Abstract

PR 106 and SML 668 cultivars of rice and mung bean respectively, were studied for their potential to serve as a nutritious snack with improved protein quality and quantity. The effect of extrusion conditions, including feed moisture content (14–18%), screw speed (400–550 rpm) and barrel temperature (130–170°C) on the physicochemical properties (bulk density, water absorption index (WAI), water solubility index (WSI) and hardness) was investigated. The replacement of rice flour at 30% level with mung bean flour for making extruded snacks was evaluated. Pasting temperature increased (84–93 °C) while peak viscosity (2768–408 cP), hold viscosity (2018–369 cP), breakdown (750–39 cP), setback (2697–622 cP) and final viscosity (4715–991 cP) decreased with increasing mung bean flour addition. Increasing feed moisture lowered the specific mechanical energy (SME), WAI and WSI of extrudates whereas increased bulk density and hardness. Higher screw speed had linear positive effect on SME of extruder and negative linear effect on WAI. Positive curvilinear quadratic effect of screw speed was also observed on WSI and density. Higher barrel temperature linearly decreased the SME, density and hardness of extrudates. Developed extrusion cooked rice-mung bean snacks with increased protein content and improved protein quality along with higher dietary fibre and minerals have good potential in effectively delivering the nutrition to the population.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Snack foods have become an indistinguishable part of modern lifestyle, and as a platform they can effectively deliver or improve the overall nutrition of the population. As snack foods are made primarily from starchy cereals, due to their good expansion characteristics but, with gradual increase in nutritional knowledge and simultaneous rise of malnutrition emphasizes to use this popular and favourable platform to deliver nutrients rather than merely providing empty calories. Pulses constitute an important source of dietary protein for large segments of the world’s population particularly in the tropics, where the consumption of animal protein is limited either due to non-availability, affordability, customs or religious habits. Although, use of pulses as part of diets in south Asia is traditional and considered as poor man’s meat but with increasing clinical evidences about the usefulness of pulses and ingredients, a steady rise in interest has been seen especially in health conscious population. Recent research studies suggest that consumption of pulses may have potential health benefits including reduced risk of cardiovascular disease, cancer, diabetes, osteoporosis, hypertension, gastrointestinal disorders, adrenal disease and reduction of LDL cholesterol (Hu 2003; Jacobs and Gallaher 2004; Pihlanto and Korhonen 2003; Tharanathan and Mahadevamma 2003). The continuously increasing demand for proteins of non-meat source, has resulted in more focused research on plant protein sources. Leguminous seeds constitute one of the richest (19–25%) and cheapest sources of proteins as compared to animal and marine proteins, therefore widely being used by governments for baby foods (Bengal gram) and other high nutrient foods such as porridges (Soybean) and mixes. The potential for blending pulses such as mung bean, pea, chickpea, lentil and beans with other locally grown cereals to meet some of the protein malnutrition problem worldwide is, therefore, of tremendous interest. Proteins derived from underutilized plant sources are becoming one of the food industry’s fast growing and innovative ingredient segments. Plant proteins have increased functionality, a bland flavour profile, additional nutritional benefits and a low-cost advantage as meat alternative. Mung bean (Vigna radiata), also known as green gram is a drought resistant, tropical legume originated in India, widely grown in Asia, particularly in Thailand, India and Pakistan. High protein (22–24%) and lysine content in mung bean (5.85–8.24 g/100 g) makes it a suitable ingredient for supplementation of cereal based human diets and that could be possible reason for introduction of this crop in Egypt by Ministry of Agriculture. Because of its high protein content, easy digestibility and being almost free from flatulence-causing factors, it is preferred for feeding babies and convalescents (El-Moniem 1999). Higher digestibility coefficient (92.2%) and starch content (37–53%) whereas lower fat (1.08%) and flatulence (29–30 ml/h) makes it perfect ingredient to supplement cereal based foods. Mung bean flour and/or starch has been successfully incorporated into a variety of products such as cookies (Pasha et al. 2011), breads (Indrani et al. 2015), vermicelli (Mestres et al. 1988), noodles (Galvez and Resurreccion 1992) and snacks (Bhattacharya 1997; Boonyasirikool et al. 1996).

