Abstract

An experiment was conducted to evaluate the conservation of blackberry, cv. Tupy, stored under refrigeration and coated with different edible coatings. Four treatments were carried out: control T1 (uncoated), T2 (chitosan 1.5 %), T3 (cassava starch 2.5 %) and T4 (kefir grains in water 20 %), stored at temperatures of 0 and 10 °C; 1.0 % (m/v) sorbitol/glycerol was added as plasticizers. Chemical and physical-chemical evaluations (weight loss, firmness, pH, titratable acidity, soluble solids, SS/TA ratio and anthocyanins) were made, besides rot incidence. The results showed that cooling to 0 °C combined with T2 showed an effect in reducing the physiological loss of weight (4.41 %), in retaining fruit firmness (19.1 N) and presenting lower incidence of rot (6.19 %). Likewise, in physical and chemical parameters: SS did not alter significantly during the whole period of 18 days of storage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the State of Parana, Brazil, the production of blackberry is still low; the cultivars Tupy and Xavante presented in the first year an average production of about 10 t/ha and 6 t/ha, respectively. The cultivar Tupy is the most promising for this region (Antunes et al. 2007). This cultivar was obtained from crossing the cultivars Uruguay vs. Comanche, in 1982, in the research unit EMBRAPA Temperate Climate. The production started from November 20 and accounts for 70 % of the cultivated area in Brazil (Antunes 2002); it is currently the most planted cultivar in the country. The blackberry cultivar Tupy has an average production from 3.6 to 4 kg/per plant, and it is recommended for fresh consumption because it presents a tough skin, besides the active aroma due to low acidity (Manica 2000; Antunes 2002).

Low temperatures are complementary methods of conservation, as well as modified atmosphere, irradiation, chemical treatments and edible coatings; however, these methods alone have unsatisfactory results (Hassimotto et al. 2008).

Coatings based on cassava starch, besides to low cost, give fruits a good appearance, glossing and transparence; this kind of product improves the visual appearance of the fruit, presenting no toxicity to humans, and can be eaten without its removal (Lucena et al. 2004). One of the most promising coating is chitosan because of its excellent properties in film formation, antimicrobial activity and a wide compatibility with other active substances in order to improve its antimicrobial efficacy (Park et al. 2005).

Piermaria et al. (2009), in their work with kefiran (produced by the microflora of kefir grains), demonstrated its ability to form edible transparent films which can be indicated for use in the food industry, in particular.

The use of coatings for formation of semi-permeable barriers that prolong fruit quality aims at reducing the gas exchange and migration of solutes and the biochemical processes and physiological disorders (Rojas-Grau et al. 2008).

Due to post-harvest short-life of blackberry fruits, new techniques of conservation, as the cooling and application of edible coatings, have been studied in order to extend the post-harvest life and to keep the fruit quality. The objective of this study is to evaluate the conservation and quality of blackberry cv. Tupy, stored under refrigeration and coated with different edible coatings.

Material and methods

Material

The blackberries cv. Tupy were purchased from Farm Samalou, in the city of Palmas, Paraná State and harvested at December 2009, in the morning; soon after the fruits were involved in 500 g plastic bags PET (polyethylene tereftalate), cooled and packed in polystyrene boxes to be transported to the Laboratory of Food Biochemistry, State University of Maringá, Maringá, Paraná.

Preparation of coatings

Chitosan (T2)

The coating of chitosan was obtained from the junction of chitosan (Polymar Company, with degree of deacetylation of 86.5 %) in a solution of ascorbic acid 0.8 % through agitation in an ultramixer (Britain brand with stainless steel blade and one speed rotor) for 2 min. So, 1.0 % of sorbitol/glycerol (m/v) indicated by Kester and Fennema (1986) was added under stirring until total homogenization.

The fruits were immersed in the solution for a period of 2 min at room temperature and then were left to dry on nylon screens; subsequently were weighed within PET packages and stored in BOD (Biochemical Oxygen Demand) camera at two temperatures: 0 and 10 °C.

