Abstract

The major objective of this study was to explore the significance of an integrated agro technology in maintenance of postharvest quality of tomato. Preharvest ComCat® treated tomatoes and untreated controls were evaluated for changes in physiological, chemical, and microbiological quality during storage at 13 °C and room temperature (16.9–25.2 °C) and a relative humidity of 34–76%. Effects of disinfection coupled with packaging were evaluated. Physiological weight loss, total soluble solids, peroxidase activity and marketability were maintained better in anolyte disinfected tomatoes. At harvest, ComCat® treated tomatoes had lower pH, glucose and microbial populations, and higher total soluble solids, total titratable acids, sucrose, peroxidase activity than controls. The total soluble solids were better retained in ComCat® treated tomatoes than in control, while the sucrose and glucose contents remained lower after ripening. Peroxidase activities were lower in ripening ComCat® treated tomatoes, and difference in polygalactronase activity was only visible after 30 days. The microbial populations were lower in ComCat® treated fruit. Marketability of ComCat® treated tomatoes was better than that of the control. Integrated technology covering preharvest ComCat® application, disinfection with anolyte water and packaging combined with cold storage at 13 °C maintained the superior quality of tomato.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Postharvest physiological, chemical, biochemical and microbiological qualities of tomatoes partly depend upon preharvest factors such as genetic, climatic, biotic, edaphic, chemical, and hormonal factors, as well as combinations of these (Leonardi et al. 2000). Five major classes of plant hormones are generally recognised: auxin, gibberellin, cytokinin, abscisic acid and ethylene gas (Davies 1995), which may change the rate of biological and biochemical changes in fruits. To achieve a given objective with preharvest treatments of new plant growth regulators or related chemicals, postharvest research on the produce is necessary whenever to evaluate positive or negative effects on the quality of fruits at harvest and or during storage. ComCat® is a substance extracted from plants and consists of combinations of plant hormones (auxin, gibberellin, brassinosteroids, and kinetins), aminoacids, natural metabolites and other ingredients that were shown to increase the yield of vegetables (Schnabl et al. 2001). In general, ComCat means communication and catalysation. An investigation on the effect of preharvest ComCat® treatment on biological and biochemical changes in a fruit was consequently carried out in this study. However, no data is available on the postharvest physiological, microbiological, chemical and biochemical quality aspects of preharvest ComCat® treated tomatoes.

Postharvest treatment factors such as environment also affects the quality attributes and shelf life of vegetables (Mandal et al. 2010; Paul et al. 2010a, b; Rayaguru et al. 2010; Singh et al., 2010). During storage of vegetables and fruits, control of micro-organisms is important to prevent decay (Harvey 1978). Vegetables are usually treated with chlorinated water after washing to reduce the microbial load prior to packaging (Bolin et al. 1977). Although it is an effective disinfecting method, an environmentally friendly and effective alternative was described in the form of ionised saline water (anolyte) (Seyoum et al. 2003). Since it showed advantages over chlorine treatment in carrots, it will be used in parallel to chlorine treatment in the current work. Furthermore, vegetables could be subjected to packaging during storage for better shelf life (Naik et al. 2001; Kudachikar et al. 2007a, b). In the current investigation, the postharvest properties of ComCat® treated tomatoes is reported during postharvest treatments, which involve different disinfection, packaging and storage environment treatments.

Materials and methods

Sample Tomato production: Tomatoes (Leucopersicon esculentum, var. Marglobe) were grown in the area of Bloemfontein South Africa. ComCat® is natural biocatalysts, which is extracted from seeds of plants and dominantly consists of aminoacids, gibberellin, kinetins, auxin (Indole-3-acitic acid), brassinosteroids, natural metabolites, pathogen-related PR-proteins with defence reactions, terpenoids, flavonoids, vitamins, inhibitors, other signal molecules and biocatalysts and cofactors (Schnabl et al. 2001). ComCat® was applied at 10 g ha−1 in 350 l of water, and control plants with 0 g ha−1. Tomato plants were sprayed twice during growth and development. The first spraying was performed prior to transplanting of the seedlings while the second spraying was at the start of flowering. All other agricultural practices were kept the same between the treatments during tomato production. At a green mature stage, ComCat® treated and untreated tomatoes were harvested manually from four randomised blocks early in the morning, and immediately transported to the vegetable laboratory of the University of Free State. Tomatoes free of observable mechanical injury, blemishes or defects were selected. The working surfaces and all tools used for processing tomatoes were washed and disinfected prior to use by 1% Chlorobac (Syndachem, Pty, LTD, Gauteng, South Africa). Tomatoes were washed with water at a temperature of 4 °C, to remove field heat, soil particles and to reduce microbial populations on the surface.

