Abstract

The study was conducted to standardize the protocol for preparation of wild apricot fruit bar. Wild apricot fruits were harvested at optimum maturity from Distt Tehri Garhwal, Uttarakhand and after thorough sorting and proper washing, used for hot extraction of pulp through a pulper. Pulp was preserved in 500 ppm SO2 (using potassium metabisulphite). For preparation of fruit bars, additives like sugar and pectin were added to the pulp in different proportions and the mixture dried in mechanical dehydrator. Dried fruit bar sheets were cut into rectangular shapes (2.5 × 4.0 cm2) using a stainless steel knife and wrapped in polythene paper. Best recipe was selected on the basis of sensory evaluation. For storage, wild apricot fruit bar was packed in aluminium laminated pouches and polyethylene pouches, kept for 6 months and analyzed periodically for changes in quality. Results of the sensory evaluation indicate that a very good quality fruit bar can be prepared by using wild apricot pulp +60% sugar +0.30% pectin and drying the mixture in a mechanical dehydrator at 55 ± 2 °C for 6 h. During 6 months of storage, there was about 3% moisture gain, 6.00 and 9.35% loss in total sugars and vitamin C respectively, along with slight losses in titratable acidity and sensory quality. The changes in chemical and sensory quality attributes were minimum in wild apricot fruit bar, packed in aluminium laminated pouches as compared to those packed in polyethylene pouches, and the product stored under vacuum than that under normal atmosphere. Further, the products were stable up to 6 months during storage under ambient condition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Apricot (Prunus armeniaca L.) is considered as one of the most delicious temperate fruits (Bhat et al. 2002). It is a rich source of carbohydrates and minerals besides having attractive colour and typical flavour (Ghorpade et al. 1995). Sugars like glucose, fructose, sucrose, sorbitol and malic acid and citric acid are the principal constituents present in it besides being a good source of minerals such as potassium, sodium and iron but deficient in protein and fat (Lal et al. 1989; Hui 1992).

Apricot is grown throughout the world including many hilly states of India i.e. Jammu and Kashmir, Himachal Pradesh and Uttarakhand. The total apricot production in the world about 38,31,823 tonnes from an area of 5,20,455 ha (FAO 2010). Out of this, India produces is about 10,000 tonnes of cultivated apricot from an area of 2,400 ha. On an average the productivity of apricot is about 4.17 tonnes/ha. In Uttarakhand, apricot (including wild forms) is grown over an area of 9,156 ha, with annual fruit production of 30,948 tonnes (Anonymous 2008). It is an important temperate fruit used as fresh and also in preserved form.

In contrast to the table purpose varieties of apricot (such as Charmagz, Shakarpara and New Castle), the fruit of wild apricot are high in acidity, low in sugar content and poor in sensory acceptability, which makes them unsuitable for fresh consumption. This is the reason why wild apricot fruit are almost totally wasted in India. Considering the high acidity of wild apricot fruits, it was thought to utilize them for the preparation of wild apricot fruit bar similar to the mango fruit bar which is very popular in India.

Fruit bar is a confectionery product, prepared by drying fruit pulp after mixing with appropriate quantities of sugar, pectin, acid and colour (Narayana et al. 2007). It is also called fruit slabs or fruit leather (Chauhan et al. 1993). It can be prepared from a wide variety of fruits including guava, banana, papaya, mango, sapota, apple, jackfruit etc. (Mathur et al. 1972). Most of the commercially available fruit bars (except mango leather) are synthetic in nature and without fruit pulp. Natural fruit pulp based fruit bars are more nutritious and organoleptically acceptable since substantial quantities of dietary fibres, minerals and vitamins are the constituents of finished product. Commercially tray drying is the common method of preparation of mango bar as it overcomes the problem of exposure to open atmosphere and requirement of long processing time. Drying characteristics of fruit pulp have been studied by using tunnel drier and forced air circulation Cabinet dryer (Rao and Roy 1980a; Lodge 1981; Mir and Nath 1993). Gowda et al. (1995) developed a method by which mango bar was prepared by addition of sugar (20%), citric acid (0.2%) and Potassium metabisulphite i.e. KMS (700 ppm) individually or in different combinations. Ekanayake and Bandara (2002) have reported about 15% sugar level and the tray load of 7.5 mm initial thickness of the leather was the best for the production of good quality banana leather. A tasty banana fruit bar could be prepared by mixing 20% sugar, 0.5% pectin and 350 ppm potassium metabisulphite with smoothly blended pulp of Karpuravalli banana (Narayana et al. 2007).

