Abstract

This study was devised to obtain a better insight into the effect of selected non-starch polysaccharides (NSP), namely carboxymethylcellulose (CMC), locust bean gum (LBG) and psyllium husk powder (PSY) on wheat dough rheological behaviour and quality attributes of Chinese steamed bread (CSB). NSP was added at levels of 0.2 % and 0.8 % w/w (wheat flour basis). Mixing properties and extensional properties of the dough produced were assessed by farinograph and extensograph, respectively. Spread ratio, specific volume and firmness of CSB were determined as a function of storage time. Addition of 0.2 % w/w NSP was found to decrease water absorption and strengthen the dough, and also to increase dough development time and dough stability. A reverse trend was observed at 0.8 % level. Among all the samples studied, addition of PSY at 0.2 % was found to confer an appropriate level of dough strength and extensibility that caused desirable spread ratio as well as specific volume in CSB. The results also revealed that NSP at high addition level helps to soften CSB and prevent staling from occurring, and hence warrant a longer shelf-life.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chinese steamed bread (CSB) is a wheat-based leavened product cooked by steaming. This steaming method renders the product with a soft, moist and uniform crumb and a thin, smooth, white skin (Huang 1999; Rubenthaler et al. 1990; Su et al. 2005). This type of steamed product can be made with or without filling, and is generally known as steamed bun or steamed bread, respectively (Huang 1999). These steamed products are gaining popularity and widely consumed by people reside in the Asian countries and has undergone changes in terms of texture and taste to meet the local preference. In view of the increasing popularity and demand of ready to eat convenient foods, these steamed products have been produced at a larger scale at factory level (Hou and Popper 2007; Wen et al. 1996). Nevertheless, food manufacturers are facing the challenges of controlling and enhancing the quality of these products due to the fact that steamed product has a short shelf-life of approximately 1 to 3 days when being stored at room temperature and the shelf-life will become shorter at a warmer and drier storage condition (Qin et al. 2007).

Bárcenas and Rosell (2005) reported that the shelf-life indicator of bread is the increased hardness due to staling, and not the microorganism or endogeneous enzyme deteriorative activity. Bread staling is a phenomenon that involves retrogradation of starch molecules whereby the product will become harder and experience desiccation on storage (Kotoki and Deka 2010). Addition of non-starch polysaccharides (NSP) in starch based products has been explored as a means to delay retrogradation. However, the results obtained are often appearing inconsistent and vary, depending on the specific NSP applied. In general, NSP causing a weakening effect on the starch structure resulting in a better water distribution and retention, hence a soft crumb produced (Armero and Collar 1996; Guarda et al. 2004). On the other hand, there were hypotheses suggested that NSP could decrease starch granules swelling and caused amylose phase separation that resulted in a firm crumb (Ghodke Shalini and Laxmi 2007; Guarda et al. 2004).

According to the work of Bloksma (1971), the rheological or mechanical properties of wheat flour dough plays a significant role in determining the quality of a baked product. The work of Bárcenas and Rosell (2005, 2007), Guarda et al. (2004), Yadaz et al. (2010), and many others have proven the fact that NSP, such as sodium alginate, κ-carrageenan, xanthan gum, and hydroxypropylmethycellulose, when added at low level, usually less than 1 %, is able to cause significant changes in bakery products due to the enhancement of dough rheological and/or mechanical properties. However, a limited amount of research work has been reported on the effects of NSP on the characteristics of CSB. Hence, the present study was carried out to gain a better insight into the effect of addition of selected NSP on the dough rheological properties and quality attributes of CSB.

