Abstract

The use of chemometrics to analyse infrared spectra to predict pork adulteration in the beef jerky (dendeng) was explored. In the first step, the analysis of pork in the beef jerky formulation was conducted by blending the beef jerky with pork at 5–80 % levels. Then, they were powdered and classified into training set and test set. The second step, the spectra of the two sets was recorded by Fourier Transform Infrared (FTIR) spectroscopy using atenuated total reflection (ATR) cell on the basis of spectral data at frequency region 4000–700 cm−1. The spectra was categorised into four data sets, i.e. (a) spectra in the whole region as data set 1; (b) spectra in the fingerprint region (1500–600 cm−1) as data set 2; (c) spectra in the whole region with treatment as data set 3; and (d) spectra in the fingerprint region with treatment as data set 4. The third step, the chemometric analysis were employed using three class-modelling techniques (i.e. LDA, SIMCA, and SVM) toward the data sets. Finally, the best result of the models towards the data sets on the adulteration analysis of the samples were selected and the best model was compared with the ELISA method. From the chemometric results, the LDA model on the data set 1 was found to be the best model, since it could classify and predict 100 % accuracy of the sample tested. The LDA model was applied toward the real samples of the beef jerky marketed in Jember, and the results showed that the LDA model developed was in good agreement with the ELISA method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The analysis of food authenticity and the detection of adulteration are major issues in the food industry, and are attracting of concern among consumers. Adulteration of food has ranged from the simple addition of natural compounds to the much more serious case of contamination with harmful substances (Defernez and Wilson 1995). In meat and meat products, major authenticity and adulteration issues concern the substitution of high value raw materials with cheaper materials, such as less costly cuts, mechanically recovered meat, offal, blood, water, eggs, gluten or other proteins of animal or vegetable origin (Al-Jowder et al. 1997). For instance, in the some food manufacturers choose to blend beef with pork to reduce production cost due to pork is the cheapest meat commonly available for these food industries.

Food products containing pork are of great concern to followers of Islamic and Jewish religions. Both religions prohibit the consumption of pork in any products (Regenstein et al. 2003; Bonne and Verbeke 2008). Besides, diets rich in pork are known to associate with certain health risk, such as hypercholesterolemia and coronary heart disease with daily intake (Rashood et al. 1995). In view of the restrictions on their consumption by some religions and the biological complications associated with pork, a proper method is urgently needed to analyse the presence of pork in food.

Currently, the analytical methods used to analyse pork adulteration rely on either protein or DNA analysis. Protein based methods include; Fourier transform infrared (FTIR) spectroscopy (Rohman and Che Man 2010; Rohman et al. 2011), near-infrared spectroscopy (Cozzolino and Murray 2002), electronic nose (Che Man et al. 2005a, b; Tian et al. 2013), chromatography (Chou et al. 2007) and electrophoresis (Montowska and Pospiech 2007). Additionally, analyses of immunoassays, which rely on the use of antibodies raised against a specific protein, are also developed as ELISA (Chen and Hsieh 2000) and imunosensors (Fajardo et al. 2010). Protein based techniques have a number of limitations. They are limited when assaying heat treated products due to denaturation of proteins during thermal processing (Fajardo et al. 2010). DNA based methods include; polymerase chain reaction (PCR) amplification of mitochondrial DNA (Aida et al. 2005, Che Man et al. 2007), PCR–restriction fragment length polymorphism (RFLP) analysis (Aida et al. 2007; Chen et al. 2010; Murugaiah et al. 2009) and PCR sequencing (Karlsson and Holmlund 2007; La Neve et al. 2008). DNA-based methods have led to a change from protein to DNA analysis, due to the advantages DNA in differentiating among different animal species (Ballin 2010). DNA is present in majority of cells and the information content of DNA, can also be extracted from all kinds of tissues (Lockley and Bardsley 2000), it is a stable molecule that allows analysis of processed and heat treated products (Aida et al. 2005), However, generally DNA analysis needs sample pretreatment and PCR amplification for their analysis, which in turn lengthening the procedure, laborious and time consuming.

