Abstract

A great deal of attention has been focused on the various health benefits apparently associated with consumption of fish oil. The incorporation of fish oils in food products is becoming increasingly widespread and a large variety of products is being marketed. However, the use of fish oil as functional nutritional ingredients in foods has been limited by its oxidative susceptibility. In the present study, attempts were made to develop fish oil fortified cookies as healthy snack foods by incorporating fish oil microencapsulate. Microencapsulation of fish oil was done by spray drying. Commercially available milk was used to form micro sized complexes with fish oil. Fish gelatin/maltodextrin were used as a wall material for encapsulation. Fish oil was added in three forms (fish oil as such, fish oil-in-water emulsion and fish oil microencapsulate) for the preparation of cookies. Cookies prepared without incorporating fish oil was served as control. The physical, chemical and sensory attributes of cookies were evaluated. Encapsulation significantly (P < 0.05) decreased lipid oxidation in the cookies. The sensory evaluation of cookies showed significant (P < 0.05) difference in the overall acceptability. Results from this study, demonstrated the possibility of fish oil incorporation into cookies through emulsification and microencapsulation which may increase the intake of omega-3 fatty acids for nutritional benefits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fish oil rich in long-chain omega-3 polyunsaturated fatty acids (n-3 PUFA) has long been recognized for its nutritional importance. The predominant dietary sources of n-3 PUFA are fish and fish oil supplements. In many countries, the average fish intake is far below the recommended minimum intake of two fish servings a week, i.e. approximately 200 mg per day of n-3 PUFA (Sanders 2000). Capsules of fish oil supplements invariably add to the overall daily energy intake and for many people, this is not desirable. So an alternative way to ensure an optimal n-3 PUFA intake is needed. Enrichment of foods with n-3 PUFA is regarded as a way of increasing dietary intake of these fatty acids in order to reduce levels of risk of various diseases (Kolanowski 2005). Fortification or enrichment usually refers to the addition of nutrients to food from which they were absent or present in negligible amounts. Fortification with fish oil will provide the health benefits to consumers expect with greater physiological benefit. However, lipid oxidation limits the utilization of these oils in processed foods and as nutritional supplements in fortified food. The quality of fish oil used, type of food fortified and the nutrient profile of the food will also influence the physiological function of n-3 PUFA (Kolanowski 2005). A major challenge in the development of enriched food products is presented by the multiple acceptance criteria, which includes addition of an active ingredient, product freshness, sensory characteristics, appearance, storage conditions, ease of preparation and safety standards (Drusch and Mannino 2009).

In developing countries like India with the increasing urbanization, the demand of processed food is also increasing rapidly. Among the processed foods, bakery products, particularly biscuits command wide popularity in rural as well as urban areas among all the age groups (Agarwal 1990). Bakery products are generally used as a source for incorporation of different nutritionally rich ingredients for their diversification (Sudha et al. 2007; Shakuntala et al. 2009). Bakery products, dairy products (Kolanowski and Laufenberg 2006; Lovegrove et al. 1997), mayonnaise (Jacobsen et al. 1999), juices and soft drinks are found to be good examples for fish oil enrichment. The objective of the present study was to prepare the fish oil fortified cookies and to evaluate its quality characteristics.

Materials and methods

Materials

Fish oil (Seacod, Universal Medicare, Mumbai, India) was used as a source of omega-3 fatty acids. Fish gelatin extracted from the skin of Ghol fish (Protonibea diacanthus), Maltodextrin (16 Dextrose Equivalent) procured from Merck, India was used as wall material for fish oil encapsulation. Commercially available pasteurized and double toned milk (Mother Dairy, Navi Mumbai) were purchased from versova market, Mumbai.