Postharvest treatment

After washing a total amount of 180 kg ComCat® treated tomatoes were subdivided into three groups of 60 kg each in preparation for dipping treatments in chlorinated water, anolyte water and tap water, at 4 °C in plastic containers. Plastic containers were used to avoid losses of charged ions from anolyte water. Chlorinated water, containing 100 μg ml−1 free chlorine was prepared from 5% sodium hypochlorite, for a 20 min dipping time of tomatoes (Nunes and Emond 1999). Anolyte water was prepared as described by Seyoum et al. (2003), for a 5 min dipping time. As control, tomatoes were dipped 20 min in tap water.

Packaging

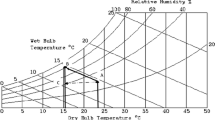

Tomatoes were subdivided into 1 kg-samples, and packed in commercial micro-perforated bags (Xtend® Film, Patent No. 6190710, StePac L.A., Ltd., Telaviv, Northern Israel), which are specifically designed for 1 kg tomato packaging and for storage at 13 °C. The permeability of the bags for O2 and CO2 was 9000 cm3 m−2 day−1, 55000 cm3 m−2 day−1 at 1 atm, respectively, with 17.2 g m−2 day−1 H2O vapour transmission rates. Unpackaged 1 kg-samples, for each treatment combination, was placed on perforated plastic bags and left open during storage at 13 °C or room temperatures. Tomatoes were stored at 13 °C and RH of 34–76% and at room temperature (16.9–25.2 °C) and a relative humidity of 34–76%. On each sampling date, packages of tomato (1 kg each) were randomly taken in triplicate from each treatment for quality analyses.

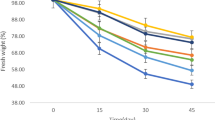

Physiological weight loss

The physiological weight loss (PWL) was determined according to the methods of Tefera et al. (2007) on 0, 8, 16, 24 and 30 after packaging. The differential weight loss was calculated for each interval and converted into percentage. The cumulative PWL was expressed in per cent with respect to different treatments.

Chemical and biochemical analysis

Clear tomato juice was prepared according to the method of Nunes and Emond (1999), and used for all further analyses. The pH value of tomato juice was measured with a Metrohm 691 pH meter. The total titratable acidity (TTA) of tomatoes was measured by the method as described by Maul et al. (2000) with an automatic titrator (665 Dosimat, Metrohm). The total soluble solid (TSS) was determined using the procedures as described by Tefera et al. (2007) with an Atago N1 hand refractometer with a range of 0 to 32 °Brix, and resolutions of 0.2 °Brix. Free sugars, sucrose and glucose, were determined by the method of Riaz and Bushway (1996). HPLC was carried out on a Waters system (501 pump) and Biorad Aminex column (7.8 mm X 300 mm) with a differential refractive index detector (R401) operated at 42 °C and a mobile phase of de-ionized water at a flow speed of 0.6 ml. min−1 and temperature of 85 °C. For polygalacturonase activity (PG) enzyme extraction was done according to Yoshida et al. (1984). The PG activity was measured by the method of Marangoni et al. (1995). The reducing groups formed during the 30 min of incubation at 37 °C were estimated by the arsenomolybdate method of Nelson (1944). The PG activity was expressed as nmole reducing groups min−1. g−1 fresh weight. For logistic reasons, the enzyme assays could not be performed on the same day as the other analyses, so that tomato samples were frozen at −20 °C on each sampling interval until analysis was possible, but within 6 weeks (Maul et al. 2000).

Microbiological analysis

Microbial populations were estimated by the poured plate methods of Brackett (1990). Total aerobic microorganisms were determined on plate count agar (Oxoid CM463), E. coli and coliform population on violet red bile agar (VBRA with MUG, Oxoid CM978) and moulds and yeasts on Rose-Bengal Chlorampehnicol Agar Base (Oxoid CM549). Microbial populations were not analysed immediately after disinfection, as they were assumed to be around 0 log10 CUF.g−1 as was previously shown (Seyoum et al. 2003).