Materials and methods

Materials

Wheat flour with 10 % protein (14 % moisture basis), 0.47 % ash and 13.3 % moisture in dry basis was procured from United Malayan Flour Mill (Butterworth, Malaysia). Psyllium husk (Plantago ovata) (Natural Psyllium Husk, 99.29 % purity) was provided by Country Farms Sdn. Bhd. (Selangor, Malaysia). Carboxymethylcellulose sodium salt (Fluka brand, product of Switzerland) and locust bean gum from Ceratonia siliqua seeds (Sigma-Aldrich brand, product of Morocco) were obtained from Sigma-Aldrich Sdn. Bhd. (Selangor, Malaysia). Sodium chloride (SYSTERM® brand) and sucrose were purchased from Classic Chemicals Sdn. Bhd. (Selangor, Malaysia) and Merck Sdn. Bhd. (Selangor, Malaysia), respectively. Shortening (Crisco brand) was manufactured by The J.M. Smucker Company (Orrville, OH, U.S.A.). Calcium propionate was obtained from Sim Company Sdn. Bhd. (Penang, Malaysia). Fresh yeast was supplied by AB Mauri Malaysia Sdn. Bhd. (Selangor, Malaysia) and used within a week of receipt.

Preparation of wheat flour blend

Wheat flour was dry-blended with non-starch polysaccharides (NSP) and sifted through a sieve of 30 mesh size using a high efficient noiseless separator (Model GY-450SSA, Kimah, Malaysia). NSP (CMC, LBG and PSY) was added into wheat flour at levels of 0.2 % and 0.8 % w/w (wheat flour basis). These levels were determined arbitrarily. Wheat flour alone without any NSP added was designated as control.

Farinograph test

The farinograph test was carried out according to AACC method 54–21 (AACC 2000) using the constant flour weight method. An amount of 300 g (corrected to 14 % moisture basis) of wheat flour, with or without NSP was mixed in a 300-g mixing bowl of a Brabender Farinograph®-E (Brabender OHG, Duisburg, Germany). Running time for the test was 50 min. Parameters such as water absorption, dough development time, dough stability and mixing tolerance index (MTI) were obtained from the farinogram. Result was reported as average of three replicates measurements.

Extensograph test

This test was performed following AACC method 54–10 (AACC 2000). Dough was prepared in the Brabender Farinograph®-E 300-g mixing bowl with 300 g wheat flour (14 % moisture basis) and 6 g of sodium chloride dissolved in part of the water added. Amount of water added was fixed by subtracting 2 % of the water absorption determined by the farinograph in order to counterbalance for the effect of salt addition. The dough was first mixed for 1 min, rested for 5 min and mixing was continued until a consistency of 500 Farinograph unit (FU) was achieved. The dough prepared was rounded and moulded and placed in a humidified chamber (> 90 % relative humidity) thermostatically controlled at 30 °C. After that, the dough was stretched using Brabender Extensograph® (Brabender OHG, Duisburg, Germany) until rupture after 45 min resting time. Same procedure was repeated for the same dough after rest for 90 min and 135 min. Maximum resistance, extensibility, and work applied to stretch the dough (which is related to the area under the curve as determined with the aid of a planimeter) were measured from the extensograms obtained. Result was reported as average of three replicates measurements.

Preparation of Chinese steamed bread (CSB)

The recipe consists of wheat flour with or without CMC, LBG and PSY, 80 % water based on farinograph water absorption, 3 % fresh yeast, 8 % sucrose, 1 % sodium chloride, 2 % shortening, and 0.2 % w/w (based on as-is moisture basis of wheat flour) calcium propionate. Before mixing the dough, fresh yeast was pre-dissolved in warm water (35–40 °C) containing 5 g sucrose and left standing for 10 min. Sodium chloride, calcium propionate, and the remaining sucrose was dissolved separately in different portions of warm water. The solutions were left to cool before use. Subsequently, sucrose solution was added slowly to the wheat flour in a mixing bowl of KitchenAid® Mixer (Model 5KSM150PS, KitchenAid, USA). Mixing speed was fixed at level 2. Fresh yeast solution was then added in, followed by sodium chloride solution, calcium propionate solution, and finally the remaining cold water. After mixing for 2 min, shortening was added in and mixing was continued for another 8 min.

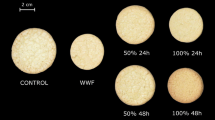

The dough was divided into 100-g pieces. Each piece was molded by using balling unit of extensograph. The dough pieces were then put in a proofer maintained at 30 °C and 85 % relative humidity for 30 min. After proofing, the dough was steamed for 15 min in a steamer. The samples prepared were tested after cooling for 1 h.