Methods

Extraction of fish gelatin

Fish gelatin was extracted by the method of Gudmundsson and Hafsteinsson (1997). Ghol fish (P. diacanthus) skins were thoroughly cleaned and rinsed with potable water to remove superfluous material and treated by soaking with 0.2 % (w/v) sodium hydroxide solution for 40 min. Then, they were soaked in 0.2 % (w/v) sulfuric acid for 40 min. This was followed by soaking in 1.0 % (w/v) citric acid. After each soaking treatment, the skins were washed under running tap water until they had a pH of about 7. Each soaking and washing treatment was repeated three times with a total time of 2 h for each treatment. The skins were then subjected to a final wash with distilled water to remove any residual matter. The final extraction was carried out in distilled water at controlled temperature within the range of 45 °C for 12 h. The ratio used was 1 kg (weight of wet skin) to 3 L of distilled water. The clear extract obtained was filtered in a Buchner funnel with a Whatman Filter Paper (No. 1, Maidstone, England), followed by vacuum oven drying and made powder by pestle and mortar and packed in air-tight container.

Preparation of fish oil-milk emulsion and microencapsulates

Emulsion was made for encapsulation at four different formulations. Milk was used as a base material in all formulation for making emulsion. Fish oil and wall material (fish gelatin/maltodextrin) was used at the ratio of 1:2. The composition of the emulsion used for encapsulation is given in Table 1. Before encapsulation process, wall material (fish gelatin/maltodextrin) was dissolved in milk under continuous stirring followed by fish oil was added. Further, it was homogenized by using tissue homogenizer (Poly system PT 2100, Kinematica, AG, Littccu-Lucerne, Switzerland). Homogenization speed was used at 25,000 rpm for 5 min. After homogenization, samples were kept for stabilization at room temperature for 1 h and they were spray dried using a table top spray dryer (S. M. Scientech, Kolkata, India) under the following experimental conditions: inlet temperature 160 °C; outlet temperature 80 °C; spray flow feed rate 5 ml/min; nozzle diameter 3 mm; drying air flow 0.5 L/h, air pressure 4 bar. The encapsulated powders obtained by spray drying were used for cookies preparation.

Preparation of Cookies fortified with fish oil

Fish oil was added in to three forms which includes fish oil as such (neat), fish oil-in-water emulsion (Fish oil was emulsified with tween 20 emulsifier) and fish oil encapsulates (spray dried) for the cookies preparation. Six different formulations were made for preparation of cookies namely; C1 – Cookies fortified with fish oil as such; C2 – Cookies fortified with fish oil in emulsion form; C3 – Cookies fortified with spray dried milk (without fish oil); C4 – Cookies fortified with fish oil encapsulates; C5 – Cookies fortified with fish oil encapsulates contained fish gelatin; C6 - Cookies fortified with fish oil encapsulates contained maltodextrin. C3 was served as control. Ingredients for the preparation of fish oil fortified cookies were optimized and set on the basis of preliminary sensory analysis (data not shown). Ingredients used for the cookies preparation are given in Table 2. Dough was prepared by mixing refined wheat flour with hydrogenated vegetable fat and fine powder of sugar followed by semolina, salt and baking powder. After mixing all ingredients, fish oil (as neat, fish oil-in-water emulsion and fish oil encapsulates) was added. Required water was added to make dough. All the ingredients were mixed using food processor (Phillips intelligent food processor, HL 1659, India) till the soft dough is formed. The prepared dough was subjected to sheeting of 6 mm thickness manually. Finally, sheets were cut in to 3.0 cm diameter by using the die and were subjected to baking at 180 °C for 15 min and cooled for 30 min. Then, the cookies were packed in low density polyethylene (LDPE) bags and stored in air-tight containers at room temperature for further analysis. Samples were drawn at monthly intervals and tested for oxidative stability up to six months.