Subjective quality attributes

The descriptive quality attributes were assessed according to Mohammed et al. (1999). On each sampling time three packages of tomatoes containing 5 fruit in each package were randomly selected from each treatment group. The number of marketable fruit was used as measure to calculate the percentage marketable fruits during storage. A rating scale of 1–9 was used, with 1 = unusable, 3 = unsaleable 5 = fair, 7 = good and 9 = excellent. The colour, shininess, surface defects, signs of mould growth and dehydration were visual parameters for the rating. Tomatoes that received a rating of 5 or above were considered marketable, while those rated less than 5 were considered unmarketable.

Experimental design and data analysis

A factorial experiment with two preharvest (10 g ha−1 and 0 g ha−1 ComCat®), three disinfection (chlorinated water, anolyte water and pure water), two packaging (flexible film and open air) and two storage environments (13 °C and room) treatments with three replications were used in the study. The experimental design was arranged in a factorial type of Randomized Complete Block Design (RCBD), with three samples from each treatment combination arranged in three different shelf locations both in the cold room (13 °C) and room conditions. A pack of tomatoes were taken randomly from each treatment group on each sampling day and used for the different quality analyses. Each replicate sample for analysis of microbiological quality and free sugar content (sucrose and glucose) was analysed in duplicate. Statistical significant differences between the treatments were determined by analysis of variance with an MSTAT-C software package (MSTAT, Michigan State Univ., East Lansing) and multiple comparison of the treatment means by Duncan’s multiple range test.

Results and discussion

Physiological weight loss

Packaging had a significant (P ≤ 0.05) effect on reducing the PWL during storage (Table 1) which is in agreement with the trends found by Dhall et al. (2010). The PWL was affected (P ≤ 0.001) by the storage temperature. The PWL was lower from packaged tomatoes stored at 13 °C. The PWL was affected by the prepackaging disinfecting + packaging treatments. The differences in PWL of tomatoes dipped in chlorinated and anolyte water observed after 24 days storage at room temperature was significantly (P ≤ 0.001) affected by the interaction between disinfecting, packaging and storage temperature treatments. The preharvest ComCat® treatment had a significant (P ≤ 0.05) effect on the PWL of tomatoes. The interaction between disinfecting, packaging and storage temperature treatments was significant (P ≤ 0.001).

Total soluble solids

The total soluble solid (TSS) of tomatoes varied between 4.0 and 4.9 °Brix (Table 1). In general, the TSS of tomatoes increased during the first 8 days of storage and dropped thereafter. Packaging, storage temperature, disinfecting + packaging, ComCat® treatment and their interaction had significant (P ≤ 0.05) influence on the TSS of tomatoes. ComCat® treatment resulted in a higher TSS content at harvest. ComCat® treated tomatoes had higher trends of TSS contents during storage after disinfection than the control, while the TSS contents were observed to be lower when not disinfected. These results suggested that coupled effects exist. Significant two-way interactions and a three-way interaction (P > 0.01), were obtained between all the treatments.

pH and total titratable acidity

The pH was higher in tomatoes stored at room temperature than at 13 °C (data not shown). The increase in pH of tomatoes at room temperature with increased storage time was in agreement with the previous findings by Mohammed et al. (1999). This could be attributed to the enhanced metabolism, ripening and senescence of these tomatoes compared to those stored at 13 °C. At harvest, the pH value of ComCat® treated tomatoes was lower than in controls. The interaction between disinfecting + packaging treatment and storage temperature was significant (P ≤ 0.001) on the changes in pH of tomatoes. Similarly, the interaction between pre-and postharvest treatments was significant (P ≤ 0.001) on the changes in the pH values. The higher storage temperature resulted in a faster decrease in TTA of tomatoes (data not shown). A higher TTA was noted for chlorine disinfected ComCat® treated tomatoes. At harvest, the TTA of ComCat® treated tomatoes were higher than TTA of control tomatoes. The importance of fruit acidity, as a major factor affecting the keeping quality of tomatoes, has been examined by Gould (1983).

