Abstract

Several active components naturally available in plants are strongly considered as good antioxidants to retard the lipid oxidation. Response surface methodology was used to investigate the effects of frying temperature (150–180 °C) and concentration of four plant-based active components (60–350 mg/kg oil); curcumin, cinnamaldehyde, thymol and carvacrol on oxidative stability of corn and palm oils. According to induction time values, the stability of oils drastically decreased with increasing temperature. Curcumin and cinnamaldehyde showed no significant effect (p > 0.05) on both oils. Carvacrol significantly increased induction times of corn and palm oils, but thymol was effective in palm oil only (p < 0.05). An actual frying experiment was carried out with only corn oil to confirm efficiency of carvacrol. The free fatty acid (%), peroxide value (meq/kg), para-anisidine, and total polar component values (%) of the fresh oil were 0.080, 2.55, 2.85, and 7.5, respectively. These values changed to 0.144, 1.47, 12.01, 10.0, respectively for the control oil; 0.138, 2.27, 11.49, 10.0 for BHT-added oil; 0.132, 1.42, 5.66, 9.5 for carvacrol-added oil after 30 frying cycles. Therefore, carvacrol could be considered as a good alternative to BHT for preservation of oils at frying temperatures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Frying, which is a popular and common cooking method gives food’s palatability because of fat absorption, crust formation and desired good flavours and odours. When frying oils are used continuously or repeatedly at high temperatures in the presence of oxygen and water from the food being fried, undesirable changes which finally results in deterioration of oil occur besides desirable changes. These negative changes in the oil affect the quality of fried food at the same time (Gertz 2008). Through lipid oxidation, which is one of the major concerns in frying of foods, the chemical structure of oil molecules is altered and the oil may eventually reach a level where it is no longer used for getting high quality of fried products and it must be discarded (Kathirvel and Rupasinghe 2011). The lipid oxidation also causes rancid odours and flavours of the food products. Besides the oil shelf life, it results in decreases in nutritional quality and safety caused by formation of potentially toxic secondary compounds.

The most preferable way to inhibit the lipid oxidation mechanism is the use of antioxidants. Because of perceived harmful effects of synthetic antioxidants, investigations have focused on the using of natural antioxidants to stabilise the oils. Many studies have proven the effectiveness of natural antioxidants in protection of the oils from lipid oxidation (Rodrigues et al. 2012; Inanc and Maskan 2012; Chen et al. 2014; Taghvaei and Jafari 2015).

Plants are well known for their antioxidant properties because of their contents of mainly phenolic compounds. Besides of that they are used to delay the oil deterioration. They can also protect the human body from many chronic diseases (Yong 2007). Extracts, essential oils of plants and their active components are commonly used as natural antioxidants for stabilising the oils. Many studies with these plant-derived compounds as natural antioxidants in food products led the researchers to conclude that some plant compounds could be considered as proper alternatives to synthetic antioxidants. However, the essential oils have been observed to have an effect on the oxidative stability of edible oils, especially during storage (Tomaino et al. 2005; Maestri et al. 2006; Al-Jaber et al. 2011; Chen et al. 2014). In our previous study, various essential oils showed poor antioxidant activity during the accelerated oxidation test of corn oil, presumably due to low concentration of active components and interference of extraneous pro-oxidative materials in the essential oils (Inanc and Maskan 2013).

In the current study, it was thus aimed to improve the heat stability of vegetable oils by using active components of these essential oils. The effects of frying temperature (150–180 °C) and the concentration of four active components (60–350 mg/kg oil); curcumin, cinnamaldehyde, thymol and carvacrol on the oxidative stability of two different vegetable oils of different unsaturation degree; corn and palm oils were examined by using response surface methodology to decide the acceptable conditions for further deep-frying experiments. As a response value, the induction time of each sample was measured by PetroOXY device. By this way, the most stable active component was determined in order to be used in deep fat frying experiments to confirm its efficiency. The results were compared with BHT to realise whether the frying stability of oils could be provided by using natural antioxidant instead of synthetic ones.