Ahmad et al. (2005) developed a method by which fruit bar was prepared from blend of ripe papaya and tomato pulps in the ratio 75:25 on weight basis. Papaya leather from pasteurized pulp was prepared with addition of 15% sugar, 0.5% citric acid and drying at 70 °C for 4.5 hrs in thin layer (4–5 mm) in tray drier (Sandhu et al. 2008). Defatted soy flour 11.20 g, stevia 3.00 g and pectin 1.57 g/100 g pulp were optimized for preparation of pineapple fruit bar (Kulshrestha et al. 2008). Apricot fruit bar prepared by dehydration of apricot pulp supplemented with soy slurry, had increased protein and fat (Chauhan et al. 1993).

There is a lot of information available on the preparation of fruit bars from various fruits including cultivated varieties of apricot, but the information on the utilization of the wild forms of apricot, which are otherwise unsuitable for table purposes and are completely treated as a waste for fresh consumption, for the preparation of wild apricot fruit bar is scanty in literature. Therefore, the present study was undertaken to standardize the protocol for the preparation of fruit bar from wild apricot grown in Uttarakhand and to evaluate the storage stability of the developed product.

Materials and methods

Ripe fruits of wild apricot were procured from the orchard of Department of Horticulture, G.B. Pant University of Agriculture and Technology, Hill Campus, Ranichauri, Distt Tehri-Garhwal, Uttarakhand, India and nearby local areas, located at an altitude of 1500–2000 m above mean sea level. After thorough sorting and proper washing, fruits were heated for 5 to 7 min in a stainless steel pan by adding water (100 ml/kg of fruit) and passed through the pulper for extraction of pulp. Wild apricot pulp was collected and stored in pre-sterilized plastic barrels with added SO2 @ 500 ppm.

For preparation of fruit bar, additives like sugar (cane sugar available in open market) and pectin (Commercial grade) were added to the pulp in different proportions i.e. T1 (Pulp +40% sugar +0.20% pectin), T2 (Pulp +40% sugar +0.30% pectin), T3 (Pulp +40% sugar +0.40% pectin), T4 (Pulp +50% sugar +0.20% pectin), T5 (Pulp +50% sugar +0.30% pectin), T6 (Pulp +50% sugar +0.40% pectin), T7 (Pulp +60% sugar +0.20% pectin), T8 (Pulp +60% sugar +0.30% pectin), T9 (Pulp +60% sugar +0.40% pectin), T10 (Pulp +70% sugar +0.20% pectin), T11 (Pulp +70% sugar +0.30% pectin), T12 (Pulp +70% sugar +0.40% pectin) and T13 (Control) i.e. Pulp without any additives. Wild apricot pulp (1.5 kg in each treatment) was boiled over a low flame till its volume reduced to half, and then weighed quantity of sugar was added. About 50 g of sugar was retained for mixing in pectin for its uniform distribution. Weighed quantities of pectin were added to the mixture of pulp and sugar by uniform sprinkling and continuous mixing. The mixture when ready in each treatment was poured into aluminium trays (smeared with butter) in layers of about 4–5 mm thickness. The trays were kept in mechanical dehydrator and product was dried at 55 ± 2 °C for about 6 h. After drying, fruit bar sheets were cut into rectangular shapes (2.5 × 4.0 cm2) using a stainless steel knife. Fruit bars were evaluated for sensory quality on the basis of colour, texture, taste, flavour and overall acceptability by semi - trained panel of 15 judges consisting of males and females of age 20–50 years on 9 point Hedonic scale (Amerine et al. 1965). The panel of judges included faculty members and students of the department of Horticulture, GB Pant University, Hill Campus Ranichauri, India. Teachers are involved in sensory evaluation of different products for the last many years and students are taught how to do sensory evaluation of food products, in one of their courses, so the sensory panel comprised of semi-trained evaluators. The best combination was selected for further studies. For storage wild apricot fruit bars were packed in two different packaging materials i.e., polythene pouches (thickness 25 μm) and aluminium laminated pouches (thickness 16 μm) with and without vacuum flushing. Polyethylene and aluminium pouches were prepared by cutting them into 13.00 × 15.00 cm2 size and sealing in a Sanco Pedal Operated Electric Polyethene Sealing Machine (SANCO, Ranjit Nagar, New Delhi). Vacuum flushing was done up to –0.6 bar pressure (vacuum) in vacuum packaging machine (Audionvac VMS 153, Sandeep Instruments, Ranjit Nagar, New Delhi). Packed fruit bars were stored for a period of 6 months and evaluated periodically i.e. Initial (immediately after preparation - S1), after 3 months (S2) and after 6 months (S3) for any changes in physico-chemical and sensory quality attributes (Fig. 1).