Texture profile analysis of dough

Textural properties of dough were determined by using texture analyser (TA-Xt2i, Stable micro system, UK) by the two-bite texture profile analysis method (Bourne 2002). Briefly, Dough was sheeted in to 6 mm thickness. Then, the sheets were cut in to 3.0 cm diameter by using the die and it was used to assess the textural properties. The texture analyser settings were kept at: pre-test speed of 1 mm/s, test speed of 2 mm/s, post –test speed of 10 mm/s and trigger force of 40 g, probe diameter-2.54 cm; compression distance in to the dough was 50 %. Nexygen software was used for the tabulation of following texture parameters: Hardness, springiness, cohesiveness, resilience, adhesiveness and chewiness.

Breaking strength of cookies fortified with fish oil

Breaking strength of cookies was measured using the HDP/BS blade. The individual samples of cookies were placed on the platform such that they were supported at two points and the blade was attached to the crosshead of the instrument. Texture profile analysis setting was kept at: pre-test speed of 2 mm/s, test speed of 3 mm/s; post-test speed of 10 mm/s. This test simulates the evaluation of hardness by consumer holding the cookies in hands and breaking the same by bending. The absolute peak force from the resulting curve was considered the breaking strength of the cookies (Bourne 2002; Singh et al. 1993).

Hardness test for cookies fortified with fish oil

Hardness of the cookies was measured using cylindrical probe P/2 of texture analyser. The individual samples of cookies were placed on the platform and the probe was attached to the crosshead of the instrument. Texture profile analysis setting was kept at: pre-test speed of 2 mm/s, test speed of 0.5 mm/s, and post-test speed of 10 mm/s. The initial significant peak force from the resulting curve was considered as the initial fracture force and the absolute peak force was considered as the hardness of the cookies (Bourne 2002; Singh et al. 1993).

Physico-chemical and sensory evaluation of cookies fortified with fish oil

Proximate composition

Proximate composition of cookies fortified with fish oil was determined by the method of AOACAOAC (2000).

Spread ratio

The weight of the cookies was measured by weighing on a weighing balance. The diameter was measured with a calibrated ruler and the spread ratio was determined using Ayo et al. (2007) method. Three rows of the five well-formed cookies were made and the height was measured. Spread ratio was derived using the following formula:

Colour analysis

Colour of cookies was measured using a Hunter- Lab scan XE – Spectrocolorimeter (Hunter Associates Laboratory, Reston, USA.). Results were expressed by CIE (Commission Internationale de L ‘Eclairage’s) colour values [L*(lightness), a*(redness), b*(yellowness)] using Hunter colorimeter D-65 illuminant and 10° observer. The instrument was calibrated using white and black standard ceramic tiles and the readings were recorded with inbuilt software.

Determination of thiobarbituric acid (TBA) value in cookies

Oxidative stability of cookies fortified with fish oil was determined by TBA value according to Tarladgis et al. (1960) and expressed as mg malonaldehyde/kg. Briefly, 10 g of homogenized sample was mixed with 97.5 ml distilled water and 2.5 ml of 4 N HCl and homogenized to slurry. This slurry was then poured in to a round bottom flask and connected to the TBA distillation apparatus. Distillation was done until 50 ml of the distillate was collected within 10 min. 5 ml of distillate was taken in a test tube and 5 ml of TBA reagent was added and heated in a boiling water bath for 35 min. A blank was carried out with distilled water. Colour developed was measured in a spectrophotometer (Thermo scientific U.K. model UV 4.1) at 538 nm.

Sensory evaluation

The sensory characteristics of the freshly prepared cookies were evaluated using 10-trained panelist (research scholars and staff from Post Harvest Technology Division, Central Institute of Fisheries Education (CIFE), Mumbai). Panelists were selected after undergoing screening tests that included the five basic taste (bitter, sweet, sour, salt and umami), an aroma identification test. Before engaging in the sensory exercise, the panelists signed a consent form informing them of the nature of the samples they would evaluate. The samples were served in a coded and covered plate. They were asked to evaluate the sensory properties of cookies based on colour, aroma, taste, texture and overall acceptability. A five point scale was used, where scores 5, 4, 3, 2, and 1 were given for excellent, very good, good, satisfactory, and poor respectively for each of the sensory characteristics (Meilgaard et al. 1991).