Storage study of CSB

CSB was kept in an air-tight container. Spread ratio, specific volume and firmness of Chinese steamed bread were determined after being stored for 0, 1, 2 and 4 days at 27 °C. Average of six replicates measurements was reported for each storage period.

Spread ratio of CSB

Spread ratio was determined following the method described in Lijuan et al. (2007). The height and bottom width of CSB were measured at three different locations with a ruler and the average was recorded. Spread ratio (width/height) was then calculated.

Specific volume of CSB

The weight of CSB was measured to the nearest of 0.01 g. The volume of CSB was determined using rapeseed displacement method. Specific volume (ml/g) was calculated as the ratio of volume to weight of the loaf.

Textural properties of CSB

Firmness of fresh and stored samples was determined by using a TA-XT Plus Texture Analyzer (Stable Micro Systems, Surrey, England) equipped with a 30-kg load cell and a 1-in. diameter Delrin ball probe. Parameter was set at a pre-test speed of 1.0 mm s−1, a test speed of 1.7 mm s−1, a post-test speed of 10.0 mm s−1, and 5.0 g trigger force. The deformation level was 75 % of the sample height and the samples were penetrated once. Change in firmness during storage was used as a parameter to evaluate CSB staling. Staling index or increase of firmness was calculated according to the following equation:

Statistical analysis

For farinograph and extensograph tests, all samples were tested in triplicate measurements with a completely randomized design. For storage study of CSB, measurements were performed on three sub-samples from each preparation. CSB preparation was done in duplicate. Statistical analysis was performed with one-way ANOVA and significant differences between mean values were compared by Duncan’s test at 95 % significance level using SPSS software for Windows Release 15.0 (SPSS Inc., Chicago, Illinois, USA).

Results and discussion

Dough mixing properties

Mixing plays a vital role in transforming wheat flour into dough which can then be leavened and made into a loaf (Wang et al. 2007). The dough mixing properties of wheat flour with and without carboxymethylcellulose (CMC), psyllium husk powder (PSY) and locust bean gum (LBG) addition is displayed in Fig. 1.

Farinograph parameters of wheat flour with or without addition of non-starch polysaccharides. The error bar represents ± standard deviation (n = 3). Bars followed by the same letter and with the same capital letter are not significantly different at 95 % confidence interval in the comparison between samples. a Water absorption corrected to 500 FU, (b) Dough development time, (c) Dough stability, (d) Mixing tolerance index

As shown in Fig. 1a, wheat flour with 0.2 % non-starch polysaccharides (NSP) showed a significant decrease in water absorption when compared to the control sample (P < 0.05). The reverse was true for samples added with 0.8 % NSP. For those added at 0.2 % level, water absorption decreased in the order of control > CMC > PSY > LBG. This behaviour indicates that a relatively lower amount of water was required for dough development when small amount of CMC, PSY or LBG was added into wheat flour in order to reach a 500 Farinograph unit (FU) consistency. One plausible explanation is that there could be a specific threshold level, below which NSP molecules tend to interact with gluten that might enhance the dough consistency. However, beyond which dough network development is inhibited, as a result of limited hydration of gluten molecules due to the high hygroscopicity of NSP (Bárcenas et al. 2009; Kotoki and Deka 2010). This was substantiated with the dough development time and dough stability results shown in Fig. 1b and c, respectively, in which a high development time and dough stability were observed in NSP added (0.2 %) samples with respect to the control dough. Dough development time refers to the time lapse between the point of first water addition and the point at which immediately before first indication of dough weakening is detected (Shuey 1997). Whereas, stability is defined as the difference in time between the point at which the top of the curve first intercepts with the 500 FU line and the point at which the top of the curve start leaving the 500 FU line (Shuey 1997). Both parameters indicate flour strength with higher values symptomatic of stronger dough (Rosell et al. 2001).