Standard procedures were followed for the estimation of physico-chemical quality parameters like moisture, acidity, reducing sugars, total sugars, ascorbic acid and sensory quality (Ranganna 1997; Sharma and Nautiyal 2009). Moisture was determined by recording change in weight of the sample during storage, sugars by Nelson-Somogyi method and ascorbic acid by direct colorimetric method using 2,6 dichlorophenol indophenols dye. Data on chemical characteristics were analyzed statistically by completely randomized design (Cochran and Cox 1967), with the factors 3 × 2 × 2 × 3, where 3 indicates the storage periods with three levels (initial i.e. at the time of product preparation, 3 months and 6 months), 2 the packaging materials with two levels (i.e. aluminium laminated pouches and polythene pouches), 2 the storage atmosphere with two levels (normal and with vacuum flushing) and 3 the number of analyses carried out (replications). The data pertaining to sensory evaluation were analyzed according to randomized block design.

Results and discussion

Figure 2 indicates the sensory scores obtained for various quality attributes on 9 point hedonic scale. Perusal of data indicates that the sensory score for colour was highest (7.95) in T8 i.e. Pulp +60% sugar +0.30% pectin, while, lowest colour score (3.50) was obtained in T13 (Control). In similarity to colour, the sensory score for taste and overall acceptability were also highest 7.95 and 7.58 respectively in T8 while lowest score for texture, flavour, taste and overall acceptability i.e. 2.30 and 3.13 respectively were obtained in T13. Thus, among the 13 recipes evaluated for the preparation of wild apricot fruit bar, T8 i.e. containing fruit pulp alongwith 60% sugar and 30% pectin was adjusted the best based on organoleptic acceptability of the product (Fig. 2) which might be due to the better sugar - acid blend of the product as compared to other recipes used. The lower score obtained by the fruit bars prepared by using 40 and 50% sugar (T1 to T6) was probably due to the high acidity of the product. On the contrary the products prepared by using 70% sugar (i.e. T10 to T12) were not liked too much due to higher sweetness. Therefore, the recipe containing Pulp +60% sugar +0.30% pectin was optimized for further studies.

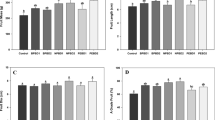

Moisture content increase from 18.89 to 20.39 and 20.12% in polyethylene pouch and aluminium laminated pouch respectively which might be due to absorption of small quantities of moisture, by the stored products, from the atmosphere (Tables 1 and 2, Fig. 3). Overall there was about 2.97% moisture gain during 6 months storage but the effects of packaging materials and atmosphere were found to be non-significant on moisture changes in wild apricot fruit bar during storage. Similar results were reported by Sharma et al. (2006) during storage of protein rich compressed bar. Titratable acidity in both the packaging materials expressed slight decline during storage which might be due to the utilization of acids during various bio-chemical reactions occurring in the product during storage (Tables 1 and 2, Fig. 3). The changes in titratable acidity were so less that the effect of all the factors i.e. storage interval, packaging material as well as atmosphere were statistically non-significant. Chauhan et al. (1993) have also recorded a similar trend in apricot - soy fruit bar.