Cassava starch 2.5 % (T3)

The cassava starch (commercial) was dissolved in distilled water; subsequently led to heating at 70 °C with constant stirring of the suspension until jellying (20 to 30 min), then it was left for resting until cool down (Campos et al. 2009); thereafter 1.0 % of sorbitol/glycerol (m/v) indicated by Kester and Fennema (1986) was added under stirring until total homogenization. The coating was applied onto the fruits as mentioned in item 2.2.1.

Kefir grain and water 20 % (T4)

Kefir grains were drained from liquid, weighed and disintegrated through an ultramixer (Britânia brand); after the disintegration distilled water was added and kept under heating at 50 °C for 30 min with low rotation. It was left to cool and then 1.0 % of sorbitol/glycerol (m/v) indicated by Kester and Fennema (1986) was applied under stirring until total homogenization. The coating was applied onto the fruits as mentioned in item 2.2.1.

Preparation of fruits

The amount of 50 kg of blackberry fruits cv. Tupy was harvested with 100 % of the surface in black; the fruits were selected according to the level of maturity and sanity and later were hygienized for the application of coatings.

A total of 24 kg of fruits were destined to the experiment; from this total 6 kg of fruits were selected for each treatment: control–T1 (uncoated), chitosan 1.5 %–(T2), cassava starch 2.5 %–(T3) and kefir 20 %–(T4). After the coating application, 250 g of fruits were coated and packed in transparent plastic boxes (190 cm × 120 cm × 63 cm) without perforations, sheltered with PET (polyethylene tereftalate) cover, and then stored in a BOD (Biochemical Oxygen Demand) chamber under two different temperatures (0 ± 1 °C and 10 ± 1 °C). All analyses were performed every 3 days for a period of 18 days, starting on 12/15/2009 and ending on 01/02/2010.

Physical and physicochemical analysis and incidence of rots

After weighing, analyzed physically and check out for rot incidence, fruits were crushed in an ultramixer (Britânia brand) for 2 min to perform chemical analysis.

Physical analysis

Initially 250 g of fruits (approximately 30 units) were weighed for each storage time. A semi-analytical balance was used (Bel Engineering Mark 2200) for determining the difference (Eq. 1) between initial and final weight throughout the storage period; results were expressed in percentages, as in Eq. 1.

Fruit firmness was measured using a compression test through a texture analyzer (Stable Micro Systems, model TAXT.plus). A cylindrical probe SMSP/36R 36 mm in diameter was used for compressing the fruit up to 40 % of its height, at a speed of 1.5 mm.s−1. Twelve fruits from each treatment were analyzed for each assessment period during storage.

Physicochemical analysis

The pH was determined by a potentiometer (pHmeter Hanna Instruments, Model pH 300). Titratable acidity (TA) was determined using NaOH (100 mM) for titration until pH 8.1; the result was expressed as grams of citric acid per 100 mL. The content of soluble solids (SS) was determined using a digital refractometer (Atago, model Pocket pal-1), with scale from 0 to 35° Brix, and then the ratio SS/TA was evaluated (Carvalho et al. 1990). The extraction and determination of anthocyanins were performed according to the methodology of Lees and Francis (1972) with modifications. The solvent used was ethanol (70 %) acidified to pH 2.0 with HCl. The fruits were weighed and triturated with ethanol, and left to stand overnight in the dark refrigerated at 4 °C. The absorbance reading was performed by Genova spectrophotometer at 532 nm.

Incidence of rots

Fruits with rot and contaminants exceeding 20 % on the surface were detached throughout the storage period and the percentage of damage incidence was determined.

Data analysis

The statistical design was completely randomized and plotted 4 × 7 × 2 (treatments, evaluation periods and temperatures).

The plot of each treatment was made with 250 g of fruits, and the physicochemical analysis performed in four replicates.

Data were statistically assessed by analysis of variance (ANOVA) and by the Tukey test (p < 0.05) applied on the averages through the SAS statistical software (2001).

Results and discussion

This study presents the results on the conservation of blackberry though the combination of two techniques: refrigeration and edible coatings. The use of these coatings on blackberry was not found in the literature.

Fruits stored at 10 °C and coated with T3 and T4 presented samples for analysis in 12 and 15 days of storage, respectively.