Results at 0.8 % level is in accordance with those reported by Ghodke Shalini and Laxmi (2007), Guarda et al. (2004), Kotoki and Deka (2010), Rosell et al. (2001) and Syama Prasad Rao et al. (2007), wherein the water absorption increased with the addition of NSP. It is believed that when NSP was added at an excessive level, the hygroscopic nature of NSP, has imparted strong water absorptive capacity and rendered an uneven distribution of water molecules within the flour blend. As a result, the water depleted starch and gluten molecules henceforth required more water for hydration in order to form a cohesive dough network that reached a 500 FU consistency (Bárcenas et al. 2009; Ghodke Shalini and Laxmi 2007; Guarda et al. 2004). Mixing tolerance index (MTI) is the difference in FU between the top of the curve at the peak and the position of the curve measured 5 min after the peak is arrived (Shuey 1997). Dough resistance towards mechanical damage is lower with greater MTI (Almeida et al. 2010). Hence, MTI (Fig. 1d) shows opposite trend with dough stability. At 0.8 % addition level, NSP was found to significantly reduced dough stability (P < 0.05). MTI of samples with 0.8 % CMC and LBG addition was found to possess significantly (P < 0.05) higher MTI. This could be attributed to weakening of gluten and starch molecules network that may be caused by inhibition of gluten and starch molecules association due to the presence of excessive NSP.

Farinographic results suggested that different mixing properties were exhibited by dough added with different types of NSP at different concentrations. The literature is also replete with examples showing similar unpredictable effects upon addition of NSPs with different chemical structures at different usage levels. Rosell et al. (2001) reported that xanthan gum and alginate significantly increased dough development time, while this parameter was not affected by κ-carrageenan or hydroxypropylmethylcellulose. On the other hand, Linlaud et al. (2009) showed that dough development time increased with progressive increase in xanthan gum and guar gum, but no significant effect was shown by locust bean gum and high-methoxyl pectin. Lazaridou et al. (2007) investigated the effects of agarose, carboxymethylcellulose, pectin, xanthan and oat β-glucan at 1 % and 2 % addition level on dough rheology and bread quality parameters in gluten-free formulations. Their results revealed that bread quality was dependent on the nature of hydrocolloid used and its usage level. It is apparent that though many works were carried out on the effect of NSP addition on dough properties, but results could not be compared because of the diversity of variables used.

Dough stretching properties

Dough extensibility can be explained from the perspective of food polymer science and the extensional properties were hypothesized to be influenced by the entanglement points formed between glutenin molecules (Singh and MacRitchie 2001). According to Termonia and Smith (1987), the tensile deformation of a solid, flexible polymer is governed by the weak attractive forces between chains as well as the slippage of the entangled chains. The same principle could be applied to a dough system. When the rate of chain slippage is greater than the rate of chain elongation, low tensile strength and elongation will be resultant (Singh and MacRitchie 2001). In contrast, if the rate of chain slippage occurs insufficiently rapidly in response to the applied stress, chain breakage will likely to happen, resulting in a short elongation. In other words, when optimum slippage take place, where the chain will slip free sufficiently rapidly in response to the applied stress, the entanglement points will contribute to resistance and effecting maximum tensile strength and elongation (Singh and MacRitchie 2001).

Figures 2 showed that the maximum resistance (Rmax), ratio of maximum resistance to extensibility (Rmax/E), and the work applied for dough stretching (A) of all samples increased progressively with resting time. The exceptions were CMC and LBG added dough after 90 min resting time at 0.2 % addition level, with a drop in A value. The rate of increment was found to be relatively higher in samples added with 0.8 % NSP when compared to the respective counterpart at 0.2 % addition level. According to Ribotta et al. (2005), higher values of Rmax and A indicating greater dough strength. This suggests that NSP facilitates chain-chain association upon proofing. Nevertheless, at a given extent of resting time, the extensibility of the dough is dependent on the type of NSP added.