Materials and methods

Materials

In this study, the materials used were two different vegetable oils; corn and palm oil, four active components; curcumin (≥94 %), cinnamaldehyde (≥95 %), thymol (≥99,5 %) and carvacrol (≥98 %) as natural antioxidants and a synthetic antioxidant, BHT. Corn oil was purchased from a local market and palm oil was supplied from a manufacturer in Gaziantep-Turkey. Active components and BHT were obtained from the Sigma Aldrich Co. (St. Louis, MO).

Accelerated oxidation experiments

Experimental design and statistical analysis

Response Surface Methodology (RSM) was applied to experimental data by using a commercial statistical package, Design-Expert (Version 6.0, Stat ease Inc., Minneapolis, MN, USA), for the generation of response surface plots. The independent variables (antioxidant concentration and temperature) and varying levels are shown in Table 1. The antioxidant concentration (A) was selected as 60–350 mg/kg oil for all active components and BHT (covering the legal limit of synthetic antioxidant, 200 mg/kg oil). Temperature (B) was selected as 150–180 ̊C in the range of frying temperatures. Induction period, which is an indicator of oxidative stability of oil samples was measured as a response by using PetroOXY.

Determination of induction period by accelerated oxidation method

Induction period is defined as the time prior to acceleration of lipid oxidation. From this definition, it can be easily understood that the substances having higher induction period have better oxidative stability. In this study, Petrotest PetroOXY device (Petrotest Instruments GmbH & Co. KG, Dahlewitz, Germany) was employed to measure the induction times of the samples. This device is new in the food science and technology researches. Therefore, it has not been widely used in oxidative stability test of foods up to now. The PetroOXY have a small hermetically sealed test chamber. Within the test chamber a small amount of sample, about 5 ml, is exposed to pure oxygen (99.9997 % purity) at a pressure of 700 kPa and heated to a desired temperature. These test conditions provide with a very fast artificial ageing process. As the oil sample oxidises, it consumes the oxygen in the sealed test chamber resulting in a pressure drop. The induction period is determined as time elapsed between starting a test and the breaking point (Fig. 1). It is defined as a pressure drop of 10 % below the maximum pressure detected in the test chamber as it warms up to test temperature as described by Neumann et al. (2008). The induction periods of control and oil samples with different antioxidant concentrations were measured by using the PetroOXY under 700 kPa of oxygen and the temperatures according to the experimental design shown in Table 1.

A representative plot showing determination of induction period (Neumann et al. 2008)

Determination of frying conditions and validation of models by experiments

By statistical analyses of the results, the most effective natural antioxidant type, its acceptable concentration in the two frying oils, and the suitable temperature (yielding maximum induction time) were determined in order to use for further frying experiments in only corn oil. In order to verify the optimised parameters and model equations, confirmation experiments were conducted.

Frying experiments

Potato slices were fried at 150 °C in only corn oil with 200 mg/kg oil antioxidant concentration. Three sets of frying experiments were performed; natural antioxidant added oil, BHT added oil and control oil (contains no antioxidant).

Frying process was conducted in an electric deep fat fryer with a thermostat to regulate temperature (Arnica, Deep Fryer, ZG 27A, China). Frying was started 30 min after the temperature of oil had reached the frying temperature. For each frying cycle, 100 g of the sliced fresh potatoes (6.0 ± 1.23*7.8 ± 1.25*49.5 ± 4.09 mm3) were used. The slices were soaked in NaCl solution (2.5 g/100 mL) for 5 min prior to frying. This reduces oil absorption capacity and prevents surface darkening of the potato slices because of oxidation. Following draining the water, potato slices were dried by blotting with a paper towel before frying. Potatoes were fried in 2 l of oil for 4 min. This period was decided from preliminary experimental studies to reach a moisture content (2 g/100 g) of potatoes. Then, the oil was heated for 5 min in order to attain frying temperature again. For each set, totally 30 fryings (cycles) were made with the same oil. Fresh oil was not added between the cycles. After each tenth frying cycle, the oil was allowed to equilibrate within 30 min at the frying temperature and 50 ml of the oil sample was collected and stored at 4 ̊C for further analyses.