There was gradual increase in reducing sugars in both the packages during 6 months of storage which might be due to the inversion of non - reducing sugars into reducing sugars and the conversion of polysaccharides to monosaccharides (Tables 1 and 2, Fig. 3). The overall net increase in reducing sugars was 6.71% corresponding to 8.29 and 5.13% changes in the products packed in polythene pouches and aluminium laminated pouches, respectively, indicating lesser changes in the reducing sugar levels of wild apricot fruit bar packed in aluminium laminated pouches as compared to that in polythene pouches. Further, the changes in reducing sugars were also lesser in vacuum packaging (atmosphere) than that under normal atmosphere with respective mean values of 45.09 and 48.36% respectively. The increase in reducing sugars has also been observed during storage of mango leather by Rao and Roy (1980b). Similar results have been recorded in sapota - papaya bar during 3 months of storage period (Sreemathi et al. 2008) and in apricot - soy toffees (Thakur et al. 2007). Contrary to the reducing sugar levels the total sugar levels decreased from initial value of 72.46% to 69.96 and 70.47% in polyethylene pouch and aluminium laminated pouch respectively during storage of 6 months (Tables 1 and 2, Fig. 3), which might be due to the participation of sugars in Maillard browning reactions. The net loss in total sugars of wild apricot fruit bar packed in aluminium laminated pouches (3.9%) and polythene pouches (4.8%) indicates superiority of the former over the later in retention of nutritional quality of the stored products. Similarly, higher level of total sugars could be retained in vacuum packaging (atmosphere) that that under normal atmosphere with respective mean values of 70.77 and 69.66% respectively. The decrease in total sugars in apricot - soy toffees and papaya leather during storage was also observed by Thakur et al. (2007) and Sandhu et al. (2008) respectively. Similar findings have been reported during storage of sapota - papaya bar by Sreemathi et al. (2008).

Loss of ascorbic acid in fruit bar samples packed in polyethylene pouch and aluminium laminated pouch from initial value of 9.52 mg/100 g to 8.43 and 8.84 mg/100 g respectively, during storage of 6 months (Tables 1 and 2, Fig. 3), might be due to its oxidation to dehydroascorbic acid followed by further degradation to 2,3 - diketogulonic acid and finally to furfural compounds which enter browning reactions. The net loss of vitamin C of wild apricot fruit bar packed in aluminium laminated pouches (0.68 mg/100 g) and polythene pouches (1.09 mg/100 g) indicates superiority of the former over the later in retention of nutritional quality of the stored products. Similarly, higher level of vitamin C could be retained in vacuum packaging (atmosphere) than that under normal atmosphere with respective mean values of 9.32 and 8.69 mg/100 g respectively. Loss of ascorbic acid has earlier been reported in mango leather during of 3 months storage by Rao and Roy (1980b). Similar results have been reported by Sreemathi et al. (2008) in sapota - papaya bar during 3 months of storage.

The overall acceptability decreased from initial score of 7.84 to 7.40 and 7.54 for products packed in polyethylene and aluminium laminated pouch respectively after 6 months of storage (Tables 1 and 2, Fig. 3). Similar reduction in sensory score during storage of 3 months has been reported by Vijayanand et al. (2000) in guava fruit bar. The decrease in mean sensory score for all the sensory attributes as well as overall acceptability during storage of 14 months was observed in protein rich compressed bar by Sharma et al. (2006). The lower mean sensory score observed in wild apricot fruit bar packed in polyethylene pouches, might be due to higher moisture absorption and gas permeability characteristics of the polyethylene. The sensory scores were significantly higher in wild apricot fruit bars packed in aluminium laminated pouches which might be due to impermeable nature of laminated pouches. Aluminium laminated pouches are near to impermeable gas and moisture exchange. Little exchange if any through aluminium laminates may be due to faulty sealing of the package. Similar evidences have also been reported by Sandhu et al. (2008) in papaya leather.

Conclusively, it emerges that the wild apricot fruit bar can successfully be prepared by using wild apricot pulp +60% sugar +0.30% pectin and drying the mixture in a mechanical dehydrator at 55 ± 2 °C for 6 h and thus the recipe was optimized. During 6 months storage, although there was about 3% moisture gain, 6.00 and 9.35% losses in total sugars and vitamin C respectively, along with slight losses in titratable acidity and sensory quality. The quality loss was least in wild apricot fruit bar, packed in aluminium laminated pouches as compared to those packed in polyethylene pouches. The results also indicated the stability of product up to 6 months at under ambient storage condition.