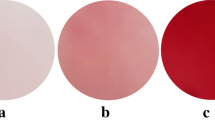

In Fig. 1 one may observe the changes in quality of blackberry during the storage period. At the temperature of 0 °C (Fig. 1a), all coatings have proved effective in reducing the mass loss in relation to T1 (control); the reduction of weight loss in fruits with coatings T2, T3 and T4 showed favorable commercial conditions, because the mass losses in these coatings did not change significantly the visual quality of fruits. Meneghel et al. (2008), studying the cultivar Comanche stored at 0 °C, report an average weight loss of 9.0 % after 18 days of storage. In this study, the same temperature with the coatings T2 and T4 may be indicated for mass loss reduction.

In Fig. 1b, the temperature of 10 °C with coatings T3 and T4 were not efficient in relation to T1. In these two treatments, there was a great mass loss at the end of 18 days of storage. Among the coatings, the T3 presented the greatest loss under the two temperatures. Park et al. (2005) reported that coatings made of polysaccharides have hydrophilic characteristics and may not be effective as a barrier to moisture loss.

Figure 1c displays the average reduction, in which the fruits of T3 and T4 showed the lowest firmness. In fruits coated with T2, the initial and final values were 19.69 and 19.34 N, respectively. During the storage period, the T2 had a average of 19.79 N.

As shown in Fig. 1d, fruit firmness decreased along with the increase of days; according Goulao and Oliveira (2008), this fact can be attributed to several physiological and biochemical changes that include the conversion of starch into sugars, biosynthesis of volatile flavor and aroma and changes in the metabolism and structure of cell wall, resulting in the loss of fruit firmness.

Mahajan et al. (2010) have worked with 1-MCP application in pears and observed fruit firmness tending to decrease during storage period. This tendency in reducing values of firmness was also observed in blackberry fruits studied in this work at temperature of 10 °C for all treatments and for 0 °C in treatments T1, T3 and T4.

Sousa (2007) stated that values of firmness have only slight variations (3.5 and 4.20 N) until the ninth day in blackberry cultivars stored at 2 °C; after this period, the firmness moves to 2.5 N. One may observe in this study that at the end of the eighteenth day, the fruits of T1 and T2 obtained forces of 3.04 and 3.01 N, respectively, stored at temperature of 10 °C; these values are higher than those observed by Sousa (2007) at the end of the storage period at 2 °C. However, under such conditions of firmness, the fruit is not adequate to consumption.

Values obtained from chemical analysis are presented in Tables 1 and 2 for storage temperatures of 0 and 10 °C, respectively. During the storage period, there was a significant increase in pH in all treatments either for 0 °C or 10 °C. At the temperature of 0 °C, the lowest pH values were obtained in T1 and T2 treatments from fifteenth day. In storage at 10 °C, treatment T2 had the lowest pH value at the end of 18 days of storage.

Tosun et al. (2008), studying the behavior of pH during blackberry ripening, observed averages of 3.20 in unripe fruits, 2.64 in red fruits and 3.14 in mature fruits. The pH of the present study showed an average similar to that reported by these authors for ripe fruits.

For cultivars Comanche and Brazos studied by Antunes et al. (2003), the initial values of pH were 3.59 and 3.39 and reached after 12 days of storage 3.94 and 4.09, respectively; there was an increase in pH of 0.40 and 0.70. In our study, an increase in pH values of 0.30 and 0.40 was observed at the end of 18 days of storage at temperatures of 10 °C and 0 °C, respectively.

One can observe as the pH increases, there is a decaying in organic acids, i.e., the values of acidity diminished. It can be emphasized that these factors are observed in the natural process of fruit senescence; however, this natural behavior may be controlled by storage at low temperatures.

In this study, in storage conditions of 10 °C, the fruits coated with T3 and T4, after an initial reduction in values of TA, were followed by increases in acidity; the reduction may be caused by increased metabolism of fruits after harvesting, in which a greater consumption of organic acids are used as substrates in the respiratory process, in which there is a greater conversion into simple sugars during maturation (Chitarra and Chitarra 2005).