Measurement of oil deterioration during frying by chemical analysis

After each tenth frying cycle, peroxide value (AOCS 1989), free fatty acid (AOCS 1989), para-anisidine value (IUPAC 1987), and total polar compound (Hampikyan et al. 2011) measurements were carried out by using collected samples in order to evaluate deterioration in the oils. The data were analysed for significant differences by one-way analysis of variance and compared by Duncan’s multiple range test at the 5 % significance level using SPSS 16.0 software.

Results and discussions

The conditions of all accelerated methods are almost unlike in a typical frying process. It is important to note that in Rancimat there is a continuous flow of air bubbling through the bulk of the sample. The availability of air has an important contribution to accelerate oxidation. This is one of the disadvantages of Rancimat. Because in actual frying process, there is no bubbling of air applied. However, accelerated tests under the conditions of Rancimat may be useful to predict the relative shelf-life of different oils and fats, but they would not give an indication of their actual frying performance. The disadvantage of the device that we used (PetroOxy) may be that the volatile components are not released during the oxidation test. However, the results from this instrument could be used to test antioxidant activity and/or to predict the relative shelf-life of different oils and fats. Since some antioxidants used in this study are volatile, they may be lost during the actual frying process. In this study, the antioxidant activity was measured in a closed system where evaporation of the antioxidant is prevented.

The behaviours of antioxidants in corn and palm oils

The induction periods of corn and palm oil samples were determined from PetroOxy in the presence of active components used as natural antioxidant and BHT as a synthetic antioxidant (60–350 mg/kg oil) at frying temperatures (150–180 °C). The regression models successfully predicted the induction period of oil samples. The quality of fit to the model equations was confirmed with the high values of coefficient of determination (R2) and significance of the model (Table 2).

Curcumin, which is the major active natural phenolic compound found in the Indian spice turmeric, is known to have a remarkable antioxidant activity (Ross et al. 2000). Banerjee et al. (2015) concluded that the rate of deterioration being more in soybean oil than the oil in which food marinated with turmeric is fried. However, in the present study, the curcumin was not significantly (p > 0.05) effective on induction period of both corn and palm oils at frying temperatures (Table 3). It may be due to the low antioxidant activity of curcumin at high temperatures, although turmeric leaf extract was found to be effective in retarding oil oxidation and deterioration in palm oil at very high temperatures in one study (Nor et al. 2009). The reason for this opposition might be due to the synergistic effect of several polyphenols present in the plant extract. But frying temperature significantly (p < 0.0001) affected the induction periods of both oils at all frying conditions (Table 3).

Cinnamaldehyde which is one of the active components of cinnamon has antioxidant activity (Singh et al. 2007). However, in this study, cinnamaldehyde did not affect significantly (p > 0.05) induction periods of both corn and palm oils in spite of some reported high antioxidant activity of cinnamon by many studies (Table 3). It might be due to its low heat stability and lack of synergy with other phenols in corn and palm oils (Yanishlieva et al. 2006; Brewer 2011; Ozcan and Arslan 2011).

Thymol is known as the main component of thyme. It is also present as active component in other plants such as cinnamon and clove (Muchuweti et al. 2007). The statistical analysis of the independent variables and the response surface plots (Fig. 2) created by using the model equations in Table 2, shows the effects of thymol and temperature on induction times of corn and palm oil samples. As shown in Fig. 2a, thymol did not have a significant effect on the induction period of corn oil at frying temperatures (p > 0.05). It might be due to the fact that the interaction of thymol with corn oil could not create a notable antioxidant activity at high temperatures. Because, the antioxidative effect depends on the frying conditions, on the degree of unsaturation of the oil and on the content and chemical structure of other oil minor compounds present exerting a synergistic effect. Marmesat et al. (2010) reported that some antioxidants rapidly degrade and cannot act as antioxidants at frying temperatures in some oils. Decomposition of thymol in corn oil (an unsaturated oil) could be one of the major reasons why carvacrol but not thymol was effective in corn oil. However, it had a significant (p < 0.05) positive effect on the retarding oxidative deterioration of palm oil, especially at low temperatures between 144 and 165 ̊C (Fig. 2b).