Maximum resistance (A), ratio of maximum resistance to extensibility (B), work applied to stretch the dough (C), and firmness increase (D) of CSB with or without non-starch polysaccharides added as a function of resting time. (a) 0.2 % addition level (b) 0.8 % addition level. [Every observation point is a mean of six replicates (n = 6). Typical coefficient of variance is not more than 10 %]

For dough added with LBG at either 0.2 or 0.8 % level, the Rmax and Rmax/E values were found to be relatively higher and the A value relatively lower than the control sample. This shows that LBG added dough demonstrated high resistance with limited elongation, therefore, the samples were failed easily upon stretching, this was evident in the lowest A value trend depicted in Fig. 2C for LBG sample. As for samples added with 0.2 % PSY, Rmax and Rmax/E were reported to be smaller than the control sample and a reverse trend was observed when the addition level was increased to 0.8 %. The A value was shown to be lower and insignificant when PSY was added to the dough at 0.2 and 0.8 % level, respectively. This pointed out that, PSY at low level (0.2 %) weakened the dough structure but enhanced it at higher level (0.8 %).On the other hand, CMC at 0.2 % level decreased both Rmax and Rmax/E values, but increased the A value, especially when the resting time was limited to the first 90 min. When the addition level increased to 0.8 %, CMC added sample showed insignificant difference as compared to the control samples in terms of Rmax and Rmax/E, but A value turned to be lower. In light of this observation, it could be deduced that addition of CMC has weakened the dough structure and resulting in a lower resistance with longer elongation.

In general, results showed that an increase in both Rmax and Rmax/E values of samples was observed after resting. In wheat gluten, high molecular weight subunits interact with each other through hydrogen linkages and disulphide linkages. Dough working facilitates the protein–protein interactions. According to Belton (1999), linear-linear protein interactions occurred by means of the “loop and train” mechanism and disulphide linkage whereas linear-globular protein interactions attained via non-bonding forces such as Van de Waals interactions. Upon stretching, the network will be deformed initially by deformation of the “loops” and followed by the “trains” being dismantled. When the “loops” are extended, the proteins will slip over one another. This is because there is no mechanism to restore the material to its original state. However, the structure will relax by re-establishment of the “loop-train” equilibrium. Extension of protein network in the same direction repeatedly gives rise to the same degree of overall structural change. This might be due to there is no new protein available on each extension, although there is incomplete relaxation of the protein between extensions occurred. An increase in beta-sheet structure takes place on repeated extensions since “trains” are related with formation of β-sheet (Belton 1999, 2005).

Characteristics of Chinese steamed bread (CSB)

Spread ratio and specific volume of CSB

Loaf volume relied on how thin the gluten-starch matrix can be stretched before attaining its limit of expansion (Sroan et al. 2009). A balance between dough viscosity and elasticity is needed for breadmaking. Dough strength up to a certain level can increase loaf volume. Conversely, dough rise can be hindered if the dough is too strong and rigid (Goesaert et al. 2005). Dough which is too elastic would be too difficult to process and likely to cause shrinkage in the finished product, while a dough which is too extensible may cause a flat-shaped product (Hou and Popper 2007).

Generally, when compared to the control sample, NSP tended to decrease spread ratio of CSB at both addition levels (Table 1). Similar result trend was observed with when alternate flour (maize or rice) was incorporated into wheat flour (Rai et al. 2011). The most obvious effects were shown in samples with LBG addition. However, when comparing between 0.2 and 0.8 % levels for each NSP added sample, it was found that CSB spread ratio became higher with the increase in NSP concentration. This observation was in line with the extensograph result discussed earlier wherein when NSP content was increased from 0.2 to 0.8 %, Rmax, Rmax/E and A values were increased at a higher rate and this was attributed to a stronger dough formed when NSP was increased. On the other hand, specific volume of CSB was reduced with addition of NSP and the value decreased with increase in NSP concentration. The higher water retention capacity caused by the presence of NSP could account for the result observed. Therefore, CSB becomes heavier per unit mass with addition of NSP. Nevertheless, our results were in contrast with those reported by Guarda et al. (2004) and Mandala (2005), who reported that an increase in specific volume of bread was observed with the addition of hydrocolloids at 0.1 and 0.5 %, and 0.16 and 0.65 %, respectively.