Meneghel et al. (2008), working with the application of coatings on blackberry cv. Comanche, showed constant values for acidity during 18 days of storage, with average values of 0.86, 0.89 and 0.85 g of citric acid per 100 g. In this study, this fact was not observed because the levels of organic acids reduced until the end of storage. A reduction in values of titratable acidity during storage period was observed in grapes (Sabir et al. 2011), guavas (Goutam et al. 2010), and purple passionfruit (Kishore et al. 2011).

During the storage time, the SS contents of fruits in T1 and T3 under 0 °C showed a variation at ninth day; however, in the fruits coated with T2 and T4 the values remained constant and did not differ among them. During storage under refrigeration at 10 °C, these levels decreased significantly. Mahajan et al. (2010) reported a weight reduction in pear fruits (control) after 60 days of storage, indicating a rapid degradation of these fruits by physiological processes. At the end of 18 days of storage, the fruits coated with T2 showed the highest value at 5 % of significance in relation to T1.

Pandey et al. (2010) reported an increase of SS in guava up to 8 days of storage at room conditions followed by a reduction in all fruits in 14 treatments.

Kishore et al. (2011) studying the effect of storage temperature on passionfruit has demonstrated a reduction of SS relatively faster in fruits stored at higher temperatures. These authors report that changing in SS contents is a natural phenomena occurring in storage period and is correlated to hydrolytic changes in carbohydrates during storage which happen during the stages of physiological development. Besides the changes occurred due to the development of microorganisms that can affect the development stages of blackberry, causing the reduction of SS, since the storage temperature with the highest reduction of SS showed the highest incidence of rot (Fig. 1f).

The SS/TA ratio is used to assess the balance of sweet/sour of fruits. Hassimotto et al. (2008) showed as the best relationship the average value of 7.4 for blackberry. Therefore, at the storage temperature of 0 °C all treatments and T2 at 10 °C showed results close to the average quoted by those researchers.

Observing the behavior of this ratio at 10 °C, a reduction occurred in the value of SS/TA for T3 and T4, and an increase was observed in the values for T1 and T2. Checking the results for all treatments at 0 °C, there was a significant increase during the storage period compared to zero time. This happened because the reduction in acidity and soluble solids remains constant, as reported by Hassimotto et al. (2008).

Acosta-Montoya et al. (2010) showed values of SS/TA for three stages of color (green, red and black) for fruits of Rubus adenotrichus Schltdl.: 1.77, 2.17 and 3.22, respectively; these results were lower than those observed in this study. The authors also reported that SS/TA ratio is also an excellent indicator of fruit maturity, because there is an increase in their values along with ripening.

For anthocyanin contents at 10 °C, the T2 kept constant levels throughout the period of 18 days, showing that this treatment did not change these constituents in blackberry; the T1 presented an increase in their values and it may be due to chemical changes during fruit ripening. At the temperature of 0 °C, there was a change in the concentrations, but the reduction of these levels was only significant for T4. According to Araújo (2006), several factors may contribute to the degradation of anthocyanins, such as sugars (especially fructose), which accelerate the darkening process, but pH between 1 and 3.5 gives greater stability. Thus, one can observe that when there was a reduction in the amount of anthocyanins in fruits stored at 0 °C, pH values were close to the threshold value for stability.

Several values of anthocyanins can be observed in the literature, such as: cv. Tupy 47.7 mg.100 g−1 and cv. Xavante 45.2 mg.100 g−1 (Jacques et al. 2009); cv. Arapaho 121.6 and 113.5 mg.100 g−1 and Navaho 120.8 and 111.0 mg.100 g−1, stored at 2 °C for 14 days in controlled atmosphere (Perkins-Veazie and Collins 2002); cv. Comanche, the content found in the beginning of storage was 53 mg.100 g−1 of fruit, showing a linear increase of its values in all treatments (control and sodium alginate) (Meneghel et al. 2008). The values recorded for blackberry are between 83 and 326 mg.100 g−1 (Elisia et al. 2007). So, the anthocyanin contents of blackberries in this study showed levels in accordance to those reported in the literature.