Several studies have been conducted on the effect of thyme on oils at various temperatures. Thyme extracts and essential oils were found to exhibit strong antioxidant effect generally at storage temperatures (Yanishlieva et al. 2006; Brewer 2011; Quiroga et al. 2011). However, Tomaino et al. (2005) revealed that thyme essential oil was not effective at high temperature although it has shown good antioxidant effect at room temperature. This result is in agreement with the present study. Nacaroglu (2006) also verified our findings by reporting in their studies that the essential oil of Thymbra spicata increased the oxidative stability of palm oil. It might be also because of its thymol content.

Carvacrol is another active component used in this study. It is the main active component of oregano, but also naturally available in several plants such as thyme, clove and cinnamon (Yanishlieva et al. 2006; Ozcan and Arslan 2011). The strong antioxidant activity of oregano was pointed out by several studies (Brewer 2011; Quiroga et al. 2011). These results support our findings. The antioxidant activity of oregano and other plants in these studies are mainly due to carvacrol and its synergistic effect with other active compounds present in the oils.

In the current study, carvacrol was found to have a highly significant linear effect on the induction period of corn oil (p < 0.05) in contrast to other active components, curcumin, cinnamaldehyde and thymol. It was obvious in the response surface plot (Fig. 2c) that an increase in the carvacrol concentration increased the induction period of corn oil in the low constant temperatures (144-165 °C). According to statistical analysis results and the response surface plot (Fig. 2d) carvacrol increased induction period of palm oil significantly as well as that of corn oil.

BHT is known as a strong synthetic antioxidant commercially used in vegetable oils for extending the storage life. However, many studies showed that it is also effective in retarding the oxidative deterioration of oils at frying temperatures (Shahidi 2005; Chen et al. 2014). In the present study, the synthetic antioxidant BHT was found to be effective in the induction periods of corn and palm oils. According to the response plots (Fig. 2e, f) and statistical analysis, linear and interaction effects were clearly realised to be significantly positive (p < 0.05).

From Table 3 and the response surface plots, it can be easily understood that temperature had a significant effect (p < 0.05) on the induction period of all the oil samples, regardless of type of antioxidant (Fig. 2). The active components and BHT were more effective on stability of corn and palm oils at low temperatures than high temperatures. At high temperatures (165–186 °C), they could not considerably increased the induction periods of corn and palm oil samples probably due to the higher negative significant effect of temperature (p < 0.0001) and their low activity at these temperatures.

It was concluded from response surface plots and statistical analysis results that only carvacrol had a statistically significant effect (p < 0.05) on the induction periods of both corn and palm oil samples (Table 3 and Fig. 2). Although, the concentration effect of thymol was found to be significant in palm oil, it had no significant effect in corn oil samples. However, two other active components; curcumin and cinnamaldehyde could not significantly increased the induction periods of both corn and palm oils. In addition, higher induction period values were obtained from palm oil samples compared to corn oil. The reason is the presence of highly polyunsaturated fatty acids in corn oil that makes it more susceptible to oxidation. The stability of palm oil is a consequence of its high palmitic acid and low linoleic acid contents (Abdulkarim et al. 2008). It is also probable that interaction among the polyphenolic compounds, tocopherols and tocotrienols in palm oil and active components resulted in a synergistic antioxidant effect as reported in a previous study (Nor et al. 2009).

Frying conditions and validation of models by experiments

Because of strong antioxidant activity of carvacrol in both corn and palm oils, it was selected as natural antioxidant to be used in frying of potatoes in corn oil. It was decided to use carvacrol at a concentration of 200 mg/kg oil, which is a legal usage limit of synthetic antioxidants. Thus, it could be comparable with the results of BHT. In addition to this, the temperature for the frying experiments was selected as 150 ̊C at which the induction periods of both oils were found to be high (Fig. 2).

Table 4 provides a comparison of experimental and predicted values of induction periods for corn and palm oils containing carvacrol and BHT (200 mg/kg oil) at various temperatures. The predicted values were obtained from the regression equations (Table 2). Paired t-test showed no statistical differences between the experimental and predicted values (p > 0.05).

It is obvious to see that carvacrol and BHT increased the induction periods significantly compared with the control oil values (Table 4). Also, as the temperature increased the effectiveness of carvacrol and BHT reduced dramatically and became insignificant.

