Abstract

The study is an extension of an optimization study, which was planned to determine the optimum spray drying conditions (the feed, outlet and inlet air temperatures) for producing yoghurt powder. The resulting yoghurt powder at each condition was subjected to the measurement of physical properties, moisture content, and reconstitution properties. All the reconstitution properties of yoghurt powders produced under 20 different spray drying conditions according to CCRD experimental design were affected by the drying outlet temperature only. Furthermore, the bulk (bulk and tapped densities, porosity, flowability, hygroscopicity and degree of caking) and particle properties (particle size distribution, particle density and morphology) of yoghurt powder obtained from optimum spray drying conditions were also determined. The bulk, tapped and particle densities of yoghurt powder were 538, 746 and 1177 kg/m3, respectively. The mean diameter (D4.3) and the span value of yoghurt powder were 3.053 and 2.487 μm, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Spray drying is a well-known process suitable for yoghurt drying because the very short time of heat contact and the high rate of evaporation give high quality, stable, functional and low moisture content products (Koc et al. 2011; Sagar and Suresh Kumar 2010; Sarala et al. 2011; Yousefi et al. 2011). A dry powder of yoghurt is highly desirable since it not only possesses long shelf life but also requires relatively low transportation cost and storage capacity. It can be used as an ingredient for the manufacture of many food products, as well as for direct consumption due to its high content of yoghurt starter bacteria. Recently, a spray drying system for yoghurt has been characterized at various combinations of inlet air, outlet air temperatures or feed rate, atomization speed and feed temperature (Kim and Bhowmik 1990; Bielecka and Majkowska 2000; Kumar and Mishra 2004a, b; Koc et al. 2010). Despite this, the spray-drying process is not well understood, mainly due to its complexity, the dispersion of droplets and particles, moisture evaporation, particle agglomeration, and changes in the morphology of the particles as they dry (Nijdam and Langrish 2005). So the detailed characteristics of spray dried yoghurt powder in terms of physicochemical properties have not yet been evaluated.

Food powder properties can be classified as physical or chemical properties. Physical properties include the reconstitution properties, particle shape, density and porosity, surface characteristics, hardness, diameter, and size (Kurozawa et al. 2009). The spray drying temperatures and the type of atomizer can affect the physical properties of food powders that are important in the storage, handling and final application (e.g. reconstitution).

The reconstitution phenomenon involves wetting, sinking, dispersing and dissolving the food powder. Wettability is the capacity of the powder particles to absorb water on their surface. Sinkability is the sinking of powder particles below the liquid surface. Dispersibility is the dispersion of particles with little stirring and solubility is dissolving of soluble particles in the liquid. These mechanisms are closely related to the particle size, density, porosity, surface charge, surface area, and morphology of the particles in the final powder product (Kwapińska and Zbiciński 2005). On the other hand, the values of these powder properties are directly dictated by the conditions of the drying operation (Birchal et al. 2005).

Morphological properties are directly related to physical properties of powder food products (Schubert 1987). It is known that complex changes in the morphologies (size, shape and appearance) of droplets occur during spray drying and that the protection of these properties is related to the porosity and integrity of the microcapsules. With respect to morphology, the particles produced by spray drying generally show a smooth surface and are spherical in shape, have lowest surface-to-volume ratio (aroma retention), highest bulk densities (best packing) and best flowability (Kurozawa et al. 2009).

One of the most important physical parameters of powders with regard to handling is particle size. Particle size can influence flow out of storage bins, the blending of different components, compaction, and the segregation of a mixture, in which smaller particles stay distributed on the bottom and larger particles on top. In addition, these properties significantly influence the essential properties of food products such as smell, texture, and appearance. As particle size decreases, the increase in the particle surface area causes higher affinity with moisture and higher ability to agglomerate during the drying process. The knowledge of food density is of fundamental use for material properties studies and for industrial processes in adjusting storage, processing, packaging, and distribution conditions. Bulk density includes the volumes of the solid and liquid materials and all pores and is generally used to characterize a final product obtained by drying (Kurozawa et al. 2009).

The aim of the present work was to evaluate the reconstitution properties (solubility index, dispersibility, and wettability), morphological properties (appearance, particle shape and size), bulk and particle density and hygroscopicity of yoghurt powder produced by spray drying.