Infrared spectroscopy has recently been applied to this problem using some experimental and statistical approaches. FTIR spectroscopy represents an important tool used for quality control and monitoring process in the food industry because it is less expensive, better in performance and easier to use than other method (Van de Voort et al. 1993). FTIR spectroscopy offers a fast and non-destructive alternative to chemical measurement techniques for qualitative characterization and quantitative measurements. Infrared spectroscopy has been used to provide information on the molecular composition and structure of a diverse range of materials (Cronin and McKenzie 1990; Guillen and Cabo 1997). In comparison with conventional instruments, FTIR has a higher energy throughput, excellent reproducibility and accuracy from the laser source. With the increasing use of computers, FTIR can easily manipulate spectral information, and its advance chemometric software is equipped to handle the calibration.

Currently, FTIR spectroscopy has received great attention to be used in the analysis of edible fats and oils. Previous research has also shown the potential of FTIR spectroscopy for analysis of lard in cake formulation (Syahariza et al. 2005), chocolate products (Che Man et al. 2005a, b), edible oils (Guillen and Cabo 1997), animal fats (Che Man and Mirghani 2001; Jaswir et al. 2003; Rohman and Che Man 2010; Rohman et al. 2011). The main objective of this study was to develop procedures for rapid analysis of pork adulteration in processed meat products, particularly in beef jerky. Since in Islamic rule, if the processed meat products already adulterated with pork, the products can be classified as haram or prohibited, which in turn can not be consumed any more by the muslim, even if the amount of pork adulterated is very small amount.

Materials and methods

Beef and pork were obtained from different slaughter houses in Jember, Indonesia (Usually the slaughter house for pig is specified for pig only) by taking into account the different feeding of corresponding animals. The materials used for making beef jerky were purchased from local market. All solvents used for analysis were of pro-analytical grade.

Beef jerky preparation and powdered of the product

Beef Jerky was prepared by emulsifying 57.5 % of fine meat (beef or pork) with brawn sugar (25 %), salt (5 %) and certain spices (12.5 %), and finally shaping it into jerkys. It is then left for 6 h and dried through oven (75 °C) for 6 h. Jerky was further cut into small pieces and blended for powdered process. Then the powder was sieved into 10 mesh. The powder yielded were further used for FTIR analysis.

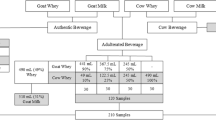

Training set and test set

The training sets was prepared by spiking pork to beef jerky in concentration range of 5.0–80.0 %. Jerky containing of 100 % beef and 100 % pork was also made to observe the spectral differentiation. For test set, another series of jerky containing the mixture of pork and beef were prepared (1, 5 & 70 %). The jerky was further subjected to powder. The powder obtained were analyzed using FTIR spectroscopy. The spectral regions where the variations were observed, they were chosen for developing class-model techniques (i.e. Linear Discriminant Analysis/LDA, Soft Independent Modelling of Class Analogy/SIMCA, and Support Vector Machines/SVM).

FTIR spectroscopy analysis

A dedicated transparant glass container was used; the powdered samples were placed in direct contact with attenuated total reflectance (ATR) crystal (platinum diamond) on a multibounce plate at controlled ambient temperature (25 °C). An Alpha FTIR spectrometer (Bruker Optics, Bellerika, MA) equipped with a detector of deuterated triglycine sulphate (DTGS), a CaF2 window, and connected to software of the OPUS softwere, were used during FTIR data collection. In order to minimize water vapor interference, the instrument was maintained with dehumidifier of silica gel. FTIR spectra were recorded from 32 scans at a resolution of 4 cm−1 at 4000–700 cm−1. These spectra were substracted against background air spectrum. After every scan, a new reference air background spectrum was taken. The ATR plate was carefully cleaned in situ by scrubbing with hexane twice followed by acetone and dried with soft tissue before filling in with the next sample. Cleanliness was verified by collecting a background spectrum and compare to the previous one. These spectra were recorded as the average of the absorbance values at each data point in triplicate. The software The Unscrambler X 10.2 (Camo Software, Madison, WI) was used for chemometrics analysis of class-models (i.e. LDA, SIMCA, and SVM). For the treated spectra, the original spectra were treated by normalised in order to achieved the lowest spectra became 0 and the highest one became 2. Then the normalised result were corrected with the baseline and smoothed for 13 times.