Statistical Analysis

The data obtained were analyzed by running one way Analysis of variance (ANOVA) using Statistical Package for Social Science (SPSS) software version 16.0. (SPSS Inc., Chicago, Llinois, USA). All mean separations were carried out by Duncan multiple range test using the significance level of 95 % (P < 0.05). Statistical significance between the different treatment of cookies is indicated by appropriate letters within the tables.

Results and discussion

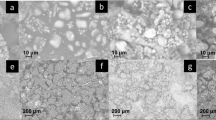

Properties of fish oil microencapsulates

In the present study, fish oil encapsulates produced with addition of fish gelatin, maltodextrin had an encapsulation efficiency ratio of 46.83 %, 49.34 % respectively. Encapsulation efficiency is used to assess the quality of the dried microcapsules because it has an effect on oxidation sensitivity and flow powder properties. Scanning electron microscopy evaluation revealed that fish oil encapsulates contained fish gelatin, maltodextrin showed microparticle in spherical shape in various size (data not shown). In our previous report on oxidative stability of fish oil microencapsultes, we have reported the properties and oxidative stability of fish oil encapsulates (Jeyakumari et al. 2014; Jeyakumari et al. 2015).

Proximate composition of cookies fortified with fish oil

The proximate composition of cookies fortified with fish oil is given in Table 3. In the present study, C3,C4,C5 and C6 samples had higher fat content (13.85–14.93 %) than C1 (11.43 %) and C2 (12.52 %). The statistical analysis revealed that there is significant difference (P < 0.05) in proximate composition of cookies. It may be due to incorporation of spray dried milk and encapsulates for the cookies preparation which resulted in considerable increase in fat, protein, and ash content of cookies. Umesha et al. (2015) observed significant increase in protein, fat and ash content in the microencapsulated garden cress oil (GCO) supplemented biscuits than control.

Physical properties of cookies fortified with fish oil

All the samples had a thickness range from 4.6 ± 0.244 mm to 7.8 ± 0.37 mm. However, fish oil encapsulates (C4, C5 and C6) incorporated cookies had less thickness (4.6–5.0 mm) than the samples with fish oil added directly (7.6–7.8 mm). Manohar and Rao (1999) observed reduced thickness of the biscuits which contained microencapsulation of fat than vegetable fat. In the present study C3, C4, C5, C6 formulation had microencapsulated fat which resulted in reduced thickness. Spread ratio of cookies ranged from 3.18 to 5.8. It was observed that cookies fortified with encapsulates had higher spread ratio (4.4–5.8) than the samples with fish oil added directly (3.1–3.6). Srivastava and Haridas (1993) reported that spread factor is highly affected by fat content, as the content of fat increased spread ratio gradually increased. In the present study, cookies contained microencapsulated powder (C3, C4, C5and C6)) had high fat content (13.85–14.93 %) than C1 (11.43 %) and C2 (12.52 %) samples. Surface browning is a common phenomenon for biscuits during baking. Brown pigments are formed in the advanced stages of browning reactions and can be measured by colour determination. Colour measurements provide a useful index to evaluate the intensity of browning reactions (Ramirez-Jimenez et al. 2000). Cookies prepared by the addition of fish oil as neat, fish oil-in-water emulsion showed highest L*(lightness) value of 74.81, 70.53 respectively (Table 4). However, C3, C4, C5, C6 showed less L* value in the range of 68.83–66.86. This indicates that microencapsulation of fat had a darkening effect on the biscuit surface. O’Brien et al. (2003) reported that biscuits containing vegetable fat showed highest L* value than the microencapsulated fat. Wehrle et al. (1999) found that biscuits containing higher free fats had low L* values/darker biscuits. The positive value of a* gives an indication of the redness fraction of the cookies colour. a* (redness) value was slightly higher (10.52–11.03) in cookies fortified with fish oil encapsulates than the fish oil added directly (7.56–10.03). The b* value is a measure of yellowness of the cookies colour which was observed to be highest in fish oil encapsulates incorporated sample (34.58–35.79). The decreased L* values and increased a* and b* values resulted in darkening of the biscuits. The present results are agreement with the similar studies reported in biscuits prepared with vegetable fat and microencapsulated fat (O’Brien et al. 2003).