Free sugar

The sucrose content increased during the first 8 days of storage, but decreased thereafter (Table 2). Storage temperature had a significant (P ≤ 0.001) effect on the sucrose content. The utilization of free sugars was faster in tomatoes stored at room temperature, compared to those stored at 13 °C. Reducing sugars are the main substrates in the respiration process to produce energy required in the metabolism of fruit. It was calculated that in green mature tomatoes, 73% of glucose degradation took place through the Embden-Meyerhof processes and 27% through the alternative oxidative path way, which functions mainly as a mechanism for the conversion of glucose to various intermediates for biosynthesis and possibly, to provide NADPH2 for this process (Hobson and Davies 1971). The preharvest ComCat® treatment had a significant (P ≤ 0.05) effect on the changes in sucrose content of tomatoes. The effect was mainly expressed in tomatoes stored at room temperature, where the sucrose content of the ComCat® treated tomatoes was observed to drop to lower levels, i.e. below 0.027 g.100g−1, from day 16 onwards, as compared to the controls. Sucrose content was influenced by the interaction of preharvest ComCat® treatment and storage temperature. In general, the glucose levels were lower after 16 days of storage at 13°C in water washed tomatoes, compared to the chlorine and anolyte washed ones, although not significant at P ≤ 0.05. ComCat® treatment also had a significant (P ≤ 0.05) effect on the glucose content of tomatoes during storage, and was, in general, lower from harvest throughout storage. The lower free sugar content associated with ComCat® treated tomatoes could also be an indication of lower respiration and metabolism rates. However, during the later stages of ripening, and in ripe ComCat® treated tomatoes, these sugars began to accumulate. The decline in reducing sugar does not continue until the end of storage in ComCat® treated tomatoes and could be attributed to the effect of the plant growth hormones (i.e. gibberellin) in ComCat® that delayed the ripening of the fruit. Such correlations were reported by Bartholomew and Criley (1983).

Peroxidase activity

The general tendency was a decrease in peroxidase activity (POX) up to 8 days of storage, followed by an increase (Table 3). In general, a greater level of the activity of POX was observed for tomatoes stored at room temperature at days 16 to 24, compared to those stored at 13 °C.

The activity of POX was higher in ComCat® treated tomatoes at harvest. In this context, increased POX activity in tomatoes is thought to be responsible for increasing resistance to pathogenic infection, at least in part (Khripach et al. 1997). This could support the results in Table 5 where lower counts in microorganisms are shown to occur on ComCat® treated tomatoes. The proposed mechanism for higher resistance against microorganisms is explained by the findings of previous researchers, who showed that ComCat® treatment induces POX, chitinase and β1-3 gluconase, which are enzymes that protect cell walls and prevent infection (Schnabl et al. 2001).

The disinfecting treatment had a highly significant (P ≤ 0.001) effect on the POX in tomatoes, but only in the ComCat® treated ones. The activities of POX in ComCat® treated tomatoes dipped in anolyte water was lower at 16 and 24 days of storage at 13 °C, when compared to tomatoes dipped in chlorinated water. POX activity was higher (P ≤ 0.05) in ComCat® treated fruits at harvest. The activity of POX was significantly (P ≤ 0.001) influenced by the interaction between preharvest ComCat® treatment and disinfecting treatment. The interaction between storage temperature and disinfecting + packaging also had a highly significant (P ≤ 0.001) effect on the changes in levels of POX activity in tomato fruits. The two-way interaction between preharvest ComCat® treatment and storage temperature was significant (P ≤ 0.05) on the changes in POX activities in fruits during 30 days at 13 °C or room temperature. The three-way interaction between all the pre-and postharvest treatments significantly (P ≤ 0.01) affected the activity of POX in ripening tomatoes.

Polygalacturonase activity

Changes in metabolic activity can also be monitored by polygalacturonase activity (PG) activities, since enzyme activities govern most of the chemical and physical effects that occur during ripening of fruit. For instance, the loss of firmness of tomatoes during ripening and storage is due to the increased activity of PG in tomatoes (Brady 1987). No PG activity was detected in tomatoes at harvest (Table 3). Storage temperature had a highly significant (P ≤ 0.001) effect on the PG activity in tomatoes. The PG activity was influenced by the disinfecting treatment during 24 days storage. The differences were more pronounced at 30 days storage at 13 °C, than during the earlier periods, where the activities of PG were higher in tomatoes disinfected in chlorinated water, than in tomatoes dipped in anolyte water. The PG activity in tomatoes has a positive correlation with the firmness of fruits (Brady 1987). The interactive effect of ComCat® and storage temperature treatments had a significant (P ≤ 0.001) influence on the changes in PG activity. Similarly, the interaction between disinfecting and storage temperature had a significant (P ≤ 0.05) effect on the PG activity. The PG activities increased faster (P ≤ 0.01) in ComCat® treated tomatoes disinfected in chlorinated water and stored at 13 °C, compared to the controls. It was also lower (P ≤ 0.01) in anolyte disinfected fruit than in those disinfected in chlorinated water.