Material and methods

Materials

Yoghurt powders used in this study were obtained by spray drying in a pilot scale spray drier (Mobile Minor Niro Atomiser, Denmark) under 20 different processing conditions according to CCRD experimental design shown in Table 1. Details of the equipment and drying method were reported by Koc et al. (2010). The optimum spray drying condition for yoghurt powder production (inlet air temperature of 171 °C, outlet air temperature of 60.5 °C and feed temperature of 15 °C) was previously determined by Koc et al. (2010), targeting the maximum survival ratio of lactic acid bacteria, maximum overall sensory attributes, minimum colour change and acceptable moisture content. As explained in previous work of Koc et al. (2010), overall sensory acceptability (total 20 scores for each of 5 points of appearance, taste and flavor, consistency in the mouth and spoon) of yoghurt powders under 20 different processing conditions of spray drying were evaluated.

Reconstitution properties (solubility index, dispersibility, wettability) of yoghurt powders were investigated under 20 different spray drying conditions and at the optimum condition (inlet air temperature of 171 ± 2 °C, outlet air temperature of 60.5 ± 2 °C and feed temperature of 15 ± 2 °C). Besides, the bulk and morphological properties were measured only at optimum spray drying condition.

Analytical methods

Moisture content

Moisture contents of yoghurt and dried powder were determined gravimetrically by oven drying at 102 °C for 2 h (AOAC 1990).

Reconstitution properties

Dispersibility and wettability

Dispersibility and wettability measurements of yoghurt powder in water were performed according to the procedure described in FIL-IDF: 87 (IDF 1979).

Solubility index

The solubility index of yoghurt powder was measured after reconstituting 13.0 g powder in 100 mL water at 24 °C (IDF 1988).

Particle properties

Particle morphology

The morphological properties of yoghurt powder (the appearance and the particle shape) were investigated by taking images via a scanning electron microscope (SEM, JSM–6060 JEOL, Japan).

Particle size distribution

The particle size distribution of the yoghurt powder was measured using a laser light diffraction particle size analyser (MasterSizer model S 2000, Malvern Instruments Ltd., Worcestershire, U.K.) in which a small quantity of powder was dispersed in water and the particle distribution was monitored during five successive trials. The particle size was expressed as mean volumetric size D4.3 (De Brouckere mean diameter), and was calculated as follows:

where ni is the number of particles of diameter di . The particle size distribution of the powder was measured as the span, which is defined as;

where d90, d10, and d50 are the equivalent volume diameters at 90%, 10%, and 50% cumulative volume, respectively.

Particle density

Particle density (ρ p ) of the powder sample was analyzed according to a study by Barbosa-Cánovas et al. (2005).

Bulk properties

Bulk and tapped densities

The bulk density (ρ b ) of the yoghurt powder was determined by measuring the weight of the powder and the corresponding volume. Approximately 20 g of powder sample was placed in a 100 ml graduated cylinder. The bulk density was calculated by dividing the mass of the powder by the volume occupied in the cylinder. For the tapped density (ρ t ), the cylinder was tapped vigorously by hand until no further change in volume occurred (Jinapong et al. 2008).

Porosity

The porosity (ε) of the powder samples was calculated using the relationship between the tapped (ρ t ) and particle (ρ p ) densities of the powders as shown below (Jinapong et al. 2008):

Flowability

Flowability of the yoghurt powder was evaluated in terms of Carr index (CI) (Carr 1965). CI was calculated from the bulk (ρ b ) and tapped (ρ t ) densities of the powder as shown below:

Hygroscopicity

About 1 g of powder was spread evenly on petri dishes (9 cm diameter) to allow for a high surface area between humid air and powder. The dishes were placed in desiccators containing saturated NaCl solutions, providing (75.3%) relative humidity at 25 °C. A 10 min interval was selected to get the kinetics of moisture sorption. Although hygroscopicity is based on the equilibrium moisture content, to compare hygroscopicities, the weight increase per gram of powder solids after being subjected to the atmosphere with relative humidity of 75.3% for 90 min was determined (Al-Kahtani and Hassan 1990; Goula and Adamopoulos 2004). The gain in weight of the samples was considerably lower after 90 min but it certainly continued. Hygroscopicity was expressed as kg moisture/100 kg dry solids.