Texture properties of dough

Texture properties of dough showed a hardness value between 4.10 ± 0.24 N to 5.70 ± 1.07 N. Sample contained fish oil as a neat (C1) and emulsion form (C2) showed higher hardness value (5.4 ± 0.98 N and 5.7 ± 1.07 N) than fish oil encapsulates added sample (4.1 ± 0.24 N to 4.92 ± 0.83 N). Similarly, chewiness, springiness, gumminess cohesiveness and resilence of dough prepared by the addition of fish oil encapsulates varied significantly to that of samples with fish oil added directly (Table 5). Water uptake by the flour,in the absence of sufficient fat also results in dough hardness (O’Brien et al. 2003). Manohar and Rao (1999) reported that hydrogenated vegetable fat produces very stiff hard doughs when compared to other fat type which supports the findings of this study.

Textural properties of cookies fortified with fish oil

Texture is one of the most important sensory attributes of snack foods. Texture is the sensory and functional manifestation of the structural, mechanical and surface properties of foods (Szczesniak 2002). Textural properties of cookies were evaluated by breaking strength, hardness and fracture force. Breaking strength is one of the criteria to measure the biscuit hardness (Larmond 1997). Cookies prepared with addition of fish oil as neat (C1), fish oil-in- water emulsion (C2) showed the breaking strength value of 75.45 ± 1.5 N, 57.06 ± 2.0 N respectively. However, cookies prepared with incorporating fish oil encapsulate showed a breaking strength of 31.02 ± 1.5 N to 38.14 ± 1.0 N. Results indicated that breaking strength of cookies prepared by using fish oil as neat, fish oil-in-water emulsion and fish oil encapsulates had significant difference (P < 0.05). The average initial fracture force is the measure of strength of biscuit. Results showed that fracture force of cookies prepared with fish oil microencapsulates (C5 and C6) had less value of 17.06 ± 1.0 N, 10.44 ± 2.5 N respectively than C1 (26.75 ± 2.3) and C2 (20.69 ± 3.8) samples which indicates the requirement of less force for initiation. The average peak force is the measure of biscuit hardness. In this case also, similar trend could be seen in the cookies (Table 6).

Sensory quality of cookies fortified with fish oil

The results of sensory evaluation showed that all the cookies received scores for over all acceptability between 2.8 ± 0.12 and 3.5 ± 0.15 out of maximum 5.0, which shows the acceptability of the finished product (Table 7). However, cookies fortified with fish oil in an emulsion form (3.2 ± 0.23) and fish oil encapsulates contained maltodextrin (3.5 ± 0.15) were comparable with control (without fish oil) (3.5 ± 0.08). Taste and perceived texture of a food depend upon the flavour components contained in it, constituent materials used to create it, and on the way the structure behaves in the mouth and flavours are released (Lucas et al. 2002). The form in which the fish oil is added, such as neat, an emulsion or microencapsulated will further influence bioavailability and oxidative stability (Nielsen and Jacobsen 2009) and the quality of biscuit is governed by the nature and quantity of the ingredients used (Manohar and Rao 1999). Results from the study, revealed the possibility of incorporating fish oil in cookies without significant modification of their sensory characteristics and increasing their nutritional value.