In the past half-century, extrusion cooking has proved and played a central role in the modern cereal-based industry for the production of snack, breakfast cereals, instant mixes, novel centre-filled snacks etc., but in recent years, it is also rapidly being preferred for food aid programs such as Fortified Blended Foods (FBFs) for efficient and continuous operation, consistency in product quality, increasing energy density and decreasing the viscosity. Rice has been an attractive ingredient in the extrusion industry due to its bland taste, attractive white colour, hypoallergenic high biological value of protein and ease of digestion. Rice-brokens are by-product of rice milling industry and as their percentage is considerably high in developing countries due to use of obsolete equipment and unskilled labour for milling and polishing, it could be desirable cereal for new product development. Higher percentage of broken rice in raw rice as compared to parboiled rice (22–30 and 15%, respectively) and loss incurs during milling (45–50%, (Singaravadivel 2008) due to broken rice further necessitates the efficient use of this cheaper starchy source. The objective of this study was to utilize mung bean in a product development and investigate the effects of feed moisture content, screw speed and barrel temperature on the extrusion behaviour and physicochemical and textural properties of mung bean based extruded snacks using response surface methodology (RSM). Further, prediction models were developed and optimum processing conditions were also generated for the preparation of nutritious snacks.

Materials and methods

Materials

Broken rice (var. PR-106) was procured from local rice mill and Mung bean (var. SML-668) was procured from Directorate of Seeds, Punjab Agricultural University, Ludhiana, India. Broken rice and mung beans were ground to pass through 200 µ sieve using lab mill (Perten Instruments, Hagersten, Sweden). Several preliminary trials were made to select the proportion of broken rice and mung bean. The broken-rice flour was mixed with the mung bean flour in the proportion of 70:30 in the ribbon blender (G L Extrusion systems, New Delhi, India) for 15 min to ensure uniform mixing. Sugar, salt, ginger powder, onion powder, cheese powder, garlic powder, chili powder and citric acid were added at 4, 2, 0.75, 1, 1, 0.75, 0.25, and 0.25% respectively.

Pre-extrusion rheological analysis using rapid visco analyzer (RVA)

The pasting properties of the rice and mung bean flour blends were determined with a Rapid Visco Analyser (RVA, Model – 4D, Newport Scientific, Sydney, NSW, Australia), according to the AACC standard method with slight modification. The sample size was 3.00 g on dry basis and the amount of water added was 25.00 ml (corrected for 14% moisture basis). Each result was the average of two measurements.

Extrusion

A co-rotating intermeshing twin-screw extruder (Model BC 21, Clextral, Firminy, Cedex, France) was used in the study. The barrel diameter and its length to diameter ratio (L/D) were 25 mm and 16:1, respectively. Twin-screws (400 mm) had segmental elements ranging from 5 to 50 mm with gradual decreasing pitch. A “conveying screw configuration” with a combination of feed screws and reverse screw element (RSE) with groove as shown in Fig. 1 and Table 1 was used. The barrel which housed the twin screws had 400 mm long sections, with three electric resistance heaters mounted on. The extruder had four barrel zones. The barrel zone at the feed hopper was not heated and was maintained at 35–40 °C by cooling water. Temperature of the second and third zone were maintained at 70 and 100 °C respectively throughout the experiments, while the temperature at last zone (compression and die section) was varied according to the experimental design. The diameter of die opening selected was 5 mm. The extruder was powered by an 8.5 kW motor with speed variable from 0 to 682 rpm. The extruder was equipped with a torque indicator, which showed percent of torque in proportion to the current drawn by the drive motor. Raw material was metered into the extruder with a single screw volumetric feeder (D.S. and M, Modena, Italy). The extruder was thoroughly calibrated with respect to the combinations of feed rate and screw speed to be used. The feed rate was varied for optimum filling of the extruder barrel corresponding to the screw speed. The moisture content of feed was varied by injecting water into extruder with water pump. A variable speed die face cutter with four bladed knives was used to cut the extrudates. The extrudates were dried, packed in polythene bags and stored in airtight containers for further analysis of physicochemical properties. The moisture content of the extrudates measured immediately whereas other physical, biochemical and sensory analyses were performed within 24 h.