Degree of caking

After the determination of hygroscopicity, the wet sample was dried in an oven at 102 °C. After cooling, the dried sample was weighed and transferred into a sieve of 500-μm size. Then the sieve was shaken for 5 min in a shaking apparatus. The weight of the powder remaining in the sieve was measured. The degree of caking was calculated as (Jaya and Das 2004):

where CD is the degree of caking (%), a is the amount of the powder used in sieving, and b is the amount of the powder that remained on the sieve after sieving.

Statistical analysis

All measurements were made in triplicates. Results are expressed as mean ± standard deviation. The analysis of variance (ANOVA) at a confidence level of 95% was performed. All the results that were obtained were analysed using Design Expert–version 7.0 software (Statease Inc., MI, USA).

Results and discussion

Spray drying of yogurt at the optimum process condition could significantly improve the survival of lactic acid bacteria and overall sensory acceptability with minimum colour change and acceptable moisture content for longer periods of storage. It was found that overall sensory acceptability scores were significantly affected by the outlet air temperature of drying and these values decreased with an increasing outlet air temperature.

The moisture content of the fresh yoghurt sample was determined as 85.8% wet basis. The moisture content (%, wet basis) of yoghurt powders obtained at twenty different experimental spray drying conditions is presented in Table 1. Moisture content values varied between 3.98 and 7.17%, wet basis.

Reconstitution properties

In the case of dried-powdered foods, a number of properties influence the overall reconstitution characteristics (Hogekamp and Schubert 2003). For instance, solubility is the final step of powder dissolution and is considered as the key determinant of the overall reconstitution quality. Commercial milk powder manufacturers often use this property as a criterion to indicate the quality of milk powders. In terms of the fundamental interpretation of solubility, it does not follow the usual chemical sense but instead is often used to represent the complete phenomenon of dairy powder reconstitution, comprising soluble components such as lactose, un-denatured whey protein, and salts, as well as dispersible components like casein (Fang et al. 2008). The rate of insoluble material formation in dairy products largely depends on the temperature of any heat application prior to drying as well as drying temperature. Generally, dispersibility and wettability depend on particle size, density, porosity, surface charge, surface area, and the presence of amphipathic substances and the surface activity of the particles (Kim et al. 2002). The poorer wettability, as reflected by lower dissolution rates, may be related to the decreased solubility of the denatured protein (Fang et al. 2008; Marabi et al. 2007; Millqvist-Fureby et al. 2001).

The solubility index values of yoghurt powder at different spray drying conditions and at the optimum spray drying condition were given in Tables 1 and 2, respectively. The analysis of variance showed that the solubility index value was affected by the outlet and inlet air temperatures (p < 0.05) (Table 3). As a similar observation, Figueroa et al. (2002) reported that the solubility index values of spray-dried yoghurt powder was affected by the outlet air temperature, but the trend of this effect could not be figured out clearly.

The dispersibility and wettability values of yoghurt powder at different spray drying conditions and at the optimum spray drying condition were also given in Tables 1 and 2, respectively. The analysis of variance showed that the dispersibility and wettability values were affected by the outlet air temperatures (p < 0.05) (Table 3). Figueroa et al. (2002) reported that the dispersibility values (%) of spray-dried yoghurt powder were affected by the outlet air temperature, but the trend of this effect could not be figured out, clearly, as in the case of solubility.

Bulk and particle properties

The physical properties of yoghurt powders, namely particle size distribution, particle density, bulk density, tapped density, porosity, degree of caking, and flowability, produced at optimum spray drying conditions were given in Table 2.

Spray-dried products are usually nonhomogeneous. For nonhomogeneous systems, with particle size distribution, the voids between big particles are filled with smaller particles, which cause an increase of the bulk density (Schubert 1987). The mean diameter (D4.3) of a sphere, which gives an indication of the diameter corresponding to the average particle volume of the particle size distribution, and the span value, were found to be 3.053 and 2.487 μm, respectively. The span-value expressing the width of the size distribution was also in the same order of magnitude. Figure 1 also shows the particle size distribution of the yoghurt powder. It can be seen that the yoghurt powder had a narrower particle size range with a relatively uniform distribution. These results show that spray drying does not produce large particles. The lower the particle size, the lower the solubility and flowability of powder (Kurozawa et al. 2009).