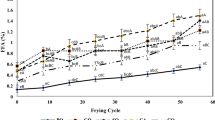

Change in free fatty acids (FFA) of corn oil during frying

During frying, oil is exposed to air and moisture at elevated temperatures resulting in hydrolysis of triacylglycerol. This causes the release of free fatty acids. The released fatty acids are more susceptible to thermal oxidation and cause off-flavours and odours in the frying medium and fried foods. The FFA values increased with number of fryings in corn oil as shown in Fig. 3a. However, carvacrol slowed down the formation of FFA significantly (p < 0.05). According to statistical analysis, the effect of number of fryings on the increase of FFA was significant (p < 0.05). This is in good agreement with several previous works (Iqbal et al. 2008; Nor et al. 2009).

Treatment of oils with antioxidants significantly decreased the FFA in corn oil as the results compared to control (p < 0.05). Carvacrol was found to be more effective than BHT. Multiple comparison tests showed that the effect of carvacrol is significantly better than BHT and control. Several researchers found similar results in their studies about the efficiency of natural antioxidant in vegetable oils (Iqbal et al. 2008; Nor et al. 2009).

Change in peroxide value (PV) of corn oil during frying

Peroxide value is an indicator of primary oxidation changes since peroxides are the first compounds formed during lipid oxidation. However, it is not actually show total degree of rancidity in the oils. Because, peroxides are rapidly broken down into secondary oxidation products and formed again during frying process (Augustin and Berry 1983; Farhoosh and Moosavi 2009).

According to Fig. 3b containing PV results of the present study, it is obvious that there was not a regular meaningful trend in change of peroxides of the corn oil samples. Romano et al. (2012) also stated that during frying, the formation of peroxides is inhibited by reduced availability of oxygen because its solubility in oil is reduced at high temperatures and also the water released from food creates a protective cloak of steam. Thus, peroxide value is not considered to be a useful test for evaluation of oxidative stability of frying oils.

Change in para- anisidine value (pAV) of corn oil during frying

The para-anisidine value is a measure of the content of aldehydes which are secondary oxidation products formed when the hydroperoxides decompose (Shahidi 2005). The changes in the pAV of the corn oil samples during a series of frying were presented in Fig. 3c. An increase in the pAV of all the oil samples with frying numbers was observed. These findings are in good agreement with several studies (Naz et al. 2008; Chen et al. 2014). The statistical analysis results also showed the significant effect (p < 0.05) of frying numbers on the increase in pAV of the oils. From Fig. 3c, it could be also seen that the pAV of the oil samples treated with antioxidants were distinctly lower than the control samples.

ANOVA and multiple comparison test results showed that there were significant (p < 0.05) differences among the antioxidant-treated oils and control. From the graph it could be easily understood that carvacrol had a greater effect on the reduction in pAV of corn oil than the synthetic antioxidant, BHT. Naz et al. (2004) similarly reported the positive effects of natural antioxidants on the reduction of pAV of corn oil.

Change in total polar compounds (TPC) of corn oil during frying

The amount of total polar compounds, that are formed through oxidation, thermal and hydrolytic reactions during frying, indicates the degree of deterioration in frying oil (Hampikyan et al. 2011; Osawa et al. 2012).

In this study, TPC was measured by an instrument, Testo 265, which provides more accurate results in a very short time compared to the traditional method. The principle of the instrument is based on the measurement of changes in dielectric constant of frying oil and directly transform the data into the percentage in weight of polar compounds (Hampikyan et al. 2011; Osawa et al. 2012). When frying oil decompose thermally or through oxidation processes, its dielectric constant increases (Hein et al. 1998).

Figure 3d shows that amount of TPC significantly increased (p < 0.05) during the first period of frying process in all oil samples. However, it was determined that there was no sharp change in TPC of the oils with respect to the successive frying numbers.

Carvacrol was found to be significantly (p < 0.05) effective on slowing down the formation of TPC during frying in corn oil. However, this effect was not statistically different from the BHT according to the multiple comparison test results (p > 0.05). Several authors also reported the positive effect of some natural antioxidants on the prevention of polar compounds formation (Iqbal et al. 2008; Nor et al. 2009).