Oxidative stability of cookies fortified with fish oil

Thiobarbituric acid (TBA) test measures the intensity of lipid oxidation by measuring the colour of the complex formed due to the reaction between a secondary oxidation product, malonaldehyde and TBA reagent. In the present study, oxidative stability of cookies fortified with fish oil was evaluated up to six months. The level of malonaldehyde formation was significantly high in C2 (1.15 mg malonaldehyde/kg) and C1 (0.89 mg malonaldehyde/kg) than fish oil encapsulates incorporated sample (0.57–0.82 mg malonaldehyde/kg). The lipid used in the food emulsions normally contain small quantities of lipid peroxides (Frankel et al. 1996) and also iron is the common contaminants of water, so it would be expected that water soluble metal irons could catalyze the oxidation of dispersed lipid at the oil–water interface. High level of unsaturation of n-3 PUFA makes it extremely susceptible to oxidation (Kolanowski 2005; Kolanowski and Weibrodt 2007). It was observed that oxidative stability of C5 and C6 samples were comparable with C3 (without fish oil). Results indicated that cookies fortified with fish oil encapsulates contained gelatin (C5) or matodextrin (C6) showed significant (P < 0.05) decrease in lipid oxidation (Fig. 1). It clearly demonstrated that fish oil encapsulated with fish gelatin or maltodextrin could provide oxidative stability against lipid oxidation.

Conclusion

Fish oil its natural state has a taste and smells that makes it less attractive to consumers. Processing technology to mask the smell and taste in food systems is facing a great challenge. In the present study, fish oil or fish oil microencapsulate was incorporated in cookies to provide omega-3 fatty acid rich biscuits. Fortification of cookies by incorporating fish oil or fish oil microencapsulates improved nutritional quality of cookies. Sensory evaluation revealed that fish oil encapsulates contained maltodextrin were comparable with control (without fish oil) Cookies fortified with fish oil encapsulates contained fish gelatin, maltodextrin showed a better oxidative stability. Results from the study, demonstrated the possibility of fish oil incorporation into cookies through emulsification and encapsulation in order to enhance the dietary intake of omega-3 fatty acids. Further investigations are required to determine the factors responsible for yielding softer texture as perceived for fish oil encapsulates contained cookies by texture analysis and also to evaluate the bioavailability of omega-3 fatty acids in the fish oil fortified cookies.

References

Agarwal SR (1990) Prospects for small-scale biscuit industry in the nineties. Indian Food Industry 9:19–21

AOAC (2000) Official methods of analysis of AOAC international, 17th Edition, pp 2000. Horwitz W, ed. Gaithersburg, Maryland, USA.

Ayo JA, Ayo VA, Nkama I, Adewori R (2007) Physical, in-vitro digestibility and organoleptic evaluation of “acha” wheat biscuit supplemented with soybean flour. Nigerian Food J 25:77–89

Bourne M (2002) Food texture and viscosity: Concept and measurement. 353–368. Academic Press.

Drusch S, Mannino S (2009) Patent-based review on industrial approaches for the microencapsulation of oils rich in polyunsaturated fatty acids. Trends Food Sci Technol 20:237–244

Frankel EN, Huang SW, Prior E, Aeschbach R (1996) Evaluation of antioxidant activity of rosemary extracts, carnosol and carnosic acid in bulk vegetable oils and fish oil and their emulsions. J Sci Food Agric 72:201–208

Gudmundsson M, Hafsteinsson H (1997) Gelatin from cod skins as affected by chemical treatments. J Food Sci 62:37–47

Jacobsen C, Adler-Nissen J, Meyer AS (1999) Effect of ascorbic acid on iron release from the emulsifier interface and on the oxidative flavour deterioration in fish oil enriched mayonnaise. J Agric Food Chem 47:4917–4926

Jeyakumari A, Kothari DC, Venkateshwarlu G (2014) Microencapsulation of fish oil-mil based emulsion by spray drying: impact on oxidative stability. Fish Technol 51:31–37

Jeyakumari A, Kothari DC, Venkateshwarlu G (2015) Oxidative stability of microencapsulated fish oil during refrigerated storage. J Food Process Preserv. doi:10.1111/jfpp.12433

Kolanowski W, Laufenberg G (2006) Enrichment of food products with polyunsaturated fatty acids by fish oil addition. Eur Food Res Technol 222(3–4):472–477

Kolanowski W, Weibrodt J (2007) Sensory quality of dairy products fortified with fish oil. Int Dairy J 17:1248–1253

Kolanowski W (2005) Bioavailability of omega-3 PUFA from foods enriched with fish oil - a mini review. J Food Nutr Sci 14/55(4):335–340

Larmond E (1997) Laboratory methods for sensory evaluation of food. Publication No. 1637, Canada Department of Agriculture Ottawa, Canada.