Microbiological changes

After 30 days at 13 °C, the populations of total aerobic bacteria were higher in unpackaged tomatoes than in packaged ones (Table 5). Although least permeable packaging might be preferred to reduce microbial growth (Batu and Thompson 1998), packaging with high permeability was reported to be protective (Seyoum et al. 2001). The current results showed that the population of microorganisms were found to be less in packaged tomatoes. Disinfecting treatments reduced the number of aerobic bacteria significantly (P ≤ 0.001).

At harvest the population of aerobic bacteria was lower in ComCat® treated tomatoes, when compared with the controls. Highly significant interactions (P ≤ 0.001) were obtained between the ComCat® treated and storage temperature, as well as between the disinfection treatments + packaging and the storage temperature (P ≤ 0.001). The population of moulds and yeasts was generally lower in packaged tomatoes, compared to unpackaged ones during storage at both temperatures (Table 4). The populations in packaged tomatoes started to exceed that of unpackaged fruits after 16 days at room temperature.

The number of viable moulds and yeasts was significantly lower in tomatoes disinfected in chlorinated and anolyte water, compared to water washed ones. The results showed that disinfecting with anolyte water seemed to be more effective than chlorinated water, as lower counts of moulds and yeasts were observed, although significant (P ≤ 0.05) differences were only observed in the packaged control tomatoes stored at room temperature. As a general trend, ComCat® treatment resulted in lower yeast and mould populations at harvest, a few significant differences (P ≤ 0.05) were observed during storage, where this trend was continued. Furthermore, at harvest, the population of aerobic bacteria, moulds and yeasts, and total coliform bacteria were lower in ComCat® treated tomatoes. These results were in agreement with the previous hypothesis on the performance of ComCat® treated products in terms of levels of photogenic infections (Schnabl et al. 2001). A reduction of plant disease symptoms up to 45% in comparison to untreated control plants has been reported.

The populations were also significantly (P ≤ 0.05) influenced by the interaction between storage temperature and ComCat® treatment, as well as disinfecting + packaging treatments and storage temperature. Populations of coliform bacteria in tomatoes were significantly (P ≤ 0.001) affected by the storage temperature. Storage at 13 °C, had a positive effect on controlling them. Disinfecting treatments reduced the number of coliform bacteria. At harvest, the numbers of viable coliforms were significantly (P ≤ 0.05) lower in ComCat® treated tomatoes compared to the controls. As a general trend, the population of total coliform bacteria was found to be lower in ComCat® treated tomatoes, stored at 13 °C or room temperature, than in control tomatoes. However, this difference was only significant (P ≤ 0.05) for the storage of disinfected tomatoes at room temperature. The population of coliform bacteria was influenced (P ≤ 0.001) by the interaction between preharvest treatment and storage temperature. The three-way interaction between pre-and postharvest treatments was also significant (P ≤ 0.01). The physical or biochemical characteristics of the fruit due to ComCat® treatments may influence the type and populations of microorganisms which develop on fresh produce (Brackett 1990). Gould (1983) and Mohammed et al. (1999) supported this view by giving example that that the higher TTA could protect fruit from fungal infection.

It was reported that chlorine treatment at 200 ppm reduced the population of pathogens by 0.35 to 3 log CFU cm−2 in tomatoes (Ukuku and Sapers 2001). In the current study, chlorinated water dipping treatment for 20 min significantly reduced the populations of total aerobic bacteria, moulds and yeasts, and total coliforms, compared to the populations in water washed tomatoes (Tables 4 and 5). However, the effectiveness of chlorine treatment decreased when tomatoes were stored at room temperature. It was also shown that 5 min dipping in anolyte water was sufficient for desirable control of microorganisms. The main reason for this is that the anolyte water contains freely available radicals, which are immediately available for action on the microorganisms, whereas in the case of chlorinated water these radicals are not freely available, and are formed slowly. The advantages of anolyte water above chlorine treatment were not only restricted to control of microorganisms. The loss of moisture was generally higher in tomatoes dipped in chlorinated water than in anolyte water (Table 1). This could be attributed to the effect of chlorine solution on the skin of tomatoes and surface tissue. It was observed that chlorinated water dipping treatment generally left a taint on the surface of tomatoes, while the surface of tomatoes dipped in anolyte water remained to be very shiny during the 30 days of storage at 13 °C.