Class-modelling techniques

The modelling techniques used in this work were LDA (Linear Discriminant Analysis), SIMCA (soft independent modelling of class analogy), and SVM (Support Vector Machines).

LDA is commonly used techniques for data classification and dimensionality reduction. LDA easily handles the case, where the within-class frequencies are unequal and their performances has been examined on randomly generated test data. This method maximises the ratio of between-class variance to the within-class variance in any particular data set thereby guaranteeing maximal separability (Miller and Miller 2010). In this case, the use of LDA for data classification is applied to classification between pure beef jerkys (pure) and pork adulterated jerky (adulterated).

SIMCA is a very flexible technique since it allows variation in a large number of parameters such as scaling or weighting of the original variables, number of components, expanded or contracted scores range, different weights for the distances from the model in the inner space and in the outer space and confidence level applied. The central feature of this method is the application of principal component analysis (PCA) to the sample category studied (e.g. authentication of product), generally after within-class autoscaling or centring. SIMCA models are defined by the range of the sample scores on a selected number of low-order principal components (PCs) and models. The scores range can be enlarged or reduced, depending mainly on the number of samples, to avoid the possibility of under or over-estimation (Forina et al. 2008).

SVM is supervised learning models with associated learning algoritms that analyze data and recognize patterns, used for classification and regression analysis. Given a set of training examples, each marked as belonging to one of two categories (e.g. pure and adulterated), an SVM training algorithm builds a model that assigns new examples into one category or the other, making it a non-probabilistic binary linear classifier). An SVM model is a representation of the examples as points in space, mapped so that the examples of the separate categories are divided by a clear gap that is as wide as possible. New examples are then mapped into that same space and predicted to belong to a category based on which side of the gap they fall on (Lee et al. 2004).

Real sample analysis

For real sample analysis, the classification model selected was tested to the real samples of beef jerky collected from supermarket in Jember. The real samples were categorised into official halal logo (MUI, Indonesia), unofficial halal logo (by the producer) and without halal logo. The real sample analysis were compared with ELISA test kit (Xema, Russia).

Results and discussions

Training set and IR spectra analysis

Meat powders obtained from the beef or pork jerkys were analysed using FTIR spectroscopy in the mid infrared region (4000–700 cm−1). The advantage of IR spectroscopy for the qualitative analysis originates from the much information contents obtained and the possibility to assign certain absorption bands related to functional groups. Therefore, most of the peaks and shoulders of the spectrum are attributable to specific functional groups (Bendini et al. 2007).

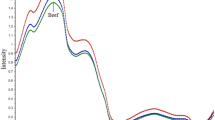

The composition of the training set used as the sample was consist of 10 pure beef jerky samples and 10 pork adulterated beef jerky samples, ranging from 5 to 80 % of adultertaion as given in Table 1. The representative spectra of jerky powder obtained from the beef and pork adulterated jerkys as training set are demonstrated in Fig. 1. These spectra look very similar and the different only in its intensity. An observation using the naked eyes, the whole range looks very similar because the main component of these meat are similar, i.e. protein. However, due to the fingerprint technique, meaning that there is no two compounds or samples having the same spectra in terms of amount and intensity of peaks, FTIR spectroscopy can be used to extract a difference among these proteins. However, the identification of functional groups in these proteins through the absorption peaks alone cannot be done with high certainty. Therefore, these spectra were used as prediction of these functional groups. For instance, as it can be observed from the spectra that at the region 3600–3200 cm−1 could be corresponding to O-H vibration, at the region 1700–1600 cm−1 could be corresponding to C-O and the amide group for protein (N-H) could be found at the region 1565–1520 cm−1. While C-H vibration of the protein could be found at the region 3000–2800 cm−1 and C = O at the region 1745–1725 cm−1. The =C-H of ester group, and alkene of fat could be found at 996 cm−1 (Guillen and Cabo 1997; Stuart 2004; Vlachos et al. 2006). Hence, these frequencies, which FTIR spectra variations were observed, are used as a basis approach for choosing the spectral regions in the classification of pork in beef jerky samples.