Experimental design and statistical analysis

The experimental design was based on a central composite rotatable design (CCRD) for three independent variables and three levels. The design required 20 experimental runs with eight factorial points, six-star corner points and six centre points. Experiments were randomized in order to minimize the systematic error and protect against confounding. The independent variables considered in this study were process parameters such as moisture (x 1 ), screw speed (x 2 ) and barrel temperature (x 2 ). The outline of experimental design with the actual level is presented in Table 2. Dependent variables were Specific Mechanical Energy (SME), expansion ratio (ER), bulk density (BD), water absorption index (WAI), water solubility index (WSI) and hardness. Response surface methodology (RSM) was applied for experimental data using a commercial statistical package, JMP Pro 12.1.0 (SAS, Cary, NC) for the generation of regression equations. The independent variable levels such as feed moisture content (14–18%), screw speed (400–550 rpm) and barrel temperature of the last zone (130–170 °C) considered for study were selected on the basis of preliminary trials. Responses obtained as a result of the proposed experimental design were subjected to regression analysis in order to assess the effects of moisture content, screw speed and temperature by using statistical software, JMP Pro 12.1.0 (SAS, Cary, NC). Variables generated as potential predictor of dependent variable (y), were further screened by Forward selection, Backward elimination and Stepwise selection. SAS university edition (SAS Institute Inc., Cary NC) was used for screening of variables. The utility of the model was checked by global F-test whereas adequacy of model was measured by the adjusted multiple coefficient of determination, denoted \( R_{a}^{2} \).

Specific mechanical energy (SME)

Specific mechanical energy (Wh/kg) was calculated by using the following formula,

where T = percent torque, T 0 = no load torque, N = screw speed (rpm), N r = rated screw speed (rpm), P r = rated motor power (8.5 kW) and \(\dot{m}\) = mass flow rate (kg/h).

Bulk density (BD)

Bulk Density (g/cc) of extrudates was determined by a volumetric displacement procedure as described elsewhere (Patil et al. 2007) with some modification. The volume of the expanded sample was measured by using a 100-mL graduated cylinder by rapeseed displacement method instead of glass beads. The volume of 20 g randomized samples was measured for each test. The ratio of sample weight and the replaced volume in the cylinder was calculated as density (w/v).

Water absorption index (WAI) and water solubility index (WSI)

WAI and WSI were determined according to the method developed for cereals (Anderson et al. 1969; Yagcı and Gogus 2008). The ground extrudates were suspended in water at room temperature for 30 min, gently stirred during this period, and then centrifuged at 3000× g for 15 min. The supernatants were decanted into an evaporating dish of known weight. The WAI was the weight of gel obtained after removal of the supernatant per unit weight of original dry solids. The WSI was the weight of dry solids in the supernatant expressed as a percentage of the original weight of sample.

Hardness

Textural quality of the snack samples was examined for compression force (CF) by applying a TA-XT 2i Texture Analyzer (Stable Microsystems, Surrey, UK). The compression probe (50 mm. dia., aluminium cylinder) was applied to measure compression force required for samples breakage which indicates hardness. Testing conditions were 1.0 mm/s pre-test speed, 2.0 mm/s test speed, 10.0 mm/s post-test speed and 5 mm distance.

Compositional analysis and mineral content analysis

Analyses of moisture content, protein (using macro-Kjeldahl procedure), fiber (using Fibertec-Foss Instrument, Hilleroed, Denmark), fat (using Soxtec 2045- Foss Instrument, Hoganas, Sweden) and ash were performed according to approved methods described in AOAC 2000. The carbohydrate content was calculated by difference. Mineral contents were determined by using standard AOAC method.

Results and discussion

Pre-extrusion rheological analysis using RVA

Table 2 shows the viscosity profile of different flour blends. A steady increase in pasting temperature was observed with increasing mung bean flour content, which could be attributed to delayed peak time or swelling of granules. Pasting temperature ranged from 84.2 to 93.6 °C for 0 to 30% replacement, respectively. Restricted swelling or delayed peak time suggested that the high protein, fibre and fat content of mung bean flour influenced the pasting temperature as well other pasting properties (Yu et al. 2012). Previously, researchers have reported that pasting temperature exhibited a positive correlation with protein content (Lim et al. 1999; Marcoa and Rosell 2008) and influenced by amylose–lipid complex (Dautant et al. 2007; Kaur and Singh 2000). A decrease in peak viscosity, hold viscosity, breakdown, setback and final viscosity was observed with increasing mung bean flour. Rationale behind this change could be increasing protein and fibre content from mung bean replacement. Peak viscosity has been previously shown to be negatively associated with protein (Lim et al. 1999; Marcoa and Rosell 2008) and fibre content (Chen et al. 2011). Swelled starch granules eventually fragmented upon further heating at elevated temperature. Breakdown viscosity decreased almost linearly with increasing mung bean flour level (r2 = 0.98). Higher breakdown viscosity of rice flour reflects higher amylopectin content of PR-106 (Amylose ≈ 16%) (Sodhi and Singh 2003), whereas steady decrease in viscosity could be due to increasing mung bean (Amylose = 29.9 to 33.6%) (Kaur et al. 2011). Holding period exposes gelatinized, fragmented or broken starch granules to high temperature and mechanical shear, which further disrupt starch granules. Adding mung bean flour decreased the ability of starches to withstand shear and temperature. Lower retrogradation and reordering of amylose chains achieved with the addition of mung bean flour, which could be attributed to lower available starch.