Through scanning via electron microscopy, the yoghurt powder particles were mostly observed as spherical and showed a crater-like structure. It is stated that, spray dried dairy powder products are generally spherical in shape although some extending parts may exist (Hall and Hedrick 1975). Also as stated by Elversson and Millqvist-Fureby (2005), the lactose particles appear as perfect spheres, which is a well-known characteristic of spray-dried lactose. The scanning electron microscopy images of yoghurt powder, produced at the optimum spray drying condition, were given in Fig. 2 with a level of magnification of 2,500×. The porous surface is expected to be advantageous for improved wetting and improved solubility (Rogers et al. 2008).

The bulk properties (bulk and tapped densities, porosity, flowability) of a food powder are highly dependent on particle size and its distribution (Barbosa-Cánovas et al. 2005). Lower bulk densities of a product are not desirable, resulting in a greater volume of package. Moreover, lower the bulk density, more occluded air within the powders would be and a greater possibility for product oxidation resulting in reduced storage stability (Goula and Adamopoulos 2008; Kurozawa et al. 2009). The bulk densities of milk and whey powder were 400 and 530 kg/m3, respectively and the particle density of most food powders is about 1,400 kg/m3 (Barbosa-Cánovas et al. 2005). The bulk, tapped and particle densities of yoghurt powder were found to be 538, 746 and 1177 kg/m3, respectively. The porosity of yogurt powder was calculated as 36.54% (Table 2). Spherical particles pack the best and thus, have the highest bulk densities and porosity (Reineccius 2004).

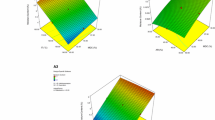

Yoghurt powders have moderate-poor flowability (CI = 27.93%) due to their small particle size. Caking and stickiness are common problems prevailing in food powder handling and processing. The caking degree of the yoghurt powder was 30.32%. Goula and Adamopoulos (2008) reported that the caking degree of tomato powders varied from 8.9 to 22.3%. Moisture adsorption of the spray-dried yoghurt powder at 25 °C and 75.3% relative humidity after 90 min is shown in Fig. 3. Yoghurt powder is not very hygroscopic as seen in the Fig. 3.

Conclusion

The solubility index, dispersibility and wettability of yoghurt powder were affected by the outlet air temperature, but the trend of this effect could not be figured out clearly. The bulk, tapped and particle densities of yoghurt powder were 538, 746 and 1177 kg/m3, respectively. These values are an indication that yoghurt powder has fair porosity (36.54%). Yoghurt powders have moderate-poor flowability (CI = 27.93%) due to their small particle size (3.053 μm), and high caking degree (30.32%) values. The resultant powder is not very hygroscopic. With respect to morphology, the yoghurt powder particles were mostly spherical and showed a crater-like structure. For purposes of understanding the particle formation process, predicting product quality and evaluating the behaviour of spray-dried yoghurt powder during reconstitution, this information will provide a helpful approach.

References

Al-Kahtani HA, Hassan BH (1990) Spray drying of roselle (Hibiscus sabdariffa L.) extract. J Food Sci 55(4):1073–1076

AOAC (1990) Official method of analysis, 15th edn. Association of Official Analytical Chemists (no 934.06), Washington, DC

Barbosa-Cánovas GV, Ortega-Rivas E, Juliano P, Yan H (2005) Food powders: physical properties, processing, and functionality. Kluwer Academic/Plenum Publishers, New York

Bielecka M, Majkowska A (2000) Effect of spray drying temperature of yoghurt on the survival of starter cultures, moisture content and sensoric properties of yoghurt powder. Nahrung 4:257–260

Birchal VS, Passos ML, Wildhagen GRS, Mujumdar AS (2005) Effect of spray-dryer operating variables on the whole milk powder quality. Dry Technol 23(3):611–636

Carr RL (1965) Evaluating flow properties of solids. Chem Eng-New York 72:163–168

Elversson J, Millqvist-Fureby A (2005) Particle size and density in spray drying-effects of carbohydrate properties. J Pharm Sci-Us 94:2049–2060

Fang Y, Selomulya C, Chen XD (2008) On measurement of food powder reconstitution properties. Dry Technol 26(1):3–14

Figueroa ER, Cervantes MAS, Rodriguez GC, Garcia HS (2002) Addition of hydrocolloids to improve the functionality of spray dried yoghurt. Milchwiss 57(2):87–89

Goula AM, Adamopoulos KG (2004) Spray drying of tomato pulp: effect of feed concentration. Dry Technol 22(10):2309–2330