Conclusion

The results of accelerated oxidation experiments revealed that temperature had a very significant negative effect on the oxidative stability of both corn and palm oils. It was also concluded that the least effective natural antioxidant on both corn and palm oil stability was found to be cinnamaldehyde, whereas the most effective one was carvacrol. This effect was also comparable to the synthetic antioxidant, BHT. Thus, carvacrol can be considered as an alternative to BHT. This strong antioxidant effect of carvacrol in corn oil at high temperatures was also correlated with the results of chemical analysis of frying oil during the frying process.

The strong and characteristic flavour of these natural antioxidants may adversely affect sensorial properties of both oil and fried food. Therefore, this important aspect should be evaluated in further studies. It is also recommended to explore these natural antioxidants by means of toxicology to conveniently use them in foods.

References

Abdulkarim SM, Frage A, Tan CP, Ghazali HM (2008) Determination of the extent of frying fat deterioration using differential scanning calorimetry. J Food Agric Environ 6:54–59

Al-Jaber NA, Awaad AS, Moses JE (2011) Review on some antioxidant plants growing in Arab World. J Saudi Chem Soc 15:293–307

AOCS (1989) Official methods and recommended practices of the American Oil Chemists’ Society, 4th edn. American Oil Chemists’ Society, Champaign

Augustin MA, Berry SK (1983) Efficacy of the antioxidants BHA and BHT in palm olein during heating and frying. J Am Oil Chem Soc 60:1520–1522

Banerjee A, Ghosh S, Ghosh M (2015) Anti-oxidative effect of turmeric on frying characteristics of soybean oil. J Food Sci Technol 52:1760–1765

Brewer MS (2011) Natural antioxidants: sources, compounds, mechanisms of action, and potential application. Compr Rev Food Sci 10:221–247

Chen XQ, Zhang Y, Zu YG, Yang L, Lu Q, Wang W (2014) Antioxidant effects of rosemary extracts on sunflower oil compared with synthetic antioxidants. Int J Food Sci Technol 49:385–391

Farhoosh R, Moosavi SMR (2009) Evaluating the performance of peroxide and conjugated diene values in monitoring quality of used frying oils. J Agric Sci Technol 11:173–179

Gertz C (2008) Optimum deep-frying: recommendations by the German Society for fat science. www.dgfett.de/material/optimum_frying.pdf, 29.06.2012

Hampikyan H, Colak H, Akhan M, Turgay I (2011) Determination of total polar compound (TPC) levels in frying oils. J Food Agric Environ 9:142–144

Hein M, Henning H, Isengard HD (1998) Determination of total polar parts with new methods for the quality survey of frying fats and oils. Talanta 47:447–454

Inanc T, Maskan M (2012) The potential application of plant essential oils/extracts as natural preservatives in oils during processing: a review. J Food Sci Eng 2:1–9

Inanc T, Maskan M (2013) Testing the antioxidant effect of essential oils and BHT on corn oil at frying temperatures: a response surface methodology. J Am Oil Chem Soc 90:1845–1850

Iqbal S, Haleem S, Akhtar M, Zia-ul-Haq M, Akbar J (2008) Efficiency of pomegranate peel extracts in stabilization of sunflower oil under accelerated conditions. Food Res Int 41:194–200

IUPAC (1987) Standard methods for the analysis of oils, fats and derivatives, 7th edn. Blackwell Scientific, London

Kathirvel P, Rupasinghe HPV (2011) Plant-derived antioxidants as potential omega-3 PUFA stabilizers. In: Dijk MV, Vitek J (eds) Fish oil: production, consumption and health benefits. Nova Science Publishers, Inc, Hauppauge, pp 158–185

Maestri DM, Nepote V, Lamarque AL, Zygadio JA (2006) Natural products as antioxidants. Res Sign 1:105–135

Marmesat S, Morales A, Velasco J, Dobarganes MC (2010) Action and fate of natural and synthetic antioxidants during frying. Grasas Aceites 61:333–340

Muchuweti M, Kativu E, Mupure CH, Chidewe C, Ndhlala AR, Benhura MAN (2007) Phenolic composition and antioxidant properties of some spices. Am J Food Technol 2:414–420