Specific mechanical energy (SME)

Moisture and barrel temperature appeared to be the most significant factors with respect to SME, although all three factors were statistically significant. Linear, crossproduct and quadratic regression models were significant and contributing to the coefficient of determination, \( R_{a}^{2} \), but linear and quadratic models appeared to be most influential with higher F value. Highest \( R_{a}^{2} \) (0.99) was observed with all three regression models, linear, crossproduct and quadratic, but by excluding crossproduct terms, \( R_{a}^{2} \) reduced to 0.92. From parameter estimates, lower t values were obtained with crossproduct terms and therefore for regression model, these crossproduct terms were removed and only terms with t value <000.1 were used. Thus, the prediction equation for SME (ŷ) with respect to moisture, x 1 , screw speed, x 2 and barrel temperature, x 3 , (order of terms is according to magnitude of t value) was as follows:

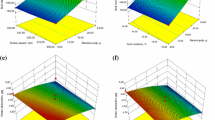

\( R_{a}^{2} \) implies that after adjusting for sample size and the number of model parameters, about 92% of the total sample variation in SME (y) could be explained by the model and the remainder will be explained by random error. Lack of fit was significant, indicating SME depends not only feed moisture, screw speed and barrel temperature but also on some other terms which haven’t included (Table 4). It will be worth full to mention here that many researchers used R 2 as a criterion to represent the variation explainable by respective models but it’s very important to remember that if using R 2 as a measure of usefulness of the model for predicting y, it should be based on a sample that contains substantially more data points than the number of parameters (in this case, three independent variables or parameters) in the model. With the above given equation, the \( R_{a}^{2} \) obtained was 0.98 with root mean square error (RMSE) of 1.86, comparatively lower than complete second-order model with \( R_{a}^{2} \) 0.99 and RMSE of 0.96. RMSE implies that the model predictions will usually be accurate to within approximately ±2(1.86) Wh/kg. The measure of mechanical energy going into the extrusion system per unit mass plays an important role in the calculations of energy consumption and product characteristics. In this experiment, the calculated SME ranged from 124.63 to 179.71 Wh/kg (Table 3). The lowest SME (124.63) was reported at processing conditions of 18% moisture, 550 rpm and 170 °C temperature whereas maximum value of SME was observed at 12.6% moisture, 475 rpm and 150 °C temperature. SME decreased with increasing moisture and barrel temperature whereas increased with increasing screw speed. Similar results were reported by other authors (Altan et al. 2008; Singh et al. 2015). Increase in feed moisture reduces energy dissipation cites and have plasticizing effect whereas barrel temperature facilitates the transformation from solid to viscoelastic or eventually melted mass, thereby reducing mechanical energy transfer and SME. High moisture acted as lubricant to reduce the inter-particle friction between screw and barrel, thus facilitated lower SME whereas high moisture along with barrel temperature decreased the motor torque due to reduced melt viscosity. An increase in SME with an increasing screw speed at constant mass flow rate might be due to increase in shear rate, thereby resulted in more fragmentation of the feed material inside barrel and thus providing more surface area to dissipate energy and required more energy to pump the material through the die. An increase in screw speed at constant feed rate increased the SME, because mechanical energy is provided by screw speed and mass feed rate acts as cites for mechanical energy dissipation so with lower cites less energy got dissipate and higher SME observed. Increasing screw speed decreases torque but the effect of increased screw speed is not compensated with decrease in torque, and the effect of screw speed dominates the effect of viscosity so increasing screw speed increases SME (Jin et al. 1994). All quadratic terms obtained were significant, indicating the curvilinear nature of response and justifies the incorporation of higher order terms in design (Fig. 2). The negative effect of barrel temperature for both linear and quadratic terms, indicating overall higher net effect than linear decrease, whereas positive and negative effects for linear and quadratic terms of screw speed indicating competition in-between for increase or decrease of SME. However, as the magnitude of t-value was higher for quadratic term, the net effect will be greater for the same than linear, consequently, SME will decrease with an increase of screw speed.