References

Ahmad S, Vashney AK, Srivastava PK (2005) Quality attributes of fruit bar made from papaya and tomato by incorporating hydrocolloids. Int J Food Properties 8(1):89–99

Amerine MA, Pangborn RM, Roesslev EB (1965) Principles of sensory evaluation of food. Academic Press Inc, New York

Anonymous (2008) Statistical Database, Directorate of Horticulture and Food Processing, Ranikhet, Uttarakhand, India

Bhat AR, Srivastava KK, Ahmad MF (2002) Apricot (Prunus armeniaca). Indian Hort 47(2): Cover II, 24

Chauhan SK, Joshi VK, Lal BB (1993) Apricot soy fruit bar - a new protein enriched product. J Food Sci Technol 30(6):457–458

Cochran WG, Cox GW (1967) Experimental designs. Wiley, New York

Ekanayake S, Bandara L (2002) Development of banana fruit leather. Ann Sri Lanka Dept Agri 4:353–358

FAO (2010) Statistical Database of the Food and Agricultural Organization, FAO Rome, Italy. www.fao.org. Accessed 12 September 2010

Ghorpade VM, Hanna MA, Kadam SS (1995) Apricot. In: Salunkhe DK, Kadam SS (eds) Handbook of fruit science and technology - production, composition, storage and processing. Marcel Dekker Inc., New York

Gowda IND, Dan A, Ramanganeya KH (1995) Studies on mango fruit bar preparation. Indian Food Packer 49(2):17–24

Hui YH (1992) Encyclopedia of food science and technology. Vol. 1. Wiley, New York

Kulshrestha N, Jha YK, Kumbhar BK (2008) Process optimization of low calorie and high protein pineapple bar using response surface methodology. Indian Food Packer 62(3):37–46

Lal BB, Joshi VK, Sharma R (1989) Physico-chemical and sensory evaluation of sauce and chutney prepared from wild apricot (Chulli). Indian Food Packer 43(3):13–16

Lodge N (1981) Kiwi fruit- two novel processed products. Food Technol NZ 19(7):35–43

Mathur VK, Das SA, Jayaraman KS, Bhatia BS (1972) Preparation of fruit bars use in combat rations. Indian Food Packer 26:33–35

Mir MA, Nath N (1993) Sorption isotherms of fortified mango bars. J Food Engg 25(1):141–150

Narayana CK, Mustaffa MM, Sathiamoorthy S (2007) Standardization of process for preparation of banana fruit bar. Indian J Hort 64(3):349–350

Ranganna S (1997) Handbook of analysis and quality control of fruit and vegetable products, 2nd edn. Tata McGraw Hill Pub Co Ltd, New Delhi, pp 1–106

Rao VS, Roy SK (1980a) Studies on dehydration of mango pulp. I: standardization for making mango sheet/leather. Indian Food Packer 34(3):64–71

Rao VS, Roy SK (1980b) Studies on dehydration of mango pulp. II: storage studies of the mango sheet/leather. Indian Food Packer 34(3):72–79

Sandhu KS, Chander R, Bajwa U, Mahajan BVC (2008) Effect of papaya ripening incorporation of sucrose liquid glucose and citric acid on papaya leather quality formulations. J Food Sci Technol 45(2):133–138

Sharma KD, Alkesh, Kaushal BBL (2006) Evaluation of apple cultivars for dehydration. J Food Sci Technol 43(2):177–181

Sharma SK, Nautiyal MC (2009) Postharvest technology of horticultural crops - practical manual seires – 2. New India Pub. Agency, New Delhi

Sreemathi M, Sankaranarayanan R, Balasubramanyan S (2008) Sapota – papaya bar. Madras Agri J 95(1/6):170–173

Thakur N, Thakur NS, Suman M, Kaushal BBL, Sharma M (2007) Apricot soya toffees - a protein enriched product. Indian Food Packer 61(4):77–81

Vijayanand P, Yadav AR, Balasubramanyam N, Narasimham P (2000) Storage stability of guava fruit bar prepared using a new process. Lebensm Wiss Technol 33(2):132–137

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, S.K., Chaudhary, S.P., Rao, V.K. et al. Standardization of technology for preparation and storage of wild apricot fruit bar. J Food Sci Technol 50, 784–790 (2013). https://doi.org/10.1007/s13197-011-0396-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0396-y