Percentage marketability

The marketability of tomatoes was significantly higher for packaged tomatoes than for unpackaged ones stored at both temperatures (Table 5). Packaging resulted in the preservation of quality attributes (Tables 1, 2, 3, 4 and 5) which is in agreement with the findings of Mangal et al. (2000) and Kudachikar et al. (2007a, b). Packaging resulted in 52.4% and 23.8% more marketable control and ComCat® treated tomatoes during the 16 days of storage at room temperature, respectively. Similarly, there were 29.7% and 40.3% more marketable ComCat® treated and control tomatoes after 30 days at 13 °C, respectively. Disinfecting helped to protect the tomatoes, as water washed tomatoes started to deteriorate, from 8 days on, at room temperature, and 16 days at 13 °C, compared to disinfected ones. The percentage marketable fruits were significantly (P ≤ 0.01) affected by the interaction between preharvest treatment and storage temperature.

Conclusions

Preharvest ComCat® treatment not only improved crop yield, but resulted in better keeping quality of fruit e.g. tomatoes. Benefits at 13 °C storage were: (1) offers a new strategy for preharvest plant protection and strong produce at harvest; (2) better microbiological quality in terms of lower populations of total aerobic bacteria, molds, yeasts and total coliform; and (4) better shelf life at 13 °C. Further benefits on the shelf life at room temperature storage, being: (1) better chemical quality in terms of higher contents of TSS and lower pH; (3) better microbiological quality in terms of lower total aerobic bacteria, molds, and yeast populations. Anolyte was shown to be a promising alternative in saving time, having less effect on the fruit and being environmentally friendly disinfectant. The observation that ComCat® treated tomatoes showed better storage performance than untreated controls, not just at 13 °C, but also at room temperature, opens the possibility to investigate the storage performance of these tomatoes at temperatures higher than the optimum storage temperature of 13 °C, but under controlled conditions. The integrated agro-technology of preharvest ComCat®, anolyte water dipping disinfection and packaging treatments maintained the superior quality of tomatoes stored under 13 °C temperature.

References

Bartholomew DP, Criley RA (1983) Tropical fruits and beverage crops. In: Nickell LE (ed) Plant growth regulating chemicals. CRC, Boca Raton, p 23

Batu A, Thompson AK (1998) Effects of modified atmosphere packaging on post harvest qualities of pink tomatoes. Turk J Agric Fores 22:365–372

Bolin HR, Stafford AE, King JR, Huxsoll CC (1977) Factors affecting the storage stability of shredded lettuce. J Food Sci 42:1319–1321

Brackett RE (1990) Changes in the microflora of packaged fresh bell peppers. J Food Prot 53:255–257

Brady CJ (1987) Fruit ripening. Annu Rev Plant Physiol 38:155–178

Davies PJ (1995) Plant Hormones: Physiol Bioch and Molec Biol. Dordrecht: Kluwer

Dhall RK, Sharma SR, Mahajan BVC (2010) Effect of packaging on storage life and quality of cauliflower stored at low temperature. J Food Sci Technol 47(1):132–135

Gould WA (1983) Composition of tomatoes. In: Gould WA (ed) Tomato production, processing and quality evaluation. AVI Publ. Co, Westport, pp 344–361

Harvey JM (1978) Reduction of losses in fresh market fruits and vegetables. Annu Rev Phytopath 16:321–341

Hobson GE, Davies JN (1971) The Tomato. In: Hulme AC (ed) The biochemstry of fruits and their products, vol 2. Academic, NY, pp 437–482

Khripach VA, Zhabinskii VM, Malevannaya NN (1997) Proc Plant Growth Regul Soc Am 24:101–112

Kudachikar VB, Kulkarni SG, Vasantha MS, Aravinda Prasad B, Aradhya SM (2007a) Effect of modifi ed atmosphere packaging on shelf-life and fruit quality of banana stored at low temperature. J Food Sci Technol 44:74–78