Goula AM, Adamopoulos KG (2008) Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: ii. Powder properties. Dry Technol 26(6):726–737

Hall CW, Hedrick TI (1975) Drying of milk and milk products, 2nd edn. The Avi Publishing Company, Inc, Wesport

Hogekamp S, Schubert H (2003) Rehydration of food powders. Food Sci Technol Int 9:223–235

IDF (1979) Determination of the dispersibility and wettability of instant dried milk (Reference method). IDF standard 87. International Dairy Federation, Brussels

IDF (1988) Determination of insolubility index of Caseins and Caseinates (Reference method). IDF standard 129A. International Dairy Federation, Brussels

Jaya S, Das H (2004) Effect of maltodextrin, glycerol monostearate and tricalcium phosphate on vacuum dried mango powder properties. J Food Eng 63:125–134

Jinapong N, Suphantharika M, Jamnong P (2008) Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng 84:194–205

Kim SS, Bhowmik SR (1990) Survival of lactic acid bacteria during spray drying of plain yoghurt. J Food Sci 55:1008–1010, 1048

Kim EHJ, Chen XD, Pearce D (2002) Surface characterization of four industrial spray-dried powders in relation to chemical composition, structure and wetting property. Colloid Surf B 26:197–212

Koc B, Sakin M, Balkir P, Kaymak-Ertekin F (2010) Spray drying of yoghurt: optimization of process conditions for improving viability and other quality attributes. Dry Technol 28:495–507

Koc M, Koc B, Susyal G, Sakin Yılmazer M, Kaymak Ertekin F, Bağdatlıoğlu N (2011) Functional and physicochemical properties of whole egg powder: effect of spray drying conditions. J Food Sci Technol 48(2):141–149

Kumar P, Mishra HN (2004a) Yoghurt powder- A review of process technology, storage and utilization. Food Bioprod Process 82(C2):133–142

Kumar P, Mishra HN (2004b) Storage stability of mango soy fortified yoghurt powder in two different packaging materials: HDPP and ALP. J Food Eng 65:569–576

Kurozawa LE, Morassi AG, Vanzo AA, Park KJ, Hubinger MD (2009) Influence of spray drying conditions on physicochemical properties of chicken meat powder. Dry Technol 27(11):1248–1257

Kwapińska M, Zbiciński I (2005) Prediction of final product properties after cocurrent spray drying. Dry Technol 23:1653–1665

Marabi A, Mayor G, Raemy A, Bauwens I, Claude J, Burbidge AS, Wallach R, Saguy IS (2007) Solution calorimetry: a novel perspective into the dissolution process of food powders. Food Res Int 40:1286–1298

Millqvist-Fureby A, Elofsson U, Bergenstahl B (2001) Surface composition of spray-dried milk protein-stabilized emulsions in relation to pre-heat treatment of proteins. Colloid Surf B 21:47–58

Nijdam JJ, Langrish TAG (2005) An investigation of milk powders produced by a laboratory-scale spray dryer. Dry Technol 23(5):1043–1056

Reineccius GA (2004) The spray drying of food flavors. Dry Technol 22(6):1289–1324

Rogers S, Wu WD, Saunders J, Chen XD (2008) Characteristics of milk powders produced by spray freeze drying. Dry Technol 26(4):404–412

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47:15–26

Sarala M, Velu V, Anandharamakrishnan C, Singh RP (2011) Spray drying of Tinospora cordifolia leaf and stem extract and evaluation of antioxidant activity. J Food Sci Technol. doi:10.1007/s13197-011-0364-6

Schubert H (1987) Food particle technology. Part I: properties of particles and particulate food systems. J Food Eng 6:1–32

Yousefi S, Emam-Djomeh Z, Mousavi SM (2011) Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). J Food Sci Technol 48(6):677–684

Acknowledgements

The authors acknowledge the financial support of TUBITAK-TOVAG (project number: 107 O 090) and Ege University, Council of Scientific Research Projects (Project Number: BAP 2006/Muh/043) and also Pinar Dairy Products Company, Izmir, Turkiye.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koç, B., Sakin-Yılmazer, M., Kaymak-Ertekin, F. et al. Physical properties of yoghurt powder produced by spray drying. J Food Sci Technol 51, 1377–1383 (2014). https://doi.org/10.1007/s13197-012-0653-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0653-8