Firmness of CSB upon storage at 27 °C

Figure 2D depicts the staling kinetics of CSB products prepared. It is obvious that a drastic increase was evident between day-0 and day-1, after which the staling rate was slowed down and eventually becomes constant. Comparatively, NSP at 0.2 and 0.8 % level increased and decreased the staling rate of CSB, in comparison with the control samples. At 0.2 % level, staling rate increased in the order of control < LBG < PSY < CMC. On the contrary, at 0.8 % level, the rate decreased following the order of control ≥ CMC ≥ PSY ≥ LBG.

Low level addition of NSP seems to provoke an increase in CSB staling rate. This result was substantiated by the observation on dough mixing properties which revealed that at low level of NSP addition, starch and gluten molecules association was facilitated and enhanced. NSP when added at high level may retard staling from occurring and render the CSB soft in texture. This effect could be partly attributed to the inhibition of chain-chain association and partly due to the higher moisture content caused by the presence of excessive hygroscopic NSP.

Conclusions

Wheat flour dough rheological properties are dependent on the compositional and functional characteristics of the ingredients present. Non-starch polysaccharides (NSP) of different chemical nature and at different levels provide different rheological profile. Commonly, an optimum balance between dough resistance and extensibility is sought after to produce bread product with high specific volume and spread ratio. From our results, NSP at 0.2 % level, especially psyllium husk powder, was found to strengthen wheat dough during mixing. However, upon resting, NSP at 0.8 % addition level seemed to enhance the dough strength through the formation of a better network. In addition, Chinese steamed bread added with 0.8 % NSP was found to show lower staling rate.

Abbreviations

- A:

-

Work applied to stretch dough

- BU:

-

Brabender Unit

- CMC:

-

Carboxymethylcellulose

- CSB:

-

Chinese steamed bread

- FU:

-

Farinograph Unit

- LBG:

-

Locust bean gum

- NSP:

-

Non-starch polysaccharide

- PSY:

-

Psyllium husk powder

- Rmax/E:

-

Ratio of maximum resistance to extensibility

- Rmax :

-

Maximum resistance

References

AACC (2000) Approved Methods of the American Association of Cereal Chemists, 10th edn, Methods 54–21, 56–10. American Association of Cereal Chemists, St. Paul, Minnesota

Almeida EL, Chang YK, Steel CJ (2010) Effect of adding different dietary fiber sources on farinographic parameters of wheat flour. Cereal Chem 87:566–573

Armero E, Collar C (1996) Antistaling additive effect on fresh wheat bread quality. Food Sci Technol Int 2:323–333

Bárcenas ME, Rosell CM (2005) Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll 19:1037–1043

Bárcenas ME, Rosell CM (2007) Different approaches for increasing the shelf life of partially baked bread: low temperatures and hydrocolloids addition. Food Chem 100:1594–1601

Bárcenas ME, De la O-Keller J, Rosell CM (2009) Influence of different hydrocolloids on major wheat dough components (gluten and starch). J Food Eng 94:241–247

Belton PS (1999) Mini review: on the elasticity of wheat gluten. J Cereal Sci 29:103–107

Belton PS (2005) New approaches to study the molecular basis of the mechanical properties of gluten. J Cereal Sci 41:203–211

Bloksma AH (1971) Rheology and chemistry of dough. In: Pomeranz Y (ed) Wheat: Chemistry and technology. American Association of Cereal Chemists Inc, St. Paul, pp 523–584

Ghodke Shalini K, Laxmi A (2007) Influence of additives on rheological characteristics of whole-wheat dough and quality of Chapatti (Indian unleavened Flat bread) Part I—Hydrocolloids. Food Hydrocoll 21:110–117

Goesaert H, Brijs K, Veraverbeke WS, Courtin CM, Gebruers K, Delcour JA (2005) Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends Food Sci Technol 16:12–30

Guarda A, Rosell CM, Benedito de Barber C, Galotto MJ (2004) Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll 18:241–247

Hou GG, Popper L (2007) Chinese steamed bread. In: Popper L, Schäfer W, Freund W (eds) Future of flour—A compendium of flour improvement. Verlag Agrimedia GmbH, Clenze, pp 309–318