The percentage of rot incidence can be seen in Fig. 1e and f, in which the T4 coating showed the highest incidence of decaying at 0 °C. The fruits under this temperature had the first rejected fruits from the sixth day for T4 coating; for other treatments, the rejection began only at 12 days of storage. At the end of 18 days, the lowest average was shown in fruits coated with T2 (6.19 %), followed by T1 (6.49 %); these averages were lower than those averages presented by Perkins-Veazie et al. (1997), who studied the storage of blackberry fruits cv. Navaho under 2 °C for 7 days, followed by 2 days at 20 °C, with rot incidence of 14 %.

Great losses at temperature of 10 °C (Fig. 1f) was observed as early as 3 days of storage; this can be occurred because of ripeness condition of fruit at harvest, post-harvest handling, transport conditions and climatic conditions during harvesting period. The highest incidences occurred in T3 and T4 coatings, and T2 was the best treatment, with an average of 32.4 % during storage.

Hernández-Muñoz et al. (2008), studying the application of chitosan coating at 1 % and 1.5 % in strawberries during 7 days of storage, reported a delay in fruit senescence and in fungal deterioration when stored at 10 °C; this benefit was enhanced when higher concentration of chitosan was applied.

At 0 °C, the contamination may be due to gray mold (Botrytis cinerea), because this fungus grows at 0 °C with a slow developing, according to the literature. To avoid this type of contamination at this temperature, sanitation and adequate care in handling from the application of coatings to packaging should be closely monitored.

Conclusion

Cooling to 0 °C combined with T2 showed the best results as to physical parameters (mass loss and firmness) and rot incidence. In the same temperature, the fruits T1 showed the largest mass loss followed by T3. The T4 followed by T3 at 0 °C showed the highest incidence of rot and mass loss in the period of 18 days of storage. The storage conditions at 10 °C and the related temperature treatments were not effective in reducing post-harvest losses (physical and physical-chemical qualities), thus shortening the fruit shelf life and accelerating the onset of contaminants and rot.

References

Acosta-Montoya Ó, Vaillant F, Cozzano S, Mertz C, Pérez AM, Castro MV (2010) Phenolic content and antioxidant capacity of tropical highland blackberry (Rubus adenotrichus Schltdl.) during three edible maturity stages. Food Chem 119:1497–1501

Antunes LEC (2002) Amora-preta: nova opção de cultivo no Brasil. Ciênc Rural 32:151–158

Antunes LEC, Duarte-Filho J, Souza CM (2003) Conservação pós-colheita de frutos de amoreira-preta. Pesq Agrop Brasileira 38:413–419

Antunes LEC, Trevisan R, Pereira IS (2007) Produção de amora-preta. In: Anais do IV Seminário Brasileiro sobre Pequenas Frutas, Bento Gonçalves, RS. pp. 65–71

Araújo JMA (2006) Química de alimentos: teoria e prática, 3ed. Revisada e ampliada, Lavras, Editora UFV. 478

Campos RP, Rodovalho MA, Clemente E (2009) Coating ‘Camarosa’ organic strawberries stored at low temperature. Braz J Food Tech 12:60–61

Carvalho CRL, Mantovan DMB, Carvalho PRN, Moraes RM (1990) Análises químicas de alimentos. Instituto de Tecnologia de Alimentos, Campinas, p 121

Chitarra MI, Chitarra AB (2005) Pós-colheita de frutas e hortaliças: fisiologia e manuseio. 2ed. revisada e ampliada, Lavras: Universidade Federal de Lavras, 785

Elisia I, Hu C, Popovich DG, Kitts DD (2007) Antioxidant assessment of an anthocyanin enriched blackberry extract. Food Chem 101:1052–1058

Goulao LF, Oliveira CM (2008) Cell wall modifications during fruit ripening: when a fruit is not the fruit—a review. Trends Food Sci Technol 19:4–25

Goutam M, Dhaliwal HS, Mahajan BVC (2010) Effect of pre-harvest calcium sprays on post-harvest life of winter guava (Psidium guajava L.). J Food Sci Tech 47:501–506

Hassimotto NMA, Mota RV, Cordenunsi BR, Lajolo FM (2008) Physico-chemical characterization and bioactive compounds of blackberry fruits (Rubus sp.) grown in Brazil. Ciênc Tecnol Aliment 28:702–708