Test set

In order to test, the reliability of the training set used, the class-models were test with the test set. The composition of the test set used as the sample was consist of 5 samples, and the composition is given in Table 2. The representative spectra of the sample obtained from the test set are given in Fig. 2. These spectra also look very similar as well, and the different only in absorbance intensity according to the degree of pork adulteration in beef jerky. Therefore, these frequencies, which FTIR spectra variations were observed, they were used as a basis approach for the classification between pure and pork adulterated beef jerky samples.

Training set class-models

Before the chemometric models were constructed, the data were grouped into four (4) data sets, i.e. (a) spectra in the whole region as data set 1; (b) spectra in the fingerprint region (1500–600 cm−1) as data set 2; (c) spectra in the whole region with treatment as data set 3; and (d) spectra in the fingerprint region with treatment as data set 4, as given in Fig. 3. In this regards, the classification of spectra into various data sets as whole region and fingerprint region could increase chemometric analysis results (Gallardo-Velázquez et al. 2009). While in this case, the spectral treatment could reduce false classification due to noise and shifting in the spectral data (Berrueta et al. 2007).

The results of the class-model of LDA as model for classification between pure and pork adulterated beef jerky for data set 1 to 4 of the training set is given in Fig. 4 as graphical classification, while the class-model of SIMCA is given in Fig. 5, respectively. The SVM model only produces the classification predicted table as given in Table 3. Figures 4 and 5 show that the training set of all data sets (data set 1 to 4) given have classification in 100 % accuracy of both LDA and SIMCA class-models, while Table 3 show that the training of both data set 3 and 4 have classification accuracy of 100 %, while data sets 1 and 2 have accuracy of classification of 90 % and 80 % respectively.

Evaluation of class-models

In order to test the reliability of the chemometric model constructed, the class-models were evaluated using the test set. Here, the test set can be used as simulated samples to evaluate the accuracy of the constructed class-models (LDA, SIMCA & SVM) for classification of each data in test set, between pure and pork adulterated beef jerkys classification.

The summary of the ability of the models constructed (LDA, SIMCA and SVM) based on the training set and its prediction (%) using test set is given in Table 4. Based on Table 4, it can be concluded that the best model constructed for classification between pure and pork adulterated beef jerkys is LDA model using data set 1 (whole range of spectra without treatment). Since, this LDA model could classified and predicted the sample in 100 % accuracy of classification. This mean that the LDA model could classify all the data in the training set (20 data samples) 100 % correct in their classification and have ability to predict all of the data in the test set (5 data samples) 100 % correct in their classification as well (Stanimirova et al. 2010). In other word, if the class-model could classify and predict classification data samples less than 100 % accuracy, meaning the model could not classify the training set data 100 % correct and could not predict the test set data 100 % correct as well. Thus, as a consequence the class-model constructed consists errors, like in the case of SIMCA and SVM for all data set used. Therefore, the LDA model using data set 1 (whole range of spectra without treatment) was used for further application using real beef jerky samples available in the market.

Application for the real samples

The LDA class-model selected using data set 1 was applied toward the real samples, which consitst 10 samples with official halal logo (sample no. 1–2), 2 samples with unofficial halal logo (sample no. 3–4) and 6 samples without halal logo (sample no.5–10). All of the beef jerky sample used were purcased from supermarket in Jember. The real sample of beef jerkys have also been tested using ELISA method as comparison, and the results have been summerised in Table 5. Table 5 shows that the LDA class-model developed was in good agreement with the ELISA method. Based on this result, it can be stated that all beef jerkys samples tested using the LDA class-model based on data set 1 (whole range of spectra without treatment) can be classified as pure beef jerky. It can be concluded that all beef jerkys tested were classified as halal and can be consumed according to Islamic law. Therefore, the proposed method based on IR spectra and LDA class-model as a rapid analytical method for the analysis of pork adulteration in beef jerky as halal autentication has been achieved.

Conclusion

The adulteration of beef jerky with pork can be analysed by means of IR spectra coupled with the class-model techniques (i.e. LDA, SIMCA, and SVM). The LDA model selected as the best class-model, can be used to classify between pure and pork adulterated beef jerky using whole region sepecta (4000–700 cm−1) without treatment. The LDA class-model has also been successfully tested to the real beef jerky samples marketed in Jember, and the results showed in good agreement with the ELISA method. Thus, the potential of FTIR spectroscopy and chemometrics as a rapid analytical tool for the analaysis of pork adultertaion in beef jerky were demonstrated. The finding from this study will serve as a basis in developing a database for monitoring food adulteration, especially for Halal authentication purposes in processed beef meat.