Bulk density (BD)

Moisture and barrel temperature appeared to be the most significant independent factors with respect to bulk density although all three factors, namely moisture (<0.0001), barrel temperature (<0.0001) and screw speed (0.033) were statistically significant. Overall, the model was statistically significant with F value 56.48 (<0.0001) before backward elimination. Linear and quadratic regression models were found significant whereas crossproduct (0.29) was not statistically significant. Thus, the prediction equation for bulk density (ŷ) with respect to moisture, x 1 , screw speed, x 2 and barrel temperature, x 3 , (order of terms is according to magnitude of t value) was as follows:

With backward elimination step, R 2 improved to 0.98 and mallows C p criterion reduced to 6.82. The utility of the model was improved with this elimination, as F value of model increased to 95.13 (<0.0001). Lack of fit was not significant (Table 4). The bulk density (BD) of the extrudates varied between 0.121 and 0.319 g/cm3 (Table 3). The BD increased significantly with increasing feed moisture content and decreased significantly with increasing barrel temperature. The lowest BD value was obtained with lower moisture and higher temperature conditions, whereas highest BD value was obtained at higher moisture and lower barrel temperature conditions respectively. Higher feed moisture content lowers melt viscosity, drop in vapour pressure gradient, causes laminar flow of melt and all these factors combined causes incomplete expansion or even collapse of bubbles after expansion. Higher barrel temperature along with lower feed moisture facilitates the vapour pressure gradient and thereby increased the pressure inside barrel, which in turn governs the degree of puffing. Temperature had a significant effect on die pressure, both in linear and squared terms (Singh et al. 2007). No significant linear effect of screw speed observed on BD of extrudates. Similar results were reported by other researchers for extrusion of chick pea flour (Meng et al. 2010), potato based snacks (Singh et al. 2015) corn starch (Chinnaswamy and Hanna 1988), amaranth (Chávez-Jáuregui et al. 2000) and rice (Hagenimana et al. 2006). From Fig. 2, we can have idea of curvilinear nature of barrel temperature for BD. The critical barrel temperature identified was near about 165 °C, above which BD started increasing with increase in barrel temperature. The positive linear and quadratic terms for feed moisture content indicated overall greater net effect than linear on BD for an increase in moisture content.

Water absorption index (WAI)

Moisture, screw speed and temperature appeared to be statistically significant with respect to WAI. From ANOVA, the F value was used to test the model adequacy, that is H 0 : β1 = β2 = β3 = 0. F value of 21.57 with corresponding p value of .000, implies that there is sufficient evidence (at α=0.05) that the model contributes information for the prediction of water absorption index, y. All three regression models, namely, linear, crossproduct and quadratic were significant and contributing to the R 2, although crossproduct model appeared to be most significant of three with R 2 of 0.34 and F value of 23.37. The prediction equation for WAI (ŷ) with respect to moisture, x 1 , screw speed, x 2 and barrel temperature, x 3 , (order of terms is according to magnitude of t value) was as follows:

With backward elimination, F value improved to 25.54, R 2 to 0.94, \( R_{a}^{2} \) to 0.91 and mallows C p criterion reduced to 8.43. Lack of fit was non-significant, implies that model fitted the data well. Water absorption index is an indirect measure of degree of cookness and instantaneous or re-constitutability of cereals or powders in excess water, depends on the amount and nature of ingredients being used and process parameters. WAI values for the extrudates ranged between 4.49 to 6.54 g/g. Feed moisture and screw speed were found to have a significant effect on the WAI of the mung bean extrudates. Increasing feed moisture and screw speed significantly decreased the WAI of mung bean extrudates. High moisture act as lubricant inside and decreases extent of cooking, and thereby decreased the solubility of starches at room temperature. Soluble starch extent increased with decreasing feed moisture content (Mercier and Feillet 1975). The negative sign of quadratic term for moisture further enhanced the overall net effect as compared to linear effect. A significant interaction found between feed moisture and screw speed, which negatively affects WAI. High screw speed could have harsher effects on biopolymers, leading to structural breakdown of molecules and loss of ability to bind water. Similarly, it was found that at lower screw speed, there were more undamaged polymer chains and a greater availability of hydrophilic groups that could bind more water molecules and result in higher value of the WAI (Jin et al. 1994). The negative linear and quadratic terms for screw speed indicated that the net effect will be greater than linear increase on WAI.