Nacaroglu S (2006) Effect of butylated hydroxytoluene and essential oils of Thymbra spicata on stability of corn and palm oils during deep-fat frying. M. Sc. Thesis, Graduate School of Natural and Applied Sciences, University of Gaziantep, Turkey

Naz S, Sheikh H, Siddiqi R, Sayeed S (2004) Oxidative stability of olive, corn and soybean oil under different conditions. Food Chem 88:253–259

Naz S, Siddiqi R, Sayeed SA (2008) Effect of flavonoids on the oxidative stability of corn oil during deep frying. Int J Food Sci Technol 43:1850–1854

Neumann A, Jebens T, Wierzbicki V (2008) A method for determining oxidation stability of petrodiesel, biodiesel, and blended fuels. Am Lab 40:22–26

Nor FM, Mohamed S, Idris NA, Ismail R (2009) Antioxidative properties of Curcuma longa leaf extract in accelerated oxidation and deep frying studies. J Am Oil Chem Soc 86:141–147

Osawa CC, Gonçalves LAG, Gumerato HF, Mendes FM (2012) Study of the effectiveness of quick tests based on physical properties for the evaluation of used frying oil. Food Control 26:525–530

Ozcan MM, Arslan D (2011) Antioxidant effect of essential oils of rosemary, clove and cinnamon on hazelnut and poppy oils. Food Chem 129:171–174

Quiroga PR, Riveros CG, Zygadlo JA, Grosso NR, Nepote V (2011) Antioxidant activity of essential oil of oregano species from Argentina in relation to their chemical composition. Int J Food Sci Technol 46:2648–2655

Rodrigues N, Malheiro R, Casal S, Manzanera MC, Asensio S, Bento A, Pereira JA (2012) Influence of spike lavender (Lavandula latifolia Med.) essential oil in the quality, stability and composition of soybean oil during microwave heating. Food Chem Toxicol 50:2894–2901

Romano R, Giordano A, Vitiello S, Le Grottaglie L, Musso SS (2012) Comparison of the frying performance of olive oil and palm superolein. J Food Sci 77:519–531

Ross L, Barclay RC, Vinqvist MR, Mukai K, Goto H, Hashimoto Y, Tokunaga A, Uno H (2000) On the antioxidant mechanism of curcumin: classical methods are needed to determine antioxidant mechanism and activity. Org Lett 2:2841–2843

Shahidi F (2005) Bailey’s industrial oil and fat products, 6th edn. Wiley, New York

Singh G, Maurya S, deLampasona MP, Catalan CAN (2007) A comparison of chemical, antioxidant and antimicrobial studies of cinnamon leaf and bark volatile oils, oleoresins and their constituents. Food Chem Toxicol 45:1650–1661

Taghvaei M, Jafari SM (2015) Application and stability of natural antioxidants in edible oils in order to substitute synthetic additives. J Food Sci Technol 52:1272–1282

Tomaino A, Cimino F, Zimbalatti V, Venuti V, Sulfaro V, De Pasquale A, Saija A (2005) Influence of heating on antioxidant activity and the chemical composition of some spice essential oils. Food Chem 89:549–554

Yanishlieva NV, Marinova E, Pokorny J (2006) Natural antioxidants from herbs and spices. Eur J Lipid Sci Technol 108:776–793

Yong YS (2007) Determination of synthetic phenolic antioxidants in food items using HPLC and total antioxidants using FIA approaches. Universiti Sains Malaysia, Malaysia

Acknowledgments

This research project was supported by the University of Gaziantep, Scientific Research Projects Governing Unit (Turkey) (Project No: MF.10.11) which led to this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Research highlights

• Accelerated oxidation of palm and corn oils was tested by PetroOxy device

• Possibility of usage of plant based active components was investigated

• Carvacrol showed significant effect on induction periods of palm and corn oils

• Curcumin and cinnamaldehyde had no effect at frying temperatures in both oils

Rights and permissions

About this article

Cite this article

İnanç Horuz, T., Maskan, M. Effect of the phytochemicals curcumin, cinnamaldehyde, thymol and carvacrol on the oxidative stability of corn and palm oils at frying temperatures. J Food Sci Technol 52, 8041–8049 (2015). https://doi.org/10.1007/s13197-015-1913-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1913-1