References

Aida AA, Che Man YB, Wong CMVL, Raha AR, Son R (2005) Analysis of raw meats and fats of pigs using polymerase chain reaction for halal authentication. Meat Sci 69:47–52

Aida AA, Che Man YB, Raha AR, Son R (2007) Detection of pig derivatives in food products for halal authentication by polymerase chain reaction–restriction fragment length polymorphism. J Sci Food Agric 87:569–572

Al-Jowder O, Kemsley EK, Wilson RH (1997) Mid-infra red spectroscopy and authenticity problems in selected meats: a feasibility study. Food Chem 59:195–201

Ballin NZ (2010) Authentication of meat and meat products. Meat Sci 86:577–587

Bendini A, Cerretani L, Di Virgilio F, Belloni P, Bonoli-Carbognin M, Lercker G (2007) Preliminary evaluation of the application of the FTIR spectroscopy to control the geographic origin and quality of virgin olive oils. J Food Qual 30:424–437

Berrueta LA, Alonso-Salces RM, Héberger K (2007) Supervised pattern recognition in food analysis. J J Chromatogr A 1158:196–214

Bonne K, Verbeke W (2008) Muslim consumer trust in halal meat status and control in Belgium. Meat Sci 79:113–123

Che Man YB, Gan HL, NorAini I, Nazimah SAH, Tan CP (2005a) Detection of lard adulteration in RBD palm olein using an electronic nose. Food Chem 90:829–835

Che Man YB, Syahariza ZA, Mirghani MES, Jinap S, Bakar J (2005b) Analysis of potential lard adulteration in chocolate and chocolate products using Fourier transform infrared spectroscopy. Food Chem 90:815–819

Che Man Y, Aida A, Raha A, Son R (2007) Identification of pork derivatives in food products by species-specific polymerase chain reaction (PCR) for halal verification. Food Control 18:885–889

Chen FC, Hsieh YHP (2000) Detection of pork in heat-processed meat products by monoclonal antibody-based ELISA. J AOAC Int 83:79–85

Che Man YB, Mirghani MES (2001) Detection of lard mixed with body fats of chicken, lamb, and cow by Fourier transform infrared spectroscopy. J Am Oil Chem Soc 78:753–761

Chen SY, Liu YP, Yao YG (2010) Species authentication of commercial beef jerky based on PCR–RFLP analysis of the mitochondrial 12S rRNA gene. J Genet Genom 37:763–769

Chou C, Lin S, Lee K, Hsu C, Vickroy TW, Zen J (2007) Fast differentiation of meats from fifteen animal species by liquid chromatography with electrochemical detection using copper nanoparticle plated electrodes. J Chromatogr B 846:230–239

Cozzolino D, Murray I (2002) Effect of sample presentation and animal muscle species on the analysis of meat by near infrared reflectance spectroscopy. J Near Infrared Spectrosc 10:37–44

Cronin DA, McKenzie K (1990) A rapid method for the determination of fat in food stuffs by infrared spectrometry. Food Chem 35:39–49

Defernez M, Wilson RH (1995) Mid-infrared spectroscopy and chemometrics for determining the type of fruit used in jam. J Sci Food Agric 67:461–467

Fajardo V, González I, Rojas M, García T, Martín R (2010) A review of current PCR-based methodologies for the authentication of meats from game animal species. Trends Food Sci Technol 21:408–421

Forina M, Oliveri P, Lanteri S, Casale M (2008) Class-modelling techniques, classic and new, for old and new problems. Chemom Intell Lab Syst 93:132–148

Gallardo-Velázquez T, Osorio-Revilla G, Zuñiga de Loa M, Rivera-Espinoza Y (2009) Application of FTIRHATR spectroscopy and multivariate analysis to the quantification of adulterants in Mexican honeys. Food Res Int 42:313–318