Water solubility index (WSI)

All independent variables, namely feed moisture, screw speed and temperature were statistically significant with respect to WSI after transformation. Transformation of data was done to fulfil assumption of normality for ANOVA. The residual plots indicated that logarithmic transformation has significantly improved the normality and thereby reduced the heteroscedasticity. Means before and after transformation are provided online in supplemental files. Highest F value (159.75) was found with feed moisture, followed by screw speed (68.98) and finally with barrel temperature (33.67). Overall significance between treatment means was assessed by ANOVA with high F value of 101.20 with a corresponding p-value of .000. Since α = 0.05 exceeds the p-value, there was sufficient evidence to conclude that the model was a statistically useful predictor of WSI. Linear, crossproduct and quadratic regression models were significant and contributing to the \( R_{a}^{2} \), with highest magnitude of F value for linear, followed by quadratic and crossproduct respectively. High \( R_{a}^{2} \) suggested that 98% of the total sample variation in WSI could be explained by this least square regression model (Table 4). Lack of fit was not significant, implies that model adequately described the functional relationship between the experimental factors and the response variable. Using the natural log transformation on dependent variable, (WSI) the prediction equation obtained (order of terms according to magnitude of t value) is as follows:

WSI, is an indication of solubility of biomolecules (starches, water soluble fibres, proteins and/or sugars etc.) before or after processing in excess of water. WSI values for the extrudates ranged between 12.4 to 20 per cent (Table 3). The prediction and interaction profiles for the WSI with respect to independent variables are presented in Fig. 2, helped to understand relation and choose interaction and quadratic terms to accurately predict the dependent response. Thus, from all above preliminary analysis and keeping in mind the overfitting, an attempt was made to fit model as per requirement and consequently a complete second order model was used to study all possible combinations by including linear, interaction and quadratic terms. Feed moisture and screw speed were found to have a significant effect on the WSI of the extrudates. Increasing feed moisture significantly decreased the WSI of extrudate, while increasing screw speed significantly increased the WSI of mung bean extrudate. Higher feed moisture content acts as plasticizer, reducing the energy dissipation, drag and shear force inside barrel and thereby could have protective effect on biomolecules. A significant positive quadratic effect of screw speed was observed, indicating net effect was greater than linear increase. Positive quadratic terms indicated that increase will be U-shaped curvilinear, as indicated in prediction profile (Fig. 2). The high mechanical shear causes breakdown of macromolecules to small molecules with higher solubility (Singh et al. 2015). Similar findings were reported in previous studies (Altan et al. 2008; Singh et al. 2015). The negative linear terms and positive quadratic term for feed moisture content indicated that decrease will be lower than linear but as effect of quadratic term was not as strong (based on magnitude of t-values), consequently decrease will be very close to linear. The critical screw speed obtained was close to 450 rpm, above which an increase in WSI observed with increasing screw speed, thus indicating significant curvilinear (quadratic) effect.

Hardness

Moisture and barrel temperature appeared to be statistically significant regressors with respect to hardness of extrudates, whereas screw speed has no statistically significant effect on hardness. The F value for testing the model adequacy before backward elimination, F=30.46 with a corresponding p-value of .000, provides sufficient evidence that (at α=0.05) the model contributes information for the prediction of hardness of extrudates, y. Linear and quadratic regressors were statistically significant and contributing (R 2=0.84 and 0.09, respectively) more to the coefficient of determination, R 2, than crossproduct regressors. \( R_{a}^{2} \) was 0.93 after adjusting the sample size and the number of model parameters, meaning that the model explained approximately 93.3% of sample variation in hardness. Thus, the prediction equation for hardness of extrudates (ŷ) with respect to moisture, x 1 , screw speed, x 2 and barrel temperature, x 3 , (order of terms is according to magnitude of t value) was as follows:

With backward elimination, above obtained equation has F value of 51.28 (Table 3) with a corresponding p-value of .000, R 2 = 0.93, \( R_{a}^{2} \) = 0.91 and RMSE of 15.66. RMSE implies that the model predictions will usually be accurate within approximately ±2(15.66) N. The hardness of expanded extrudates is a subjective perception of consumers and is associated with expansion, number and size of bubbles and cell wall structure of the product. The higher the value of maximum peak force required, the higher the hardness of the sample. The hardness of the extrudates ranged from 80.27 to 266.04 N. Feed moisture content and barrel temperature were found to have the most significant effect on extrudate hardness. Increasing feed moisture content significantly increased the hardness whereas increasing barrel temperature significantly decreased the hardness of extrudates. Higher moisture acts as plasticizer to the material inside barrel, reducing its viscosity, energy dissipation and thereby cooking, vapour pressure and thus the bubble growth compressed at exit and product becomes dense. Moreover, a significant positive quadratic effect of moisture content was observed, indicating net effect was greater than linear increase. Similar conditions for feed rate, moisture content and screw speed, highlighted the effect of barrel temperature in Table 4. Higher barrel temperature significantly produced lower dense product with higher crispness at 170 °C. An increase in temperature would increase vapour pressure of superheated steam inside barrel and decrease the melt viscosity, causing quick and more bubble growth with thinner wall thickness of bubbles. No significant effect on screw speed observed on hardness of extrudates. Previous studies also reported that the hardness of the extrudates increased as the feed moisture content increases (Gat and Ananthanarayan 2015; Liu et al. 2000; Singh et al. 2015) while decreases as barrel temperature increased (Gat and Ananthanarayan 2015; Singh et al. 2015). A greater net effect than linear was observed for feed moisture content, as both linear and quadratic terms were positive (Fig. 2).

Optimization and validation

Optimization can be defined as the processing conditions that give the optimum (maximum or minimum) value of a function of certain decided variables subject to constraints that are imposed. The values of the processing variables that produce the desired optimum value are called optimum conditions. Optimum conditions for extrusion of rice and mung bean flours were determined to obtain the minimum density and hardness, maximum WAI and WSI, whereas SME was not considered for optimization for being as a process parameter and lack of fit significant. The optimum values for moisture content, temperature and screw speed were observed as 14%, 148 °C and 549 rpm respectively. It can be noted that the variation of actual response values was within 5% of the predicted values. By applying these optimal conditions, extrudates with a density equal to 0.128 g/cm3, WAI equal to 6.06 g/g, WSI equal to 18.07% and hardness (peak force) 90.54 N could be produced. Extruded snacks were having 5.91% moisture, 75.14%, carbohydrate, 12.7% protein, 2.94% fibre, 0.68% fat and 2.56% ash. The extruded snacks from broken rice and mung bean contains phosphorous (P) 504.7, magnesium (Mg) 102.3, calcium (Ca) 72.8, sodium (Na) 7.1, iron (Fe) 3.9, zinc (Zn) 2.0, manganese (Mn) 0.84 and copper (Cu) 0.51 mg/100 g respectively.

Conclusion

Designed experiments using CCRD successfully exhibited the effect of processing variables on the responses of extrudates. The models were found to be statistically valid and demonstrated adequate information regarding the behaviour of the responses upon variation in the processing variables. Feed moisture having the greatest influence on the properties of the extrudates followed by temperature and screw speed. The products with high expansion ratio and low density and hardness, which are generally good characteristics of an extruded snack, were obtained at low feed moisture, high screw speed and medium barrel temperature within the range of our process variables. Optimum processing conditions and the corresponding predicted response could be obtained with the help of the models.

References

Altan A, Mccarthy KL, Maskan M (2008) Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J Food Eng 84:231–242

Anderson R, Conway H, Pfeifer V, Griffin E (1969) Gelatinization of corn grits by roll-and extrusion-cooking. Cereal Sci Today 14:4

Bhattacharya S (1997) Twin-screw extrusion of rice-green gram blend: extrusion and extrudate characteristics. J Food Eng 32:83–99

Boonyasirikool P, Charunuch C, Phongpipatpong M (1996) Production of snack foods from mungbean by using laboratory twin screw extruder. Food 26(1):14–33

Chávez-Jáuregui RN, Silva MEMP, Areas JAG (2000) Extrusion cooking process for amaranth (Amaranthus caudatus L.). J Food Sci 65:1009–1015

Chen JS, Fei MJ, Shi CL, Tian JC, Sun CL, Zhang H, Ma Z, Dong HX (2011) Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J Cereal Sci 53(2):217–224

Chinnaswamy R, Hanna M (1988) Optimum extrusion-cooking conditions for maximum expansion of corn starch. J Food Sci 53:834–836

Dautant FJ, Simancas K, Sandova AJ, Miler AJ (2007) Effect of temperature, moisture and lipid content on the rheological properties of rice flour. J Food Eng 78:1159–1166

El-Moniem GMA (1999) Sensory evaluation and in vitro protein digestibility of mung bean as affected by cooking time. J Sci Food Agric 79:2025–2028