Kudachikar VB, Kulkarni SG, Vasantha MS, Aravinda Prasad B, Aradhya SM (2007b) Effect of modifi ed atmosphere packaging on shelf-life and fruit quality of banana stored at low temperature. J Food Sci Technol 44:74–78

Leonardi C, Guichard S, Bertin N (2000) High vapour pressure deficit influences growth, transpiration and quality of tomato fruits. Sci Hortic 84:285–296

Mandal G, Dhaliwal HS, Mahajan BVC (2010) Effect of pre-harvest calcium sprays on post-harvest life of winter guava (Psidium guajava L.). J Food Sci Technol 47(4):501–506

Mangal JL, Kumar J, Batra V, Singh J, Arora SK (2000) Effect of different storage conditions and packing materials on the shelflife of fi ve caulifl ower cultivars. Haryana J Hortic Sci 29:131–132

Marangoni AG, Jackman RL, Stanley DW (1995) Chilling-associated softening of tomato fruit is related to increased pectinmethylesterase activity. J Food Sci 606:1277–1281

Maul F, Sargent SA, Sims CA, Baldwin EA, Balaban MO, Huber DJ (2000) Tomato flavour and aroma quality as affected by storage temperature. J Food Sci 65:1229–1237

Mohammed M, Wilson LA, Gomes PI (1999) Postharvest Sensory and physiochemical attributes of processing and non-processing tomato cultivars. J Food Qual 22:167–182

Naik JP, Nagalakhsmi S, Balasubrahmanyam N, Dhanaray S, Shankaracharya NB (2001) Packaging and storage studies oncommercial varieties of Indian chillies (Capsicum annuum L). J Food Sci Technol 38:227–230

Nelson N (1944) A photometric adaptation of the Somogyi method for determination of glucose. J Biol Chem 153:375–380

Nunes MCN, Emond JP (1999) Chlorinated water treatments affects postharvest quality of green bell peppers. J Food Qual 22:353–361

Paul V, Pandey R, Srivastava GC (2010a) Ripening of tomato (Solanum lycopersicum L.). Part II: regulation by its stem scar region. J Food Sci Technol 47(5):527–533

Paul V, Rakesh P, Srivastava GC (2010b) Ripening of tomato (Solanum lycopersicum L.). Part I: 1-methylcyclopropene mediated delay at higher storage temperature. J Food Sci Technol 47(5):519–526

Rayaguru K, MdK K, Sahoo NR (2010) Water use optimization in zero energy cool chambers for short term storage of fruits and vegetables in coastal area. J Food Sci Technol 47(4):437–441

Riaz MN, Bushway AA (1996) Compositional analysis of four red raspberry cultivars grown in Maine. J Food Qual 19:457–465

Schnabl H, Roth U, Friebe A (2001) Brassinosteroids-induced stress tolerances of plants. Recent Res Dev Photochem 5:169–183

Seyoum TW, Osthoff G, Steyn MS (2001) Effect of modified atmosphere packaging on microbiological, physiological and chemical qualities of stored carrots. J Food Technol Afr 6:138–143

Seyoum TW, Osthoff G, Pretorius JC, Hugo CJ (2003) Comparison of anolyte and chlorinated water as disinfecting dipping treatment for stored carrots. J Food Qual 26(3):34–43

Singh S, Singh AK, Joshi HK, Lata K, Bagle BG (2010) Effect of zero energy cool chamber and post-harvest treatments on shelf-life of fruits under semi-arid environment of Western India. Part 1. Ber fruits. J Food Sci Technol 47(4):446–449

Tefera T, Seyoum T, Woldetsdik K (2007) Effect of disinfection, packaging, and storage environment on the shelf life of mango. Biosyst Eng 96:1537–1550

Ukuku DO, Sapers GM (2001) Effect of sanitizer treatments on Salmonella Stanley attached to the surface of cantaloupe and cell transfer to fresh-cut tissues during cutting practices. J Food Prot 64:1286–1291

Yoshida O, Nakagawa H, Ogura N, Sato T (1984) Effect of heat treatment on the development of polygalacturonase activity in tomato fruit during ripening. Plant Cell Physiol 25(3):505–509

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Workneh, T.S., Osthoff, G. & Steyn, M. Effects of preharvest treatment, disinfections, packaging and storage environment on quality of tomato. J Food Sci Technol 49, 685–694 (2012). https://doi.org/10.1007/s13197-011-0391-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0391-3