Guillen MD, Cabo N (1997) Characterization of edible oils and lard by fourier transform infrared spectroscopy. Relationships between composition and frequency of concrete bands in the fingerprint region. J Am Oil Chem Soc 74:1281–1286

Jaswir I, Mirghani MES, Hassan TH, Mohd Said MZ (2003) Determination of lard in mixtures of body fats of mutton and cow by fourier transform-infra red (FTIR) spectroscopy. J Oleo Sci 52:633–638

Karlsson AO, Holmlund G (2007) Identification of mammal species using speciesspecific DNA pyrosequencing. Forensic Sci Int 173:16–20

La Neve F, Civera T, Mucci N, Bottero MT (2008) Authentication of meat from game and domestic species by SNaPshot minisequencing analysis. Meat Sci 80:216–224

Lee Y, Lin Y, Wahba G (2004) Multicategory support vector machines. J Am Stat Assoc 99:67–75

Lockley AK, Bardsley RG (2000) DNA-based methods for food authentication. Trends Food Sci Technol 11:67–77

Miller JN, Miller JN (2010) Statistics and chemometrics for analytical chemistry, 6th edn. Pearson Education, Harlow

Montowska M, Pospiech E (2007) Species identification of meat by electrophoretic methods. ACTA Sci Pol Technol Alimen 6:5–16

Murugaiah C, Noor ZM, Mastakim M, Bilung LM, Selamat J, Radu S (2009) Meat species identification and halal authentication analysis using mitochondrial DNA. Meat Sci 83:57–61

Rashood KA, Shaaban RRA, Moety EMA, Rauf A (1995) Triacylglycerols profiling by high performance liquid chromatography: a tool for detection of pork fat in processed foods. J Liq Chromatogr 18:26–31

Regenstein JM, Chaudry MM, Regenstein CE (2003) The kosher and halal food laws. Comp Rev Food Sci Food Safe 2:111–127

Rohman A, Che Man YB (2010) FTIR spectroscopy combined with chemometrics for analysis of lard in the mixtures with body fats of lamb, cow, and chicken. Int Food Res J 17:519–527

Rohman A, Sismindari EY, Che Man YB (2011) Analysis of pork adulteration in beef meatball using fourier transform infrared (FTIR) spectroscopy. Meat Sci 88:91–95

Stanimirova I, Ustun B, Cajka T, Riddlelova K, Hajslova J, Buydens LMC, Walczak B (2010) Tracing the geographical origin of honeys using the GCxGC-MS and pattern recognition techniques. Food Chem 118:171–176

Stuart B (2004) Infrared spectroscopy: fundamental and applications. Saunders College Publishing, Philadelphia

Syahariza ZA, Che Man YB, Selamat J, Bakar J (2005) Detection of lard adulteration in cake formulation by Fourier transform infrared (FTIR) spectroscopy. Food Chem 92:365–371

Tian X, Wang J, Cui S (2013) Analysis of pork adulteration in minced mutton using electronic nose of metal oxide sensors. J Food Eng 119:744–749

Van de Voort FR, Sedman J, Ismail AA (1993) A rapid FTIR quality-control method for determining fat and moisture in highfat products. Food Chem 48:213–221

Vlachos N, Skopelitis Y, Psaroudaki M, Konstantinidou V, Chatzilazarou A, Tegou E (2006) Applications of Fourier transform-infrared spectroscopy to edible oils. Anal Chim Acta 573:459–465

Acknowledgments

The authors thank the DitLitabMas, Higher Education, Ministry of Education and Culture, Republic of Indonesia, for supporting this work via the International Research Collaboration & Publication Program 2014 (No. 2303/UN25/LT/2014).

Compliance with ethics requirements

ᅟ

Conflicts of interest statement

All authors declares that they have no conflict of interest.

Author contributions statement

First author contributed for whole project starting from experimental work to manuscript preparation.

Second author contributed to experimental work.

Third author contributed to the analysis of data.

Fourth author constributed to evaluation of data analysis and the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuswandi, B., Putri, F.K., Gani, A.A. et al. Application of class-modelling techniques to infrared spectra for analysis of pork adulteration in beef jerkys. J Food Sci Technol 52, 7655–7668 (2015). https://doi.org/10.1007/s13197-015-1882-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1882-4