Galvez FCF and Resurreccion AVA (1992) Reliability of the focus group technique in determining the quality characteristics of mungbean [Vigna Radiata (L.) Wilczec] noodles. J Sens Stud 7:315–326

Gat Y, Ananthanarayan L (2015) Effect of extrusion process parameters and pregelatinized rice flour on physicochemical properties of ready-to-eat expanded snacks. J Food Sci Technol 52:2634–2645

Hagenimana A, Ding X, Fang T (2006) Evaluation of rice flour modified by extrusion cooking. J Cereal Sci 43:38–46

Hu FB (2003) Plant-based foods and prevention of cardiovascular disease: an overview. Am J Clin Nutr 78:544S–551S

Indrani D, Sakhare SD, Inamdar AA, Rao GV (2015) Development of protein and fiber enriched breads by supplementation of roller milled fractions of green gram. J Food Sci Technol 52:415–422

Jacobs DR Jr, Gallaher DD (2004) Whole grain intake and cardiovascular disease: a review. Curr Atheroscler Rep 6:415–423

Jin Z, Hsieh F, Huff H (1994) Extrusion cooking of corn meal with soy fiber, salt, and sugar. Cereal Chem 71:227–233

Kaur K, Singh N (2000) Amylose–lipid complex formation during cooking of rice flour. Food Chem 71:511–517

Kaur M, Sandhu KS, Singh N, Lim ST (2011) Amylose content, molecular structure, physicochemical properties and in vitro digestibility of starches from different mung bean (Vigna radiata L.) cultivars. Starch 63:709–716

Lim ST, Lee JH, Shin DH, Lim HS (1999) Comparison of protein extraction solutions for rice starch isolation and effects of residual protein content on starch pasting properties. Starch 51(4):120–125

Liu Y, Hsieh F, Heymann H, Huff HE (2000) Effect of process conditions on the physical and sensory properties of extruded oat-corn puff. J Food Sci 65:1253–1259

Marcoa C, Rosell CM (2008) Effect of different protein isolates and transglutaminase on rice flour properties. J Food Eng 84(1):132–139

Meng X, Threinen D, Hansen M, Driedger D (2010) Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res Int 43:650–658

Mercier C, Feillet P (1975) Modification of carbohydrate components by extrusion-cooking of cereal products [Wheat, rice, corn]. Cereal Chem 52:283–297

Mestres C, Colonna P, Buleon A (1988) Characteristics of starch networks within rice flour noodles and mungbean starch vermicelli. J Food Sci 53:1809–1812

Pasha I, Rashid S, Anjum FM, Sultan MT, Qayyum MMN, Saeed F (2011) Quality evaluation of wheat-mungbean flour blends and their utilization in baked products. Pak J Nutr 10:388–392

Patil R, Berrios JDJ, Tang DJ, Swanson B (2007) Evaluation of methods for expansion properties of legume extrudates. Appl Eng Agric 23:777–783

Pihlanto A, Korhonen H (2003) Bioactive peptides and proteins. Adv Food Nutr Res 47:175–276

Singaravadivel K (2008) ‘Extruded rice’ to hit market soon. The Hindu

Singh B, Sekhon KS, Singh N (2007) Effects of moisture, temperature and level of pea grits on extrusion behaviour and product characteristics of rice. Food Chem 100:198–202

Singh B, Rachna Hussain SZ, Sharma S (2015) Response surface analysis and process optimization of twin screw extrusion cooking of potato-based snacks. J Food Proc Preserv 39:270–281

Sodhi NS, Singh N (2003) Morphological, thermal and rheological properties of starches separated from rice cultivars grown in India. Food Chem 80(1):99–108

Tharanathan R, Mahadevamma S (2003) Grain legumes—a boon to human nutrition. Trends Food Sci Technol 14:507–518

Yagci S, Gogus F (2008) Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. J Food Eng 86:122–132

Yu S, Menager L, Sun DW (2012) Physicochemical properties of starch and flour from different rice cultivars. Food Bioprocess Technol 52(2):626–637

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Rights and permissions

About this article

Cite this article

Sharma, C., Singh, B., Hussain, S.Z. et al. Investigation of process and product parameters for physicochemical properties of rice and mung bean (Vigna radiata) flour based extruded snacks. J Food Sci Technol 54, 1711–1720 (2017). https://doi.org/10.1007/s13197-017-2606-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2606-8