Hernández-Muñoz P, Almenar E, Valle VD, Velez D, Gavara R (2008) Effect of chitosan coating combined with postharvest calcium treatment on strawberry (Fragaria ananassa) quality during refrigerated storage. Food Chem 110:428–435

Jacques AC, Pertuzzati PB, Barcia MT, Zambiazi RC (2009) Compostos bioativos em pequenas frutas cultivadas na região sul do Estado do Rio Grande do Sul. Braz J Food Tech 12:123–127

Kester JJ, Fennema OR (1986) Edible films and coatings: a review. Food Tech 40:47–59

Kishore K, Pathak KA, Shukla R, Bharali R (2011) Effect of storage temperature on physico-chemical and sensory attributes of purple passion fruit (Passiflora edulis Sims). J Food Sci Tech 48:484–488

Lees DH, Francis FJ (1972) Stamdardization of pigment analyses in cranberries. Hortic Sci 7:83–84

Lucena CC, Silva AC, Silva AC, Feitosa HO, Almeida FFD, Coneglian RCC, Vasconcellos MAS (2004) Efeito da película de amido na conservação pós-colheita de frutos de banana cv. “nanicão”. Agronomia 38:34–37

Mahajan BVC, Singh K, Dhillon WS (2010) Effect of 1-methylcyclopropene (1-MCP) on storage life and quality of pear fruits. J Food Sci Tech 47:351–354

Manica I (2000) Frutas nativas silvestres e exóticas 1., técnicas de produção e mercado: abiu, amora-preta, araçá, bacuri, biribá, carambola, cereja-do-riogrande, jabuticaba, Porto Alegre, Cinco Continentes, 327

Meneghel RFA, Benassi MT, Yamashita F (2008) Revestimento comestível de alginato de sódio para frutos de amora-preta (Rubus ulmifolius). Semin Ciênc Agrárias 29:609–618

Pandey SK, Joshua JE, Bisen A (2010) Influence of gamma-irradiation, growth retardants and coatings on the shelf life of winter guava fruits (Psidium guajava L.). J Food Sci Tech 47:124–127

Park SI, Stan SD, Daeschel MA, Zhao Y (2005) Antifungal coatings on fresh strawberry (Fragaria x ananassa) to control mold growth during cold storage. J Food Sci 70:202–207

Perkins-Veazie P, Collins JK (2002) Quality of erect-type blackberry fruit after short intervals of controlled atmosphere storage. Posth Bioltech 25:235–239

Perkins-Veazie P, Collins JK, Clark JR, Risse L (1997) Air shipment of ‘Navaho’ blackberry fruit to Europe is feasible. HortSci 32:132

Piermaria JA, Pinotti A, Garcia MA, Abraham AG (2009) Films based on kefiran, an exopolysaccharide obtained from kefir grain: development and characterization. Food Hydrocolloids 23:684–690

Rojas-Grau MA, Tapia MS, Martín-Belloso O (2008) Using polysaccharide-based edible coatings to maintain quality of fresh-cut Fuji apples. LWT 41:139–147

Sabir A, Sabir FK, Kara Z (2011) Effects of modified atmosphere packing and honey dip treatments on quality maintenance of minimally processed grape cv. Razaki (V. vinifera L.) during cold storage. J Food Sci Tech 48:312–318

Sousa MB (2007) Amora: qualidade pós-colheita. Folhas de Divulgação AGRO 556. N° 7. Ministério da Agricultura Pecuária e Abastecimento, 28

Tosun I, Ustun NS, Tekguler B (2008) Physical and chemical changes during ripening of blackberry fruits. Sci Agric 65:87–90

Acknowledgments

The National Council of Scientific and Technological Development (CNPq) for the scholarship granted.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oliveira, D.M., Kwiatkowski, A., Rosa, C.I.L.F. et al. Refrigeration and edible coatings in blackberry (Rubus spp.) conservation. J Food Sci Technol 51, 2120–2126 (2014). https://doi.org/10.1007/s13197-012-0702-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0702-3