observed when roasted in microwave oven at 720 W. Also, roasting in microwave oven at 540 W provided a major increase in gallic acid. It can be stated that the 3,4-Dihydroxybenzoic Acid, catechin, 1,2-Dihydroxybenzene, syringic, caffeic, trans-ferulic, quercetin, trans-Cinnamic Acid contents of the pecan kernels roasted either in microwave or oven exhibited significantly differences when compared to control group (p < 0.05). Significant differences were not observed in case of apigenin 7 glucoside, trans-cinnamic acid, kaempferol contents of roasted at 360, 540 and 720 W. The main phenolic acid of raw pecan kernel was ellagic acid (2.96 mg/g), followed by chlorogenic acid and p-hydroxybenzoic acids (Yang et al. 2015). It can be observed that microwave roasting did not cast much effect on phenolic compounds as observe din case of conventional oven roasting.

Conclusion

The oil yields of pecan roasted in microwave oven were higher than those of oil contents of pecan kernel oil roasted in conventional oven. The roasting in both conventional and microwave resulted in peroxides degradation. There were significant differences between roasted and control samples for free acidity. The dominant fatty acids of pecan oil were oleic, linoleic, palmitic and stearic acids. Both conventional oven and microwave roasting process affected the fatty acid profiles of oils in comparison to control samples. Both roasting processing did not caused any significant change in tocopherol content, but tocopherol content exhibited significant differences according to control group. It can be stated that some phenolic constituents (3,4-dihydroxybenzoic acid, catechin, 1,2-dihydroxybenzene, syringic, caffeic, trans-ferulic, quercetin, trans-cinnamic acid) of the pecan kernels roasted in microwave and conventional oven exhibited significant differences when compared to control group.

References

Anderson KJ, Teuber SS, Gobeille A, Cremin P, Waterhouse AL, Steinberg FM (2001) Walnut polyphenolics inhibit in vitro human plasma and LDL oxidation. J Nutr 131:2837–2842

AOAC (1990) Official Methods of Analysis, 15th edn. Association of Official Analytical Chemists, Washington

AOCS (1989) Official methods and recommended practices of the American Oil Chemists’Society, 4th edn. American Oil Chemists’ Society, Champaign, Method, pp 5–41

AOCS (1992) Official methods and recommended practices of the American Oil Chemists’ Society, 4th edn. American Oil Chemists’ Society, Champaign, Method Cd, pp 8–53

Arinola SO, Adesina K (2014) Effect of thermal processing on the nutritional, antinutritional, and antioxidant properties of Tetracarpidium conophorum (African walnut). J Food Process 1–4

Azadmard-Damirchi S, Emami Sh, Hesari J, Peighambardoust SH, Nemati M (2011) Nuts composition and their health benefits. Int J Biol Biomol Agric, Food Biotechnol Eng 544–548

Berteli MN, Marsaioli A Jr (2005) Evaluation of short cut pasta air dehydration assisted by microwaves as compared to the conventional drying process. J Food Eng 68:175–183

Cang SK, Alasalvar C, Bolling BW, Shahidi F (2016) Nuts and their co-products: the impact of processing (roasting) on phenolics, bioavailability, and healh benefits—a comprehensive review. J Funct Foods 26:88–122

ISO-International Organization for Standardization (1978) Animal and vegetable fats and oils preparation of methyl esters of fatty acids, ISO. Geneve, Method ISO 5509, pp 1–6

Kowalski B (1991) Thermal oxidative decomposition of edible oil and fats: DSC studies. Thermochim Acta 184:49–57

Magnuson SM, Kelly B, Koppel K, Reid W (2016) A comparison of flavor differences between pecan cultivars in raw and roasted forms. J Food Sci 81(5):1243–1253

Mertens-Talcott SU, Percival SS (2005) Ellagic acid and quercetin interact synergistically with resveratrol in the induction of apoptosis and cause transient cell cycle arrest in human leucemia cells. Cancer Lett 218:141–151

Püskülcü H, İkiz F (1989) Introduction to statistic. Bilgehan Press, Bornova, p 333 (in Turkish)

Qu Q, Yang X, Fu M, Chen Q, Zhang X, He Z, Qiao X (2016) Effect of three conventional drying methods on the lipid oxidation, fatty acid composition, and antioxidant activities of walnut (Juglans regia L.). Drying Technol 34(7):822–829

Saklar S, Ungan S, Katnas S (1999) Instrumental crispness and crunchiness of roasted hazelnuts and correlations with sensory assessment. J Food Sci 64:1015–1019

Santos JCO, Santos IMG, Conceição MM, Sl Porto, Trindade MFS, Souza AG, Prasad S, Fernandes Junior VJ, Araújo AS (2004) Thermoanalytical, kinetic and rheological parameters of commercial edible vegetable oils. J Thermal Anal Calorim 75:419–428

Silva FA, Marsaioli A Jr (2003) Drying Brazil nuts using hot air assisted by microwaves compared to conventionally dried samples. In: Binner J (ed) Proceedings of the 9th International conference on microwave and the high frequency heating. Loughborough, UK, Sept 1–5, pp 341–344

Silva FA, Marsaioli A Jr, Maximo GJ, Silva MAAP, Goncalves LA (2006) Microwave assisted drying of macadamia nuts. J Food Eng 77(3):550–558

Slatnar A, Mikulic-Petkovsek M, Stampar F, Veberic B, Solar A (2015) Identification and quantification of phenolic compounds kernels, oil and bagasse of common walnut (Juglans regia L.). Food Res Int 67:255–263

Spika MJ, Kraljic K, Koprivnjak O, Skevin D, Zanetic M, Katalinic M (2015) Effect of agronomical factors and storage conditions on the tocopherol content of Oblica and Leccino virgin olive oil. J Am Oil Chem Soc 92:1293–1301

Tam NN, Nyska A, Maronpot RR, Kissling G, Lomnitski L, Suttie A, Balshi S, Bergman M, Grossman S, Ho SM (2006) Differential attenuation of oxidative/nitrosative injuries in early prostatic neoplastic lesions in TRAMP mice by dietary antioxidants. Prostate 66:57–69

Vaidya B, Eun JB (2013) Effect of roasting on oxidative and tocopherol stability of walnut oil during storage in the dark. Eur J Lipid Sci Technol 115:348–355

Wesolowski M, Erecinska J (1998) Thermal analysis in quality assessment of rapeseed oils. Thermochim Acta 323:137–143

Yang J, Zhou F, Xiong L, Mao S, Hu Y, Lu B (2015) Comparison of phenolic compounds, tocopherols, phytosterols and antioxidant potential in Zhejiang pecan [Carya cathayensis] at different stir-frying steps. LWY-Food Sci Technol 62:541–548

Acknowledgements

The authors extend their appreciation to the International Scientific Partnership Program ISPP at King Saud University for funding this research work through ISPP# 0015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Juhaimi, F.A., Özcan, M.M., Uslu, N. et al. Pecan walnut (Carya illinoinensis (Wangenh.) K. Koch) oil quality and phenolic compounds as affected by microwave and conventional roasting. J Food Sci Technol 54, 4436–4441 (2017). https://doi.org/10.1007/s13197-017-2921-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2921-0