Lovegrove JA, Brooks CN, Murphy MC, Gould BJ, Williams CM (1997) Use of manufactured foods enriched with fish oil as a means of increasing long-chain n-3 polyunsaturated fatty acids intake. Br J Nutr 78:233–238

Lucas PW, Prinz JF, Agrawal KR, Bruce IC (2002) Food physics and oral physiology. Food Qual Prefer 13:203–213

Manohar RS, Rao PH (1999) Effect of emulsifiers, fat level and type on the rheological characteristics of biscuit dough and quality of biscuit. J Sci Food Agric 79(10):1223–1231

Meilgaard M, Civille GV, Carr BT (1991) Sensory evaluation techniques, 2nd Ed, 135–235. CRC Press Inc, Boca Raton, Florida

Nielsen NS, Jacobsen C (2009) Methods for reducing lipid oxidation in fish-oil enriched energy bars. Int J Food Sci Technol 44:1536–1546

O’Brien CM, Chapman D, Neville DP, Keogh MK, Arendt EK (2003) Effect of varying the microencapsulation process on the functionality of hydrogenated vegetable fat in short dough biscuits. Food Res Int 36:215–221

Ramirez-Jimenez A, Guerra-Hernandez E, Garcia-Villanova B (2000) Browning indicators in bread. J Agric Food Chem 48(9):4176–4181

Sanders TAB (2000) Polyunsaturated fatty acids in the food chain in Europe. Am J Clin Nutr 71:176–181

Shakuntala B, Masur SB, Tarachand KC, Kulkarni UN (2009) Development of high protein biscuits from Bengal gram flour. Karnataka J Agr Sci 22(4):862–864

Singh B, Bajaj M, Kaur A, Sharma S, Sidhu JS (1993) Studies on the development of high protein biscuits from composite flour. Plant Food Hum Nutr 43(2):181–189

Srivastava AK, Haridas RP (1993) Studies on low-fat soft dough biscuits. J Food Sci Technol 30(1):21–24

Sudha ML, Vetrimani R, Leelavathi K (2007) Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem 100(4):1365–1370

Szczesniak SA (2002) Texture is a sensory property. Food Qual Prefer 13:215–225

Tarladgis GB, Watts MB, Younathan TM (1960) A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc 37:44–50

Umesha S, Sai Manohar R, Indiramma AR, Akshitha S, Akhilender Naidu K (2015) Enrichment of biscuits with microencapsulated omega-3 fatty acid (alpha-linolenic acid) rich garden cress (lepidium sativum) seed oil: physical, sensory and storage quality characteristics of biscuits. LWT Food Sci Technol 62:654–661

Wehrle K, Gallagher E, Neville DP, Keogh MK, Arendt EK (1999) Microencapsulated high-fat powders in biscuit production. Eur Food Res Technol 208:388–393

Acknowledgments

The authors thank Director, Dr. W. S. Lakra, Central Institute of Fisheries Education, Mumbai for providing the required facilities. The first author acknowledges Indian Council of Agricultural Research (ICAR), New Delhi for awarding Senior Research Fellowship to carry out Ph.D. programme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeyakumari, A., Janarthanan, G., Chouksey, M.K. et al. Effect of fish oil encapsulates incorporation on the physico-chemical and sensory properties of cookies. J Food Sci Technol 53, 856–863 (2016). https://doi.org/10.1007/s13197-015-1981-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1981-2