Huang SD (1999) Wheat products: 2. Breads, cakes, cookies, pastries, and dumplings. In: Ang CYW, Liu K, Huang Y-W (eds) Asian foods science and technology. Technomic Publishing, Lancaster, pp 71–109

Kotoki D, Deka SC (2010) Baking loss of bread with special emphasis on increasing water holding capacity. J Food Sci Technol 47:128–131

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng 79:1033–1047

Lijuan S, Guiying Z, Guoan Z, Zaigui L (2007) Effects of different milling methods on flour quality and performance in steamed breadmaking. J Cereal Sci 45:18–23

Linlaud NE, Puppo MC, Ferrero C (2009) Effect of hydrocolloids on water absorption of wheat flour and Farinograph and textural characteristics of dough. Cereal Chem 86:376–382

Mandala IG (2005) Physical properties of fresh and frozen stored, microwave-reheated breads, containing hydrocolloids. J Food Eng 66:291–300

Qin P, Cheng S-H, Ma C-X (2007) Effect of waxy wheat flour blends on the quality of Chinese steamed bread. Agric Sci China 6:1275–1282

Rai S, Kaur A, Singh B, Minhas KS (2011) Quality characteristics of bread produced from wheat, rice and maize flours. J Food Sci Technol 46(6):786–789

Ribotta PD, Ausar SF, Beltramo DM, León AE (2005) Interactions of hydrocolloids and sonicated-gluten proteins. Food Hydrocoll 19:93–99

Rosell CM, Rojas JA, Benedito de Barber C (2001) Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll 15:75–81

Rubenthaler GL, Huang ML, Pomeranz Y (1990) Steamed bread. I. Chinese steamed bread formulation and interactions. Cereal Chem 67:471–475

Shuey WC (1997) Interpretation of the farinogram. In: D’Appolonia BL, Kunerth WH (eds) The Farinograph handbook, 3rd edn. American Association of Cereal Chemists Inc, St. Paul, pp 31–32

Singh H, MacRitchie F (2001) Application of polymer science to properties of gluten. J Cereal Sci 33:231–243

Sroan BS, Bean SR, MacRitchie F (2009) Mechanism of gas cell stabilization in bread making. I. The primary gluten–starch matrix. J Cereal Sci 49:32–40

Su D, Ding C, Li L, Su D, Zheng X (2005) Effect of endoxylanases on dough properties and making performance of Chinese steamed bread. Eur Food Res Technol 220:540–545

Syama Prasad Rao R, Sai Manohar R, Muralikrishna G (2007) Functional properties of water-soluble non-starch polysaccharides from rice and ragi: effect on dough characteristics and baking quality. LWT Food Sci Technol 40:1678–1686

Termonia Y, Smith P (1987) Kinetic model for tensile deformation of polymers. I. Effect of molecular weight. Macromolecules 20:835–838

Wang J-S, Zhao M-M, Zhao Q-Z (2007) Correlation of glutenin macropolymer with viscoelastic properties during dough mixing. J Cereal Sci 45:128–133

Wen QB, Lorenz KJ, Martin DJ, Stewart BG, Sampson DA (1996) Carbohydrate digestibility and resistant starch of steamed bread. Starch-Starke 48(Nr.5.S):180–185

Yadaz DN, Rajan A, Sharma GK, Bawa AS (2010) Effect of fiber incorporation on rheological and chapati making quality of wheat flour. J Food Sci Technol 47(2):166–173

Acknowledgements

This work was financially supported by Kuok Foundation and Malayan Sugar Manufacturing Co. Bhd through a research grant (304/PTEKIND/650441/K132). S.Y. Sim wishes to thank Institute of Postgraduate Studies, Universiti Sains Malaysia for fellowship support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sim, S.Y., Noor Aziah, A.A. & Cheng, L.H. Quality and functionality of Chinese steamed bread and dough added with selected non-starch polysaccharides. J Food Sci Technol 52, 303–310 (2015). https://doi.org/10.1007/s13197-013-0967-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-0967-1